Technical Contents

Engineering Guide: Mm Sheet Metal

Engineering Insight: Precision in mm Sheet Metal Fabrication

In the realm of modern manufacturing, sheet metal components measured in millimeters demand more than just dimensional accuracy—they require engineering excellence. At Wuxi Lead Precision Machinery, we understand that even a deviation of 0.1 mm can compromise the structural integrity, fit, or functionality of a final product. This level of precision is not merely a technical benchmark; it is a commitment to reliability, performance, and long-term value in high-stakes applications.

Our expertise in mm-scale sheet metal fabrication has been rigorously tested in projects requiring the highest standards—ranging from structural components for Olympic-grade sports infrastructure to mission-critical enclosures and support systems for military and defense applications. These projects demand not only repeatability and consistency but also an in-depth understanding of material behavior, thermal expansion, stress distribution, and geometric tolerancing. It is through these demanding engagements that Lead Precision has refined its processes, ensuring that every cut, bend, and weld meets exacting specifications.

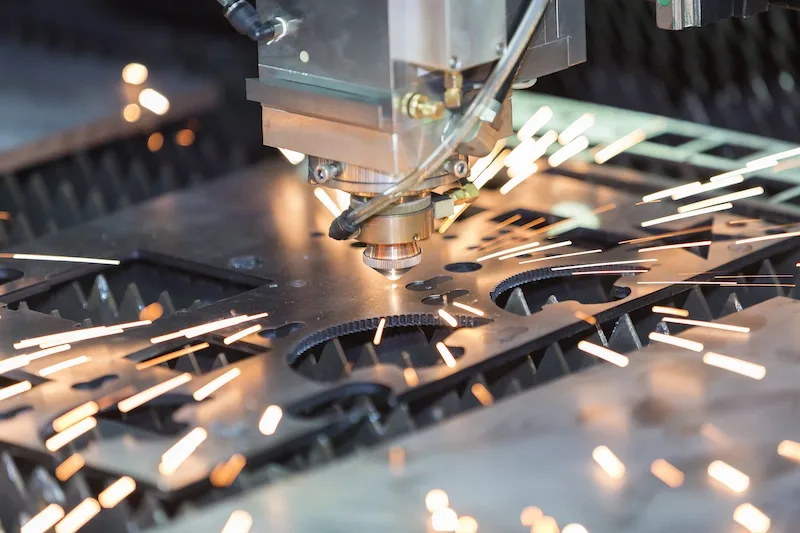

Precision begins with material selection. We work with a broad range of sheet metals, including cold-rolled steel, stainless steel, aluminum, and specialty alloys, all processed to tight thickness tolerances. Our advanced laser cutting systems achieve kerf widths within ±0.05 mm, while our CNC press brakes apply controlled tonnage to deliver bend angles accurate to ±0.2°. These capabilities are supported by real-time monitoring and in-process inspection using coordinate measuring machines (CMM) and optical comparators, ensuring compliance with ISO 2768 and customer-specific geometric dimensioning and tolerancing (GD&T) requirements.

Beyond equipment, precision is driven by process discipline. Our fabrication workflow integrates digital twin modeling, finite element analysis (FEA), and first-article inspection reports (FAIR), enabling full traceability and predictive quality control. This systems-level approach minimizes variability and ensures that every mm-scale feature—whether a mounting hole, flange, or emboss—performs as designed.

In industries where failure is not an option, the margin for error vanishes. At Wuxi Lead Precision Machinery, we engineer every sheet metal component with the understanding that precision is not a feature—it is the foundation.

Typical Sheet Metal Fabrication Tolerances at Wuxi Lead Precision Machinery

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| Cutting (Laser/Plasma) | ±0.1 mm | ±0.05 mm |

| Bending Angle | ±0.5° | ±0.2° |

| Hole Position Tolerance | ±0.15 mm | ±0.1 mm |

| Edge-to-Edge Dimension | ±0.2 mm | ±0.1 mm |

| Surface Flatness (per 100 mm) | 0.1 mm | 0.05 mm |

| Material Thickness Range | 0.5 – 25 mm | 0.5 – 12 mm (optimal) |

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Sheet Metal Fabrication

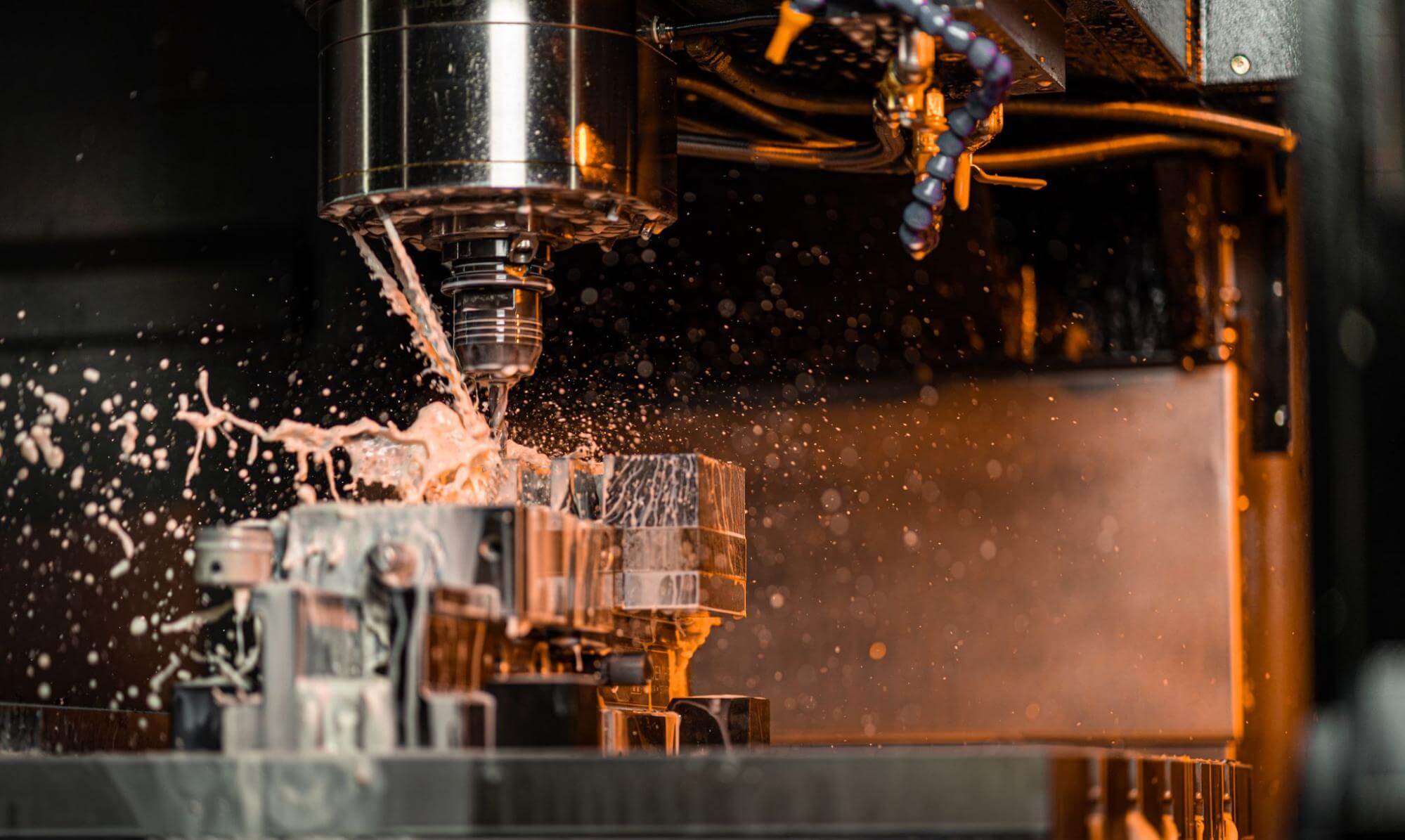

Wuxi Lead Precision Machinery delivers uncompromising accuracy in mm-scale sheet metal fabrication through integrated 5-axis CNC machining centers. Our HAAS and DMG MORI platforms execute complex geometries in a single setup, eliminating cumulative errors from multi-stage processing. This capability is critical for aerospace brackets, medical enclosures, and semiconductor components requiring tight tolerances on features like countersunk holes, chamfered edges, and contoured surfaces under 0.5mm thickness. The 5-axis system dynamically adjusts tool orientation to maintain optimal cutting angles, reducing material stress and preventing deformation in thin-gauge alloys such as 5052 aluminum and 304 stainless steel.

Rigorous quality control begins with SPC-monitored machining parameters and concludes with Zeiss CONTURA CMM verification. Every batch undergoes full 3D dimensional analysis against CAD models, with first-article reports documenting critical feature conformity. Our metrology lab validates flatness within 0.05mm per 100mm and positional accuracy to ±0.02mm, ensuring seamless assembly in multi-part systems. Non-destructive testing including dye penetrant inspection is available for mission-critical applications.

Tolerance performance is systematically controlled across all production phases. The table below defines our standard and enhanced capabilities for sheet metal components:

| Feature Type | Standard Tolerance | Enhanced Capability |

|---|---|---|

| General Linear | ±0.10 mm | ±0.05 mm |

| Hole Diameter | ±0.08 mm | ±0.03 mm |

| Positional (Holes) | ±0.15 mm | ±0.05 mm |

| Critical Milled Features | ±0.08 mm | ±0.02 mm |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm |

These specifications apply to materials from 0.2mm to 6.0mm thickness across carbon steel, aluminum, copper, and titanium alloys. Our process engineers collaborate with clients during DFM reviews to identify opportunities where enhanced tolerances can reduce downstream assembly costs—such as optimizing hole patterns to eliminate shimming in sub-assemblies.

Material handling protocols prevent micro-scratches and warpage during processing. Automated sheet loaders, non-marring vacuum tables, and climate-controlled staging areas maintain part integrity from raw stock to final inspection. This holistic approach ensures that every component shipped meets the dimensional stability demands of high-reliability sectors. For projects requiring certified conformance to AS9100 or ISO 13485 standards, our documentation package includes full traceability from heat lot to calibrated measurement data. Partner with Wuxi Lead to transform complex sheet metal designs into production-ready assets with engineering-grade precision.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material for sheet metal components is a critical decision in high-performance manufacturing. At Wuxi Lead Precision Machinery, we specialize in precision fabrication of aluminum, steel, and titanium—three of the most widely used metals in industrial applications. Each material offers distinct mechanical, thermal, and chemical properties that influence performance, durability, and cost-efficiency.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is ideal for aerospace, automotive, and electronics enclosures where weight reduction is paramount. Grade 6061-T6 is commonly used due to its weldability and machinability, while 5052-H32 is selected for enhanced corrosion resistance in marine environments. Aluminum’s natural oxide layer provides inherent protection, but for enhanced surface durability and aesthetic control, anodizing is recommended.

Steel remains the backbone of heavy-duty industrial applications. Mild steel (such as Q235 and Q345) offers high tensile strength and cost-effective formability, making it suitable for structural frames, enclosures, and machinery components. For environments requiring corrosion resistance, stainless steel grades like 304 and 316 are preferred. These alloys contain chromium and nickel, forming a passive oxide layer that resists rust and chemical degradation. Stainless steel is commonly used in food processing, medical devices, and outdoor installations.

Titanium, though more expensive, delivers unmatched performance in extreme conditions. With a superior strength-to-density ratio and exceptional resistance to high temperatures and corrosive media, titanium is the material of choice for aerospace, defense, and chemical processing applications. Grade 2 is commonly used in sheet form for its good weldability and ductility, while Grade 5 (Ti-6Al-4V) offers higher strength for critical load-bearing components.

Surface finishing plays a vital role in extending service life and enhancing appearance. Anodizing is a controlled electrochemical process primarily applied to aluminum. It thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for paint or primers. Decorative anodizing also allows for color coding with options such as black, red, or blue, while maintaining electrical insulation properties. Hard anodizing (Type III) is used in high-wear applications, achieving surface hardness comparable to tool steel.

Below is a comparative overview of key material properties for common sheet metal alloys.

| Material | Typical Grades | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 2.7 | 290–320 | High (with anodizing) | Aerospace, Electronics, Marine |

| Mild Steel | Q235, Q345 | 7.85 | 370–500 | Low (requires coating) | Industrial Frames, Machinery |

| Stainless Steel | 304, 316 | 7.93 | 505–620 | Very High | Medical, Food Processing |

| Titanium | Gr 2, Gr 5 | 4.51 | 345–1000 | Exceptional | Aerospace, Defense, Chemical |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and lifecycle costs. Our engineering team collaborates closely with customers to ensure every fabricated component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Sheet Metal Fabrication: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our sheet metal production process is engineered for uncompromising quality and efficiency, delivering true Zero Defects outcomes for demanding industrial applications. We rigorously integrate advanced technology with disciplined workflows across three critical phases: Design, Prototyping, and Mass Production. This seamless progression ensures every component meets exacting specifications before and during volume manufacturing.

The foundation is meticulous digital design validation. Our engineering team utilizes industry-leading CAD/CAM software to develop detailed 3D models, incorporating precise geometric dimensioning and tolerancing (GD&T) from the outset. Finite element analysis (FEA) simulates real-world stresses and assembly interactions, identifying potential weaknesses or interferences early. Crucially, we conduct comprehensive Design for Manufacturability (DFM) reviews, optimizing the design for our specific laser cutting, bending, and welding capabilities. This proactive approach eliminates costly errors and rework downstream, ensuring the digital blueprint is fully manufacturable to zero-defect standards before any material is cut.

Prototyping serves as the vital physical verification step. Using the same high-precision equipment intended for mass production – including multi-axis CNC punch presses, fiber laser cutters, and automated bending cells – we produce functional prototypes. These units undergo rigorous first-article inspection (FAI) against all critical dimensions and material properties. Dimensional metrology via CMM and optical comparators validates conformance to the validated digital model. Any discrepancies trigger immediate root cause analysis and design or process refinement. This phase confirms not only part accuracy but also the robustness of the planned manufacturing sequence, guaranteeing the process itself is defect-proofed prior to volume commitment.

Mass production leverages the perfected process with integrated, automated quality assurance. Our smart factory environment utilizes IoT-connected machinery for real-time process monitoring and automatic parameter adjustment. Every critical operation incorporates in-process inspection: laser systems verify cut edge quality and dimensions after cutting; automated bend angle measurement ensures geometric accuracy after forming; and final assembly checks utilize calibrated fixtures. Statistical process control (SPC) data is continuously analyzed, enabling predictive maintenance and immediate corrective action to prevent deviation. Full traceability, from raw material lot to finished part, is maintained throughout, supporting our ISO 9001-certified quality management system and absolute Zero Defects commitment.

Wuxi Lead Precision Sheet Metal Capabilities

| Parameter | Capability Range | Precision Standard |

|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | ±0.05 mm |

| Cutting Tolerance | Laser/Punch | ±0.05 mm |

| Bend Angle | Standard / Complex | ±0.5° / ±1.0° |

| Hole Position | Critical Features | ±0.03 mm |

| Surface Finish | Mill Standard / Deburred / Anodized | Ra ≤ 1.6 μm (as required) |

| Max. Part Size | 3000 mm x 1500 mm | N/A |

This integrated Design-Prototype-Production methodology, underpinned by advanced technology and rigorous quality gates, ensures Wuxi Lead consistently delivers sheet metal components that perform flawlessly in your most critical applications, eliminating waste and maximizing your operational reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end manufacturing. As a trusted leader in sheet metal fabrication based in China, we specialize in delivering engineered solutions that meet the exacting standards of industries ranging from aerospace and medical devices to industrial automation and advanced electronics. When you choose to partner with us, you gain more than a supplier—you gain a precision engineering ally committed to your project’s success from concept to completion.

Our advanced manufacturing capabilities are built around state-of-the-art CNC punching, laser cutting, bending, and welding technologies. We work with a broad range of metals including stainless steel, aluminum, carbon steel, and copper alloys, supporting thicknesses from 0.5 mm to 10 mm with tight tolerances down to ±0.05 mm. Whether your project demands low-volume prototypes or high-volume production runs, our agile manufacturing floor ensures consistency, repeatability, and rapid turnaround—without compromising quality.

What sets Lead Precision apart is our end-to-end process control. From initial design review and DFM optimization to final assembly and packaging, every step is managed in-house under ISO 9001-certified quality systems. Our engineering team collaborates directly with your designers to resolve manufacturability challenges, reduce costs, and accelerate time-to-market. We also offer value-added services such as surface finishing (powder coating, anodizing, plating), hardware insertion, and custom packaging to meet your exact logistics and branding needs.

We serve global clients with seamless communication, real-time project tracking, and on-time delivery—backed by decades of experience in exporting precision components to North America, Europe, and Asia. Our commitment is not just to meet your specifications, but to exceed your expectations in quality, responsiveness, and technical support.

For mission-critical sheet metal components, precision is not optional—it’s essential. Let Wuxi Lead Precision Machinery be your strategic partner in achieving manufacturing excellence.

Contact us today at [email protected] to discuss your next project. Our engineering team is ready to provide a detailed quote, technical consultation, or design review—ensuring your sheet metal components are built to perform.

| Specification | Capability |

|---|---|

| Material Types | Stainless Steel, Aluminum, Carbon Steel, Copper Alloys |

| Thickness Range | 0.5 mm – 10 mm |

| Tolerance | ±0.05 mm (typical) |

| Max Part Size | 1500 mm × 3000 mm |

| Processes | Laser Cutting, CNC Punching, Bending, Welding, Assembly |

| Finishing Options | Powder Coating, Anodizing, Passivation, Plating |

| Quality Standards | ISO 9001:2015 Certified |

| Production Volume | Prototypes to High-Volume Production |

| Lead Time | As fast as 5–7 days for prototypes |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.