Technical Contents

Engineering Guide: Mm Cnc

Engineering Insight: The Critical Role of Precision in CNC Machining

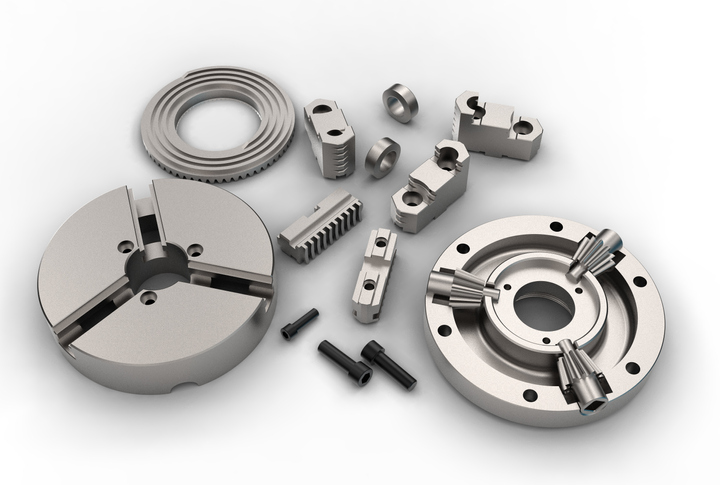

In high-performance manufacturing, the distinction between success and failure often lies within a fraction of a millimeter. At Wuxi Lead Precision Machinery, we understand that precision in CNC machining is not merely a technical target—it is a foundational requirement for reliability, safety, and performance across industries where failure is not an option. Whether producing components for aerospace systems, defense applications, or high-stakes industrial equipment, our engineering philosophy centers on achieving and sustaining micron-level accuracy across every machining operation.

The term “mm CNC” may suggest a focus on millimeter-scale tolerances, but in modern precision engineering, the real benchmark lies well beneath that threshold. Today’s advanced machining demands tolerances measured in microns—often ±0.005 mm or tighter. At this level, even minor thermal expansion, tool wear, or vibration can compromise part integrity. Achieving such precision requires not only state-of-the-art CNC equipment but also deep expertise in material behavior, cutting dynamics, and process validation.

Wuxi Lead Precision Machinery has spent over a decade refining these capabilities, earning recognition for delivering mission-critical components under extreme performance demands. Our involvement in projects supporting Olympic-standard timing systems and precision-guided military equipment underscores our commitment to excellence. These applications demand zero-defect manufacturing, where every component must perform flawlessly under dynamic loads, extreme environments, and long operational cycles.

Our CNC machining processes integrate multi-axis milling, turning, and grinding technologies, all calibrated within temperature-controlled environments and monitored through real-time feedback systems. We employ advanced metrology tools—including coordinate measuring machines (CMM), laser interferometers, and optical profilometers—to verify dimensional accuracy and surface integrity. This closed-loop quality assurance ensures that each part conforms to design specifications, batch after batch.

Beyond equipment, our engineering team’s experience is our greatest asset. With over 15 years in high-precision manufacturing, we have developed proprietary process optimizations that enhance repeatability, reduce cycle times, and minimize material waste—without sacrificing accuracy.

The following table outlines key specifications achievable through our precision CNC machining services:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Positional Accuracy | ±0.008 mm | ±0.002 mm |

| Material Compatibility | Aluminum, Steel, Stainless, Titanium, Plastics | Inconel, Tungsten, Composite Alloys |

| Maximum Work Envelope | 1200 x 800 x 600 mm | 800 x 500 x 400 mm |

| CNC Axes | 3 to 5-axis simultaneous | 5-axis simultaneous |

At Wuxi Lead, precision is not an outcome—it is engineered into every stage of production. From initial design consultation to final inspection, we ensure that every millimeter matters.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered to Your Specifications

Wuxi Lead Precision Machinery delivers uncompromising dimensional accuracy and complex geometry realization through our advanced 5-axis CNC machining center and rigorous quality control protocols. Our core strength lies in transforming demanding engineering concepts into physically perfect components, consistently meeting the stringent requirements of aerospace, medical device, and high-performance industrial sectors where micron-level precision is non-negotiable. We understand that tolerances define functionality; therefore, every process is engineered to achieve and verify the tightest specifications reliably.

5-Axis Machining Capabilities

Our state-of-the-art 5-axis CNC machining centers, featuring知名品牌 like DMG MORI and Makino, enable the complete machining of highly complex parts in a single setup. This simultaneous multi-axis movement eliminates cumulative errors inherent in multiple setups, significantly improving geometric accuracy and surface finish integrity. We excel at producing intricate contours, deep cavities, undercuts, and organic shapes common in turbine blades, orthopedic implants, and fluid dynamics components. Material versatility is a cornerstone, with proven capability machining titanium alloys, Inconel, stainless steels, aluminum alloys, and high-performance engineering plastics to exacting standards. Advanced toolpath strategies and high-speed machining techniques ensure optimal material removal rates while maintaining thermal stability critical for micron-level tolerances.

Quality Control: CMM Inspection Verification

Precision is meaningless without verification. Every critical feature undergoes comprehensive inspection using our fleet of high-accuracy Coordinate Measuring Machines (CMMs), including蔡司 CONTURA and Hexagon GLOBAL systems. Operating within a temperature-controlled metrology lab (20°C ±0.5°C), our certified technicians perform full first-article inspections (FAI) and statistical process control (SPC) throughout production runs. Utilizing advanced probing systems and PC-DMIS software, we generate detailed inspection reports aligned with AS9102 or customer-specific formats, providing absolute traceability and confidence in every dimension. This ISO 17025 accredited process ensures that measured values are statistically validated against your blueprint requirements before shipment.

Achievable Tolerance Benchmarks

The following table represents our standard achievable tolerance capabilities under controlled production conditions for common features. Actual tolerances are always defined by the specific engineering drawing and material stability.

| Feature Type | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | Up to 100mm; tighter achievable |

| Geometric (Flatness) | 0.003 mm (0.0001″) | Per 100mm surface area |

| Geometric (Roundness) | 0.002 mm (0.00008″) | For critical diameters |

| Positional (Holes) | ±0.008 mm (±0.0003″) | True position, diameter dependent |

| Surface Finish (Ra) | 0.4 µm (16 µin) | Machined; finer finishes via polishing |

Integrated Process Excellence

The seamless integration of 5-axis precision machining and metrology-grade CMM inspection forms the backbone of our technical capability. This closed-loop system allows for immediate process adjustment based on real-time measurement data, minimizing scrap and ensuring first-time-right production. We partner with clients from design for manufacturability (DFM) review through final inspection, providing the engineering expertise and technical documentation necessary to guarantee components perform exactly as intended in your most critical applications. Trust Wuxi Lead to deliver precision that meets the exacting demands of modern advanced manufacturing.

Material & Finish Options

Material selection is a critical decision in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance machining of advanced engineering materials, with aluminum, steel, and titanium being the most widely used in aerospace, medical, and industrial applications. Each material offers distinct mechanical properties and compatibility with finishing processes such as anodizing, enabling tailored solutions for demanding environments.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is commonly selected for structural components due to its weldability and corrosion resistance, while 7075-T6 offers higher strength for aerospace applications. Aluminum is highly compatible with anodizing, a process that enhances surface hardness and wear resistance. Type II (sulfuric acid) anodizing provides a protective oxide layer with optional dyeing for identification, while Type III (hardcoat) anodizing delivers thicker, more durable coatings suitable for high-wear environments.

Steel remains the standard for applications requiring high tensile strength, rigidity, and wear resistance. We frequently machine alloy steels such as 4140 and 4340, which respond well to heat treatment for enhanced mechanical properties. Stainless steels like 304 and 316 are preferred in medical and food-grade applications due to their corrosion resistance and cleanability. While steel cannot be anodized, it benefits from alternative surface treatments such as passivation, plating, or powder coating to improve longevity and appearance.

Titanium, particularly Grade 5 (Ti-6Al-4V), is essential in high-performance sectors due to its exceptional strength-to-density ratio and resistance to extreme temperatures and corrosion. It is commonly used in aerospace, defense, and biomedical implants. However, titanium’s low thermal conductivity and high chemical reactivity require specialized tooling and slower machining parameters to prevent work hardening and tool wear. Titanium does not support conventional anodizing for protection, but decorative or identification anodizing is possible through specialized electrolytic processes.

Understanding material behavior under operational stress and environmental exposure ensures optimal part function and lifecycle. Our engineering team at Wuxi Lead Precision Machinery collaborates with clients to match material and finish selection with application-specific requirements, ensuring precision, reliability, and compliance with industry standards.

The following table summarizes key properties and processing characteristics of commonly machined materials:

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Features | Compatible Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Lightweight, high thermal conductivity | Type II & III Anodizing, Powder Coat |

| Steel | 4140, 4340, 304 | 655–1000 | 7.8 | High strength, durable | Passivation, Zinc Plating, Painting |

| Stainless Steel | 304, 316 | 505–760 | 8.0 | Corrosion-resistant, hygienic | Electropolishing, Passivation |

| Titanium | Ti-6Al-4V (Gr5) | 900–1000 | 4.4 | High strength-to-weight, biocompatible | Decorative Anodizing, Passivation |

Selecting the right combination of material and finish is foundational to achieving performance targets in precision CNC machining. Wuxi Lead Precision Machinery provides expert consultation and advanced manufacturing capabilities to support optimal material utilization across industries.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and repeatability in high-precision CNC machining. We execute a rigorously controlled sequence spanning Design, Prototyping, and Mass Production, all unified by our Zero Defects commitment. This methodology ensures every component meets exacting specifications before, during, and after full-scale manufacturing.

The foundation is meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients during the design phase, scrutinizing CAD models for geometric dimensioning and tolerancing (GD&T), material suitability, and manufacturability. We identify potential stress points, tool access limitations, and thermal considerations early, optimizing the design for CNC efficiency and inherent quality. This proactive step eliminates theoretical flaws before metal is cut, preventing costly errors downstream and establishing the blueprint for defect prevention.

Prototyping is not merely a validation step but a critical phase of process refinement. Utilizing the same multi-axis CNC centers and qualified tooling intended for production, we manufacture functional prototypes under controlled conditions. These parts undergo comprehensive metrology, including CMM inspection, surface roughness testing, and material verification against the finalized DFM parameters. Any deviation triggers immediate root cause analysis and process adjustment. This rigorous validation ensures the manufacturing process itself is proven capable and stable before committing to volume, directly feeding our Zero Defects objective by eliminating process uncertainty.

Mass Production leverages the validated process through stringent statistical process control (SPC). Every machining center operates under real-time monitoring of critical parameters like spindle load, tool wear, and environmental conditions. In-process inspections at defined intervals, coupled with final 100% critical dimension checks using calibrated metrology equipment, guarantee conformance. Our closed-loop correction system instantly adjusts parameters if trends approach tolerance limits, preventing non-conforming parts from progressing. Material traceability and documented process records provide full transparency and accountability throughout the production run.

This integrated approach delivers measurable precision. Key process capabilities are consistently maintained as shown below.

| Process Phase | Typical Tolerance Capability | Surface Finish (Ra) | Material Compatibility | Key Control Mechanism |

|---|---|---|---|---|

| Prototyping | ±0.005 mm (±0.0002″) | 0.8 μm (32 μin) | Metals, Plastics, Composites | Full CMM Validation, Process FMEA |

| Mass Production | ±0.002 mm (±0.00008″) | 0.4 μm (16 μin) | Metals, Plastics, Composites | SPC, In-Process Gauging, 100% Critical Dimension Check |

The seamless transition from optimized design through proven prototyping to controlled mass production is the core of our Zero Defects philosophy. By embedding quality into every stage and leveraging advanced process control, Wuxi Lead ensures your precision components arrive not just on time, but with the absolute dimensional integrity and reliability your application demands. This is how we transform specifications into predictable, defect-free outcomes.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

When your manufacturing projects demand the highest levels of precision, reliability, and technical expertise, partnering with Wuxi Lead Precision Machinery is the strategic decision that sets your operations apart. As a leading provider of high-end CNC machining services in China, we specialize in delivering complex, mission-critical components for industries where tolerances are tight, performance is non-negotiable, and consistency is paramount. From aerospace and medical devices to advanced automation and energy systems, our engineering-driven approach ensures your parts meet global standards with zero compromise.

At Lead Precision, we combine state-of-the-art CNC technology with decades of craftsmanship to deliver precision-machined components in both prototype and high-volume production runs. Our facility is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, multi-spindle lathes, and integrated quality inspection systems. Every process is governed by strict ISO 9001:2015 protocols, ensuring repeatable accuracy and full traceability across every production batch. Whether you’re working with exotic alloys, hardened steels, or engineered plastics, our team applies deep material science knowledge to optimize tool paths, surface finishes, and dimensional stability.

What truly differentiates Lead Precision is our commitment to being more than a supplier—we are your engineering partner. From the initial design review to final inspection and logistics, we collaborate closely with your team to identify opportunities for cost reduction, lead time optimization, and performance enhancement. Our engineers provide detailed DFM (Design for Manufacturability) feedback early in the process, helping you avoid costly revisions and accelerate time-to-market.

We understand that in high-stakes manufacturing, specifications matter. Below are key technical capabilities that define our production floor:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, turning, mill-turn, Swiss machining |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials Processed | Aluminum, stainless steel, titanium, Inconel, brass, PEEK, Delrin, and custom alloys |

| Surface Finish | As fine as Ra 0.4 μm (16 μin) |

| Quality Standards | ISO 9001:2015, full CMM inspection, first-article reporting, PPAP documentation |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Our clients choose Lead Precision not only for our technical capacity but for our responsiveness, transparency, and long-term partnership model. We support global clients with seamless communication in English, real-time production updates, and secure IP handling.

Take the next step toward precision excellence. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a virtual factory tour. Let Wuxi Lead Precision Machinery be the foundation of your next high-performance manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.