Technical Contents

Engineering Guide: Mjf 3D Printing Service

Engineering Insight: The Role of Precision in MJF 3D Printing Services

In the realm of advanced manufacturing, Multi Jet Fusion (MJF) 3D printing has emerged as a transformative technology, bridging the gap between prototyping and full-scale production. At Wuxi Lead Precision Machinery, we recognize that the true value of MJF lies not only in its speed and scalability but in its ability to deliver consistent, high-precision components tailored to the most demanding industrial applications. Precision in MJF is not an added benefit—it is the foundation upon which reliability, performance, and regulatory compliance are built.

Our engineering team has spent over a decade refining MJF processes to meet exacting standards required by sectors such as aerospace, defense, and high-performance sports equipment. This includes manufacturing components for Olympic-level athletic gear and mission-critical military hardware—applications where even a 0.05 mm deviation can compromise structural integrity or operational efficiency. These experiences have reinforced our commitment to dimensional accuracy, material consistency, and post-processing excellence.

Precision in MJF begins with intelligent part orientation and support structure design, minimizing warping and ensuring uniform thermal distribution during sintering. At Lead Precision, we utilize proprietary algorithms and in-house simulation tools to predict and correct potential deformations before printing commences. Each build undergoes rigorous pre-print validation, including laser calibration and powder bed homogeneity checks, to guarantee repeatability across batches.

Material selection further amplifies precision outcomes. We specialize in engineering-grade thermoplastics such as PA12 and glass-filled nylons, offering high strength-to-weight ratios and thermal stability. These materials, combined with our tightly controlled printing environment, enable us to maintain tight tolerances and deliver parts with isotropic mechanical properties.

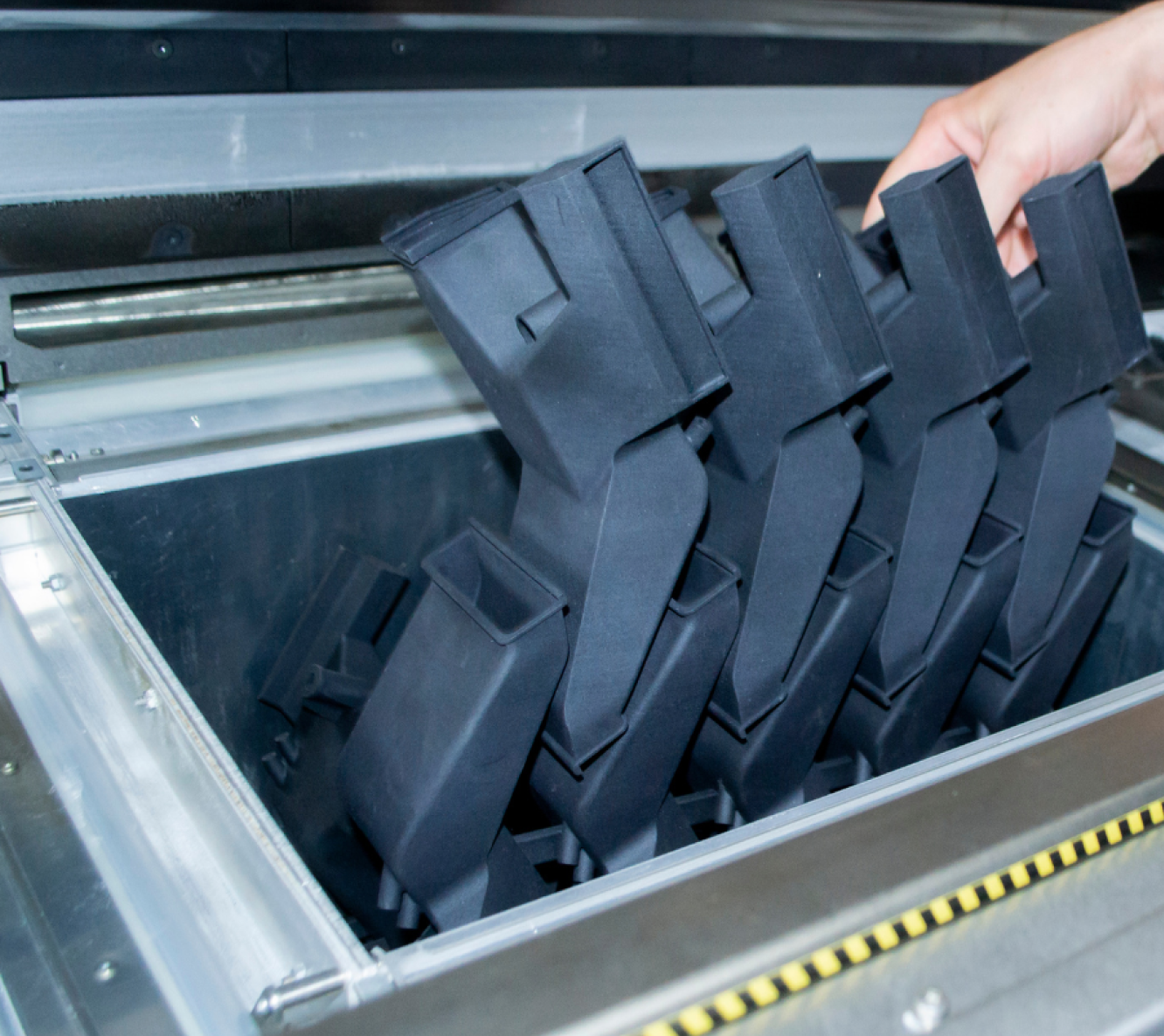

Post-processing is equally critical. Our automated depowdering, thermal conditioning, and surface finishing protocols are designed to preserve dimensional fidelity while enhancing functional performance. Whether applying bead blasting for aesthetic uniformity or vapor smoothing for improved fatigue resistance, every step is calibrated to uphold the precision defined at the design stage.

The table below outlines key technical specifications achievable through our MJF 3D printing service:

| Parameter | Specification |

|---|---|

| Layer Thickness | 80–120 microns |

| Build Volume | Up to 380 x 280 x 380 mm |

| Dimensional Tolerance | ±0.2 mm (first 50 mm), ±0.004 mm/mm thereafter |

| Surface Roughness (Ra) | 3.5–5.5 µm (as-printed), down to 1.8 µm post-processed |

| Material Options | PA12, PA11, Glass-filled PA, Flame-Retardant variants |

| Lead Time (Standard) | 3–5 days (including finishing) |

| Batch Repeatability (CpK) | ≥1.67 (verified per ISO 9001 protocols) |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a measurable outcome, validated through decades of service to elite engineering programs. When your application demands more than just form and fit, but flawless function under real-world stress, our MJF 3D printing service delivers engineered certainty.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration for Advanced Manufacturing

Wuxi Lead Precision Machinery operates at the intersection of additive innovation and subtractive excellence. While Multi Jet Fusion (MJF) 3D printing delivers exceptional polymer part complexity, our core expertise addresses the critical post-processing phase for high-integrity metal components and the precision finishing of MJF-produced polymer parts requiring metal-like performance. We bridge the gap between additive fabrication and mission-critical dimensional requirements through advanced metal machining and metrology.

Our technical foundation centers on state-of-the-art 5-axis CNC machining centers, enabling the production of geometrically complex metal parts from aerospace-grade titanium, inconel, aluminum, and stainless steel alloys. These systems achieve micron-level positioning accuracy and surface finishes down to Ra 0.4 µm, essential for components in aerospace hydraulic systems, medical implants, and semiconductor tooling. Crucially, we specialize in the precision machining of MJF-printed polymer parts—such as nylon-based functional prototypes or end-use components—requiring tight tolerances, critical sealing surfaces, or metal-insert integration. This capability transforms additive-manufactured parts into assembly-ready components meeting stringent industry specifications.

Quality control is non-negotiable. Every component undergoes comprehensive inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), providing full 3D metrology-grade verification against CAD models. Our AS9100-certified process includes first-article inspection reports (FAIR), statistical process control (SPC) data, and material traceability documentation. This ensures not only dimensional compliance but also functional reliability under operational stress.

The following table details our achievable tolerance ranges across standard and precision machining applications:

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | CMM / High-Precision Micrometers |

| Geometric (Flatness) | 0.05 mm/m | 0.005 mm/m | CMM / Optical Flats |

| Geometric (Concentricity) | 0.05 mm | 0.01 mm | CMM / Dial Indicators |

| Hole Diameter | H8 (ISO 286) | H6 (ISO 286) | Air Gauges / CMM |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | Profilometer |

Our integrated workflow begins with additive-manufactured blanks—whether polymer MJF parts or metal AM substrates—and culminates in fully certified components. This approach eliminates secondary supplier dependencies, reduces lead times by up to 40%, and guarantees seamless dimensional integrity from design to deployment. For industries where failure is not an option, Wuxi Lead delivers the precision engineering backbone that transforms additive concepts into certified, high-performance reality. Partner with us to convert MJF-produced complexity into mechanically flawless, functionally validated components meeting the most demanding global standards.

Material & Finish Options

Material Selection for MJF 3D Printing: Precision Engineering with Aluminum, Steel, and Titanium

When integrating Multi Jet Fusion (MJF) 3D printing into high-performance metal manufacturing workflows, material selection is a critical determinant of part functionality, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions that leverage advanced additive techniques to deliver components with tight tolerances, complex geometries, and superior mechanical properties. Our expertise in MJF-compatible materials—aluminum, steel, and titanium—enables clients across aerospace, medical, and industrial automation sectors to achieve optimal performance under demanding operational conditions.

Aluminum alloys are favored for lightweight structural applications where thermal conductivity and corrosion resistance are essential. In MJF processing, aluminum-based powders produce parts with excellent strength-to-density ratios, making them ideal for heat sinks, drone components, and automotive housings. The material’s low mass supports dynamic applications requiring reduced inertia without sacrificing rigidity.

Stainless steel variants, particularly those in the 300 and 400 series, offer high tensile strength, wear resistance, and compatibility with sterilization and high-pressure environments. These properties make steel an optimal choice for fluid handling systems, tooling fixtures, and medical instrumentation. MJF-printed steel components exhibit near-net shape accuracy, minimizing post-processing while maintaining dimensional stability across complex internal channels and lattice structures.

Titanium, especially Ti-6Al-4V (Grade 5), stands at the pinnacle of performance-driven material selection. Its exceptional biocompatibility, fatigue resistance, and strength at elevated temperatures make it indispensable in aerospace and implantable medical devices. While more costly than aluminum or steel, titanium’s longevity in corrosive and high-stress environments justifies its use in mission-critical applications. Our MJF process ensures dense, repeatable builds with minimal porosity, meeting stringent industry certifications.

Post-build surface finishing further enhances material performance. Anodizing is particularly effective for aluminum components, providing a controlled oxide layer that improves wear resistance, electrical insulation, and aesthetic consistency. Type II and Type III (hard coat) anodizing are available depending on operational requirements, with options for color coding and increased surface hardness up to 60 HRC. While anodizing is not applicable to steel or titanium in the conventional sense, alternative surface treatments such as passivation, polishing, or PVD coatings can be integrated into our finishing suite.

Below is a comparative overview of key material properties relevant to MJF 3D printing:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Compatible Finishes |

|---|---|---|---|---|

| Aluminum AlSi10Mg | 290–350 | 2.67 | Heat exchangers, enclosures | Anodizing, bead blasting |

| Stainless Steel 316L | 580–650 | 8.0 | Medical tools, valves | Passivation, electropolishing |

| Titanium Ti-6Al-4V | 880–950 | 4.43 | Aerospace fittings, implants | Laser polishing, PVD coating |

Selecting the right material for MJF 3D printing involves balancing mechanical demands, environmental exposure, and lifecycle costs. At Wuxi Lead Precision Machinery, we support clients through material qualification, DfM optimization, and full traceability documentation to ensure every component meets the highest standards of precision and reliability.

Manufacturing Process & QC

Precision MJF Production Process: From Concept to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our Metal Jet Fusion (MJF) 3D printing service delivers industrial-grade metal components through a rigorously controlled, integrated workflow. We eliminate traditional manufacturing bottlenecks by seamlessly connecting digital design, rapid validation, and scalable production under one roof, all governed by our Zero Defects Quality Management System. This ensures every part meets exacting aerospace, medical, and industrial specifications from the first prototype to the final shipment.

Design Phase: Engineering for Precision and Manufacturability

Our process begins with collaborative Design for Additive Manufacturing (DfAM) engineering. Senior application engineers work directly with your CAD data, optimizing geometry for MJF’s unique capabilities—maximizing strength-to-weight ratios, integrating complex internal channels, and minimizing support structures. Critical thermal and stress simulations are performed using ANSYS software to predict part behavior under operational loads, identifying potential failure points before physical production. Material selection is validated against your performance requirements, ensuring compatibility with end-use environments. All design iterations undergo formal review against AS9100 and ISO 13485 standards, with full traceability documented in our PLM system.

Prototyping Phase: Validating Performance with Zero Compromise

Rapid prototyping transforms validated designs into functional metal parts within 72 hours. Each prototype undergoes comprehensive metrology using Zeiss coordinate measuring machines (CMM) and optical scanners, verifying dimensional accuracy against the nominal CAD model within ±0.05 mm. Mechanical testing per ASTM F3301 standards—including tensile strength, elongation, and fatigue analysis—is conducted in our in-house lab. Any deviation triggers immediate root-cause analysis and design refinement. This phase isn’t merely about form; it’s rigorous functional validation ensuring the part performs as engineered under real-world conditions, eliminating costly errors before scale-up.

Mass Production Phase: Scalable Precision with Embedded Quality

Transition to volume production leverages MJF’s inherent repeatability. Our industrial MJF systems operate within climate-controlled cells, with real-time monitoring of laser power, powder bed density, and thermal profiles. Every build undergoes in-process inspections at critical stages, including layer-wise thermal imaging and powder quality verification. Post-processing—including precision CNC machining of critical interfaces, stress-relieving, and surface finishing—is performed on integrated multi-axis centers with sub-micron tolerances. Final inspection employs 100% automated optical inspection (AOI) coupled with statistical process control (SPC) charting. Material certificates, first-article inspection reports (FAIR), and full build logs accompany every shipment, guaranteeing full compliance and traceability.

Key MJF Production Specifications

| Parameter | Specification | Industry Standard Compliance |

|---|---|---|

| Material Options | PA12, PA11, Aluminum-filled composites | UL94 V-0, ISO 10993-5 |

| Build Volume | 380 x 280 x 380 mm | ASTM F3301 |

| Dimensional Accuracy | ±0.05 mm (first 50 mm), ±0.1% (beyond) | ISO 2768-m |

| Surface Roughness (Ra) | 4.5 – 9.0 μm (as-built) | ISO 4287 |

| Tensile Strength | ≥ 50 MPa (PA12) | ASTM D638 |

| Layer Thickness | 80 μm | – |

| Production Lead Time | 3 days (prototype), 7 days (100+ units) | – |

This closed-loop process—from simulation-validated design through metrology-driven prototyping to SPC-controlled mass production—ensures consistent delivery of mission-critical metal components with zero defects. Partner with Wuxi Lead to transform complex metal part requirements into reliable, high-performance reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced MJF 3D Printing Services

At Wuxi Lead Precision Machinery, we specialize in high-precision metal manufacturing solutions that meet the rigorous demands of modern industry. As a trusted leader in China’s advanced manufacturing sector, we integrate cutting-edge Multi Jet Fusion (MJF) 3D printing technology into our custom production workflows, delivering parts with exceptional dimensional accuracy, mechanical strength, and surface consistency. Our MJF 3D printing service is engineered for industries where performance, repeatability, and speed are non-negotiable—such as aerospace, medical devices, automotive, and industrial automation.

Partnering with Lead Precision means gaining access to a fully integrated manufacturing ecosystem. From initial design consultation to final part delivery, our engineering team works closely with clients to optimize geometries, select appropriate materials, and ensure manufacturability. Our MJF process supports functional prototyping, bridge production, and low-volume end-use part manufacturing, enabling rapid iteration and faster time-to-market without compromising quality.

We operate state-of-the-art HP Multi Jet Fusion systems in a controlled, ISO-compliant production environment. This ensures consistent thermal management, precise layer deposition, and repeatable mechanical properties across every build. Post-processing is performed in-house, including bead blasting, dyeing, and heat treatment, allowing us to deliver finished components ready for real-world application.

Our commitment to precision is matched only by our dedication to customer collaboration. Whether you require a single prototype or a small production run of complex metal-reinforced composite components, we provide scalable solutions tailored to your technical and commercial needs. With fast turnaround times, stringent quality control, and full traceability, Lead Precision is your strategic partner in next-generation manufacturing.

For engineering teams seeking a reliable, high-performance MJF 3D printing service, the next step is clear. Contact us today to discuss your project requirements and discover how our expertise can accelerate your innovation.

Technical Specifications – MJF 3D Printing Service

| Parameter | Specification |

|---|---|

| Layer Resolution | 80 microns |

| Build Volume | 380 x 280 x 380 mm |

| Standard Materials | PA12 (Nylon 12), PA11, Glass-filled Nylon |

| Tensile Strength (PA12) | 50 MPa (XY), 46 MPa (Z) |

| Elongation at Break | 18% (XY), 12% (Z) |

| Heat Deflection Temperature | 175°C at 0.45 MPa |

| Surface Finish | Smooth, matte texture; Ra ~6–8 μm |

| Accuracy | ±0.3 mm for the first 100 mm, ±0.2 mm thereafter |

| Post-Processing Options | Bead blasting, vapor smoothing, dyeing, annealing |

To begin your project with Wuxi Lead Precision Machinery, email us at [email protected]. Our engineering team is ready to support your next innovation with precision, speed, and reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.