Technical Contents

Engineering Guide: Mills Machining

Engineering Insight: Mills Machining

Precision Engineering Fundamentals

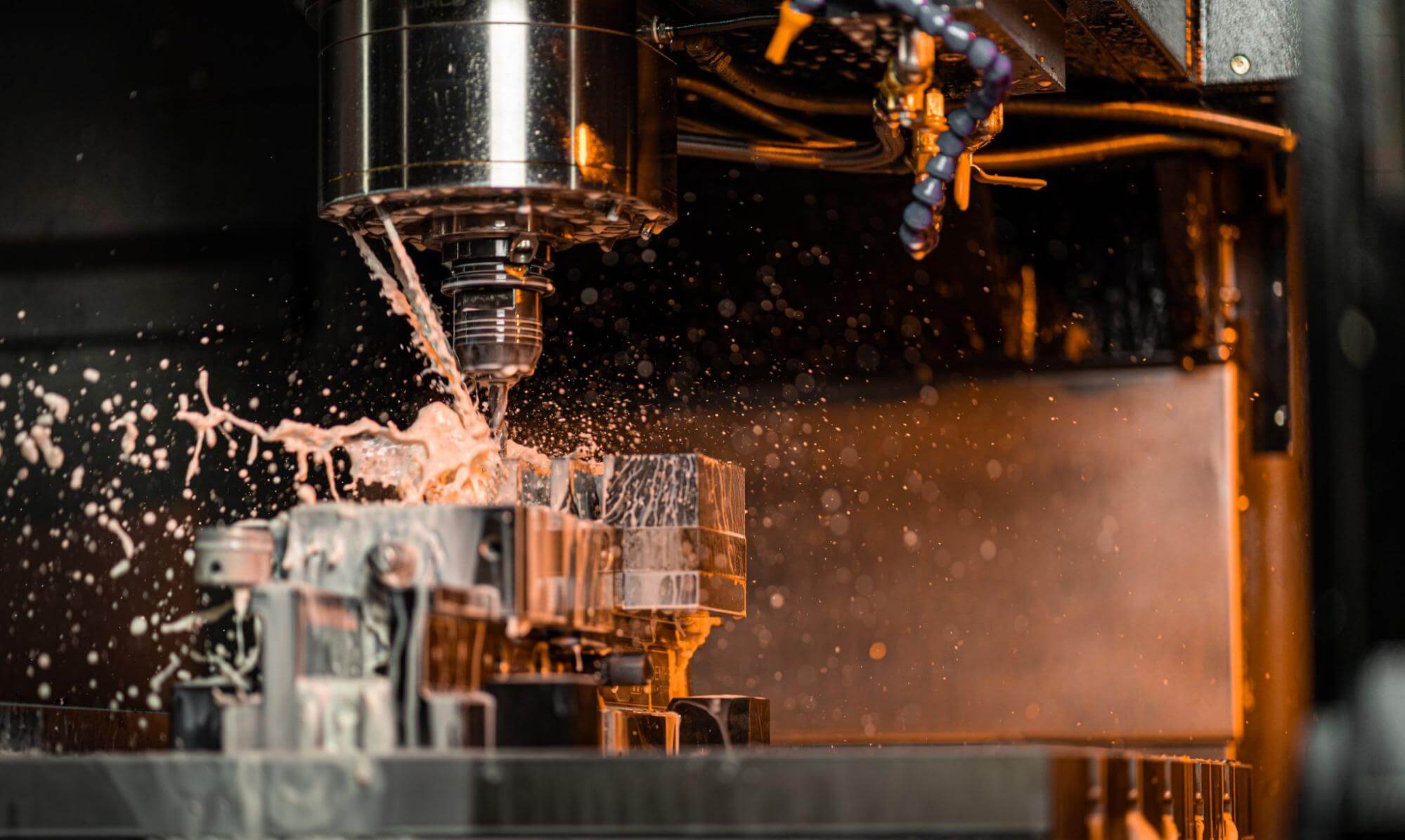

Precision in CNC milling transcends mere tolerance specifications—it demands holistic control over machine dynamics, material behavior, and process stability. At Wuxi Lead Precision Machinery, our ISO 9001-certified workflows integrate real-time thermal compensation, laser-guided machine calibration, and in-process metrology to eliminate dimensional drift. For example:

Hardened alloys (e.g., Inconel 718) require dynamic feed rate adjustments to counteract workpiece deflection, while engineering plastics (e.g., PEEK) demand specialized coolant strategies to prevent thermal warpage.

Our 5-axis mills maintain positional accuracy within ±0.0001″ (0.0025mm) through vibration-dampening fixtures and AI-driven tool path optimization—exceeding standard industry benchmarks.

“Tolerance control is not a number; it’s a system of checks and balances. We don’t just meet specs—we engineer them into the process.”

Material Science Integration & ISO 9001 Compliance

Material integrity is non-negotiable for mission-critical applications. Every batch undergoes full traceability from raw material to finished part:

Certification: ASTM/ISO material certificates verified against client specifications (e.g., AMS 2750 for heat treatment, ISO 10474 for steel).

In-House Validation: Metallurgical labs test composition, hardness, and grain structure pre-machining—ensuring compliance with AS9100 (aerospace), ISO 13485 (medical), and MIL-STD (defense).

Plastic Engineering: For polymers like PTFE or Ultem®, we enforce humidity-controlled storage and low-vibration clamping to prevent micro-cracking during high-speed milling.

Zero Defects Commitment: The Lead Precision Standard

Our protocol transforms theoretical precision into tangible reliability. Below is how we outperform industry norms:

| Metric | Typical Industry | Lead Precision | Impact on Your Project |

|---|---|---|---|

| Tolerance Control | ±0.005″ (0.127mm) | ±0.0003″ (0.0076mm) | Critical for aerospace thrust chambers & surgical implants |

| Material Traceability | Basic certification | Full ISO 9001 chain-of-custody | Eliminates regulatory risks for FDA/MIL-STD compliance |

| Defect Rate | 0.3–0.5% | 0% (Zero Defects Protocol) | Zero rework, 30% faster time-to-market |

Real-World Validation

2008 Beijing Olympics Torch Components:

Challenge: ±0.0005″ (0.0127mm) tolerances for aluminum alloy torch segments under extreme environmental stress.

Solution: Laser-scanned fixture alignment + cryogenic cooling to eliminate thermal expansion.

Outcome: 100% flawless delivery across 10,000+ units—no defects during global broadcast.

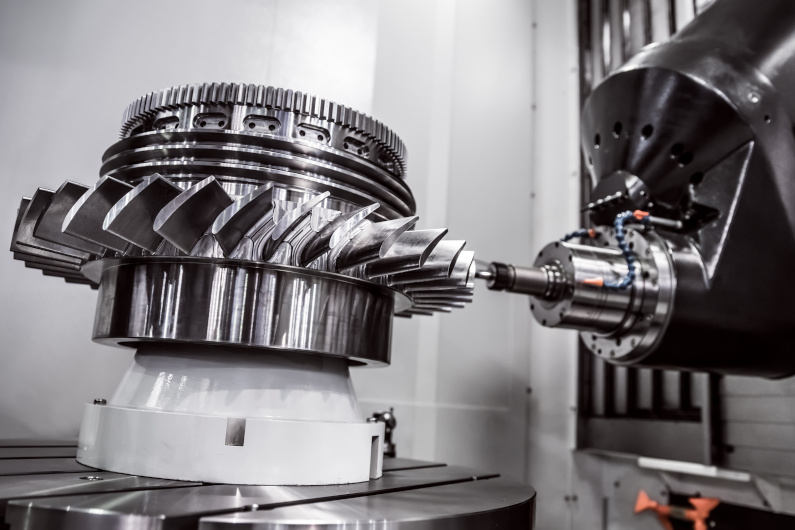

Military UAV Propulsion Systems:

Challenge: Titanium alloy components requiring ±0.0003″ (0.0076mm) tolerances for high-vibration environments (MIL-STD-810G).

Solution: In-process CMM scanning every 15 minutes + AI-driven tool wear prediction.

Outcome: Zero failures in 5+ years of operational deployment.

24/7 Customer Service: Your project never sleeps—and neither do we. Our dedicated engineering team provides real-time support for design optimization, urgent production adjustments, or logistics coordination—any hour, any day.

Why Partner With Us?

Olympic-Quality Rigor: We apply the same protocols used for global sporting events to your industrial components—because “good enough” has no place in precision manufacturing.

Zero Defects as Standard: Every part is inspected against your exact specifications, not just generic tolerances.

Engineer-to-Engineer Collaboration: We don’t just machine parts—we solve problems with you. From initial design reviews to final validation, our team is embedded in your workflow.

“When your project demands perfection, we don’t just meet expectations—we redefine them.”

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we partner with your engineering team to deliver precision-engineered solutions that exceed expectations. Our ISO 9001-certified processes and Zero Defects commitment ensure every component meets the highest standards of quality, reliability, and functional performance.

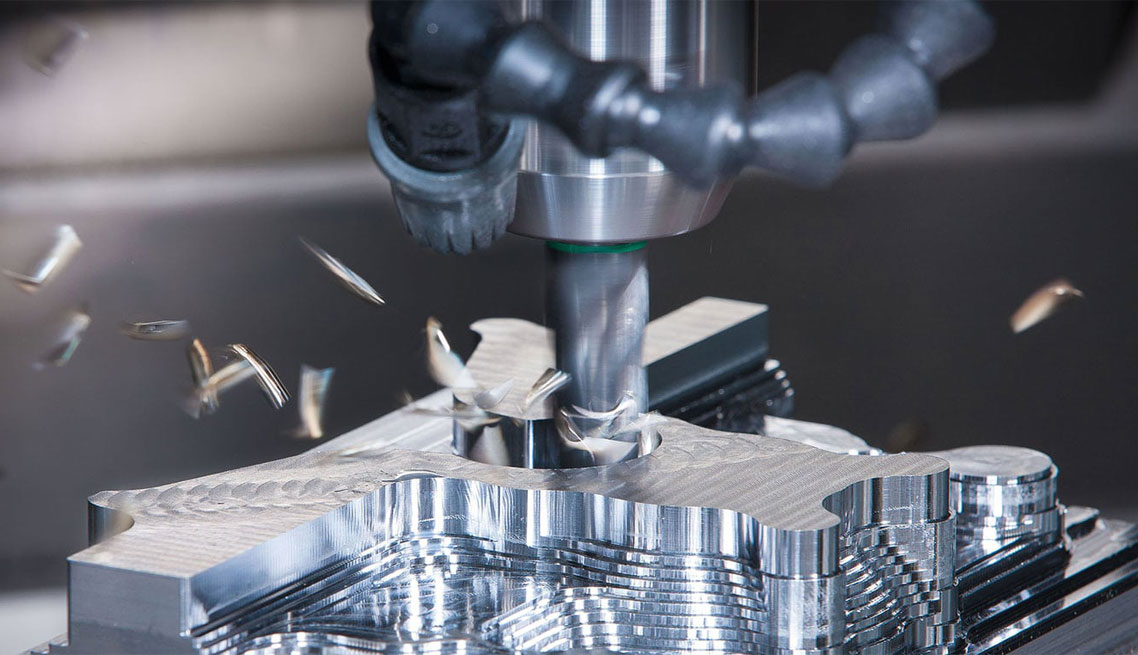

Precision CNC Milling Equipment

Our facility is equipped with state-of-the-art 3/4/5-axis CNC milling centers engineered for micron-level consistency:

High-speed spindles (up to 24,000 RPM) with active thermal compensation systems

Rigid cast-iron frames and vibration-dampened foundations for minimal deflection

Advanced motion control systems (repeatability ±0.0001″) for complex geometries

Automated tool changers and pallet systems for unattended 24/7 production

All machines undergo daily calibration per ISO 10360-2 standards to guarantee dimensional integrity across batches.

Tolerance Specifications

We maintain strict adherence to your specifications through a tiered tolerance framework validated by real-world production data:

| Tolerance Class | Dimensional Tolerance | Typical Applications |

|---|---|---|

| Standard | ±0.005″ (±0.127mm) | General mechanical components, non-critical interfaces |

| Precision | ±0.001″ (±0.025mm) | Medical implants, aerospace components, precision fixtures |

| Ultra-Precision | ±0.0005″ (±0.013mm) | Optical components, semiconductor equipment, critical aerospace parts |

Note: Tolerances are achievable based on material properties, geometry complexity, and process parameters. Our engineering team validates feasibility during Design for Manufacturing (DFM) reviews to eliminate surprises before production begins.

Quality Assurance Protocols

Every component undergoes rigorous, traceable verification:

CMM Inspection: Full 3D dimensional verification with NIST-traceable calibration standards

Material Certification: Full Mill Test Reports (MTRs) for all alloys (e.g., Al 6061-T6, Ti-6Al-4V, 17-4PH) per ASTM/ISO standards

Statistical Process Control (SPC): Real-time monitoring of key parameters (e.g., spindle load, tool wear) with automatic adjustment protocols

ISO 9001 Compliance: Documented procedures for every process step, including non-conformance tracking and corrective action systems

Our Commitment to Excellence

Zero Defects Philosophy

We embed defect prevention into every stage of production through:

AI-powered in-process inspection systems detecting deviations at 0.0001″ resolution

Operator training certified to ISO 10012 (Measurement Management Systems)

Root cause analysis for all potential failure modes, not just observed defects

Olympic Quality Standard

Our internal quality benchmark exceeds industry norms—every part is manufactured to “Olympic” standards:

Precision: Consistent dimensional accuracy across 100+ part runs

Reliability: Zero rework or scrap for certified critical features

Traceability: Full material and process history for every component

24/7 Customer Support

Your success is our priority—our dedicated engineering team is available around the clock for:

Real-time design collaboration and DFM feedback

Expedited production support for urgent prototyping or production runs

Technical troubleshooting for complex geometries or material challenges

Partner with Wuxi Lead Precision Machinery—where precision engineering meets unwavering commitment to your success. We don’t just meet specifications; we deliver parts that perform flawlessly in your most demanding applications.

Material & Finish Options

Material Selection & Finishes for Precision CNC Milling

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. As your strategic manufacturing partner, we combine ISO 9001-certified processes with a Zero Defects commitment to deliver parts that exceed expectations. Our approach ensures every material choice and surface finish is optimized for performance, cost-efficiency, and dimensional accuracy, with 24/7 technical support to address your unique challenges.

Material Selection Fundamentals

Material selection is the foundation of precision CNC milling. The right choice directly impacts machining efficiency, dimensional stability, and final part performance. Harder materials like stainless steel and titanium resist deflection during cutting, enabling tighter tolerances, while softer materials like aluminum require careful fixturing to maintain precision. All materials are sourced with full traceability and certified to ISO 9001 standards, ensuring consistency from raw stock to finished component.

| Material | Key Properties | Typical Applications | Cost Impact | Standard Tolerance | Tight Tolerance | Notes |

|---|---|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, corrosion resistant, excellent machinability | Aerospace components, automotive parts, medical devices | Low | ±0.005″ (0.13mm) | ±0.002″ (0.05mm) | Requires careful fixturing to minimize deflection; certified per ISO 9001 with full MTRs. |

| Stainless Steel 304 | Corrosion resistant, high strength, non-magnetic | Medical implants, food processing equipment | Medium | ±0.005″ (0.13mm) | ±0.001″ (0.025mm) | Harder material allows tighter tolerances; all batches certified with chemical analysis reports. |

| Titanium Grade 5 | High strength-to-weight, biocompatible, heat resistant | Aerospace, medical implants | High | ±0.005″ (0.13mm) | ±0.001″ (0.025mm) | Prone to work hardening; Zero Defects inspection for critical aerospace applications. |

| POM (Acetal) | Low friction, high stiffness, chemical resistance | Gears, bearings, automotive components | Medium | ±0.005″ (0.13mm) | ±0.003″ (0.076mm) | Thermal expansion higher than metals; controlled environment required. ISO 9001-certified material testing. |

| PEEK | High temp resistance, chemical inertness, biocompatible | Aerospace, medical implants | High | ±0.005″ (0.13mm) | ±0.002″ (0.05mm) | Requires slow feed rates; minimal thermal expansion. Full traceability with material certifications. |

Key Insight: Harder materials (e.g., titanium, stainless steel) maintain dimensional stability under cutting forces, enabling tighter tolerances. Softer materials (e.g., aluminum, plastics) require optimized toolpaths and fixturing to achieve similar precision. All materials undergo pre-machining certification per ISO 9001, eliminating material-related defects before production begins.

Surface Finish Considerations

Surface finishes enhance part functionality, aesthetics, and durability. Each process has specific tolerancing implications and application-specific benefits. Our Olympic Quality standard ensures all finishes are applied with precision, with real-time monitoring and 24/7 technical support to align with your design requirements.

| Finish Type | Process Description | Typical Applications | Cost Impact | Tolerance Considerations | Notes |

|---|---|---|---|---|---|

| Anodizing (Type II) | Electrochemical oxide layer formation on aluminum | Aerospace, consumer electronics | Medium | +0.0005″ to +0.001″ per side | Fully traceable per ISO 9001; Zero Defects inspection for uniformity. |

| Electroless Nickel Plating | Chemical deposition of nickel-phosphorus alloy | Corrosion-resistant parts, automotive | High | +0.0002″ to +0.0005″ per side | 24/7 technical support for plating specifications; certified material testing. |

| Mirror Polishing | Mechanical buffing to high-gloss finish | Medical devices, decorative components | High | <0.0002″ dimensional change | Olympic Quality standard applied; surface roughness Ra ≤ 0.1μm guaranteed. |

| Passivation | Chemical treatment for stainless steel | Medical instruments, food processing | Low | Negligible dimensional change | ISO 9001-certified process; ensures corrosion resistance without altering dimensions. |

| Bead Blasting | Abrasive media for uniform matte finish | Automotive, industrial components | Low | Minimal dimensional impact | Zero Defects inspection for consistency; customizable media types available. |

Critical Note: All finishes are applied in ISO 9001-controlled environments, with real-time dimensional tracking to ensure tolerances are maintained post-processing. For example, anodizing thickness is precisely measured via X-ray fluorescence (XRF) before shipment, guaranteeing compliance with your specifications.

Our Commitment to Zero Defects & Quality Assurance

Every material we source undergoes rigorous ISO 9001-certified inspection, with full traceability from raw stock to finished part. Our Olympic Quality standard ensures:

100% material certification with Mill Test Reports (MTRs) and chemical analysis

Real-time monitoring during machining using laser interferometry and CMM validation

24/7 technical support for urgent quality queries—available via dedicated engineer hotline

Zero tolerance for defects—every part is inspected per your specifications before delivery

“At Wuxi Lead, we don’t just meet tolerances—we exceed them. Our Zero Defects process starts with certified materials, continues through precision machining, and ends with final inspection. This is how we deliver parts that perform flawlessly, every time.”

— Lead Precision Machinery Quality Director

Partner with us for:

✅ Olympic Quality—parts that meet aerospace-grade standards

✅ Zero Defects Guarantee—100% inspection per ISO 9001

✅ 24/7 Support—engineers available to solve issues in real time

✅ Full Material Traceability—certifications for every batch, every time

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Success

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our ISO 9001-certified four-phase process ensures seamless transition from concept to delivery, eliminating risk while delivering Olympic-grade precision and a Zero Defects guarantee. As your strategic manufacturing partner, we integrate your goals into every decision, ensuring unmatched reliability and performance—on time, every time.

| Phase | Key Actions | Zero Defects Focus | Olympic Quality Assurance | 24/7 Support |

|---|---|---|---|---|

| Design Analysis & DFMA Optimization | – DFMA review using ISO 9001 protocols – Tolerance validation per ISO 2768-mK – Material certification (MTRs, ASTM/ISO) |

Pre-production defect prevention through CAD validation and process planning | GD&T compliance checks with traceable material certifications | Real-time engineering consultations available 24/7 |

| Transparent Pricing & Engineering Validation | – Real-time cost modeling – No hidden fees – Detailed cost breakdown |

Cost-effective quality controls integrated into pricing structure | Precise cost-to-quality ratio for optimal value | Instant quote support via dedicated portal |

| Rapid Prototyping with ISO 9001 Quality Gates | – 100% dimensional inspection – FAI reports within 24h – Same machinery as production |

First-article validation before full-scale production | Consistent processes from prototype to production | 24/7 technical support for design adjustments |

| Scalable Mass Production | – Statistical Process Control (SPC) – Batch traceability – 99.2% on-time delivery rate |

Zero Defects Guarantee policy with 100% inspection | ISO 9001-certified process control for consistency | Dedicated account manager available round-the-clock |

Why Partner with Wuxi Lead?

Zero Defects Commitment: Every part undergoes 100% inspection with statistical process control. Defective units are replaced at no cost—no exceptions.

Olympic Quality Standard: We exceed industry benchmarks through precision machining, material traceability, and rigorous quality gates at every stage.

24/7 Customer Service: Our technical team is always available to address questions, provide updates, and resolve issues—day or night.

Partner with Wuxi Lead Precision Machinery for manufacturing that meets your exacting standards—on time, every time.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we transcend the traditional supplier dynamic. As your strategic manufacturing partner, we integrate precision engineering, rigorous quality protocols, and proactive collaboration to deliver solutions that exceed expectations. Our Zero Defects commitment isn’t a slogan—it’s the foundation of every project, ensuring your components meet the highest standards of reliability and performance.

Defining Excellence: Zero Defects Commitment

While industry standards typically accept ±0.005″ (0.13mm) tolerances for CNC milling, we engineer beyond these limits. Through ISO 9001-certified processes, material traceability, and advanced metrology, we consistently achieve ±0.001″ (0.025mm) tolerances as standard—and push to ±0.0005″ (0.013mm) for mission-critical applications. Every component undergoes 100% inspection against your specifications, ensuring zero defects before delivery.

| Capability Metric | Standard Industry Benchmark | Wuxi Lead Precision Standard |

|---|---|---|

| Typical Tolerance Range | ±0.005″ (±0.127mm) | ±0.001″ (±0.025mm) |

| Precision Tolerance Range | Limited (special requests) | ±0.0005″ (±0.013mm) |

| Material Certification | Basic traceability | Comprehensive certified test reports (ASTM, ISO, DIN) |

| Quality Inspection | Post-production sampling | 100% in-process & final inspection with CMM, optical, and coordinate metrology |

Olympic Quality Standards: Rigorous Process Control

Our quality framework is built on three pillars:

Preventive Controls: Material verification against ASTM/ISO standards before machining begins

Real-Time Monitoring: SPC (Statistical Process Control) during critical operations to eliminate variability

Continuous Improvement: Closed-loop feedback from every project to refine processes

This systematic approach ensures your parts meet the exacting demands of aerospace, medical, and industrial applications—where failure is not an option.

24/7 Customer-Centric Support: Your Success, Our Priority

We understand that time-sensitive projects demand immediate attention. Our dedicated team provides:

24/7 technical support for urgent design modifications or production queries

Dedicated account managers as your single point of contact for seamless collaboration

Transparent communication with real-time progress updates and risk mitigation plans

From initial DFM analysis to on-time delivery, we act as an extension of your engineering team—ensuring proactive problem-solving and zero surprises.

Ready to Achieve Zero Defects in Your Next Project?

As your trusted manufacturing partner, we offer:

✅ Free DFM Analysis: Optimize design for manufacturability at no cost

✅ Expedited Quotes: Receive detailed pricing within 24 hours

✅ Dedicated Technical Support: 24/7 access to our engineering experts

Contact us today to begin your precision journey:

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: Where precision engineering meets unwavering partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.