Technical Contents

Engineering Guide: Micro 3D Printing Services

Engineering Insight: Micro 3D Printing Services Demand Absolute Precision

In the realm of micro-scale additive manufacturing for metal components, precision transcends mere specification; it becomes the fundamental determinant of functional success. Manufacturing parts with features measured in microns—often below 50µm—introduces unique engineering challenges distinct from conventional or even standard additive processes. At this scale, thermal management during the laser melting phase is critical. Minute variations in energy density or cooling rates induce microscopic distortions or residual stresses, potentially rendering intricate lattice structures or fluidic channels non-functional. Material behavior shifts significantly; surface tension effects dominate over gravitational forces, and powder particle size distribution must be meticulously controlled to achieve layer uniformity. Achieving true dimensional accuracy and surface finish requires not only advanced hardware but deep process understanding. A deviation of even 10µm can compromise the sealing integrity of a micro-valve, alter the resonant frequency of a sensor element, or block capillary flow in medical diagnostics. This level of control separates prototyping capability from viable, repeatable production for demanding industries.

Wuxi Lead Precision Machinery approaches micro metal 3D printing with this uncompromising precision mindset embedded in our core engineering philosophy. Our systems undergo rigorous calibration protocols exceeding industry standards, focusing on laser spot stability, inert gas flow dynamics within the build chamber, and real-time melt pool monitoring. We leverage proprietary parameter optimization techniques developed through extensive material science research, specifically tailored for challenging alloys like titanium, Inconel, and specialized tool steels at micro-scales. This ensures consistent density, minimized porosity, and predictable mechanical properties even in the most delicate geometries. Our process validation is stringent, employing high-resolution metrology including scanning electron microscopy (SEM) and micro-CT scanning to verify internal and external features invisible to standard inspection methods.

The technical capabilities required for successful micro metal additive manufacturing are quantifiable. Our dedicated micro-printing platforms deliver the following baseline performance:

| Parameter | Specification | Application Impact |

|---|---|---|

| Minimum Feature Size | 20 µm | Enables complex micro-fluidics & optics |

| Layer Thickness | 10 – 30 µm | Critical for surface finish & fine detail |

| Positional Accuracy | ± 5 µm | Ensures assembly integrity in micro-systems |

| Build Volume (Typical) | 50 x 50 x 50 mm | Optimized for high-value micro-components |

| Surface Roughness (As-Built) | Ra 5 – 10 µm | Reduces need for extensive post-processing |

This precision capability is not theoretical. It has been rigorously proven through mission-critical applications. Wuxi Lead has successfully manufactured micro-components validated for use in next-generation aerospace subsystems requiring extreme thermal stability and for precision instrumentation deployed in demanding military field environments. Furthermore, our processes contributed to components utilized within timing systems for international sporting events, where absolute reliability under pressure is non-negotiable. These projects demanded not only micron-level accuracy but also full traceability, stringent material certification, and zero-defect delivery—benchmarks we consistently meet. For engineers specifying micro metal 3D printed parts, understanding that true precision encompasses the entire value chain—from powder characterization to final inspection—is paramount. Partnering with a manufacturer possessing proven, high-stakes experience ensures your micro-innovation transitions reliably from design intent to functional reality.

Precision Specs & Tolerances

Advanced Technical Capabilities in Micro 3D Printing and Precision Machining

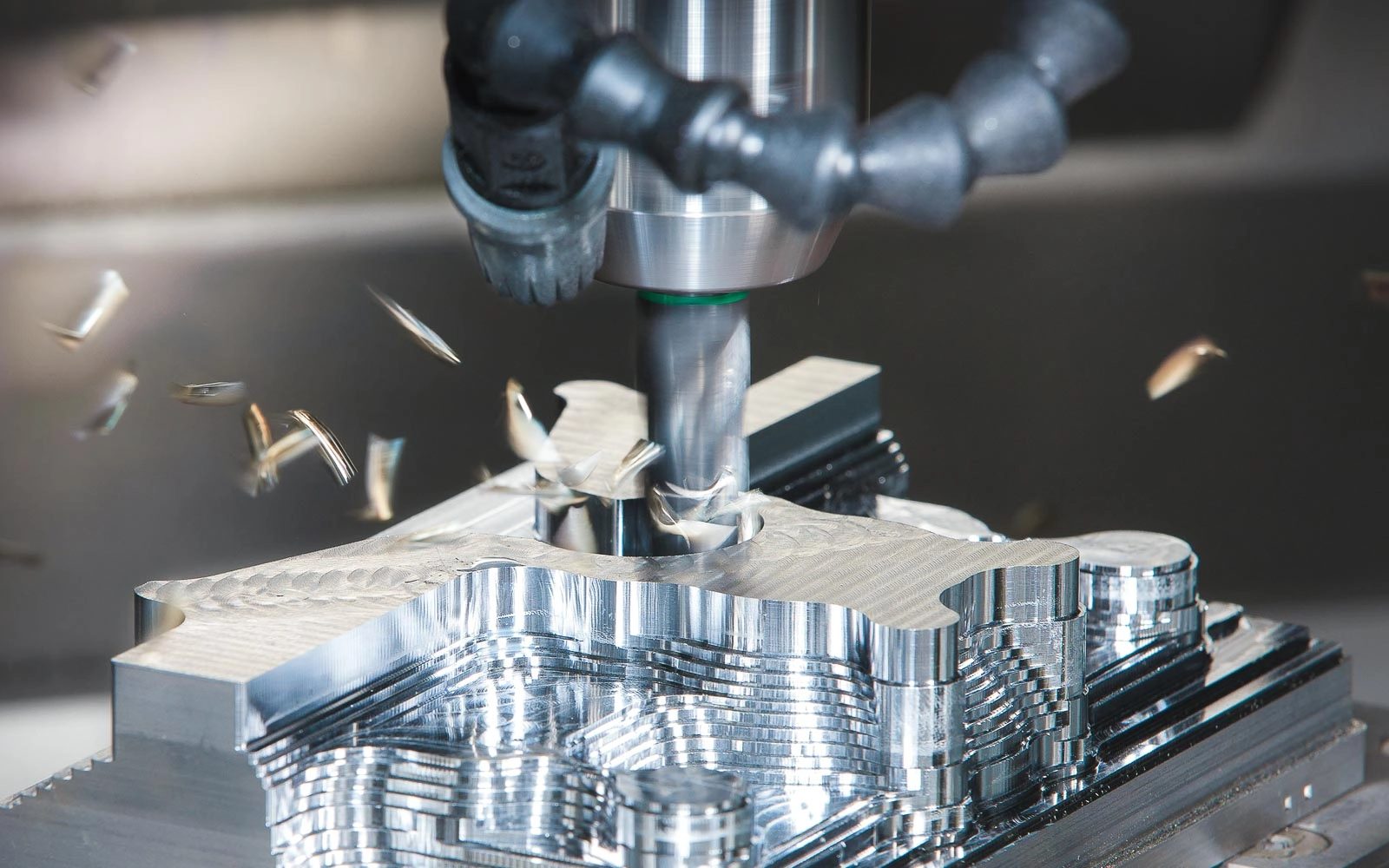

Wuxi Lead Precision Machinery delivers cutting-edge micro 3D printing services integrated with high-precision metal manufacturing, enabling the production of complex, miniaturized components for aerospace, medical devices, and high-performance industrial applications. Our technical infrastructure combines additive manufacturing with advanced 5-axis CNC machining, ensuring dimensional accuracy, superior surface finish, and repeatability at microscopic scales. This hybrid approach allows us to overcome the limitations of standalone 3D printing by enhancing structural integrity and achieving tight tolerances unattainable through additive processes alone.

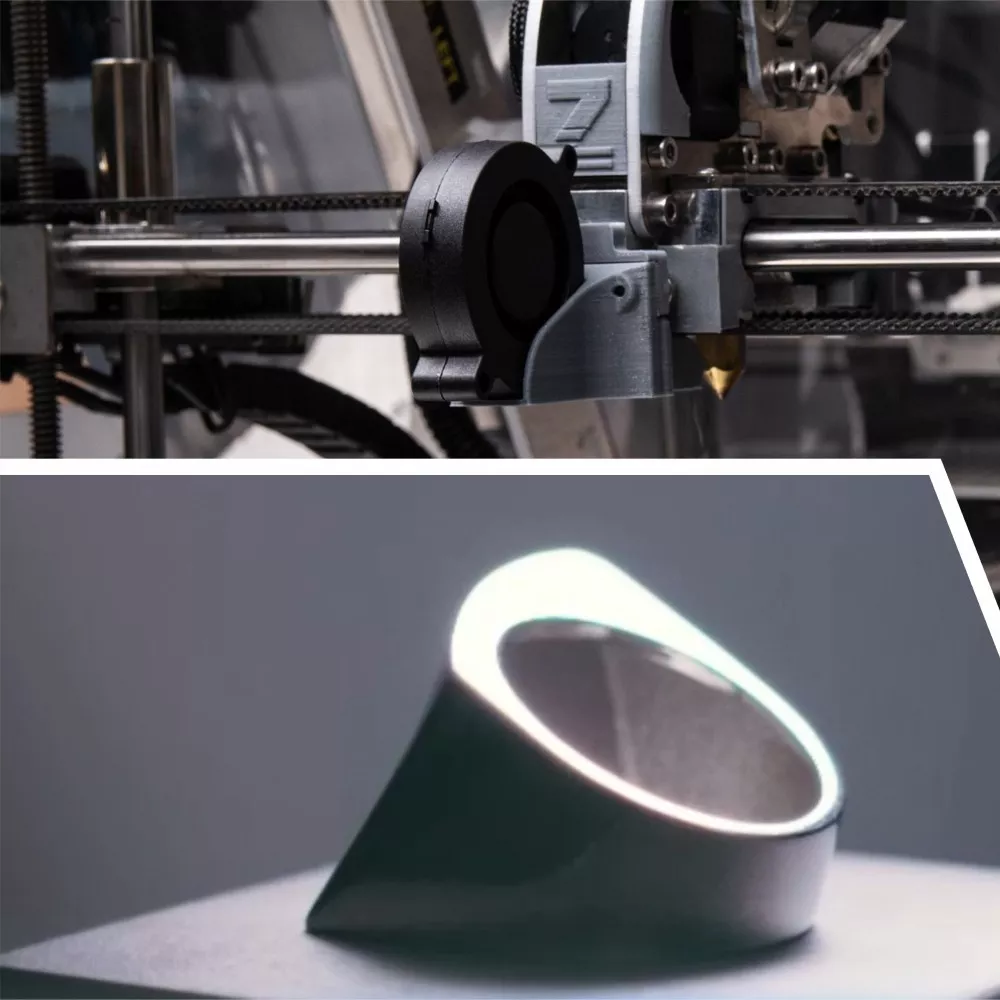

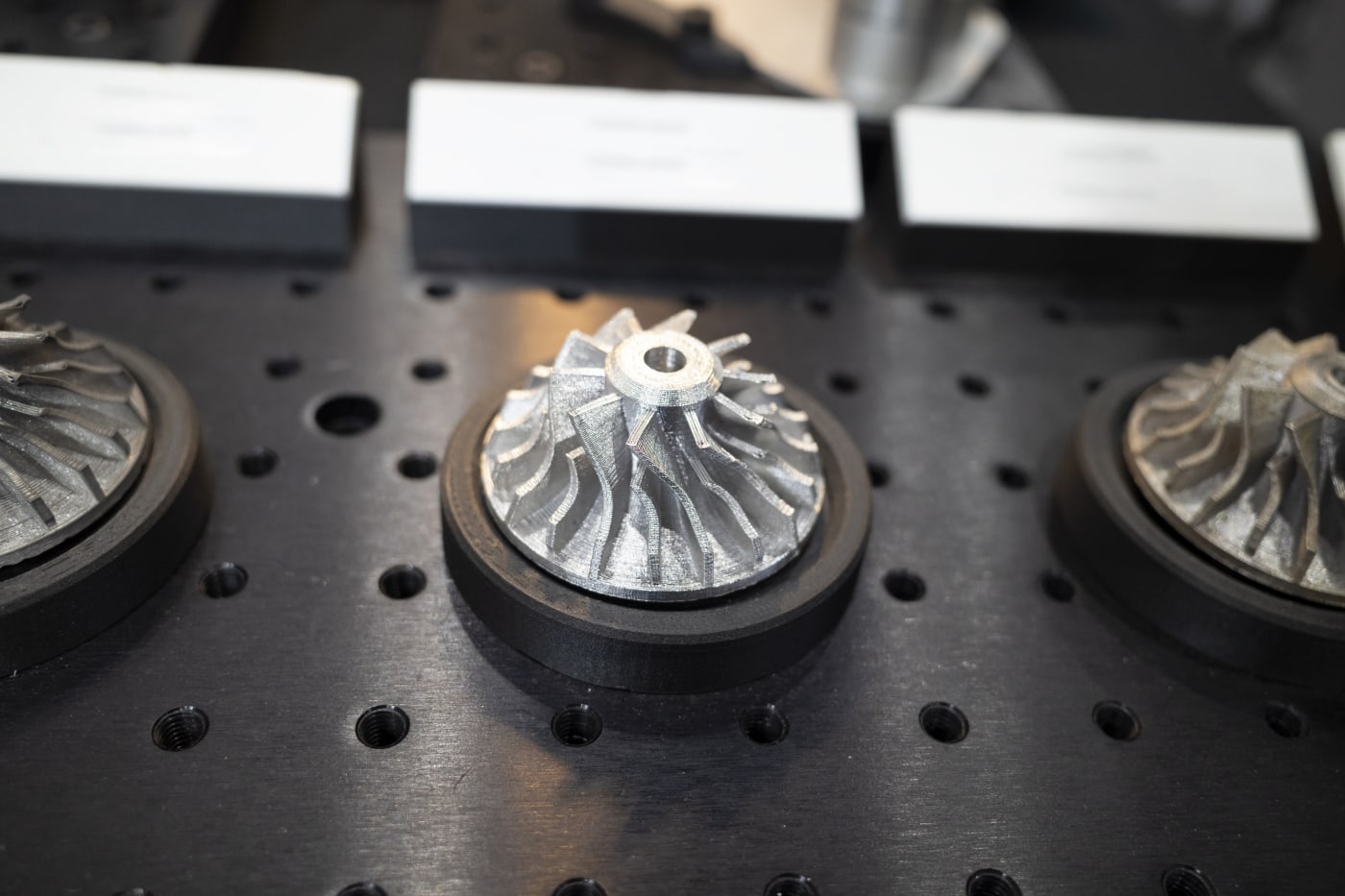

Our micro 3D printing processes utilize laser powder bed fusion (LPBF) technology, optimized for high-resolution metal parts with intricate internal geometries and thin walls as small as 0.1 mm. Materials include titanium alloys (Ti6Al4V), stainless steels (316L, 17-4PH), Inconel 718, and aluminum alloys, all processed under controlled inert atmospheres to ensure material purity and mechanical consistency. Post-printing, components undergo stress-relief heat treatment followed by precision machining on our 5-axis CNC platforms, which provide simultaneous multi-directional cutting for complex contours and undercuts. This integration ensures that even the most challenging micro-scale features are machined with micron-level precision.

Quality assurance is central to our manufacturing philosophy. Every component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machine (CMM) systems, capable of sub-micron measurement resolution. Our CMM inspection routines are fully programmable and traceable, supporting GD&T (Geometric Dimensioning and Tolerancing) analysis for compliance with ISO 1101 and ASME Y14.5 standards. Inspection data is documented and provided with each production batch, ensuring full traceability and process validation for regulated industries.

We maintain strict environmental controls in our cleanroom manufacturing zones to prevent contamination and ensure consistent print quality. All processes are governed by ISO 9001-certified quality management systems, with continuous process monitoring and SPC (Statistical Process Control) implemented across production lines.

The following table outlines the key technical specifications and achievable tolerances for our micro 3D printing and precision machining services:

| Parameter | Capability |

|---|---|

| Minimum Feature Size | 0.1 mm wall thickness, 0.2 mm pin features |

| Layer Thickness (Additive) | 20–40 μm |

| Build Envelope (Max) | 250 x 250 x 300 mm |

| Positional Tolerance (CNC) | ±0.005 mm |

| Surface Roughness (As-Machined) | Ra 0.4–1.6 μm |

| Dimensional Accuracy (LPBF) | ±0.05 mm for first 50 mm, +0.02 mm per additional 100 mm |

| Material Options | Ti6Al4V, 316L, 17-4PH, Inconel 718, AlSi10Mg |

| CMM Measurement Accuracy | ±1.5 + L/350 μm (L in mm) |

This combination of micro-additive fabrication and 5-axis precision machining positions Wuxi Lead as a leader in high-integrity micro manufacturing, capable of delivering fully validated, production-ready components for the most demanding technical environments.

Material & Finish Options

Material Selection for Micro 3D Printing: Precision at Scale

Selecting the optimal material for micro-scale metal 3D printing is critical for achieving functional integrity, dimensional accuracy, and long-term performance in demanding applications. At Wuxi Lead Precision Machinery, our expertise in additive manufacturing for miniature components ensures you leverage the inherent properties of advanced metals while navigating the unique challenges of sub-millimeter feature production. Material choice directly impacts print resolution, surface finish, mechanical behavior, and post-processing viability. We focus on Aluminum, Stainless Steel, and Titanium alloys, each offering distinct advantages for micro-engineered parts in aerospace, medical devices, and precision instrumentation.

Aluminum alloys, particularly AlSi10Mg, provide an exceptional strength-to-weight ratio and excellent thermal conductivity, making them ideal for lightweight micro-components requiring heat dissipation. However, aluminum’s higher thermal expansion coefficient demands precise parameter control during printing to minimize warpage in intricate geometries. Stainless Steel variants like 17-4 PH deliver high strength, corrosion resistance, and biocompatibility, essential for micro-surgical tools or fluidic systems. Achieving fine features requires managing thermal stress to prevent cracking, especially in thin walls below 100 microns. Titanium Grade 5 (Ti6Al4V) remains the benchmark for high-strength, biocompatible, and corrosion-resistant micro-parts, prevalent in implantable medical devices and aerospace actuators. Its low thermal conductivity necessitates specialized laser strategies to ensure consistent melt pool stability and avoid porosity in minute structures.

Surface finishing, particularly anodizing, requires specialized consideration for micro-features. Standard anodizing processes can obscure critical details or cause dimensional shifts in features under 500 microns. Wuxi Lead employs precision-controlled thin-film anodizing, maintaining layer thicknesses between 5-15 microns to preserve micro-geometry while enhancing corrosion resistance and enabling color coding for identification. Achieving uniform color and adhesion on complex micro-surfaces demands proprietary electrolyte management and voltage ramping protocols.

Material performance specifications for micro-scale printing differ significantly from bulk properties. The following table outlines key parameters relevant to sub-millimeter additive manufacturing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Micro-Print Resolution Limit (Wall Thickness) | Key Micro-Application Examples |

|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400-450 | 80 µm | Micro-heat exchangers, drone components |

| 17-4 PH Stainless | 7.75 | 1000-1300 | 60 µm | Micro-valves, surgical instrument tips |

| Ti6Al4V (Grade 5) | 4.43 | 900-1000 | 70 µm | Bone screws, micro-satellite components |

Material selection is not merely about base properties but understanding how those properties manifest during the micro-additive process and subsequent finishing. Wuxi Lead Precision Machinery combines deep metallurgical knowledge with advanced printing capabilities to ensure your micro-components meet exacting functional and dimensional requirements. Consult our engineering team early in the design phase to optimize material choice, printing strategy, and surface treatment for your specific micro-scale application. We validate every parameter set through rigorous metrology, ensuring repeatability down to the micron level. Trust precision-engineered solutions where every micron matters.

Manufacturing Process & QC

Wuxi Lead Precision Machinery delivers precision-driven micro 3D printing services tailored for high-performance industries such as aerospace, medical devices, and advanced electronics. Our production process is engineered for zero defects, ensuring every component meets the most stringent quality standards from concept to mass production.

The journey begins with Design, where our engineering team collaborates closely with clients to translate technical requirements into manufacturable micro-scale metal components. Utilizing advanced CAD and simulation software, we perform design for additive manufacturing (DfAM) analysis to optimize part geometry, minimize stress concentrations, and ensure dimensional stability. Thermal and structural simulations are conducted to predict behavior during printing and post-processing, reducing the risk of failure before physical production begins.

Next, we move to Prototyping, a critical phase where design integrity is validated. Using laser powder bed fusion (LPBF) technology, we produce functional prototypes with layer resolutions as fine as 20 microns. Each prototype undergoes full metrological inspection using coordinate measuring machines (CMM) and 3D optical scanning to verify dimensional accuracy within ±5 µm. Material properties are tested according to ASTM standards, including tensile strength, hardness, and microstructure analysis. Feedback from this stage is integrated into final design refinements, ensuring readiness for volume production.

Mass Production follows a fully controlled workflow across our automated manufacturing cells. Each build is monitored in real time with in-situ thermal imaging and layer-wise defect detection systems. Our production environment adheres to ISO 13485 and ISO 9001 standards, with full traceability maintained for every batch, including powder lot tracking, machine calibration logs, and environmental data. Post-processing—including stress relief, support removal, precision machining, and surface finishing—is performed in-house under tightly controlled parameters to maintain consistency.

Quality assurance is embedded at every stage. We implement statistical process control (SPC) and first-article inspection (FAI) protocols to detect deviations before they propagate. Final parts are subjected to non-destructive testing (NDT), such as micro-CT scanning, to verify internal integrity down to the micron level. Only components that pass 100% inspection are released for delivery.

Our commitment to zero defects is not a target—it is a standard. By integrating precision engineering, advanced monitoring, and rigorous validation, Wuxi Lead ensures that every micro 3D printed component performs reliably in the most demanding applications.

| Specification | Detail |

|---|---|

| Minimum Feature Size | 50 µm |

| Layer Thickness Range | 20–50 µm |

| Dimensional Accuracy | ±5 µm |

| Surface Roughness (as-printed) | Ra 8–12 µm |

| Post-Processed Surface Finish | Ra 0.4–1.6 µm |

| Material Options | 316L Stainless Steel, Inconel 718, Ti6Al4V, CoCr, Tool Steel |

| Build Envelope | 100 × 100 × 100 mm |

| In-Process Monitoring | Real-time thermal imaging, layer defect detection |

| Quality Standards | ISO 9001, ISO 13485, ASTM F857, ISO 17025 |

Why Choose Wuxi Lead Precision

Elevate Your Micro-Scale Manufacturing with Precision Engineering

Complex micro-components demand manufacturing partners who transcend standard additive capabilities. Generic micro 3D printing services often falter when confronted with the stringent tolerances, material integrity requirements, and geometric intricacies essential for aerospace actuators, medical implants, or semiconductor tooling. At Wuxi Lead Precision Machinery, we solve this critical gap. Our dedicated micro metal additive manufacturing division operates at the absolute forefront of precision engineering, delivering parts where conventional processes reach their limits. We are not merely a service provider; we are an integrated engineering partner committed to your project’s success from initial concept through certified production.

Our proprietary micro-scale metal AM platform, developed and refined over years of specialized application, achieves resolutions and repeatability unattainable with standard industrial systems. We combine ultra-fine powder handling, advanced laser calibration, and in-process monitoring within a strictly controlled environment. This results in components featuring sub-10-micron feature resolution, exceptional surface finish as-built, and mechanical properties meeting or exceeding wrought material standards. Crucially, our process is fully integrated with secondary precision operations – including micro-machining, laser polishing, and non-destructive testing – ensuring your final part meets every dimensional and functional specification without external handoffs or quality compromises.

The technical foundation of our micro 3D printing service is engineered for uncompromising results. Key specifications demonstrate our capability:

| Parameter | Specification | Significance for Your Project |

|---|---|---|

| Build Volume | 50 x 50 x 50 mm | Optimized for true micro-part production |

| Layer Thickness | 5 – 20 µm | Enables intricate geometries & fine features |

| Feature Resolution | < 10 µm (critical dimensions) | Achieves micron-level precision reliably |

| Surface Roughness | Ra 1.5 – 5.0 µm (as-built) | Minimizes need for extensive post-processing |

| Standard Materials | 316L, 17-4PH, Ti6Al4V, Inconel 718 | Aerospace, medical, & industrial grade alloys |

| Positional Accuracy | ± 5 µm over 10 mm | Ensures dimensional integrity for assembly |

Partnering with Wuxi Lead Precision Machinery means access to deep application engineering expertise alongside cutting-edge technology. Our engineers collaborate directly with your R&D and production teams to optimize designs specifically for micro-additive manufacturing, identify potential failure points early, and establish robust, repeatable production protocols. We understand that in high-value micro-manufacturing, process validation and traceability are non-negotiable. Our ISO 9001 certified facility provides full material traceability, comprehensive first-article inspection reports, and statistical process control data for every production run.

The competitive advantage in micro-scale metal components lies not just in the print, but in the guaranteed precision and reliability of the final part. Stop compromising on quality or lead times with solutions not built for true micro-engineering demands. Contact our precision engineering team today to discuss your specific micro 3D printing challenge. Send your project details and requirements to [email protected]. Let Wuxi Lead Precision Machinery become your trusted partner in pushing the boundaries of what’s possible in micro metal manufacturing. Your next breakthrough component starts with a conversation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.