Technical Contents

Engineering Guide: Micro 3D Printing Service

Engineering Insight: Precision as the Foundation of Micro 3D Printing

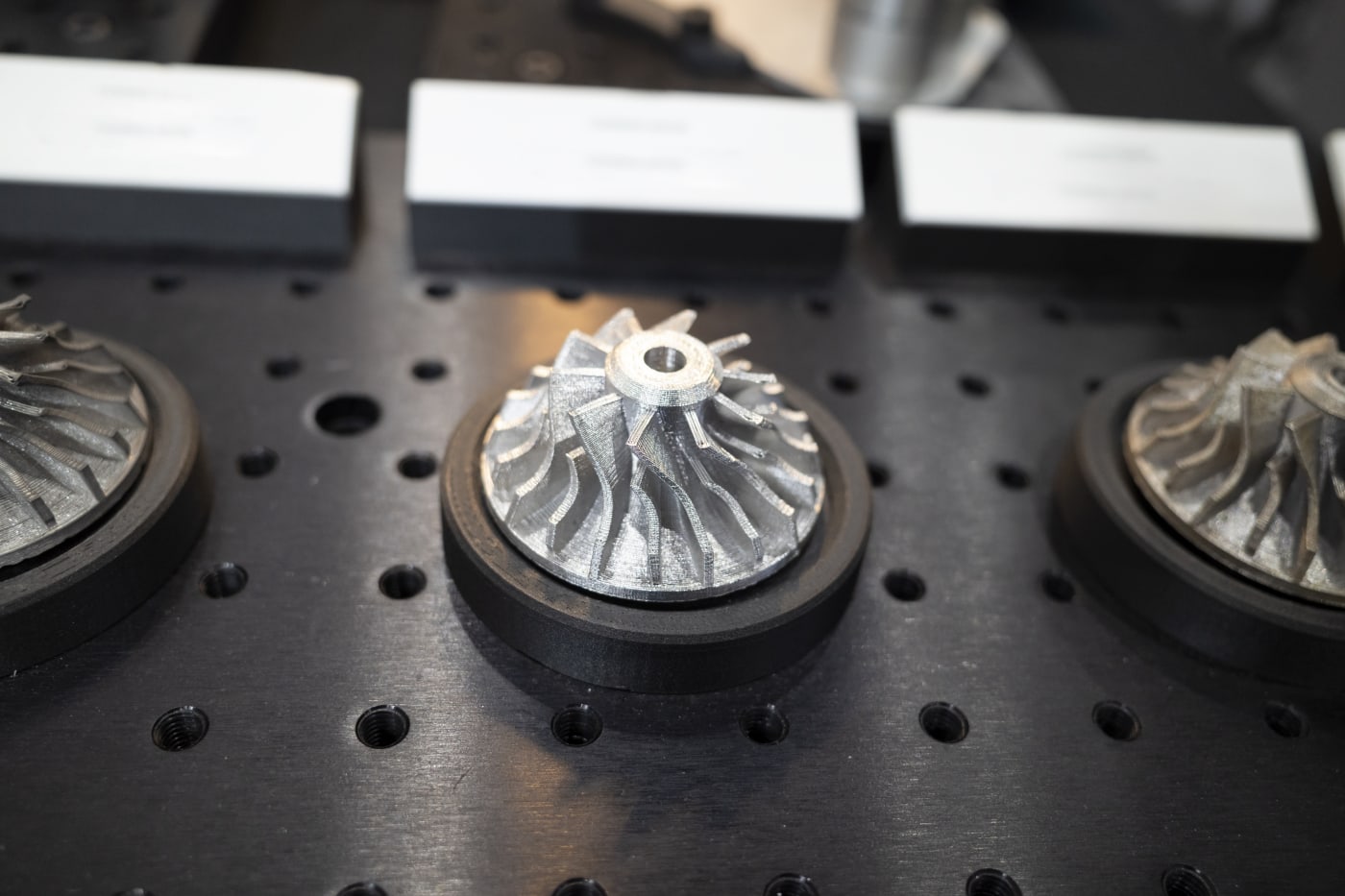

In the realm of custom metal micro 3D printing, precision transcends mere specification; it is the absolute prerequisite for functional viability. Components operating at sub-100 micron scales—common in aerospace fuel injectors, medical micro-surgical tools, and semiconductor handling systems—demand dimensional accuracy and surface integrity unattainable through conventional subtractive methods. At this scale, a single micron deviation can compromise fluid dynamics, structural fatigue life, or biocompatibility. Achieving true micron-level repeatability requires more than advanced hardware; it necessitates deep process mastery controlling thermal dynamics, powder characteristics, and residual stress management inherent in metal additive manufacturing. Without this control, micro-features collapse, internal channels distort, and critical tolerances become statistical outliers rather than guaranteed outcomes.

Wuxi Lead Precision Machinery operates at this demanding threshold daily. Our engineering protocols are forged not only in commercial applications but through rigorous validation in environments where failure is non-negotiable. We have successfully delivered mission-critical micro-components for precision timing systems in Olympic sporting events, where nanosecond accuracy dictates athletic records, and for specialized military hardware requiring absolute reliability under extreme operational stress. These projects demanded and validated our ability to consistently hold tolerances below ±5μm on complex geometries—a standard far exceeding typical industry benchmarks. This experience translates directly to client projects: your micro-fluidic manifold or implantable sensor array receives the same uncompromising scrutiny as defense-grade systems.

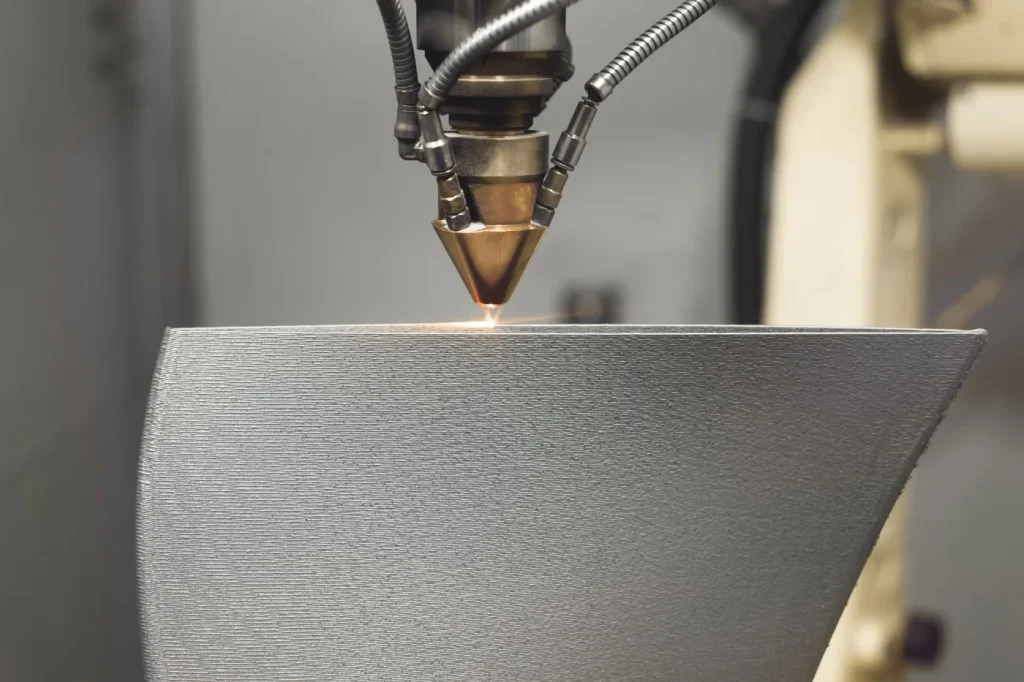

The technical foundation for this precision lies in our integrated process chain. We utilize specialized laser systems with spot sizes under 20μm, coupled with inert gas purification maintaining oxygen levels below 25ppm to prevent micro-porosity. In-situ monitoring tracks melt pool stability layer-by-layer, while our proprietary thermal management algorithms minimize distortion in overhangs and thin walls. Post-processing employs micro-machining and isotropic finishing techniques calibrated to preserve micron-level features. This holistic approach ensures that design intent becomes physical reality.

Key performance parameters defining our micro 3D printing capability are summarized below:

| Parameter | Capability Range | Typical Performance |

|---|---|---|

| Minimum Feature Size | 20 – 50 μm | 30 μm |

| Layer Thickness | 20 – 50 μm | 30 μm |

| Dimensional Tolerance | ±5 – ±15 μm | ±7 μm |

| Surface Roughness (As-Built) | Ra 5 – 15 μm | Ra 8 μm |

| Build Volume (Optimized) | 100 x 100 x 100 mm | Focused for micro |

| Material Options | Stainless Steels, Ti6Al4V, Inconel 718, CuCrZr | Fully qualified |

For industries where microscopic performance dictates macroscopic success, precision is not an optional upgrade—it is the core engineering requirement. Wuxi Lead Precision Machinery delivers this through proven process discipline, validated by the most exacting global standards. Partner with us to transform your most intricate micro-metal designs into reliable, high-performance realities. Our commitment is measured not in millimeters, but in microns.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced micro 3D printing services tailored for high-precision metal components in demanding industrial sectors. Our technical capabilities integrate cutting-edge additive manufacturing with precision subtractive processes, enabling the production of complex, high-integrity metal parts with micron-level accuracy. At the core of our manufacturing ecosystem is a suite of 5-axis CNC machining centers, which provide the dynamic range and rigidity required for post-processing of micro 3D printed components. These machines support multi-directional cutting paths, allowing for the precise finishing of intricate geometries that are common in aerospace, medical, and semiconductor applications.

Our micro 3D printing process utilizes laser powder bed fusion (LPBF) technology with a focus on materials such as titanium alloys, stainless steels, Inconel, and tool steels. Layer resolution down to 20 microns ensures exceptional surface fidelity and dimensional control, while our in-house 5-axis CNC systems enable stress relief, precision leveling, and critical feature machining to meet tight tolerance requirements. This hybrid approach—combining additive freedom with subtractive precision—ensures that every component not only achieves design intent but also complies with functional performance standards.

Quality assurance is embedded throughout the manufacturing workflow. Every part undergoes comprehensive inspection using a coordinate measuring machine (CMM) calibrated to international standards. Our CMM systems provide full 3D geometric dimensioning and tolerance (GD&T) verification, ensuring compliance with ASME Y14.5 and ISO 1101 specifications. Data from each inspection is documented and traceable, supporting full production lot accountability for regulated industries.

We maintain strict environmental controls in our cleanroom-class manufacturing zones to prevent contamination and ensure process repeatability. In addition, our engineering team performs pre-build simulation and support optimization to minimize residual stress and distortion during printing. This proactive approach reduces post-processing time and enhances first-time yield, especially for high-mix, low-volume production runs.

The following table outlines the key technical specifications and achievable tolerances for our micro 3D printing and precision machining services:

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–50 µm |

| Build Envelope | 140 x 140 x 140 mm |

| Material Options | Ti6Al4V, 316L, Inconel 718, 17-4 PH, Tool Steel |

| Minimum Feature Size | 50 µm |

| Surface Roughness (as-printed) | Ra ≤ 8 µm |

| Surface Roughness (CNC finished) | Ra ≤ 0.8 µm |

| Dimensional Tolerance (CNC) | ±5 µm (for features < 50 mm) |

| Positional Accuracy (CMM) | ±2 µm repeatability |

| Post-Processing Capabilities | Stress relief, HIP, precision CNC, polishing |

Wuxi Lead Precision Machinery is committed to delivering micro-scale metal components that meet the highest standards of precision and reliability. Through the integration of micro 3D printing, 5-axis CNC finishing, and rigorous CMM-based quality control, we provide a comprehensive solution for advanced manufacturing challenges.

Material & Finish Options

Material Selection Fundamentals for Micro Metal 3D Printing

Selecting the optimal material for micro-scale 3D printed metal components is critical for achieving functional performance, dimensional accuracy, and longevity in demanding applications. At Wuxi Lead Precision Machinery, our deep expertise in micro additive manufacturing ensures materials are matched precisely to your component’s operational environment, mechanical requirements, and geometric complexity. The unique thermal dynamics and fine feature resolution inherent in micro 3D printing necessitate careful evaluation beyond standard additive processes. Aluminum alloys, specific steels, and titanium represent the core high-performance options, each offering distinct advantages for miniature parts in aerospace, medical devices, and precision instrumentation.

Aluminum alloys, particularly AlSi10Mg, are favored for lightweight micro-components requiring good thermal conductivity and moderate strength. Their lower density reduces inertia in moving micro-parts, while inherent corrosion resistance suits certain environmental exposures. However, aluminum’s higher thermal conductivity demands precise laser parameter control during micro-printing to prevent heat dissipation issues that could compromise fine feature integrity or cause warpage in intricate geometries. Post-processing remains essential for achieving critical surface finishes.

High-strength steels, including maraging grades like 18Ni300 and tool steels, deliver exceptional hardness, wear resistance, and structural stability for micro-tools, inserts, and load-bearing components. These materials maintain dimensional stability under stress and high temperatures, crucial for micro-mechanisms. Printing steels at micro-scales requires meticulous management of residual stresses to avoid cracking in thin walls or small cross-sections. Achieving the required mechanical properties often involves specific heat treatments tailored to the miniature part geometry.

Titanium alloys, primarily Ti6Al4V, are indispensable for micro-components demanding the highest strength-to-weight ratio, biocompatibility, and extreme corrosion resistance. Common in medical micro-implants and aerospace sensors, titanium’s biocompatibility and fatigue resistance are unmatched. Its lower thermal conductivity compared to aluminum simplifies thermal management during micro-printing but necessitates strict atmospheric control to prevent embrittlement. Surface finish optimization is paramount for titanium micro-parts intended for biological integration.

Anodizing: Precision Surface Enhancement for Micro-Parts

Anodizing is the premier surface finishing process for aluminum micro-components produced via 3D printing. This electrochemical treatment creates a dense, corrosion-resistant oxide layer that significantly enhances surface durability and wear resistance without compromising the part’s micron-level tolerances. For micro-features, precise control of anodizing thickness (typically 5-15µm for functional micro-parts) is non-negotiable; excessive growth can obliterate fine details or alter critical dimensions. Our process ensures uniform layer formation even on complex micro-geometries, providing excellent adhesion for subsequent coatings or meeting stringent biocompatibility standards where required. Color anodizing options also support micro-part identification in assemblies.

Material properties directly impact micro-printing success and final part performance. The following specifications guide critical decision-making:

| Material | Key Properties | Micro-Printing Suitability | Common Micro-Applications |

|---|---|---|---|

| Aluminum AlSi10Mg | Low density, Good thermal conductivity, Moderate strength | Requires precise thermal management; prone to warpage in ultra-thin features | Lightweight brackets, Heat sinks, Sensor housings |

| Steel 18Ni300 | High strength, Excellent toughness, Wear resistance | Demands stress management; post-heat treatment critical | Micro-molds, Precision gears, Surgical tools |

| Titanium Ti6Al4V | High strength-to-weight, Biocompatible, Corrosion resistant | Needs inert atmosphere control; surface finish critical | Medical implants, Aerospace sensors, Micro-valves |

Material choice fundamentally dictates the achievable performance envelope for your micro 3D printed metal component. Wuxi Lead Precision Machinery leverages extensive process knowledge to navigate the interplay between material behavior, micro-scale physics, and your application’s exacting demands, ensuring optimal material and finish selection from the outset.

Manufacturing Process & QC

From Concept to Mass Production: The Zero-Defect Micro 3D Printing Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, our micro 3D printing service is engineered for clients demanding micron-level accuracy, structural integrity, and repeatable precision in custom metal components. We specialize in high-performance applications across aerospace, medical devices, and advanced electronics, where failure is not an option. Our production process follows a rigorously controlled sequence—Design, Prototyping, and Mass Production—ensuring zero defects and full traceability at every stage.

The process begins with collaborative design engineering. Our team works directly with client CAD models, applying deep expertise in additive manufacturability to optimize geometry, support structures, and thermal behavior. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are employed to predict performance under operational loads, enabling preemptive refinement. Material selection is critical—our platform supports Inconel 718, Ti-6Al-4V, 316L stainless steel, and custom cobalt-chrome alloys, each chosen for specific mechanical, thermal, and corrosion-resistant properties.

Prototyping follows a closed-loop validation protocol. Components are printed using laser powder bed fusion (LPBF) with layer resolutions as fine as 20 µm, enabling intricate lattice structures and internal channels unachievable through traditional methods. Each prototype undergoes full metrology inspection via coordinate measuring machines (CMM) and micro-computed tomography (micro-CT) scanning to detect internal porosity, dimensional deviation, or surface anomalies. First article inspection (FAI) reports are generated, and any deviation triggers immediate process adjustment—never a compromise on specification.

Only after prototype approval do we transition to mass production. Our production cells operate under ISO 13485 and AS9100-certified conditions, with real-time environmental monitoring and in-situ melt pool analysis during every print cycle. Automated powder handling, inert gas control, and batch traceability ensure material consistency across thousands of parts. Post-processing—including stress relieving, hot isostatic pressing (HIP), precision machining, and surface finishing—is integrated into the workflow with calibrated parameters unique to each component.

Throughout the process, data is logged and audited. Every part is traceable to its raw material lot, build chamber, and inspection record. This digital thread enables full quality assurance and rapid root-cause analysis, should any anomaly arise—even one.

We define zero defects not as a goal, but as a standard. By integrating precision engineering, closed-loop validation, and industrial-grade process control, Wuxi Lead delivers micro 3D printed metal components that perform reliably in the most demanding environments.

Micro 3D Printing Technical Specifications

| Parameter | Capability |

|---|---|

| Minimum Feature Size | 50 µm |

| Layer Thickness | 20–40 µm |

| Build Volume | 140 × 140 × 140 mm |

| Positional Accuracy | ±5 µm |

| Surface Roughness (as-printed) | Ra 8–12 µm |

| Supported Materials | Inconel 718, Ti-6Al-4V, 316L, CoCr, Custom Alloys |

| Post-Processing Options | HIP, CNC Machining, Polishing, Passivation |

Why Choose Wuxi Lead Precision

Where Micro-Scale Precision Meets Industrial Production

At Wuxi Lead Precision Machinery, we transform the theoretical potential of micro 3D printing into certified, production-ready metal components. For over 15 years, we have engineered solutions for aerospace, medical implant, and semiconductor clients demanding features below 100 microns—where conventional subtractive or casting methods fail. Our proprietary Micro-Laser Powder Bed Fusion (µLPBF) platform achieves repeatability unattainable in standard additive systems, validated through ISO 13485 and AS9100-certified workflows. This is not prototyping; it is volume-capable micro-manufacturing with full material traceability and NDT validation.

Partnering with Lead Precision eliminates the risk of scaling micro-features from lab to factory. Our integrated engineering team collaborates from initial design feasibility through to serial production, applying decades of CNC machining expertise to optimize support structures, thermal management, and post-processing for micro-geometries. We resolve the critical pain points others overlook: residual stress in sub-50µm lattice structures, surface roughness control for fluidic microchannels, and geometric accuracy in overhanging features under 20µm. Your complex micro-component requires more than a printer—it demands a manufacturing ecosystem built for micron-level yield.

Technical Capabilities for Mission-Critical Micro-Components

| Key Parameter | Lead Precision Specification | Industry Context |

|---|---|---|

| Minimum Feature Size | 10 µm | Enables microfluidic valves, neural probes |

| Layer Resolution | 5–20 µm | Critical for optical surface finishes |

| Build Volume | 50 x 50 x 50 mm | Optimized for high-value micro-parts |

| Material Options | Ti-6Al-4V ELI, 316L, Inconel 718, Custom Alloys | Biocompatible & high-temp grades |

| Surface Roughness (as-built) | Ra 3–5 µm | Eliminates secondary polishing for many applications |

| Positional Accuracy | ±5 µm over 10 mm | Meets semiconductor tooling tolerances |

We do not sell machine time—we deliver certified micro-components ready for integration. Every build undergoes in-situ melt pool monitoring, followed by CT scanning and micro-CT verification of internal channels. Our closed-loop powder management ensures material consistency across 500+ production runs, while our post-processing suite—including micro-shot peening and electrochemical polishing—achieves medical-grade surface integrity. When your design pushes the boundaries of miniaturization, our engineers co-develop the process to achieve >95% first-pass yield.

Your Next Step: Precision Engineered for Your Timeline

Contact us to receive a micro-manufacturing feasibility assessment within 48 hours. Share your CAD file or technical specifications with our engineering team, and we will provide a detailed analysis of achievable tolerances, material performance data, and a validated production timeline. Do not compromise on micro-scale reliability with generic additive services. At Lead Precision, we measure success in microns—not just millimeters.

Request your technical consultation today. Email [email protected] with subject line “Micro 3D Printing Feasibility” to initiate direct engineering support. Let us prove why global leaders in precision manufacturing trust Wuxi Lead for the smallest details that define their largest innovations.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.