Technical Contents

Engineering Guide: Metal Sheet Parts

Engineering Insight: Metal Sheet Parts – The Critical Role of Precision in High-Performance Manufacturing

In the realm of custom metal manufacturing, metal sheet parts serve as foundational components across aerospace, defense, medical, and high-end industrial systems. These parts, often subjected to extreme environments, must meet exacting dimensional tolerances and structural integrity standards. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a quality metric—it is a performance imperative.

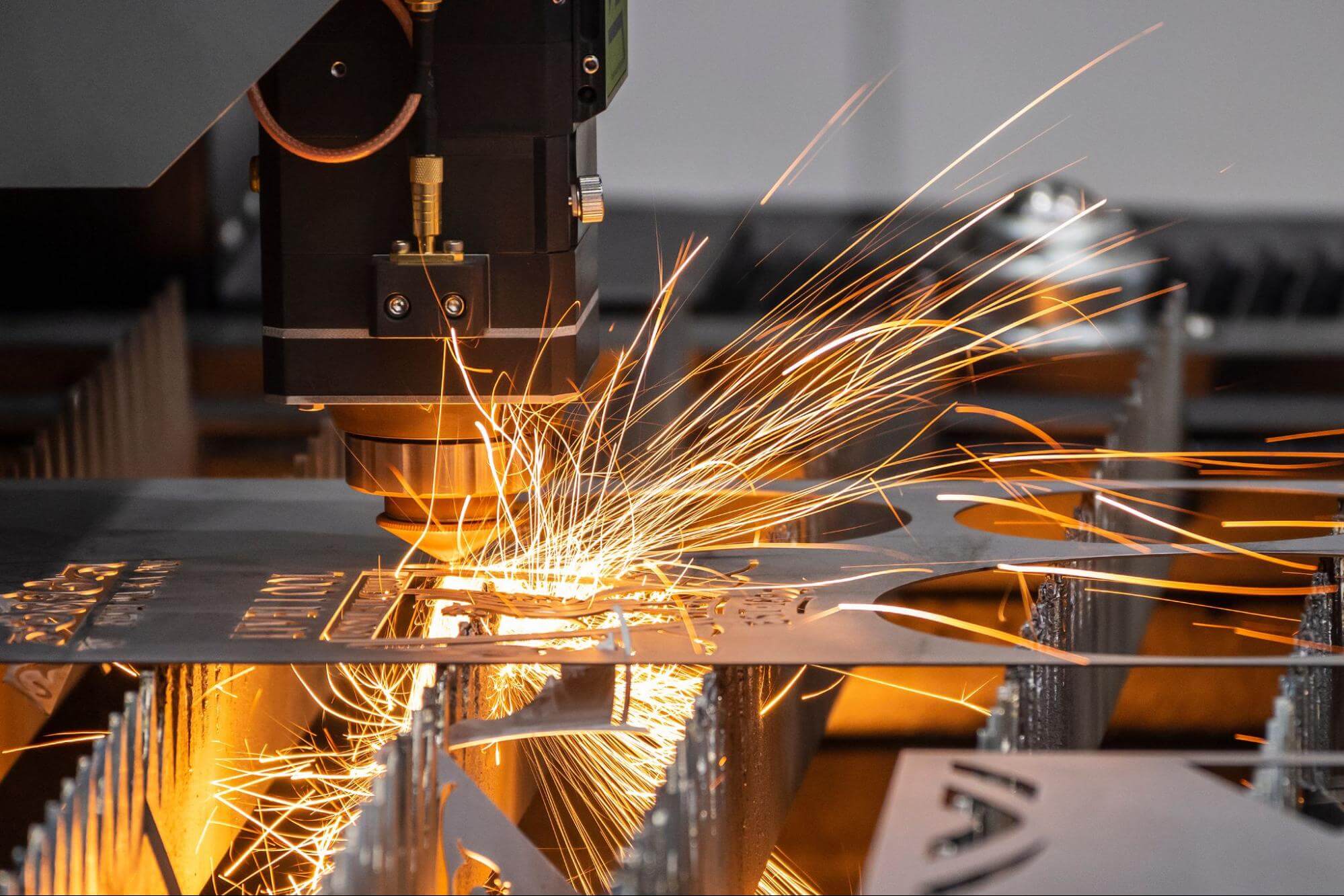

Metal sheet fabrication involves cutting, bending, and assembling thin sheets of metal into complex geometries. Even minor deviations in thickness, edge alignment, or hole placement can cascade into system-level failures. For instance, in military-grade enclosures or Olympic-grade timing equipment, where environmental resilience and operational reliability are non-negotiable, sub-millimeter inaccuracies can compromise shielding effectiveness, thermal management, or signal integrity. Our engineering team approaches every project with a zero-defect mindset, integrating advanced CNC laser cutting, precision press braking, and automated inspection systems to ensure consistency down to ±0.05 mm.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in high-tolerance sheet metal fabrication. Our portfolio includes mission-critical components for defense communication systems, where EMI shielding and ruggedized durability are essential, and precision timing housings deployed in Olympic athletic events, where flawless synchronization and environmental stability define success. These applications demand more than technical capability—they require a deep understanding of material behavior, geometric complexity, and regulatory compliance.

Our process begins with material selection, where we evaluate alloys such as aluminum 5052, stainless steel 304/316, and cold-rolled steel based on mechanical, thermal, and corrosion resistance requirements. Each sheet is inspected upon receipt, then processed through our climate-controlled workshop to minimize thermal distortion. Utilizing fiber laser cutting systems with kerf widths under 0.15 mm, we achieve clean, burr-free edges that reduce secondary finishing needs. Bending operations are guided by 3D CAD models and executed on CNC press brakes with real-time angle feedback, ensuring angular accuracy within ±0.5°.

Post-fabrication, parts undergo rigorous inspection using coordinate measuring machines (CMM) and optical comparators. First-article inspections and batch sampling are standard, with full traceability maintained through our ERP system. This disciplined approach enables us to deliver components that not only meet but exceed customer expectations in performance and reliability.

Below is a summary of our core fabrication capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.1 mm – 6.0 mm |

| Tolerance (Cutting) | ±0.05 mm |

| Tolerance (Bending) | ±0.5° angular, ±0.1 mm linear |

| Max Working Area (Laser) | 1500 mm × 3000 mm |

| Common Materials | Aluminum 5052/6061, Stainless Steel 304/316, CR Steel |

| Surface Finishes | Anodizing, Powder Coating, Passivation, Plating |

| Quality Standards | ISO 9001:2015, MIL-STD-810, RoHS |

Precision in metal sheet parts is not an incremental advantage—it is the foundation of functional excellence. At Wuxi Lead Precision Machinery, we combine engineering rigor with proven field experience to deliver components that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities for Precision Metal Sheet Parts

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for complex metal sheet components, serving demanding industries including aerospace, medical devices, and industrial automation. Our integrated facility combines cutting-edge 5-axis CNC technology with rigorous quality control protocols to ensure dimensional accuracy, repeatability, and material integrity across diverse production volumes. We specialize in transforming raw sheet stock into mission-critical parts with minimal lead times, leveraging digital workflows from CAD/CAM programming through final inspection.

Our core strength lies in 5-axis CNC machining centers, which enable simultaneous multi-directional cutting, milling, and drilling operations on sheet metal substrates. This capability eliminates secondary setups, reduces cumulative error, and achieves intricate geometries unattainable with conventional 3-axis systems. Materials ranging from stainless steel and aluminum alloys to titanium and specialty composites are processed with micron-level precision. Advanced toolpath strategies optimize material removal rates while preserving surface finish requirements, critical for components requiring weld prep or sealing interfaces. High-speed spindles and rigid machine structures ensure stability during deep cavity milling or thin-wall feature creation, preventing deformation in delicate sheet forms.

Quality assurance is embedded at every stage, anchored by Zeiss CONTURA G2 Coordinate Measuring Machine (CMM) systems for full first-article and batch inspection. Each component undergoes comprehensive dimensional validation against 3D CAD models, with reports detailing positional tolerances, form deviations, and critical feature conformance. Our AS9100-compliant process includes in-process gauging, statistical process control (SPC) data tracking, and material traceability from certified mills. This systematic approach guarantees that every sheet part meets stringent regulatory and functional specifications before shipment.

The following table details our standard and precision tolerance capabilities for key sheet metal processes:

| Process | Material Thickness Range | Standard Tolerance | Tight Tolerance Option |

|---|---|---|---|

| Fiber Laser Cutting | 0.5 mm – 25 mm | ±0.1 mm | ±0.05 mm |

| CNC Bending | 0.8 mm – 6.0 mm | ±0.2° / ±0.2 mm | ±0.1° / ±0.1 mm |

| Precision Punching | 0.5 mm – 3.2 mm | ±0.1 mm | ±0.05 mm |

| 5-Axis Milling | All sheet forms | ±0.05 mm | ±0.02 mm (GD&T) |

Wuxi Lead’s technical infrastructure supports rapid prototyping through high-volume production, with seamless integration of design for manufacturability (DFM) analysis during quoting. Our engineering team collaborates directly with clients to optimize part geometry for cost efficiency without compromising performance. All capabilities are backed by real-time production monitoring and a zero-defect quality culture, ensuring your metal sheet components arrive ready for assembly—on time, every time. Partner with us to transform complex sheet metal challenges into precision-engineered realities.

Material & Finish Options

Material Selection for Precision Metal Sheet Parts

Selecting the appropriate material for metal sheet parts is a critical decision in high-performance manufacturing. At Wuxi Lead Precision Machinery, we specialize in custom fabrication using aluminum, steel, and titanium—three materials that dominate industrial applications due to their distinct mechanical properties, cost profiles, and environmental resistance. Understanding the strengths and limitations of each allows engineers and procurement teams to optimize performance, longevity, and cost-efficiency.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for aerospace, transportation, and electronics enclosures where weight reduction is essential. Grade 6061-T6 is commonly used for structural components due to its weldability and moderate strength, while 5052-H32 offers superior corrosion resistance for marine environments. Aluminum’s natural oxide layer provides inherent protection, but for enhanced durability and aesthetics, anodizing is recommended.

Steel remains the backbone of heavy-duty applications. Cold-rolled steel (CRS) and stainless steel (particularly 304 and 316 grades) are staples in industrial machinery, medical equipment, and architectural components. CRS offers high strength and dimensional accuracy, making it ideal for precision chassis and brackets. Stainless steel adds significant corrosion resistance, with 316 excelling in chloride-rich environments. While heavier than aluminum, steel provides superior wear resistance and structural integrity under high loads.

Titanium, though more expensive, delivers unmatched performance in extreme conditions. Grade 2 and Grade 5 (Ti-6Al-4V) are commonly used in aerospace, defense, and medical implants. Titanium offers exceptional strength-to-density ratio, outstanding corrosion resistance—even in seawater—and the ability to perform at elevated temperatures. Its use is typically justified in mission-critical applications where failure is not an option.

Surface Finishing: The Role of Anodizing

Anodizing is a key finishing process for aluminum components. This electrochemical treatment thickens the natural oxide layer, significantly enhancing surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, offering a range of color options. Type III, or hard anodizing, produces a thicker, denser coating suitable for high-wear environments. Anodized surfaces also provide excellent adhesion for paint and primers, making them ideal for hybrid finishing systems.

Below is a comparative overview of key material specifications:

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 290–320 | 2.7 | Aerospace, electronics, transport | Anodizing, powder coating |

| Steel (Stainless) | 304, 316 | 505–585 | 8.0 | Medical, food processing, machinery | Passivation, polishing |

| Steel (CRS) | 1008–1022 | 340–420 | 7.85 | Enclosures, brackets, frames | Zinc plating, painting |

| Titanium | Gr 2, Gr 5 (Ti-6Al-4V) | 345–1000 | 4.5 | Aerospace, defense, medical implants | Bead blasting, anodizing (specialty) |

At Wuxi Lead Precision Machinery, we support material and finish selection with in-house engineering consultation, ensuring every metal sheet part meets exact functional and environmental demands.

Manufacturing Process & QC

Production Process: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our production process for custom metal sheet parts is engineered for uncompromising precision and zero-defect delivery. We treat manufacturing as a continuous, integrated workflow where each phase rigorously validates the next, eliminating errors before they escalate. This methodology ensures your components meet exact specifications while optimizing cost and lead time.

The process begins with collaborative design engineering. Our team leverages advanced CAD/CAM systems to translate your concepts into manufacturable models, performing comprehensive Design for Manufacturability (DFM) analysis. We scrutinize material selection, bend allowances, and geometric dimensioning to preempt production challenges. This phase includes virtual stress testing and tolerance band validation, ensuring the design aligns with both functional requirements and our machining capabilities. Early-stage alignment prevents 90% of potential defects, reducing rework and accelerating time-to-market.

Prototyping serves as our critical validation checkpoint. Using the same CNC press brakes, laser cutters, and stamping equipment deployed in mass production, we fabricate functional prototypes from your approved design. Each prototype undergoes rigorous dimensional inspection against your CAD model via CMM (Coordinate Measuring Machine) and surface finish analysis. We validate weld integrity, hole alignment, and form accuracy to confirm the process parameters. Client sign-off on prototypes is mandatory before scaling, guaranteeing mass production will replicate validated results without deviation.

Mass production deploys our zero-defect framework through integrated process control. Every sheet metal part progresses through automated, in-line inspection checkpoints. Real-time SPC (Statistical Process Control) monitors critical dimensions during bending and forming, while vision systems detect surface imperfections or misaligned features. Our ERP system tracks material batches, machine calibration records, and operator certifications for full traceability. Components exceeding tolerance thresholds are automatically quarantined, analyzed for root cause, and corrected before resuming production. This closed-loop system ensures consistent adherence to specifications across volumes from 10 to 100,000+ units.

Our commitment to zero defects is quantified through measurable performance metrics, as demonstrated below.

| Specification Category | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Material Thickness | 0.5mm – 12.7mm | 0.8mm – 6.0mm |

| Tolerance Precision | ±0.05mm | ±0.1mm |

| Surface Roughness (Ra) | ≤0.8µm | ≤1.6µm |

| Production Volume | 1 – 500,000+ | 100 – 10,000 |

| Lead Time (Prototype) | 5–7 days | 10–14 days |

This structured progression—from precision design through validated prototyping to monitored mass production—forms the backbone of our zero-defect promise. By embedding quality at every stage, Wuxi Lead delivers metal sheet parts that perform flawlessly in aerospace, medical, and industrial applications, where failure is not an option. Your design integrity is our operational mandate.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Sheet Fabrication

At Wuxi Lead Precision Machinery, we don’t just manufacture metal sheet parts—we engineer precision solutions that meet the exact demands of high-performance industries. With over 15 years of specialized experience in custom metal manufacturing, our facility in Wuxi, China, serves as a trusted extension of global supply chains across aerospace, medical equipment, industrial automation, and advanced electronics. When you partner with us, you gain more than a supplier; you gain a committed engineering ally focused on quality, consistency, and on-time delivery.

Our end-to-end capabilities include laser cutting, CNC bending, precision stamping, robotic welding, and comprehensive surface finishing—all performed in a fully ISO 9001:2015-certified environment. We specialize in low to mid-volume production runs with rapid prototyping, enabling clients to accelerate time-to-market without sacrificing dimensional accuracy or material integrity. Whether working with stainless steel, aluminum, carbon steel, or exotic alloys, our team ensures every component meets or exceeds your engineering specifications.

We understand that in high-end manufacturing, tolerances matter. That’s why our facility is equipped with state-of-the-art CNC machinery and coordinate measuring machines (CMM) for real-time quality verification. From first article inspection to batch traceability, we maintain full documentation and process control, ensuring every metal sheet part is manufactured with repeatable precision.

Our engineering team collaborates directly with your design and procurement staff to optimize manufacturability, reduce material waste, and identify cost-saving alternatives—all while preserving functional performance. This collaborative approach has enabled long-term partnerships with Tier-1 suppliers and OEMs across Europe, North America, and Southeast Asia.

Below are our core technical specifications, reflecting our capacity to handle demanding custom projects:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.2 mm – 25 mm |

| Max. Sheet Size | 4000 mm × 1500 mm |

| Tolerance (Standard) | ±0.05 mm |

| Laser Cutting Accuracy | ±0.1 mm |

| Bend Tolerance | ±0.2° |

| Welding Processes | MIG, TIG, Spot, Robotic |

| Surface Finishes | Anodizing, Powder Coating, Passivation, Brushing, Zinc Plating |

| Quality Standards | ISO 9001:2015, RoHS, REACH Compliant |

We invite you to experience the Lead Precision difference. Contact us today at [email protected] to discuss your next metal sheet fabrication project. Our engineering team is ready to review your drawings, provide a detailed quote, and support you from prototype to full-scale production. Partner with a manufacturer who values precision as much as you do.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.