Technical Contents

Engineering Guide: Metal Shaping Services

Engineering Insight: The Critical Role of Precision in Metal Shaping Services

In the realm of custom metal manufacturing, precision is not merely a quality benchmark—it is the foundation upon which performance, reliability, and safety are built. At Wuxi Lead Precision Machinery, we understand that even the most advanced design is only as effective as the accuracy with which it is realized. Metal shaping services must meet exacting dimensional tolerances, surface integrity standards, and material consistency requirements, especially when serving industries where failure is not an option.

Precision in metal shaping directly influences component functionality, assembly compatibility, and long-term durability. Whether producing complex aerospace housings, high-strength military components, or structural elements for Olympic-grade sports facilities, deviations measured in microns can lead to catastrophic system failures or costly rework. Our engineering team employs multi-axis CNC machining, precision forging, and laser-assisted forming techniques to ensure every part conforms to the strictest specifications. This level of control is achieved through continuous process validation, real-time metrology, and a closed-loop feedback system integrated across our production floor.

Wuxi Lead Precision Machinery has earned its reputation through decades of delivering mission-critical components for high-profile and high-demand applications. Our involvement in supporting infrastructure for Olympic venues underscores our ability to meet aggressive timelines without compromising accuracy or material integrity. Similarly, our work with defense and military contractors demands adherence to MIL-STD and ISO certifications, where traceability, repeatability, and zero-defect manufacturing are non-negotiable. These experiences have refined our approach to metal shaping, embedding precision into every phase—from initial material selection to final inspection.

Our facility leverages advanced simulation software to model thermal deformation, stress distribution, and toolpath optimization prior to physical production. This predictive engineering capability minimizes trial runs and ensures first-time-right outcomes, reducing lead times and material waste. Moreover, our quality assurance protocols include CMM (Coordinate Measuring Machine) inspection, ultrasonic testing, and 3D scanning for full geometric validation.

The following table outlines key performance specifications achievable through our metal shaping services:

| Parameter | Typical Capability | High-Precision Range |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | ±0.005 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.4 – 0.8 µm |

| Maximum Part Weight | 5,000 kg | Up to 2,000 kg (tight tol.) |

| Material Thickness Range | 1 – 300 mm | 2 – 150 mm (precision cut) |

| Positional Accuracy | ±0.02 mm/m | ±0.005 mm/m |

| Process Repeatability (CpK) | ≥1.33 | ≥1.67 |

At Wuxi Lead Precision Machinery, precision is not an afterthought—it is engineered into every process, verified at every stage, and guaranteed in every delivery. For industries where performance is paramount, our metal shaping services provide the confidence that every component will perform exactly as designed, every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Shaping at Scale

Wuxi Lead Precision Machinery delivers exceptional custom metal shaping services engineered for the most demanding aerospace, medical, and industrial applications. Our core strength lies in integrating advanced multi-axis machining with rigorous quality assurance protocols, ensuring components meet exacting global standards. We specialize in transforming complex geometries from challenging materials including titanium alloys, Inconel, hardened steels, and aluminum with unwavering consistency.

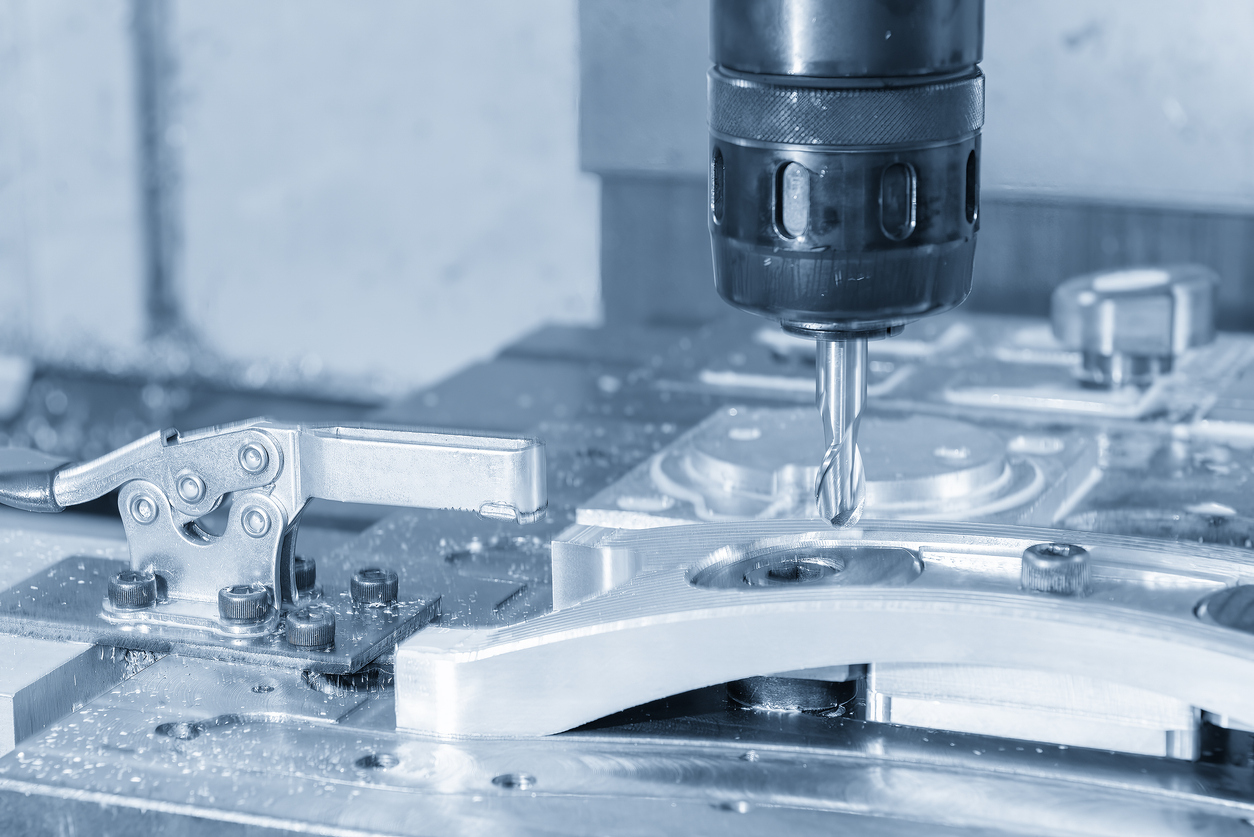

Central to our capability is a modern fleet of high-torque, high-precision 5-axis CNC machining centers. These systems enable simultaneous multi-directional tool movement, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is critical for producing intricate contoured surfaces, deep cavities, and undercuts inherent in turbine blades, surgical implants, and fluid dynamics components. Our machines achieve sub-micron repeatability through thermal compensation systems and rigid construction, ensuring dimensional stability across extended production runs. Advanced CAM software drives efficient toolpath generation, optimizing material removal rates while maintaining surface integrity and part accuracy.

Quality is not a final checkpoint but an integrated process. Every component undergoes comprehensive in-process and final inspection utilizing state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs, operating in a climate-controlled metrology lab, provide traceable measurements to national standards. Full first-article inspection reports (FAIR) and Production Part Approval Process (PPAP) documentation are standard, meeting AS9100 and ISO 13485 requirements. Statistical process control (SPC) methodologies are applied to critical features, enabling proactive correction and guaranteeing sustained conformance throughout the production lifecycle. This systematic approach minimizes scrap, ensures batch-to-batch uniformity, and provides clients with absolute confidence in part performance.

The following table details our standard achievable tolerances across common materials and features, reflecting our commitment to precision engineering:

| Feature Type | Standard Tolerance (mm) | Tight Tolerance Capability (mm) | Material Applicability | Surface Finish (Ra µm) |

|---|---|---|---|---|

| Linear Dimensions | ±0.010 | ±0.005 | All (Ti, Inconel, Steel, Al) | 0.8 – 3.2 |

| Hole Diameter | ±0.008 | ±0.003 | All | 0.4 – 1.6 |

| Positional (Holes) | ±0.015 | ±0.008 | All | N/A |

| Profile of Surface | 0.020 | 0.010 | All | 0.4 – 1.6 |

| Flatness | 0.015 / 100mm | 0.005 / 100mm | All | 0.2 – 0.8 |

| Concentricity | 0.025 | 0.010 | All | N/A |

These capabilities, combined with our engineering support from prototyping through volume production, position Wuxi Lead as a strategic partner for mission-critical metal components. We translate complex design intent into tangible, high-performance parts with the precision and reliability demanded by advanced manufacturing sectors. Partner with us to overcome the most challenging metal shaping requirements.

Material & Finish Options

Material Selection for Precision Metal Shaping Services

Selecting the appropriate material is critical in custom metal manufacturing, where performance, environment, and application dictate long-term success. At Wuxi Lead Precision Machinery, we specialize in shaping high-integrity components from aluminum, steel, and titanium—each offering distinct mechanical properties, weight characteristics, and corrosion resistance. Understanding these materials ensures optimal part functionality, cost efficiency, and durability in demanding industrial environments.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is ideal for aerospace, automotive, and electronics applications where weight reduction is essential without sacrificing structural integrity. The most commonly used alloy is 6061-T6, which combines magnesium and silicon for enhanced weldability and moderate strength. Aluminum also responds exceptionally well to surface treatments such as anodizing, which improves wear and corrosion resistance while allowing for color customization.

Steel remains the backbone of heavy-duty industrial applications due to its high tensile strength, durability, and cost-effectiveness. Carbon steel (e.g., 1045) is often selected for mechanical parts requiring toughness and rigidity, while stainless steel (e.g., 304 and 316) offers superior corrosion resistance, making it suitable for medical devices, food processing equipment, and marine environments. Although heavier than aluminum, steel’s versatility in heat treatment and surface finishing makes it indispensable in precision manufacturing.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers exceptional strength-to-density performance and outstanding resistance to extreme temperatures and corrosive media. It is the material of choice in aerospace, defense, and high-performance automotive sectors. While more challenging to machine and higher in cost, titanium’s longevity in aggressive environments justifies its use in mission-critical components. Its biocompatibility also makes it a preferred option in medical implant manufacturing.

Anodizing: Enhancing Aluminum Performance

Anodizing is an electrochemical process that transforms the surface of aluminum into a durable, corrosion-resistant oxide layer. This finish not only improves wear resistance but also provides excellent adhesion for paint primers and bonding agents. Type II (sulfuric acid anodizing) is commonly used for general-purpose applications and allows for dyeing in various colors, beneficial for branding or part identification. Type III, or hardcoat anodizing, produces a thicker, harder surface suitable for high-wear environments such as hydraulic systems or industrial tooling. Anodized layers are integral to the base metal, ensuring they do not chip or peel under stress.

Below is a comparative overview of key material properties.

| Material | Typical Alloy | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 2.7 | 310 | Moderate to High | Aerospace, Electronics, Automotive |

| Carbon Steel | 1045 | 7.85 | 570 | Low (uncoated) | Machinery, Tools, Structural Parts |

| Stainless Steel | 304 | 8.0 | 515 | High | Medical, Food Processing, Marine |

| Titanium | Ti-6Al-4V | 4.43 | 950 | Very High | Aerospace, Defense, Medical Implants |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on operational demands, ensuring every component meets exacting standards for performance and reliability.

Manufacturing Process & QC

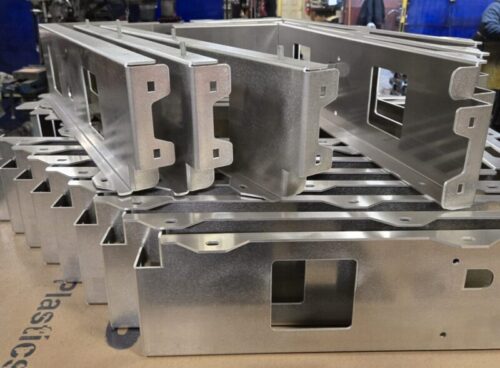

Production Process: Achieving Zero Defects in Custom Metal Shaping

At Wuxi Lead Precision Machinery, our production process for custom metal shaping services is engineered from inception to delivery with an uncompromising focus on Zero Defects. This rigorous methodology ensures every component meets the exacting standards demanded by aerospace, medical, and high-performance industrial applications. The journey begins with collaborative Design Engineering. Our team works directly with your specifications, utilizing advanced CAD/CAM software and Finite Element Analysis (FEA) to optimize geometry, material selection, and manufacturability. This phase is critical for identifying potential stress points, thermal deformation risks, or assembly conflicts before metal is cut. We conduct thorough Design for Manufacturability (DFM) reviews, ensuring the design translates flawlessly into a robust, repeatable process, eliminating theoretical defects at the source.

Prototyping is not merely a formality; it is a vital validation step under our Zero Defects mandate. We produce functional prototypes using the same materials, tooling, and CNC programming intended for full production. Each prototype undergoes comprehensive First Article Inspection (FAI) against your original CAD model and engineering drawings. Dimensional verification is performed using calibrated Coordinate Measuring Machines (CMM) and optical comparators, checking critical features to micron-level tolerances. Material properties, surface finishes, and functional performance are rigorously tested. Any deviation triggers immediate root cause analysis and process refinement. This iterative validation ensures the manufacturing process is proven and stable, guaranteeing that what works in prototype will succeed identically in mass production.

Mass Production leverages the validated process with relentless statistical process control (SPC) and real-time monitoring. Our state-of-the-art CNC machining centers, multi-axis mills, and precision lathes operate under strict environmental controls. Every machine cycle incorporates in-process gauging and automated tool wear compensation. SPC charts continuously track critical dimensions on sampled parts, enabling predictive adjustments before any parameter drifts beyond specification limits. Full traceability is maintained from raw material lot to finished component via our integrated MES system. Final inspection is non-negotiable: 100% of critical features on every part undergo CMM verification, with full reports provided. This closed-loop system, built on the foundation of validated design and prototyping, is the cornerstone of our statistically proven 99.98% defect-free delivery rate.

Our core capabilities enable this precision across diverse requirements:

| Parameter | Capability | Standard Tolerance (Metric) | Standard Tolerance (Imperial) |

|---|---|---|---|

| Max. Work Envelope | 1500 x 800 x 650 mm (59 x 31.5 x 25.6 in) | ||

| Min. Feature Size | 0.1 mm (0.004 in) | ||

| Positional Accuracy | ±0.005 mm (±0.0002 in) | ||

| Surface Finish | Ra 0.2 µm (8 µin) achievable | ||

| Material Range | Aluminum, Steel, Stainless, Titanium, Brass | ||

| Volume Flexibility | 1-off Prototypes to 50,000+ Series Runs |

This integrated Design-Prototype-Production workflow, governed by systematic quality gates and advanced metrology, transforms your specifications into flawless metal components. Zero Defects is not an aspiration; it is the measurable outcome of Wuxi Lead’s engineered process discipline.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Shaping Services

At Wuxi Lead Precision Machinery, we don’t just manufacture metal components—we engineer precision solutions that drive performance, reliability, and efficiency across industries. As a trusted leader in custom metal shaping services, we specialize in delivering high-tolerance, complex parts for aerospace, automotive, energy, medical, and industrial equipment sectors. Our advanced CNC machining, forming, and fabrication capabilities are backed by decades of engineering experience, ensuring your most demanding projects are executed with accuracy and consistency.

When you choose to partner with Lead Precision, you gain more than a supplier—you gain a strategic manufacturing ally. Our facility in Wuxi, China, is equipped with state-of-the-art machinery and staffed by skilled engineers who understand the nuances of material behavior, geometric complexity, and production scalability. From prototype development to high-volume production runs, we offer end-to-end support, rapid turnaround, and rigorous quality control compliant with international standards including ISO 9001:2015.

Our commitment to precision begins with material selection and extends through every stage of production. Whether working with stainless steel, aluminum, titanium, or exotic alloys, we apply optimized toolpaths, in-process inspection, and real-time monitoring to maintain tolerances down to ±0.005 mm. This level of control ensures that every component meets your exact specifications and performs reliably in the field.

We understand that every client brings unique challenges. That’s why our engineering team collaborates closely with yours from the outset—reviewing designs for manufacturability, recommending material and process improvements, and providing detailed feedback to reduce lead times and lower total cost of ownership. Our digital-first workflow enables seamless communication, secure file sharing, and full traceability across batches.

Below are key capabilities that define our metal shaping services:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| Materials Processed | Stainless Steel, Aluminum, Titanium, Brass, Copper, Inconel, Tool Steels |

| Processes Available | CNC Milling (3/4/5-axis), CNC Turning, Wire EDM, Laser Cutting, Press Brake Forming |

| Surface Finishes | As-machined, Anodizing, Powder Coating, Passivation, Polishing |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), CMM Reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Partnering with Wuxi Lead Precision Machinery means gaining access to scalable, high-precision manufacturing without compromise. We are committed to being an extension of your engineering team—responsive, transparent, and focused on your success.

For project inquiries, technical consultations, or to request a quote, contact us today at [email protected]. Let’s shape the future of your products—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.