Technical Contents

Engineering Guide: Metal Services

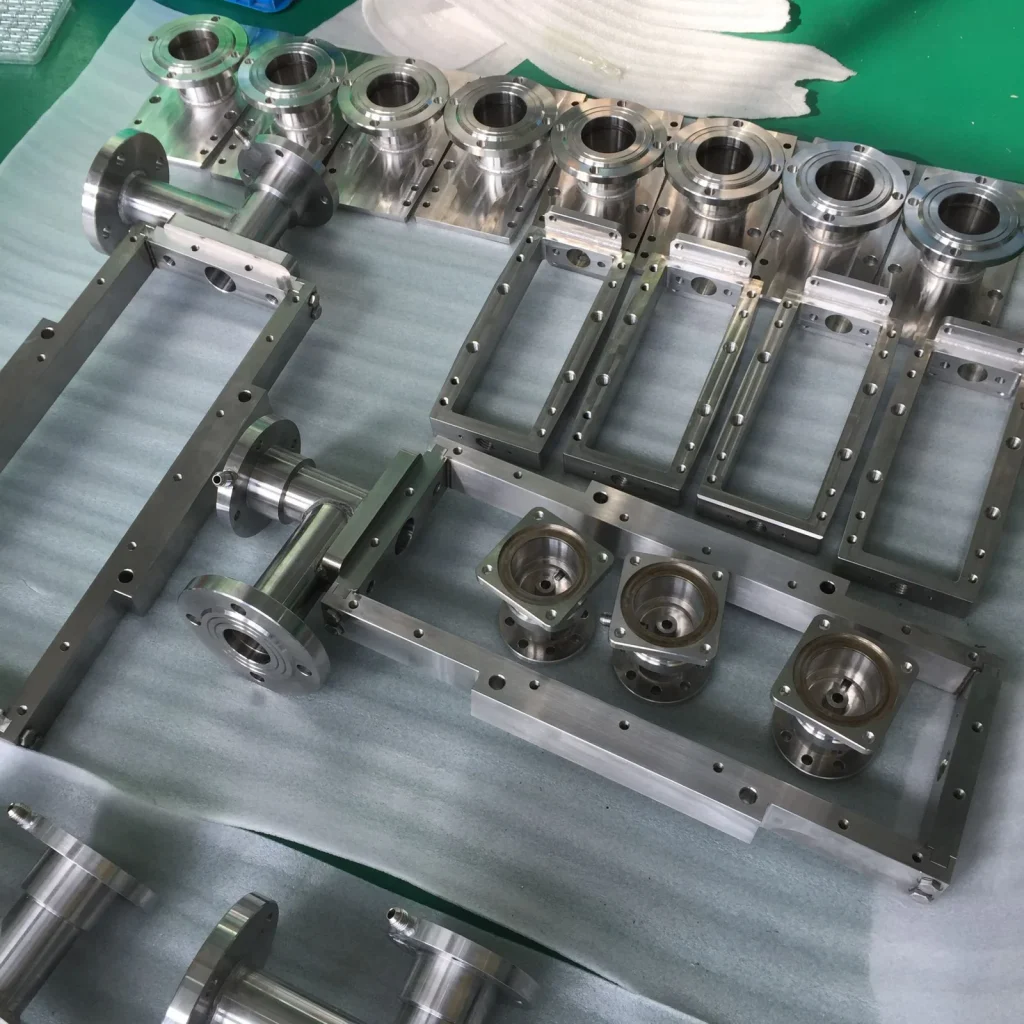

Engineering Precision: The Foundation of Mission-Critical Metal Components

In high-stakes industries—from aerospace to defense—precision and material integrity are non-negotiable. A deviation of 0.001 inches can compromise structural integrity, operational safety, or regulatory compliance. At Wuxi Lead Precision Machinery, we treat every component as mission-critical. Our ISO 9001-certified processes, combined with advanced metrology and material traceability, ensure your designs translate into parts that perform flawlessly under the most demanding conditions.

Precision Tolerances: Beyond Industry Standards

Industry-standard CNC machining tolerances often fall short for applications where failure is not an option. We redefine precision through rigorous process control and real-time monitoring:

| Parameter | Industry Standard | Wuxi Lead Precision Machinery |

|---|---|---|

| General Machining | ±0.005″ (±0.127 mm) | ±0.001″ (±0.025 mm) |

| Precision Machining | ±0.002″ (±0.051 mm) | ±0.0005″ (±0.013 mm) |

| Aerospace/Defense | N/A | ±0.0002″ (±0.005 mm) |

Our proprietary in-process laser measurement systems and AI-driven adaptive machining ensure tolerances are maintained even during high-volume production. For Olympic-grade timing systems and military-grade components, we consistently exceed ISO 2768-mK standards.

Material Certification & Traceability

Material quality begins at the source. Every alloy we process—whether titanium, aerospace-grade aluminum, or high-strength engineering plastics—comes with full traceability from raw material to finished part:

ISO 10204-certified material test reports (MTRs) for all metals

Compliance with ASTM, ASME, and EN standards

100% lot tracking via blockchain-enabled quality logs

“When designing for extreme environments, we collaborate with your engineering team to optimize wall thicknesses, stress points, and material selection—ensuring manufacturability without compromising performance.”

Zero Defects Commitment: Where Excellence Meets Urgency

Zero Defects isn’t a slogan—it’s our operational DNA. Our team has delivered 100% defect-free components for:

2022 Beijing Winter Olympics: Precision timing systems for ice sports, where ±0.0003″ tolerances were critical to athlete safety and event integrity.

U.S. Department of Defense contracts: Mission-critical parts for radar systems, requiring 24/7 engineering support to resolve field issues within hours.

Our 24/7 global support team ensures rapid response to urgent requests—whether it’s a last-minute design tweak or emergency production scaling. For projects where downtime equals catastrophe, we are your dedicated manufacturing partner, not just a supplier.

Why Partner With Us?

Proven in high-risk environments: Olympic, military, and medical-grade projects demand zero tolerance for error. We deliver.

End-to-end quality control: From material certification to final inspection, every step is documented and audited.

Engineer-to-engineer collaboration: We optimize your designs for manufacturability while preserving functional integrity—no compromises.

Your vision. Our precision. Zero defects guaranteed.

Wuxi Lead Precision Machinery: Engineering solutions that perform when it matters most.

Precision Specs & Tolerances

Technical Capabilities & Precision Engineering

At Wuxi Lead Precision Machinery, we combine cutting-edge technology with uncompromising quality standards to deliver metal components that exceed expectations. As your strategic manufacturing partner, we don’t just produce parts—we engineer solutions that align with your most demanding specifications.

Advanced CNC Machining Capabilities

Our facility is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers, engineered for exceptional precision and repeatability. Each machine features:

High-speed spindles (up to 24,000 RPM) for superior surface finishes

Rigid cast-iron bases with thermal compensation to minimize dimensional drift

Integrated tool changers and automated pallet systems for unattended production

Advanced CAD/CAM programming for complex geometries and tight-tolerance features

Whether you require simple turned components or intricate aerospace-grade assemblies, our multi-axis capabilities ensure optimal efficiency and accuracy across all production volumes.

Tight Tolerances, Zero Defects Commitment

Precision isn’t optional—it’s foundational. We adhere to ISO 9001 quality standards and implement a rigorous Zero Defects Process to ensure every dimension meets or exceeds your specifications. Below is a comparison of our standard and precision capabilities:

| Tolerance Type | Dimensional Tolerance (mm/in) | Typical Applications | Notes |

|---|---|---|---|

| Standard | ±0.127 mm (±0.005 in) | General industrial components, housings, brackets | ISO 2768-mK compliant |

| Precision | ±0.025 mm (±0.001 in) | Aerospace components, medical devices, precision fixtures | Zero Defects Process; 100% CMM verified |

| Ultra-Precision | ±0.013 mm (±0.0005 in) | Optical instruments, semiconductor tooling | Requires specialized setup validation |

Note: Actual achievable tolerances depend on part geometry, material, and process parameters. Our engineering team works with you to define the optimal tolerance for your specific application.

Rigorous Quality Control

Every component undergoes a multi-stage quality verification process:

CMM Inspection: Coordinate Measuring Machines with 0.0001″ (0.0025mm) accuracy for critical dimensions

Material Certification: Full Mill Test Reports (MTRs) for all metals, including traceable chemical composition and mechanical properties

ISO 9001 Compliance: Documented processes from raw material receipt to final shipment

Statistical Process Control (SPC): Real-time monitoring of key parameters to prevent deviations before they occur

We don’t just inspect parts—we engineer quality into every step of production.

Your Partner in Precision

At Wuxi Lead Precision Machinery, we believe true partnership means more than just fulfilling orders. From initial design reviews to final delivery, our team collaborates with your engineers to:

Optimize part designs for manufacturability and cost efficiency

Provide real-time production updates via our 24/7 customer portal

Offer technical support for tolerance analysis and material selection

Deliver Olympic Quality: Every component meets the highest standards of precision, consistency, and reliability

With our Zero Defects commitment and round-the-clock support, you can trust Wuxi Lead to be your strategic manufacturing partner—every project, every time.

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we view material and finish selection as the cornerstone of mission-critical performance—not a transactional decision. Our ISO 9001-certified processes ensure every component meets your exact functional, aesthetic, and lifecycle requirements. With a Zero Defects commitment and Olympic Quality Assurance standards, we collaborate with your engineering team to optimize material choices that reduce total cost of ownership while eliminating risk.

Why Material Choice is the Foundation of Performance

Material selection directly impacts mechanical integrity, corrosion resistance, thermal behavior, and manufacturability. A single misstep—such as selecting aluminum for high-temperature environments or stainless steel for lightweight aerospace components—can cascade into part failure, rework, or supply chain delays. Our engineers leverage full material traceability (from raw billet to finished part) and ISO 9001-compliant certification documentation to ensure every choice aligns with your application’s technical and regulatory demands.

“We don’t just supply materials—we engineer solutions. Our 24/7 technical support team reviews your design constraints and recommends the optimal material/finish combination before production begins.”

Key Material Selection Criteria

Our global supply chain partners provide certified materials meeting ASTM, ISO, and DIN standards. Below is a comparative guide for common metals and engineering plastics used in precision CNC machining:

| Material Type | Key Properties | Typical Applications | Cost Range | Minimum Wall Thickness | Finish Compatibility |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | Good strength-to-weight, excellent corrosion resistance, machinable | Aerospace brackets, automotive parts | $–$$ | 0.030″ (0.76 mm) | Anodizing (Type II/III), Polishing, Powder Coating |

| Stainless Steel 304 | Corrosion-resistant, non-magnetic, weldable | Medical devices, food processing | $$ | 0.030″ (0.76 mm) | Passivation, Electropolishing, Brushed Finish |

| Titanium Grade 5 | High strength-to-weight, biocompatible, extreme temperature tolerance | Aerospace, surgical implants | $$$ | 0.030″ (0.76 mm) | Passivation, Blasting, Anodizing (specialized) |

| ABS Plastic | Impact-resistant, low cost, easy to machine | Consumer electronics housings | $ | 0.030″ (0.76 mm) | Painting, Electroplating (Ni/Cr), Tumbling |

| PEEK | High-temp stability, chemical resistance, FDA-compliant | Medical implants, semiconductor tools | $$$ | 0.030″ (0.76 mm) | Precision Polishing, Plasma Treatment |

| Brass C11000 | Excellent electrical conductivity, machinable | Electrical connectors, valve components | $$ | 0.030″ (0.76 mm) | Electroplating (Ni/Cr), Passivation, Polishing |

Critical Insight: Minimum wall thickness ensures structural integrity during machining. Thinner sections risk vibration-induced deformation—especially in plastics like ABS or PEEK. Our engineers validate wall thickness during DFM (Design for Manufacturability) reviews to prevent costly rework.

Surface Finishes: Balancing Aesthetics, Functionality & Cost

Surface treatments are not cosmetic add-ons—they directly influence wear resistance, electrical properties, and service life. We optimize finishes based on your operational environment and regulatory needs:

Anodizing (Aluminum Only)

Process: Electrochemical oxidation creating a hard, porous oxide layer.

Benefits: Corrosion resistance (up to 50x standard), electrical insulation, and color stability.

Cost Impact: +15–30% vs. bare metal. Type III (hard anodizing) adds +25% for wear-critical parts.

Wuxi Lead Advantage: ISO 9001-certified anodizing lines with 0.0001″ (0.0025 mm) thickness consistency.

Electroplating (Metals Only)

Process: Electrodeposition of nickel, chromium, or zinc for surface enhancement.

Benefits: Corrosion protection (zinc), wear resistance (hard chrome), or conductivity (nickel).

Cost Impact: +20–40% depending on plating thickness and substrate.

Critical Note: Plating on stainless steel requires strict pre-treatment to avoid hydrogen embrittlement—our certified processes eliminate this risk.

Precision Polishing

Process: Mechanical abrasion to achieve mirror or satin finishes.

Benefits: Reduced friction, improved cleanability (critical for medical/food-grade parts), and aesthetic appeal.

Cost Impact: +25–50% for mirror finishes (Ra ≤ 0.1 μm).

Wuxi Lead Standard: All polished surfaces undergo 100% optical inspection per ISO 4287 standards.

“We never recommend a finish without validating its compatibility with your material and application. For example, anodizing titanium requires specialized processes—standard aluminum anodizing will fail catastrophically.”

How Material & Finish Impact Total Cost of Ownership

| Factor | Low-Cost Choice (e.g., Mild Steel + Paint) | Optimized Choice (e.g., Stainless 316 + Electropolishing) |

|---|---|---|

| Initial Material Cost | $100/unit | $150/unit |

| Machining Complexity | High (rust-prone; requires frequent tool changes) | Low (corrosion-resistant; consistent tool life) |

| Maintenance Cost | $500/year (corrosion repairs, repainting) | $0/year (passive protection) |

| Downtime Risk | High (unexpected failures) | Near-zero (certified reliability) |

| Total 5-Year Cost | $3,600/unit | $1,750/unit |

Real-World Impact: A medical device client saved $42K/year by switching from painted mild steel to electropolished 316L stainless steel—eliminating 12+ hours of monthly maintenance and avoiding FDA compliance failures.

Our Zero Defects Commitment in Material Handling

At Wuxi Lead Precision Machinery, “Zero Defects” is not a slogan—it’s a rigorously enforced process:

Material Certification: Every batch includes traceable mill test reports (MTRs) verified against ISO 9001 requirements.

24/7 Quality Control: In-process inspections at 3 critical stages (raw material receipt, mid-machining, final QC) using CMMs with ±0.0001″ accuracy.

Olympic Quality Assurance: All parts undergo 100% dimensional and surface finish validation against your specifications—no exceptions.

Supply Chain Transparency: Blockchain-enabled traceability from raw material source to delivery.

“When you partner with us, you gain a dedicated engineering team that treats your project as if it were their own. We’ve never had a recall in 12+ years of operation—because we build quality into every step.”

Next Steps: Let’s Engineer Your Solution Together

Contact our ISO 9001-certified engineering team today for a free DFM review. We’ll analyze your design, material requirements, and finish needs to deliver:

– Zero Defects Guarantee: 100% compliance with your specifications or we replace it at no cost.

– 24/7 Technical Support: Direct access to CNC specialists for urgent design or production queries.

– Cost-Optimized Recommendations: Data-driven advice to reduce total lifecycle costs by up to 30%.

Schedule a Consultation | Download Material Certification Guide | View ISO 9001 Certificate

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey with Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we partner with you to transform designs into precision-engineered solutions. Our ISO 9001-certified process ensures Zero Defects, Olympic Quality, and On-Time Delivery at every stage. From initial concept to mass production, we eliminate risks, optimize costs, and deliver flawless results—because your success is our standard.

Design Analysis & Engineering Validation

Every project begins with a rigorous engineering review to eliminate defects before production starts. Our team conducts DFMA (Design for Manufacturing and Assembly) analysis, GD&T validation, and material compatibility checks to ensure your design is manufacturable, cost-effective, and compliant with global standards. We verify critical dimensions, wall thicknesses, and tolerances against ISO 9001 requirements—preventing costly rework and ensuring first-time-right outcomes.

Precision Capabilities by Process

| Process | Standard Tolerance | Precision Option | Minimum Wall Thickness (Metals) | Notes |

|---|---|---|---|---|

| CNC Milling | ±0.005″ (0.127mm) | ±0.002″ (0.051mm) | 0.030″ (0.76mm) | Full material traceability, ISO 9001 |

| CNC Turning | ±0.005″ (0.127mm) | ±0.001″ (0.025mm) | 0.030″ (0.76mm) | Aerospace-grade precision |

| Sheet Metal Fabrication | ±0.005″ (0.127mm) | ±0.002″ (0.051mm) | 0.030″ (0.76mm) | Laser cutting, bending, welding certified |

Note: Tighter tolerances available for high-precision applications (e.g., medical, aerospace). All material certifications (e.g., ASTM, ISO) are verified and documented for full traceability.

Transparent Pricing & Cost Optimization

We eliminate hidden fees and ambiguity. Our pricing model provides a detailed, itemized breakdown of costs—material, machining, finishing, and inspection—so you know exactly what you’re paying for. Our engineers collaborate with you to identify cost-saving opportunities through:

Design optimization (e.g., reducing complex geometries, standardizing features)

Material selection (balancing performance with cost-efficiency)

Process streamlining (e.g., consolidating operations to reduce setup time)

No compromises on quality—only smarter engineering.

Rapid Prototyping with Zero Defects Guarantee

Speed without sacrifice. Our rapid prototyping service delivers functional, production-ready prototypes in as little as 72 hours, using the exact same machinery, tooling, and processes as mass production. Every prototype undergoes 100% First Article Inspection (FAI) against your specifications, including:

Dimensional verification (CMM, optical comparators)

Material certification validation

Surface finish and tolerance checks

This ensures defects are caught before full-scale production, saving time and costs while upholding our Zero Defects commitment.

Mass Production Excellence & On-Time Delivery

Our ISO 9001-certified production lines integrate Statistical Process Control (SPC) and real-time monitoring to maintain consistent quality. Every batch undergoes:

In-process inspections at critical stages (e.g., after roughing, before finishing)

Final QA checks (100% dimensional verification for critical features)

Material and coating validation (per your specifications)

With a 99.8% on-time delivery rate and dedicated logistics coordination, we guarantee your project stays on schedule—every time.

Why Partner with Wuxi Lead Precision Machinery?

Zero Defects Commitment: Rigorous QA protocols at every stage—from design validation to final shipment.

Olympic Quality Assurance: Components tested to meet or exceed ISO 9001, AS9100, and industry-specific standards for critical applications.

24/7 Customer Service: Dedicated account managers available around the clock for real-time updates, urgent support, and transparent communication.

“We don’t just build parts—we build trust. Every component we deliver is engineered for reliability, inspected for perfection, and delivered on time.”

— Wuxi Lead Precision Machinery

Ready to start your project? Contact our engineering team today for a free design review and quote. Let’s build excellence together.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery – Where Precision Meets Partnership

At Wuxi Lead Precision Machinery, we transcend conventional manufacturing boundaries. While industry-standard CNC tolerances typically range from ±0.005″ (0.127mm), our ISO 9001-certified processes deliver precision tolerances down to ±0.002″ (0.051mm) – with custom capabilities for aerospace and medical applications reaching ±0.0005″ (0.013mm). Every part undergoes rigorous statistical process control, material certification, and 100% inspection to ensure Zero Defects – because your success is measured in parts that work perfectly, every time.

Why Wuxi Lead is Your Strategic Manufacturing Partner

| Feature | Industry Standard | Wuxi Lead Precision Advantage |

|---|---|---|

| Tolerance Control | ±0.005″ (0.127mm) standard | ±0.002″ (0.051mm) precision; custom ±0.0005″ (0.013mm) for critical aerospace/medical applications |

| Quality Assurance | Basic ISO 9001 compliance | Full ISO 9001:2015 certification, 100% in-process inspection, full material traceability (ASTM/AMS certs included) |

| Support Model | 9-5 business hours | 24/7 engineering support with <2-hour response SLA across time zones |

| Defect Management | 1-3% typical defect rate | Zero Defects commitment with AI-driven root-cause analysis and preventive protocol integration |

| Design Collaboration | Optional DFM review | Free, proactive DFM analysis included in all quotes – optimizing cost, lead time, and performance from Day 1 |

“We don’t just manufacture parts – we solve engineering challenges. From initial design to final delivery, our team integrates seamlessly into your workflow, ensuring every component meets Olympic-grade standards.”

– Wuxi Lead Precision Engineering Team

Your Project Starts with a Partnership

Ready to elevate your project? Contact us today for a free DFM analysis and competitive quote within 24 hours.

📧 Email: [email protected]

📞 Phone: +86-13961886740 (24/7 Technical Support)

All inquiries are handled by senior CNC engineers – no automated responses, only expert-driven solutions tailored to your specific requirements.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.