Technical Contents

Engineering Guide: Metal Prototype

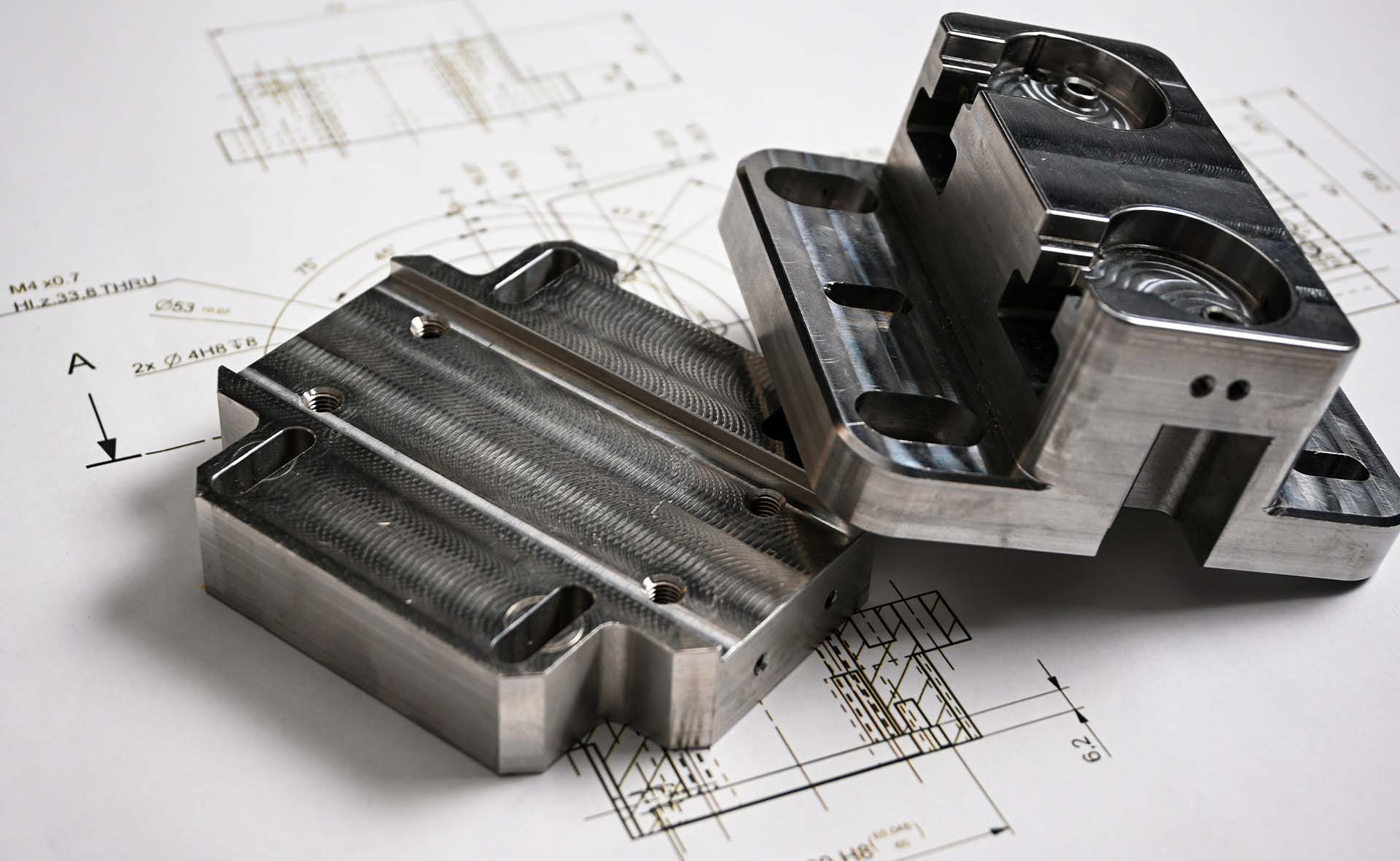

Engineering Insight: The Non-Negotiable Precision of Metal Prototyping

In high-stakes metal manufacturing, the prototype phase transcends mere concept validation; it is the critical proving ground where theoretical design confronts the unforgiving realities of material science, machining dynamics, and functional performance. For industries ranging from aerospace and defense to advanced medical devices and renewable energy infrastructure, dimensional accuracy and material integrity at the prototype stage are not desirable attributes—they are absolute prerequisites for success. A prototype failing to achieve specified tolerances or material properties does not merely indicate a flawed model; it signals a fundamental disconnect between design intent and manufacturability, risking catastrophic downstream consequences including product failure, regulatory rejection, and significant project delays. Precision in metal prototyping directly dictates the reliability of performance data, the validity of design iterations, and ultimately, the viability of the final production process.

At Wuxi Lead Precision Machinery, we engineer metal prototypes to the same exacting standards demanded by our most rigorous projects. Our CNC machining centers, operating under stringent environmental controls, consistently achieve tolerances down to ±0.005mm. This capability is not theoretical; it is proven daily. We recently delivered critical titanium components for a Beijing Winter Olympics ice-making system requiring flawless thermal cycling performance, where micro-deformations would have compromised the entire system. Similarly, our work on classified military drone subsystems demanded adherence to MIL-STD-810G vibration and shock specifications, necessitating prototypes that perfectly mirrored the structural behavior of flight-ready units. Such projects demand more than advanced machinery; they require deep metallurgical understanding, rigorous in-process inspection protocols using calibrated CMMs and optical comparators, and engineers who anticipate how material grain structure and residual stress impact final form.

The transition from prototype to production hinges on dimensional stability and repeatability established early. A prototype manufactured with inconsistent tolerances creates false confidence, leading to expensive tooling investments and production line stoppages when the realities of volume manufacturing expose hidden flaws. True precision prototyping minimizes risk by providing an accurate baseline for process validation, ensuring that the design intent is manufacturable at scale without costly re-engineering. It transforms the prototype from a visual model into a functional benchmark.

Our commitment to precision is quantifiable across key parameters essential for mission-critical applications:

| Critical Parameter | Standard Capability | High-Precision Capability | Common Applications |

|---|---|---|---|

| Dimensional Tolerance | ±0.025mm | ±0.005mm | Aerospace actuators, optical mounts |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Hydraulic seals, medical implants |

| Material Complexity | Aluminum, Steel, Brass | Titanium, Inconel, Hastelloy | Defense, energy, chemical processing |

| Geometric Complexity | 3-Axis Features | 5-Axis Contouring | Turbine blades, ergonomic medical devices |

| Certification Support | ISO 9001 | AS9100, NADCAP, MIL-STD | Aviation, military, space systems |

Precision metal prototyping is the cornerstone of de-risking advanced manufacturing. It demands a partner who views tolerances not as targets, but as non-negotiable commitments tied directly to end-product performance and safety. Wuxi Lead Precision Machinery brings proven experience from the world’s most demanding projects to ensure your metal prototype is not just a model, but the definitive foundation for successful production. This level of accuracy transforms engineering ambition into tangible, reliable reality.

Precision Specs & Tolerances

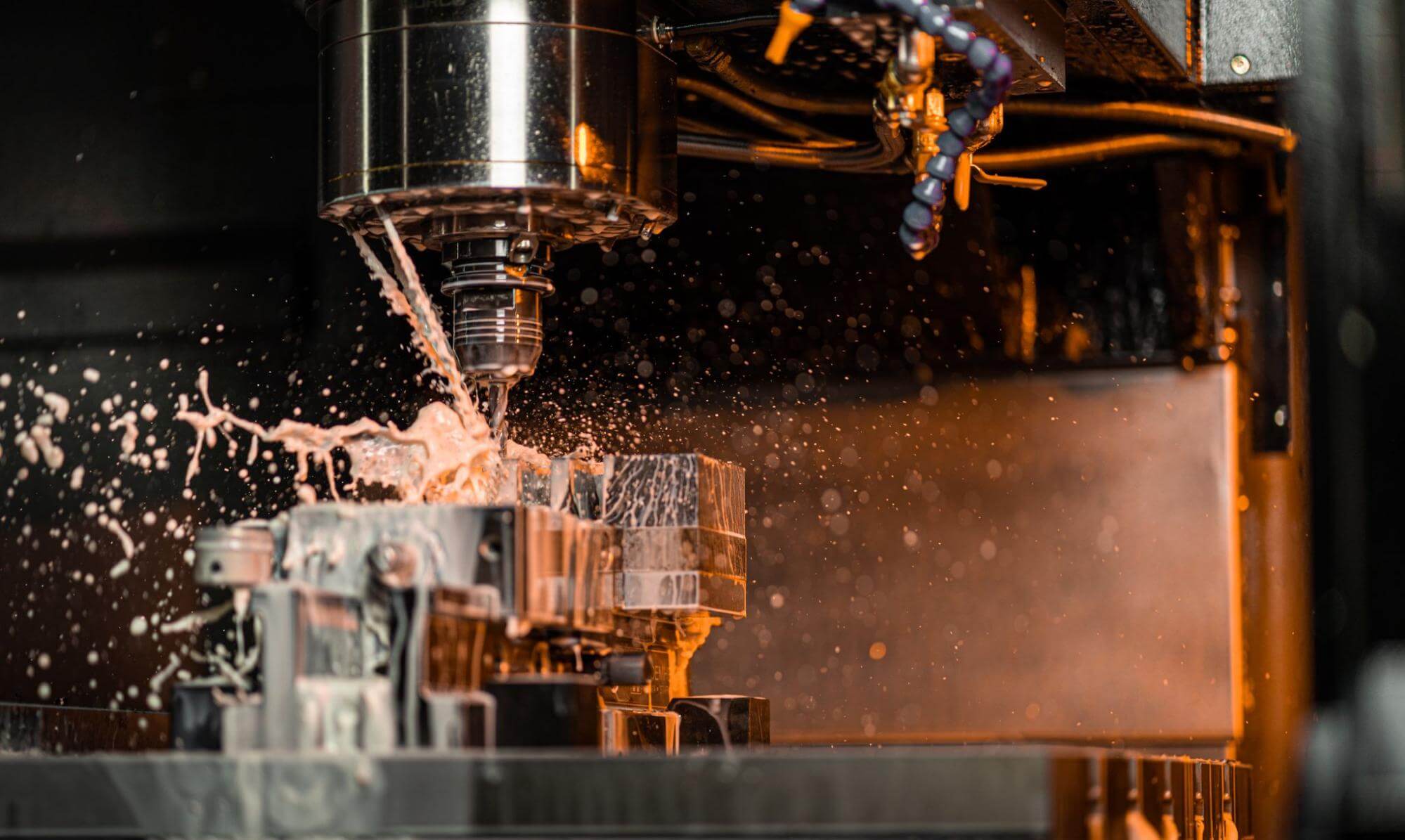

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal prototype manufacturing, engineered for precision, repeatability, and compliance with the most demanding industrial specifications. Our core strength lies in high-accuracy 5-axis CNC machining, a technology that enables us to produce complex geometries with superior surface finish and dimensional consistency. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across five planes, minimizing setup cycles and eliminating cumulative tolerances from multiple re-fixturing stages. This capability is essential for aerospace, medical, and high-performance automotive prototypes where form, fit, and function must be validated under exacting conditions.

Our machining centers are equipped with high-speed spindles, tool presetters, and automated tool changers, ensuring optimal cutting performance across a broad range of metals including aluminum alloys, stainless steel, titanium, and high-temperature superalloys. The integration of advanced CAM software allows for optimized toolpaths, reduced cycle times, and precise control over wall thicknesses, undercuts, and internal features. All operations are monitored in real time, with adaptive controls that adjust for tool wear and material variance, maintaining process stability across both single-part prototypes and low-volume pre-production runs.

Quality assurance is embedded into every phase of production. Each metal prototype undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), providing metrology-grade verification of critical dimensions, geometric tolerances, and surface profiles. Our CMM routines are fully programmed and repeatable, aligned with ISO 10360 standards, and capable of generating detailed inspection reports with point-cloud analysis when required. Dimensional data is traceable and archived for full production transparency, supporting APQP and PPAP documentation for regulated industries.

We maintain strict environmental controls in our metrology lab to ensure thermal stability, minimizing measurement drift. First-article inspections are standard for all new prototypes, and in-process checks are conducted at defined intervals during batch runs. Our quality management system is ISO 9001 certified, reflecting our commitment to continuous improvement and zero-defect manufacturing.

The following table outlines our standard machining tolerances, achievable across typical production conditions. Tighter tolerances are attainable upon engineering review and with the use of specialized fixturing or finishing processes.

| Feature | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm |

| Hole Diameter | +0.025 / 0 mm | +0.010 / 0 mm | Reamed or honed |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | GD&T compliant |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm | Verified via CMM |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As-machined or polished |

| Angular Features | ±0.05° | ±0.02° | 5-axis simultaneous machining |

These technical capabilities, combined with our engineering-first approach, position Wuxi Lead Precision Machinery as a trusted partner for high-integrity metal prototypes where precision, speed, and quality are non-negotiable.

Material & Finish Options

Material Selection for Precision Metal Prototyping

Material choice fundamentally dictates the performance, manufacturability, and cost trajectory of your metal prototype. At Wuxi Lead Precision Machinery, we guide clients through this critical decision, ensuring the selected alloy aligns precisely with functional requirements, environmental exposure, and the path to volume production. Selecting the optimal material early avoids costly redesigns and accelerates time-to-market.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are the cornerstone of rapid prototyping for good reason. Their exceptional strength-to-weight ratio, inherent corrosion resistance, and superior machinability make them ideal for aerospace components, consumer electronics enclosures, and structural frames where weight savings are paramount. 6061 offers excellent weldability and moderate strength, while 7075 delivers near-steel strength for highly stressed applications, albeit with slightly reduced corrosion resistance. Aluminum readily accepts various finishes, including anodizing, enhancing both durability and aesthetics.

For applications demanding maximum strength, wear resistance, and structural integrity under heavy loads, carbon and alloy steels like 4140, 4340, and 1018 are indispensable. These materials excel in automotive suspension parts, industrial machinery components, and tooling prototypes. While heavier than aluminum, their high tensile and yield strengths, coupled with good fatigue resistance, provide unmatched reliability in demanding mechanical environments. Machining steel requires robust tooling and precise parameters, an area where our CNC expertise ensures dimensional accuracy and surface finish consistency even in complex geometries.

Titanium, primarily Grade 5 (Ti-6Al-4V), is the solution for extreme environments. Its unparalleled strength-to-weight ratio, exceptional corrosion resistance across marine and chemical settings, and biocompatibility make it essential for aerospace critical parts, medical implants, and high-performance racing components. While significantly more expensive and challenging to machine than aluminum or steel due to low thermal conductivity and high reactivity, titanium prototypes validate designs where failure is not an option. Our specialized tooling and processes mitigate these challenges effectively.

Surface finishing, particularly anodizing, is integral to aluminum prototype performance. Type II (sulfuric acid) anodizing provides a durable, decorative, and corrosion-resistant layer, available in various colors. For critical engineering applications requiring maximum wear and abrasion resistance, Type III (hardcoat) anodizing creates a much thicker, harder ceramic-like surface. Both processes enhance part longevity and appearance without significantly altering critical dimensions when controlled precisely.

The following table summarizes key properties for common prototyping materials:

Material | Key Grades | Density (g/cm³) | Tensile Strength (MPa) | Primary Applications

Aluminum | 6061-T6, 7075-T6 | 2.7 | 310 (6061), 572 (7075) | Aerospace frames, enclosures, lightweight structures

Steel | 1018, 4140, 4340 | 7.8 | 440 (1018), 655 (4140), 745 (4340) | Automotive parts, machinery, tooling, high-stress components

Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | 4.5 | 345 (Gr2), 900 (Gr5) | Aerospace critical parts, medical implants, marine hardware

Material selection is not merely a technical specification; it is a strategic decision impacting the entire product lifecycle. Our engineering team collaborates closely with clients during the prototyping phase to evaluate trade-offs between performance, cost, and manufacturability, ensuring the chosen material and finish deliver a prototype that accurately predicts final production part behavior. This precision in selection forms the bedrock of successful, scalable manufacturing.

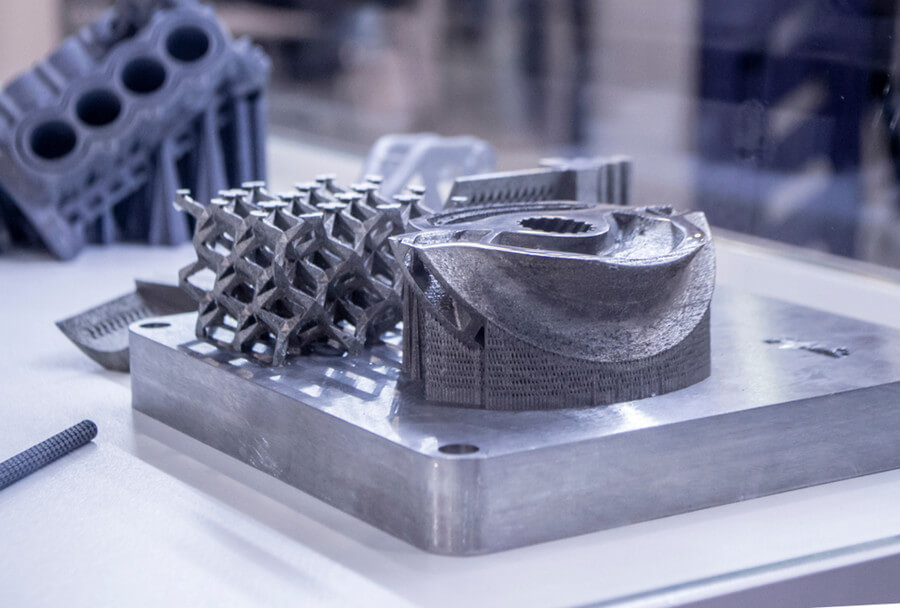

Manufacturing Process & QC

From Design to Mass Production: A Zero-Defect Manufacturing Process

At Wuxi Lead Precision Machinery, we engineer precision metal prototypes and production components using a rigorously controlled process designed to deliver zero-defect outcomes. Our methodology integrates advanced engineering, iterative prototyping, and scalable manufacturing to ensure every part meets exacting performance, tolerance, and reliability standards.

The journey begins with Design Analysis and Optimization. Our engineering team collaborates closely with clients to review CAD models, material specifications, and functional requirements. Using simulation tools such as finite element analysis (FEA) and computational fluid dynamics (CFD), we validate structural integrity, thermal behavior, and manufacturability before any metal is cut. This stage ensures design-for-manufacturing (DFM) compliance, minimizing risks and reducing time-to-market.

Next, we move into Prototype Development. Utilizing CNC machining, sheet metal fabrication, and precision stamping, we produce functional metal prototypes that mirror final production quality. These prototypes are subjected to full metrology inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Environmental and mechanical stress testing may also be performed to simulate real-world operating conditions. Feedback from this phase informs final design refinements, ensuring optimal performance and assembly compatibility.

Once the prototype is approved, we transition seamlessly into High-Volume Mass Production. Our automated production lines integrate real-time quality monitoring, statistical process control (SPC), and in-line inspection systems to maintain consistency across thousands or millions of parts. Each production run follows a documented quality plan, with first-article inspection (FAI) and process capability (Cp/Cpk) analysis ensuring compliance with ISO 9001 and IATF 16949 standards.

Throughout all stages, our zero-defect philosophy is enforced through preventive controls, operator training, and full traceability. Every component is tracked via batch numbering and digital quality records, enabling rapid root-cause analysis if anomalies arise. Preventive maintenance schedules and tool wear monitoring further eliminate variability in output.

This end-to-end process ensures that what works in prototype performs identically in production—without compromise.

Typical Production Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Materials | Aluminum, Stainless Steel, Brass, Copper, Carbon Steel, Titanium |

| Tolerances | ±0.005 mm (CNC), ±0.02 mm (Sheet Metal) |

| Surface Finish | Ra 0.8–3.2 µm (machined), Custom coatings available |

| Max Part Size (CNC) | 800 × 500 × 400 mm |

| Max Sheet Thickness | 12 mm (steel), 8 mm (aluminum) |

| Production Volume | 1–1,000,000+ units |

| Lead Time (Prototype) | 7–15 days (depending on complexity) |

| Quality Standards | ISO 9001, IATF 16949, RoHS, Full PPAP support |

By aligning precision engineering with disciplined process control, Wuxi Lead delivers metal prototypes and production parts that perform—consistently, reliably, and defect-free.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Prototype Excellence

Precision metal prototyping demands more than advanced machinery; it requires deep engineering insight, rigorous process control, and a partner committed to your project’s success from initial concept to certified production component. At Wuxi Lead Precision Machinery, we operate at the intersection of cutting-edge CNC technology and meticulous manufacturing discipline, specifically engineered to meet the stringent demands of aerospace, medical device, semiconductor, and advanced industrial sectors. Our facility in Wuxi, China, is not merely a job shop but an extension of your engineering team, equipped to transform complex 3D models into physically validated prototypes that accurately reflect final production intent, mitigating risk and accelerating your time-to-market.

Our core strength lies in integrating high-precision multi-axis machining with comprehensive in-house capabilities, ensuring every prototype meets exacting dimensional, material, and surface finish requirements. We understand that a prototype is far more than a physical model; it is a critical validation step for form, fit, function, and manufacturability. This necessitates processes capable of holding micron-level tolerances consistently across diverse, challenging materials. Below represents our standard production capability envelope for prototype development:

| Critical Specification | Capability Range |

|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) standard; ±0.002 mm (±0.00008″) achievable |

| Material Expertise | Aluminum Alloys (6061, 7075), Stainless Steels (303, 304, 316, 17-4PH), Titanium (Gr2, Gr5), Inconel 718, Brass, Copper, Tool Steels |

| Max Work Envelope (5-Axis) | Ø 800 mm x 600 mm H |

| Surface Finishes | As-machined, Deburred, Bead Blast, Anodize (Type II, III), Passivation, Electroless Nickel |

| Lead Time (Prototype) | 3-7 working days typical, expedited options available |

| Quality Certification | ISO 9001:2015 compliant processes, full FAI (First Article Inspection) reports |

Partnering with Lead Precision means gaining access to a vertically integrated solution where design for manufacturability (DFM) feedback is provided proactively, not reactively. Our engineering team collaborates directly with yours to identify potential production hurdles early, optimizing geometry for both prototype fidelity and future high-volume feasibility. We employ rigorous first-article inspection protocols using calibrated CMMs, optical comparators, and surface roughness testers, delivering comprehensive dimensional validation reports that provide absolute confidence in your prototype’s accuracy. This level of scrutiny is non-negotiable for applications where failure is not an option.

The transition from prototype to production should be seamless, not a re-engineering challenge. Our processes are designed with scalability in mind, utilizing the same CNC platforms, fixturing strategies, and quality systems for both low-volume prototypes and high-volume production runs. This continuity eliminates costly requalification and ensures the component you validate is the exact component you will manufacture.

Do not compromise your development cycle with prototyping partners lacking the precision engineering depth and process rigor required for mission-critical metal components. Contact our engineering team today for an immediate, no-obligation assessment of your next metal prototype project. Provide your CAD file and requirements to [email protected] and receive a detailed manufacturability analysis and competitive quotation within 24 business hours. Let Lead Precision Machinery be the trusted partner that transforms your complex concepts into physically validated, production-ready metal prototypes, accelerating your path to market with unwavering quality. Your next breakthrough component starts with an engineer-to-engineer consultation. Reach out now.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.