In today’s globalized world, the demand for precision-engineered metal parts has skyrocketed. Whether it’s for the automotive sector, electronics, or aerospace, the need for high-quality components is paramount. China, with its advanced manufacturing capabilities and competitive pricing, has emerged as a frontrunner in this domain. This article delves into the intricacies of metal parts manufacturing in China, highlighting the top players in the industry, the process of creating custom metal parts, and the unparalleled offerings of Wuxi Lead Precision Machinery. Whether you’re a business looking to source components or an enthusiast eager to understand the manufacturing landscape, this guide has got you covered.

Why China is the Go-To Destination for Metal Parts Manufacturing

China has rapidly emerged as a global powerhouse in the metal parts manufacturing industry. With its vast resources, state-of-the-art technologies, and a highly skilled workforce, the country offers unparalleled advantages for businesses seeking high-quality metal components.

Abundant Resources and Skilled Workforce: China boasts a rich pool of raw materials essential for metal parts manufacturing. This abundance ensures a steady supply chain, reducing lead times and ensuring timely deliveries. Additionally, the country’s educational system, with a strong focus on engineering and technical disciplines, produces a workforce adept at handling the intricacies of metal parts production.

Competitive Pricing and Advanced Technologies: One of the primary reasons businesses turn to China for their manufacturing needs is cost-effectiveness. Chinese manufacturers can offer competitive prices without compromising on quality, thanks to the country’s economic scale and efficient production methods. Moreover, China continually invests in research and development, ensuring that its manufacturers are equipped with the latest technologies, from CNC machines to advanced metal stamping equipment.

In the next section, we’ll delve deeper into the top metal parts manufacturers in China, highlighting their unique offerings and specialties.

Top Metal Parts Manufacturers in China introduce and compare

China’s metal parts manufacturing landscape is vast and varied, with numerous companies vying for the top spot. Here’s a brief overview of some of the leading manufacturers:

- Yijin Hardware: Located in Shenzhen, Yijin Hardware Co., Ltd. stands out for its commitment to customer satisfaction. They specialize in CNC machining, rapid prototyping, stamping, and die casting.

- Sage Metal Parts: An ISO 9001:2008 certified company, Sage Metal Parts offers a holistic solution for all metal component needs, including hardware insertion, welding, grinding, and more.

- Feng Yu: With over 50 years of experience, Feng Yu is a trusted name in the stamping dies sector, known for its efficient and cost-effective metal stamping process.

- Runpeng Precision Hardware: Catering to industries like aerospace and automotive, Runpeng Precision Hardware is known for its mold design and production capabilities.

- Nice Rapid: Nice Rapid is a top manufacturer offering rapid prototyping and tooling solutions, ensuring top-notch service and product quality.

- Wuxi Lead Precision Machinery: A beacon of excellence in the metal parts manufacturing industry, Wuxi Lead Precision Machinery offers a diverse product range, from aluminum parts to brass pieces, and is known for its commitment to precision and quality.

here’s a comparison table for the top metal parts manufacturers in China, focusing on company name, specialization, and location:

| Company Name | Specialization | Location |

|---|---|---|

| HuaYi Precision Metal | CNC Machining and Turning | Shenzhen |

| QINGDAO XINGHEXING PRECISION INDUSTRY | CNC Steelautomotive/Scooter/Hydraulic/Turbocharger/Turbo/Automobile/Truck/Trailer/Elevator/Car/Motorcycle/Bicycle/Auto Aluminium Precision Machining Part | Qingdao |

| Wenzhou Lianggong Forging | Customized Steel Forging Parts in Construction Machinery and Agricultural Machinery | Wenzhou |

| Qing Dao Xiang Bai Mu Machinery | CNC Machining Laser Cutting Bending Welding Metal Parts with Powder Coated | Qingdao |

| Wujiang Tianfu Metal Products | Custom Metal Sheet Stamping Parts, Stainless Steel Sheet Metal Fabrication | Wujiang, Suzhou |

| Ningbo Runcheng Import and Export Trade | CNC Precision Hardware Auto Ss/Stainless Steel/Aluminum Machining Spare Customed Parts | Ningbo |

| Shanghai Sheetwell Metal Manufacture | OEM CE Certificate Professional Factory Directly Supply Laser Cutting Parts | Shanghai |

| Xiamen Huaxinrong Industry and Trade | Quality Plastic Turning Precision Stainless Custom Parts Aluminum CNC Machining | Xiamen |

| Huizhou Hongchuang Precision Machinery | CNC Machining of Car Camera Accessory | Huizhou |

| Qingdao Difon Machinery | Factory Custom Made Glock Auto Metal Sear Switch CNC Machining Milling Precision Parts | Qingdao |

| Wuxi Lead Precision Machinery | Specialized in precision metal parts manufacturing | Wuxi |

This table provides a quick overview of the top metal parts manufacturers in China, highlighting their specialization and location. It can serve as a handy reference for businesses or individuals looking to collaborate or source products from these manufacturers.

Spotlight: Wuxi Lead Precision Machinery

Nestled in the heart of Yangjian Industrial Park, Wuxi, Wuxi Lead Precision Machinery stands as a beacon of excellence in the metal parts manufacturing industry. With a keen focus on precision and quality, the company has carved a niche for itself in the global market.

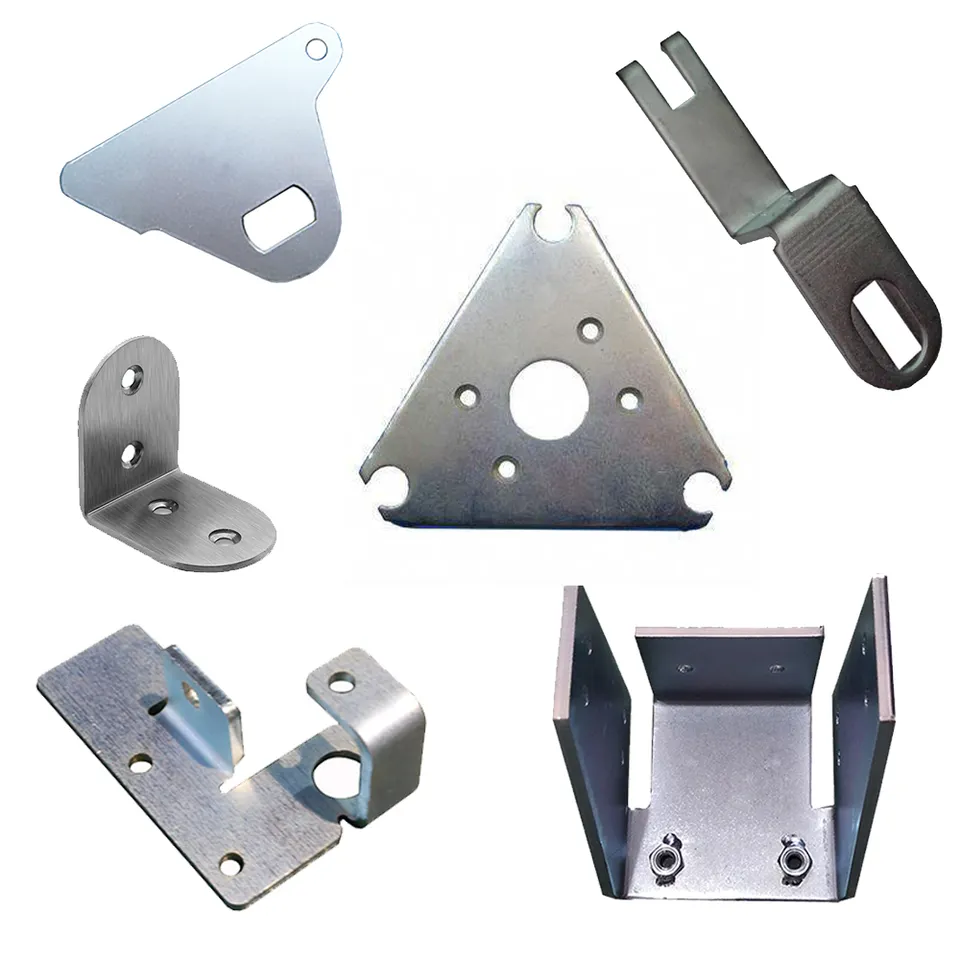

- Diverse Product Range: Whether you’re in the market for aluminum parts, stainless steel components, or brass pieces, Wuxi Lead Precision Machinery has you covered. Their extensive product range ensures that clients’ diverse needs are met with precision.

- Commitment to Excellence: Every product that leaves the Wuxi Lead facility undergoes rigorous quality checks. Their state-of-the-art CNC machining and turning capabilities ensure that each component is crafted to perfection.

- Customer-Centric Approach: At Wuxi Lead, the customer is king. From the initial design phase to the final product delivery, the company ensures a seamless experience for its clients. Their prompt response time and attention to detail have earned them accolades from clients worldwide.

How to Make Custom Metal Parts

Custom metal parts manufacturing is a meticulous process that requires precision, expertise, and a deep understanding of the client’s requirements. Here’s a step-by-step guide on how custom metal parts are made

1. Understanding Client Requirements:

- Initial Consultation: The process begins with a detailed consultation with the client to understand their specific needs, design preferences, and application of the part.

- Design Review: The design, if provided by the client, is reviewed for feasibility. If not, a design is created based on the client’s specifications.

2. Material Selection:

- Depending on the application, durability requirements, and budget, the appropriate material is selected. Common materials include aluminum, stainless steel, brass, and titanium.

3. Prototyping:

- Before mass production, a prototype is often created to ensure the design meets the client’s expectations.

- This step allows for any necessary modifications and ensures that the final product will be of the desired quality.

4. Production Process Selection:

- CNC Machining: Ideal for complex parts requiring high precision. Computer-controlled machines cut, drill, and shape the material.

- Metal Stamping: Suitable for producing large quantities of the same part. Flat metal sheets are molded into specific shapes using a stamping press.

- Sheet Metal Fabrication: This involves cutting, bending, and assembling metal structures from various metal sheets.

5. Quality Control:

- Every custom part undergoes rigorous quality checks to ensure it meets the set standards.

- Measurements are taken, and the part is tested under real-world conditions to ensure its durability and functionality.

6. Finishing:

- Depending on the client’s requirements, the part might undergo various finishing processes like polishing, painting, or anodizing to enhance its appearance and durability.

7. Packaging and Delivery:

- Once the custom metal parts pass all quality checks, they are packaged securely to prevent any damage during transit.

- The parts are then shipped to the client, with all necessary documentation included.

8. After-Sales Support:

- A reputable manufacturer will offer after-sales support to address any concerns or issues the client might have after receiving the custom parts.

Custom metal parts manufacturing is a blend of art and science. It requires a deep understanding of both design and engineering principles. Companies like Wuxi Lead Precision Machinery excel in this domain, ensuring that clients receive parts that not only meet but exceed their expectations.

The Manufacturing Process: A Glimpse into Precision

The journey of transforming a raw metal sheet into a functional component is intricate. Here’s a sneak peek into the manufacturing process:

- CNC Machining: Computer Numerical Control (CNC) machining is the backbone of modern metal parts manufacturing. It allows for precise cutting, drilling, and shaping of metal components, ensuring accuracy and consistency.

- Metal Stamping: This process involves placing flat metal sheets in a stamping press, where they are molded into specific shapes. It’s ideal for producing large quantities of the same part.

- Sheet Metal Fabrication: This involves cutting, bending, and assembling metal structures from various metal sheets. The process is versatile and can be used to create a wide range of products.

Key Questions International Buyers Should Ask Their Chinese Suppliers

Engaging with a new supplier, especially from a different country, can be daunting. Here are some pivotal questions to ask:

- What certifications do you hold? This helps ascertain the quality standards the manufacturer adheres to.

- Can you provide references or case studies? Past work can give insights into the manufacturer’s capabilities.

- What is the lead time for production? This helps in planning and inventory management.

- How do you handle quality control? Ensuring the final product meets the desired standards is crucial.

Why Choose Wuxi Lead Precision Machinery?

Choosing a metal parts supplier is a significant decision, and Wuxi Lead Precision Machinery makes it easy. Their commitment to quality, diverse product range, and customer-centric approach make them a preferred choice for businesses worldwide.

FAQ Tips

- What sets Wuxi Lead Precision Machinery apart from other manufacturers? Their focus on precision, quality, and customer satisfaction sets them apart. They offer a diverse range of products, ensuring that clients’ diverse needs are met with precision.

- How does the company ensure the quality of its products? Rigorous quality checks and state-of-the-art manufacturing processes ensure top-notch products. Their commitment to excellence is evident in every product that leaves their facility.

- What industries can benefit most from their offerings? From aerospace to electronics, Wuxi Lead caters to a wide range of industries. Their diverse product range ensures that they can meet the needs of various sectors.

- How does Wuxi Lead handle international orders and shipping? Wuxi Lead has a streamlined process for handling international orders, ensuring timely delivery and adherence to international shipping standards.

- Are there any customization options available for products? Yes, Wuxi Lead offers customization options for its products, allowing clients to get components tailored to their specific requirements.

- How does Wuxi Lead handle after-sales services and support? Wuxi Lead has a dedicated customer support team that handles after-sales queries, ensuring that clients have a seamless experience even after the purchase.

In the ever-evolving world of metal parts manufacturing, China stands tall as a global leader. With companies like Wuxi Lead Precision Machinery leading the charge, businesses worldwide can rest assured of top-quality products. Whether you’re a seasoned buyer or a newbie, understanding the landscape and making informed choices can make all the difference.