Technical Contents

Engineering Guide: Metal Mould

Engineering Insight Metal Mould Precision as the Non-Negotiable Foundation

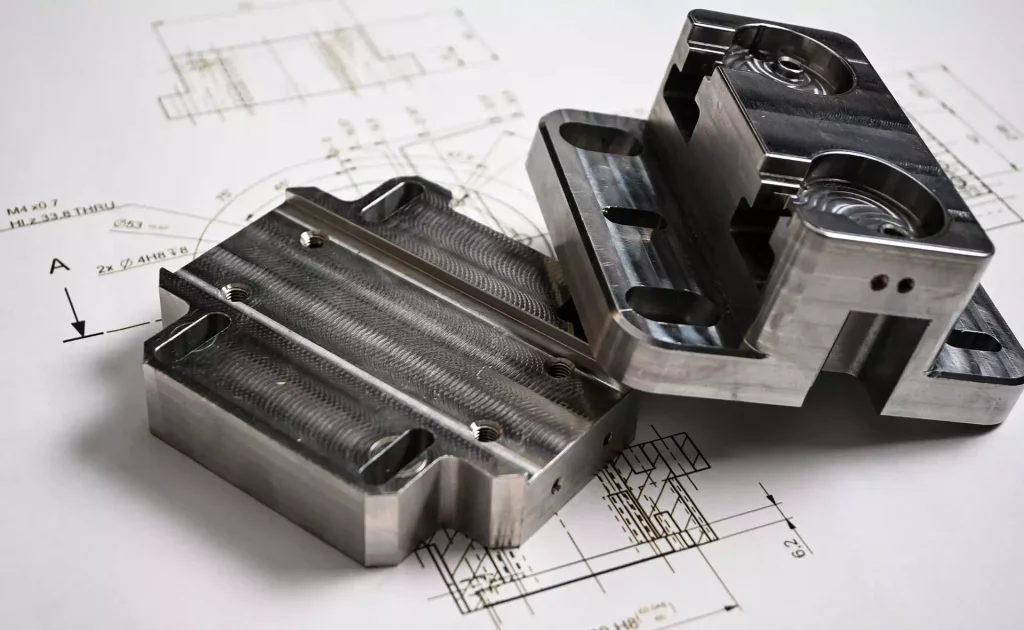

In high-stakes metal manufacturing, the metal mould is far more than a simple tool; it is the definitive master controlling the geometric integrity, surface quality, and functional performance of every single part produced. Precision in mould design and fabrication is not merely desirable—it is the absolute prerequisite for success in demanding applications where failure carries significant cost, safety, or reputational risk. Minute deviations in cavity dimensions, core alignment, or cooling channel placement translate directly into part warpage, dimensional instability, excessive scrap rates, and accelerated tool wear. Achieving micron-level tolerances consistently demands mastery of advanced CNC machining, sophisticated metrology, and deep material science understanding. This precision ensures optimal filling dynamics, controlled solidification, and predictable ejection, directly impacting cycle times, part longevity, and the ultimate viability of the production process. For industries like aerospace, medical device manufacturing, and high-performance automotive, where components operate under extreme stress or require absolute biocompatibility, the mould’s precision is the bedrock upon which product certification and field reliability are built.

Wuxi Lead Precision Machinery operates at this critical precision frontier. Our engineering team possesses over 15 years of specialized expertise in developing and manufacturing complex metal moulds for the world’s most exacting specifications. This is not theoretical knowledge; it is proven through tangible, high-profile projects. We have delivered mission-critical mould solutions supporting Olympic-level sporting equipment production, where marginal performance gains are measured in milliseconds and material consistency is paramount. Furthermore, our processes and quality systems are rigorously aligned to meet stringent military-grade standards, where component failure is not an option and traceability down to the raw material batch is mandatory. This experience instills an uncompromising culture of precision within every stage of our workflow, from initial CAD/CAM programming through to final inspection and validation.

The quantitative outcome of this precision-focused methodology is reflected in the consistent performance metrics we achieve for our clients. Key specifications consistently met or exceeded include

| Parameter | Typical Capability | Critical Application Impact |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | Ensures perfect assembly fit and function |

| Surface Roughness (Ra) | 0.05 µm | Critical for sealing surfaces, optics, biocompatibility |

| Material Options | Tool Steels (H13, S7), Stainless, Aluminum Alloys | Tailored for thermal management, wear resistance, cycle life |

| Metrology Standard | CMM, Optical Scanning, 3D Comparison | Full GD&T verification against CAD model |

| Industry Alignment | ISO 9001, AS9100, ITAR Compliant Processes | Meets aerospace, defense, medical regulatory demands |

This level of controlled precision eliminates costly downstream corrections, minimizes production downtime, and delivers parts that perform reliably in the field. At Wuxi Lead Precision Machinery, we understand that your product’s success is inextricably linked to the fidelity of the mould. We engineer that fidelity into every cavity, core, and cooling circuit, providing the stable, high-precision foundation your critical manufacturing operations require. Partner with us to transform demanding design specifications into flawless, high-volume reality.

Precision Specs & Tolerances

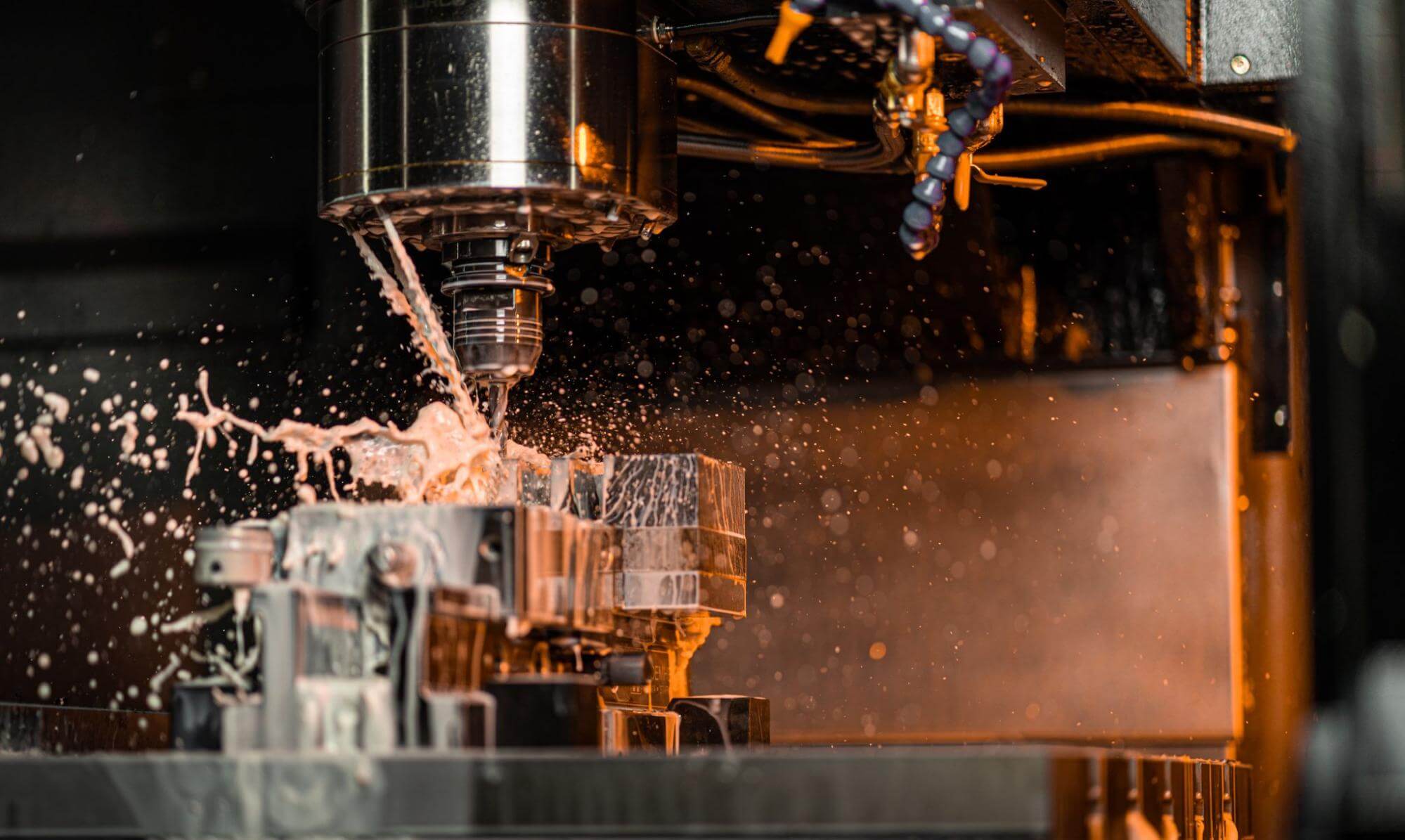

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision metal mold production for demanding industrial applications. Our expertise lies in transforming complex engineering designs into fully functional, production-ready metal molds with exceptional accuracy and repeatability. At the core of our manufacturing process is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to execute intricate geometries and multi-faceted mold components in a single setup. This eliminates cumulative alignment errors, reduces cycle times, and ensures superior surface integrity critical for high-performance molds.

Our 5-axis CNC systems provide simultaneous motion across all five axes, allowing tool access to deep cavities, undercuts, and contoured surfaces that are typical in injection, die-casting, and stamping molds. This capability supports the production of molds from a wide range of materials, including hardened steels, aluminum alloys, titanium, and high-temperature alloys, all machined to exacting specifications. With continuous tool path optimization and high spindle speeds, we achieve fine surface finishes and tight dimensional control, minimizing the need for post-processing and accelerating time-to-market.

Quality assurance is rigorously maintained throughout every phase of production. Each metal mold undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring full compliance with design intent and industry standards. Our CMM systems provide metrology-grade verification of critical dimensions, geometric tolerances, and surface profiles with micron-level precision. Data from each inspection is documented and traceable, supporting full quality documentation packages for audit and certification purposes.

All manufacturing and inspection processes are conducted in a climate-controlled environment to minimize thermal variation, further enhancing measurement reliability and process stability. Our engineering team employs integrated CAD/CAM/CAE software to simulate machining operations and validate tool paths prior to physical production, reducing risk and ensuring first-time-right outcomes.

The following table outlines the typical tolerances we consistently achieve in our metal mold manufacturing processes:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Flatness | 0.01 mm / 100 mm | 0.005 mm / 100 mm |

| Circular Runout | 0.01 mm | 0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm (polished finishes available) |

| Angular Tolerance | ±0.05° | ±0.02° |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for OEMs and Tier 1 suppliers requiring mission-critical metal molds in aerospace, automotive, medical, and industrial equipment sectors. Our integrated approach—combining advanced 5-axis CNC technology with stringent CMM-based quality control—ensures every mold meets the highest standards of performance, durability, and precision.

Material & Finish Options

Material Selection for High-Performance Metal Molds

Selecting the optimal material for metal mold construction is a critical engineering decision directly impacting part quality, production efficiency, tool longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we leverage decades of precision CNC expertise to guide clients through this complex choice, balancing performance requirements with economic realities. The primary contenders—Aluminum, Tool Steel, and Titanium—each offer distinct advantages suited to specific production scenarios and part specifications.

Aluminum alloys, particularly 6061-T6 and 7075-T6, excel in rapid prototyping and low-to-medium volume production runs. Their high thermal conductivity significantly reduces cycle times by accelerating part cooling within the mold cavity. This property, combined with ease of machinability, allows for faster lead times and lower initial tooling costs. While less durable than steel under high-pressure, high-cycle conditions, modern aluminum grades treated with hard anodizing achieve surface hardness sufficient for many plastic injection and low-pressure casting applications, especially with abrasive-filled resins. Aluminum molds are the pragmatic choice when speed to market and iterative design validation are paramount.

Tool steels, especially air-hardening grades like H13 and P20, remain the industry standard for high-volume, high-pressure production. Their superior hardness, wear resistance, and thermal stability withstand the rigors of millions of cycles required in automotive, medical, and consumer goods manufacturing. Properly heat-treated and polished steel molds deliver exceptional surface finish replication on final parts and maintain dimensional stability under sustained thermal cycling. The higher initial investment is justified by extended service life and consistent part quality over extensive production runs, making steel the backbone of demanding industrial applications.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), address extreme niche requirements where exceptional strength-to-weight ratio, corrosion resistance in highly aggressive chemical environments, or operation at elevated temperatures beyond steel’s capability are non-negotiable. While significantly more expensive and challenging to machine than steel, titanium’s unique properties are indispensable for specialized aerospace components, corrosive chemical processing molds, or applications demanding minimal thermal distortion under severe conditions. Its use is typically reserved for highly engineered, low-volume, mission-critical tooling.

Surface finishing, particularly hard anodizing for aluminum molds, is integral to material performance. This electrochemical process creates a dense, wear-resistant aluminum oxide layer (typically 25-50µm thick) that dramatically enhances surface hardness (up to 600 HV), improves abrasion resistance against glass-filled polymers, and provides excellent corrosion protection. Anodized aluminum molds achieve significantly longer service life compared to bare aluminum, bridging the performance gap towards steel for many applications while retaining thermal advantages.

The comparative properties below guide initial material screening:

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Primary Mold Applications |

|---|---|---|---|---|

| Aluminum 6061 | 95 HB | ~170 | Medium (High w/ Anod) | Prototypes, Low-Volume Production |

| Steel H13 | 48-52 HRC | ~28 | High (Polished) | High-Volume Injection Molding, Die Casting |

| Titanium Gr5 | 36 HRC | ~7 | Very High | Extreme Environments, Aerospace, Medical |

Wuxi Lead Precision Machinery provides comprehensive material consultation, leveraging advanced simulation and our ISO-certified manufacturing capabilities. Partner with our engineering team early in your design phase to select the optimal material and finish, ensuring your mold delivers maximum value, precision, and longevity for your specific production goals. Contact us for a detailed technical assessment.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal moulds engineered for performance, durability, and zero-defect consistency. Our production process is a meticulously structured workflow that ensures every component meets exacting industrial standards. From initial concept to full-scale manufacturing, we integrate advanced engineering with rigorous quality control to deliver moulds that perform reliably in high-demand applications.

The process begins with Design, where our engineering team collaborates closely with clients to translate technical requirements into optimized 3D models. Using industry-leading CAD/CAM software, we analyze structural integrity, thermal distribution, and material flow dynamics to ensure the mould design supports both manufacturability and long-term performance. Finite Element Analysis (FEA) is applied to simulate real-world operating conditions, minimizing risks before physical production begins. All designs are reviewed and validated with the client to ensure alignment with functional and dimensional expectations.

Next is Prototyping, a critical phase that bridges design intent with production reality. We fabricate functional prototypes using CNC machining, EDM, or additive manufacturing, depending on the complexity and material requirements. These prototypes undergo comprehensive testing, including fit checks, cycle time evaluation, and initial output sampling. This stage allows us to identify and correct potential issues early, reducing downstream risks and ensuring process stability. Every prototype is inspected using coordinate measuring machines (CMM) and optical measurement systems to verify dimensional accuracy within ±0.002 mm.

Once the prototype is approved, we transition to Mass Production, where scalability and consistency are paramount. Our automated production lines are equipped with real-time monitoring systems that track tool wear, temperature, pressure, and cycle times. Each metal mould is manufactured using high-grade tool steels or specialty alloys, heat-treated to enhance hardness and wear resistance. Throughout production, in-process inspections and statistical process control (SPC) methodologies are employed to maintain tight tolerances and ensure zero-defect output. Final inspection includes full dimensional reporting, surface finish analysis, and non-destructive testing where applicable.

Our commitment to excellence is reflected in every stage of the process. By integrating precision engineering, advanced technology, and a zero-defect philosophy, Wuxi Lead Precision Machinery delivers metal moulds that exceed performance expectations in automotive, aerospace, and industrial manufacturing sectors.

| Specification | Detail |

|---|---|

| Dimensional Accuracy | ±0.002 mm |

| Surface Finish | Ra 0.1 – 1.6 μm (polished or textured) |

| Materials | P20, 718H, S136, H13, 420 Stainless, Custom Alloys |

| Heat Treatment | Up to 52 HRC (varies by material) |

| Tolerance Control | ISO 2768-mK or customer-specific |

| Inspection Tools | CMM, Optical Comparator, Roughness Tester, Hardness Tester |

| Production Capacity | 50–200 moulds/month (based on complexity) |

Why Choose Wuxi Lead Precision

Elevate Your Metal Mould Production with Engineering Precision

At Wuxi Lead Precision Machinery, we transform complex metal mould challenges into competitive advantages for global manufacturers. With over 15 years of specialized expertise in high-tolerance CNC machining and mould fabrication, we deliver solutions where micron-level accuracy directly impacts your product performance and production stability. Our ISO 9001-certified facility in Wuxi integrates cutting-edge 5-axis milling, wire EDM, and grinding technologies with rigorous material science protocols, ensuring every component meets the exacting standards of aerospace, medical, and automotive industries. We understand that a mould is not merely a tool—it is the foundation of your manufacturing integrity, and we engineer it accordingly.

Our commitment begins with deep technical collaboration. Before a single chip is cut, our engineering team conducts a comprehensive feasibility analysis of your design, material selection, and production volume. We proactively identify potential stress points, thermal dynamics, and wear factors to optimize mould longevity and part consistency. This preventative engineering approach reduces costly iterations and accelerates time-to-market, whether you require single-cavity prototypes or multi-cavity production systems for hardened tool steels, aluminum alloys, or exotic superalloys. Below are core capabilities defining our precision standard:

| Specification Category | Performance Range |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 µm (mirror grade) |

| Material Compatibility | P20, H13, S136, 420SS, Aluminum 7075, Titanium Grade 5, Inconel 718 |

| Machine Capabilities | 5-axis milling (travel: 1,200 x 800 x 600 mm), Wire EDM (±0.001 mm), CMM inspection (0.5 + L/600 µm) |

| Typical Lead Time | 15–25 days (complex mould bases) |

Partnering with Lead Precision means accessing a dedicated technical alliance. Our engineers provide real-time process transparency through digital work logs and in-process inspection reports, allowing you to validate progress against your quality benchmarks. We mitigate supply chain volatility through strategic material partnerships and buffer inventory for critical alloys, ensuring your production schedules remain uncompromised. When dimensional drift or surface defects threaten your output, our rapid-response team implements corrective actions within 24 hours—minimizing downtime and scrap rates.

Your next mould investment demands a partner who treats your specifications as non-negotiable engineering mandates. We do not merely manufacture; we safeguard your production yield, brand reputation, and operational efficiency through uncompromising precision. Contact our engineering team today to initiate a collaborative review of your most demanding metal mould requirements. Submit your CAD files and technical dossier to [email protected] for a confidential feasibility assessment and timeline proposal. Let us demonstrate how Lead Precision becomes your invisible force multiplier in high-stakes manufacturing. The path to zero-defect production starts with one email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.