Technical Contents

Engineering Guide: Metal Milling Services

Engineering Insight Precision in Metal Milling Services

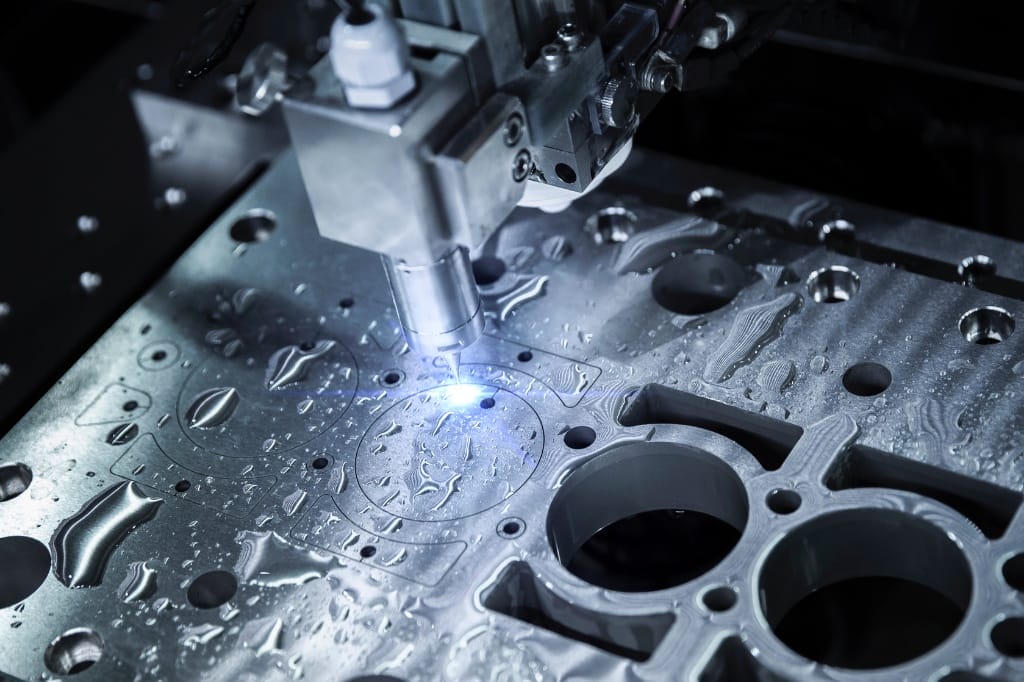

Precision in metal milling transcends mere dimensional accuracy; it defines functional integrity, safety, and lifecycle performance for critical components across aerospace, defense, medical, and energy sectors. In high-stakes applications, tolerances measured in microns directly impact assembly success, operational reliability, and regulatory compliance. A deviation of ±0.005mm in a turbine blade or surgical implant can trigger catastrophic failure or compromise patient safety. At Wuxi Lead Precision Machinery, we treat precision not as a target but as a non-negotiable engineering mandate, rigorously enforced through closed-loop metrology and process validation.

Our commitment to ultra-precision is proven through decades of delivering mission-critical components for Olympic-standard equipment and Tier-1 military systems. For the Beijing Winter Olympics, we manufactured sub-assembly parts for high-speed ice-resurfacing machinery requiring thermal stability under extreme cold, achieving repeatability within ±0.002mm across 500+ units. Similarly, our work for defense contractors involves milling hardened steel housings for navigation systems where vibration resistance and geometric perfection are paramount—components that operate flawlessly in environments where failure is not an option. This heritage instills our team with the discipline to treat every client project with the same urgency and exactitude.

Achieving such results demands more than advanced machinery; it requires integrated process control. Our facility combines multi-axis CNC mills with in-process probing, laser tool measurement, and climate-controlled inspection labs. The table below outlines our core precision capabilities:

| Specification | Performance Range |

|---|---|

| Positional Accuracy | ±0.001 mm |

| Repeatability | ±0.0005 mm |

| Surface Finish (Ra) | 0.1 µm to 1.6 µm |

| Max Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Titanium, Inconel, Tool Steel, Aluminum Alloys |

| Machine Types | 5-Axis Milling Centers, High-Speed VMCs |

Every milling operation begins with a tolerance-critical analysis, where our engineers deconstruct GD&T requirements and simulate toolpaths to preempt thermal drift or deflection. We deploy adaptive machining strategies that adjust feed rates in real-time based on load sensors, ensuring consistent chip formation and eliminating micro-vibrations that degrade surface integrity. Post-process, components undergo CMM validation against CAD models, with full traceability from raw material to final inspection.

For industries where precision equals performance, partnering with a manufacturer that operates at the intersection of Olympic-caliber standards and military-grade reliability is essential. Wuxi Lead Precision Machinery delivers this through unwavering process discipline, cutting-edge technology, and a legacy of solving the most demanding milling challenges. Contact our engineering team to discuss how our precision-first approach can secure your next critical project.

Precision Specs & Tolerances

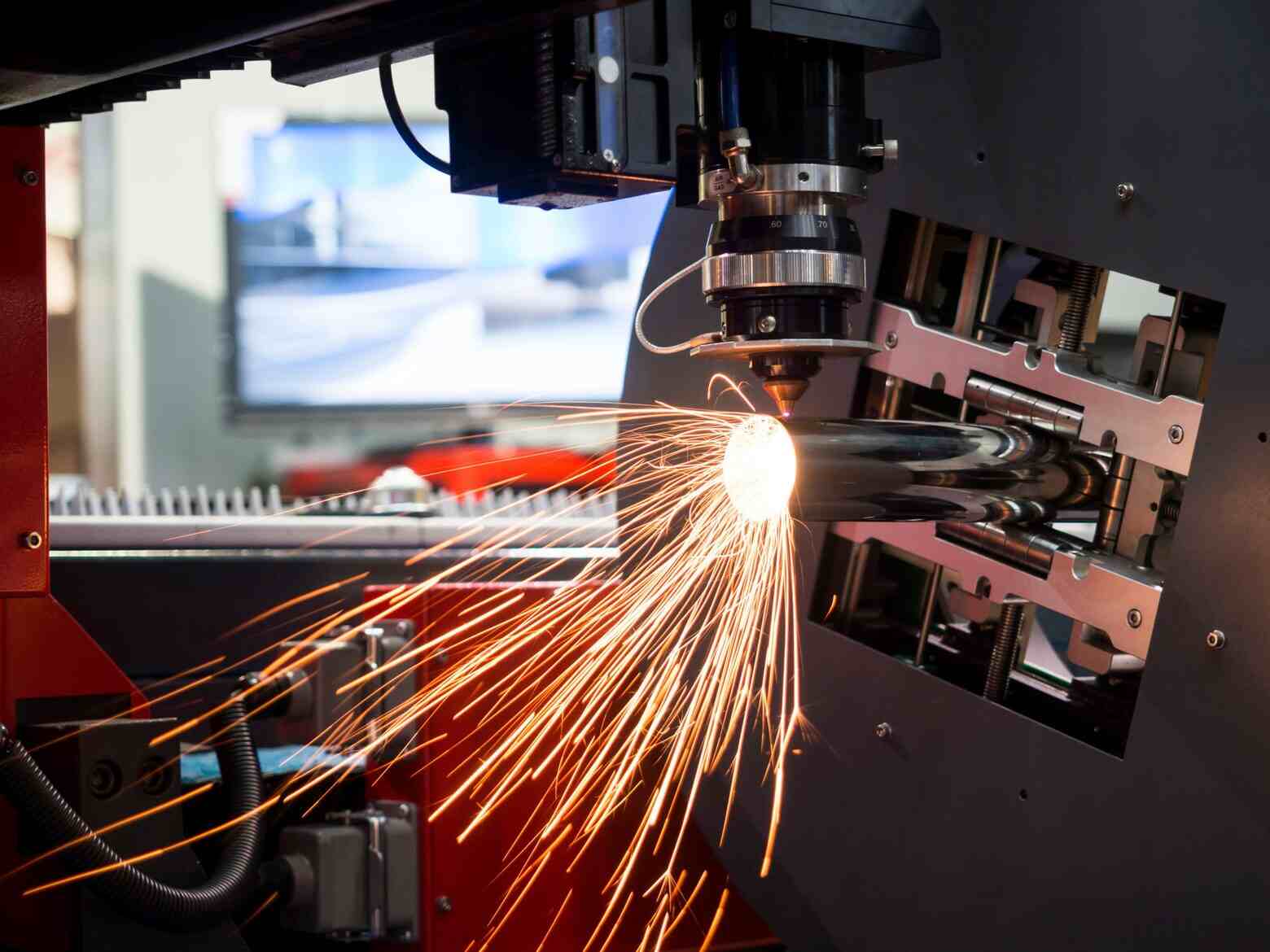

Advanced 5-Axis CNC Milling Capabilities for Mission-Critical Components

Wuxi Lead Precision Machinery delivers high-precision metal milling services engineered for complex, high-performance applications across aerospace, medical, energy, and industrial automation sectors. At the core of our technical capabilities is a fully integrated fleet of 5-axis CNC machining centers, enabling us to produce intricate geometries with superior surface finishes and dimensional accuracy. Our 5-axis technology allows simultaneous movement across all five axes, minimizing setup cycles and eliminating the need for multiple fixtures. This results in improved part consistency, reduced lead times, and the ability to machine deep cavities, undercuts, and organic contours that are unattainable with conventional 3-axis systems.

All machining operations are supported by advanced CAD/CAM software, ensuring optimized toolpaths and precise material removal strategies. We work with a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, Inconel, and hardened tool steels. Our machining envelope accommodates parts up to 1,200 mm × 800 mm × 750 mm, balancing flexibility with rigidity for both prototyping and low-to-mid volume production runs. In-house tooling management and high-speed spindles (up to 24,000 RPM) further enhance productivity and surface integrity, particularly for thin-walled or high-precision components.

Quality assurance is embedded at every stage of production. Each component undergoes rigorous inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing traceable, metrology-grade verification of critical features. Our inspection protocols comply with ISO 10360 standards, ensuring measurement uncertainty remains within certified limits. First-article inspections, in-process checks, and final batch validations are standard practice, with full inspection reports available upon request.

Our technical team combines decades of CNC programming and machining experience with a deep understanding of material behavior and GD&T principles. This expertise allows us to advise on design for manufacturability (DFM), recommend optimal fixturing solutions, and resolve potential production challenges before machining begins—delivering not just parts, but engineering partnership.

The following table outlines our standard and precision tolerance capabilities based on material, geometry, and feature type:

| Feature Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 | ±0.01 | Up to 300 mm; tighter tolerances achievable over shorter lengths |

| Hole Diameter | ±0.03 | ±0.01 | Reamed or honed features; positional tolerance ±0.02 mm |

| Flatness | 0.05 mm | 0.01 mm | Over 100 mm² area; dependent on material stability |

| Positional Accuracy | ±0.03 | ±0.01 | Relative to datum; verified via CMM |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | Achieved with fine milling or polishing passes |

| Angular Features | ±0.1° | ±0.05° | Critical for multi-face interfaces |

All tolerances are achievable under stable environmental conditions and proper design considerations. Actual performance may vary based on part complexity, aspect ratio, and material anisotropy. Wuxi Lead Precision Machinery remains committed to pushing the boundaries of what precision metal milling can achieve—delivering reliability, repeatability, and excellence in every component.

Material & Finish Options

Material Selection Fundamentals for Precision CNC Milling

Selecting the optimal material is a critical engineering decision impacting part performance, manufacturability, cost, and longevity in precision CNC milling. At Wuxi Lead Precision Machinery, we guide clients through this process based on rigorous application analysis. Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio, superior machinability, and good thermal conductivity. These properties enable high-speed milling with excellent surface finishes and tight tolerances, though 7075 requires more careful parameter control than 6061 due to higher strength. Steel alloys, including 4140, 1018, and 304/316 stainless, are indispensable where maximum strength, wear resistance, or structural integrity under heavy loads is paramount. Machining steels demands robust tooling and controlled parameters to manage higher cutting forces and heat generation, especially with stainless grades prone to work hardening. Titanium alloys, primarily Ti-6Al-4V (Grade 5), are essential for extreme environments like aerospace components and medical implants, offering unmatched strength-to-weight ratios and corrosion resistance at high temperatures. However, titanium’s low thermal conductivity and chemical reactivity necessitate specialized CNC strategies: lower cutting speeds, rigid setups, and dedicated toolpaths to prevent heat buildup and galling, significantly influencing production timelines and cost.

Material properties directly dictate milling parameters and achievable precision. Below are key comparative specifications:

| Material Group | Common Grades | Typical Hardness (HB) | Thermal Conductivity (W/m·K) | Key Milling Consideration | Primary Application Drivers |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 95-150 | 150-205 | High speed feasible; low cutting forces; excellent chip evacuation | Weight reduction; electrical/thermal conductivity; cost efficiency |

| Steel | 1018, 4140, 304 SS | 120-280 | 15-50 | Moderate to high cutting forces; requires stable setup; stainless prone to work hardening | High strength; wear resistance; structural integrity; magnetic properties |

| Titanium | Ti-6Al-4V (Gr5) | 330-360 | 6-7 | Very low cutting speeds; high heat generation; requires sharp tools & rigid machine; strict coolant control | Extreme strength-to-weight; corrosion resistance; biocompatibility; high-temp stability |

Surface finish selection, particularly anodizing for aluminum, is integral to the material strategy. Anodizing (Type II Sulfuric or Type III Hardcoat) significantly enhances corrosion and wear resistance while providing electrical insulation and aesthetic options. Type III hardcoat anodizing delivers a much thicker, harder surface layer suitable for high-wear applications but requires precise dimensional allowances (typically +0.002″ to +0.005″ per side) due to the oxide layer growing inward and outward from the base metal. We emphasize early collaboration during design to integrate anodizing requirements into the CNC milling process, ensuring critical tolerances and surface finishes are maintained post-treatment. Material choice and finish specification are not isolated decisions; they form a cohesive system where machining parameters, tooling strategy, and post-processing must align for optimal part performance and cost-effectiveness. Consult our engineering team to determine the precise material-grade-finish combination maximizing your component’s value and manufacturability.

Manufacturing Process & QC

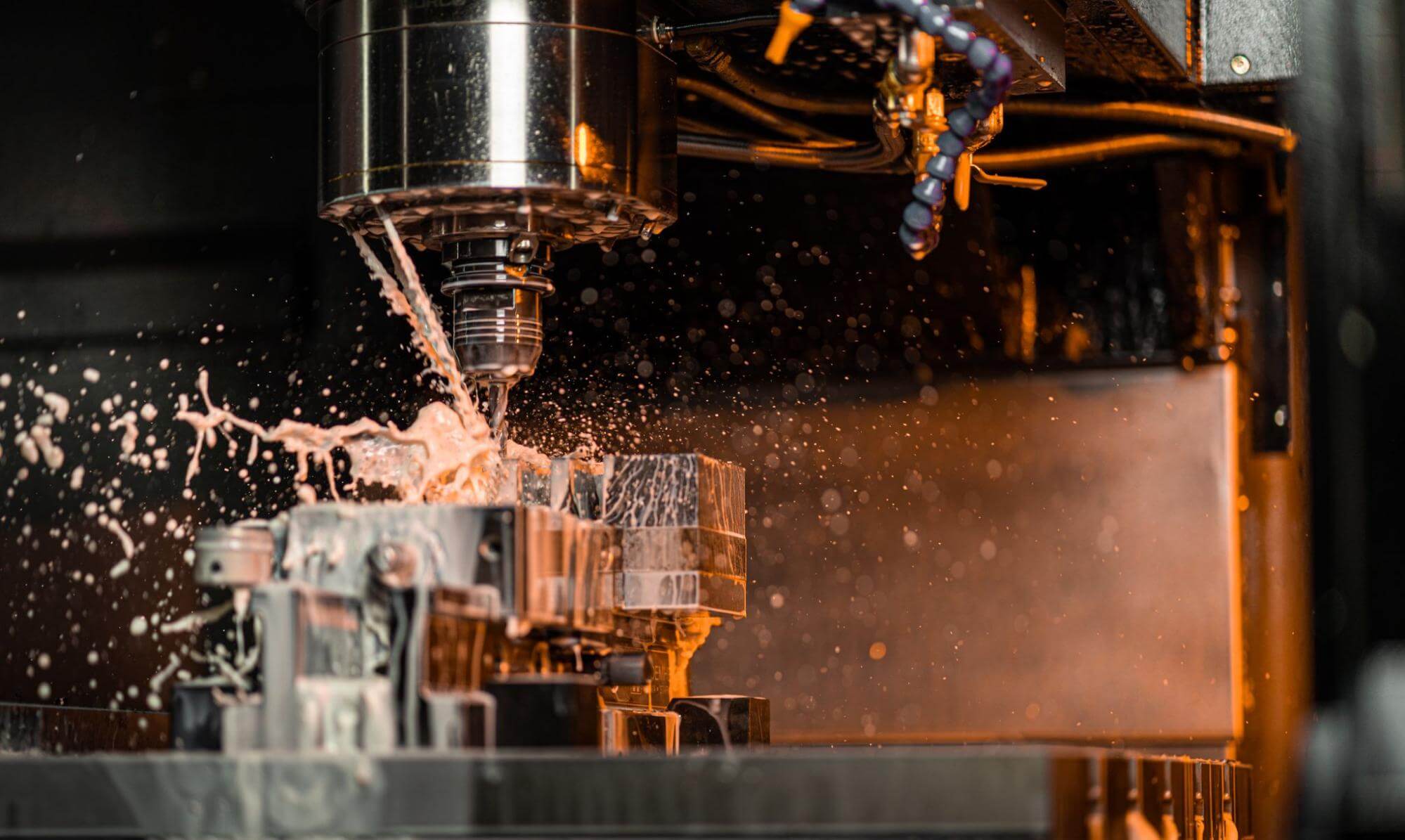

At Wuxi Lead Precision Machinery, our metal milling services are engineered for uncompromising precision, consistency, and performance. We specialize in high-end CNC machining for industries where failure is not an option—such as aerospace, medical, and advanced automation. Our production process is structured into three critical phases: Design, Prototyping, and Mass Production. Each stage is governed by strict quality protocols to ensure zero defects and full compliance with international standards.

The process begins with Design, where our engineering team collaborates closely with clients to interpret technical drawings, 3D models, and functional requirements. Using advanced CAD/CAM software, we optimize part geometry for manufacturability, material efficiency, and structural integrity. This phase includes comprehensive tolerance analysis, surface finish planning, and material selection based on application demands. Our engineers also conduct Design for Manufacturing (DFM) reviews to preemptively resolve potential production challenges.

Once the design is finalized, we move to Prototyping. This stage is critical for validating form, fit, and function. We produce a limited batch of parts using the same CNC milling machines and processes intended for full-scale production. This ensures that the prototype accurately reflects the final product. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from this stage is used to fine-tune tool paths, fixturing, and inspection routines. Client approval is required before advancing to mass production.

Mass Production is executed on our precision CNC milling centers, which include 3-axis, 4-axis, and 5-axis machines equipped with automatic tool changers and high-precision spindles. All equipment is maintained to ISO 5270 standards and monitored in real time for thermal stability and tool wear. Our production floor operates under a documented Quality Management System (QMS) compliant with ISO 9001:2015. Every part is traceable through batch numbers, machine logs, and inspection records. In-process inspections occur at predefined intervals, and final inspection includes full dimensional reporting and material certification.

To ensure zero defects, we implement Statistical Process Control (SPC) and First Article Inspection (FAI) protocols. Any deviation triggers immediate corrective action, including machine recalibration or process review. Our defect rate across all milling operations is consistently below 50 PPM (parts per million).

The table below outlines key capabilities of our metal milling services:

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish | As fine as Ra 0.4 µm |

| Materials | Aluminum alloys, stainless steel, titanium, brass, tool steels, and engineered plastics |

| Tolerances | Down to ±0.01 mm (tight-tolerance applications) |

| Quality Standards | ISO 9001:2015, ISO 5270, SPC, FAI, CMM inspection |

From concept to final delivery, Wuxi Lead Precision Machinery ensures that every milled component meets the highest benchmarks in precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Milling Excellence

For over 15 years, Wuxi Lead Precision Machinery has engineered mission-critical metal components for aerospace, medical, and industrial leaders who demand zero-defect performance. Our CNC milling services transcend basic contract manufacturing by integrating German-engineered machinery, MIL-STD quality protocols, and a 24/7 engineering support team—ensuring your parts arrive on spec, on time, and ready for integration. In an era of volatile supply chains and rising quality failures, partnering with Lead Precision eliminates production bottlenecks while guaranteeing dimensional stability down to ±0.0002″ (5µm). We do not merely machine metal; we solve your most complex precision challenges through proactive collaboration from prototype to serial production.

Our technical capabilities are validated by rigorous in-process metrology and material traceability systems meeting AS9100 and ISO 13485 standards. Every component undergoes multi-axis verification on Zeiss CMMs, with real-time SPC data accessible via your dedicated client portal. Below are core specifications defining our milling precision:

| Capability | Specification Range | Key Technology |

|---|---|---|

| Tolerance Control | ±0.0002″ (5µm) standard | Renishaw probing + thermal compensation |

| Max Work Envelope | 2000 x 1000 x 800 mm | 5-axis DMG MORI machines |

| Material Expertise | Aluminum 7075-T6 to Inconel 718, Titanium Gr5 | High-pressure coolant systems |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Sub-micron toolpath optimization |

| Lead Time | 10–15 days for complex prototypes | Digital twin simulation pre-machining |

Unlike commodity suppliers, we assign a dedicated CNC engineering lead to your account—someone who speaks your technical language and anticipates challenges before they impact your timeline. When your project requires exotic alloys, tight-tolerance cavities, or hermetic sealing surfaces, our team leverages 30+ years of collective expertise in high-mix, low-volume production to de-risk your supply chain. This is precision engineering as a strategic partnership, not a transaction.

Your next project demands a partner who treats your specifications as non-negotiable. Contact us today to schedule a technical consultation and receive a capacity assessment within 4 business hours. Forward your CAD files and requirements to [email protected]—our engineers will respond with a detailed process plan, including machine allocation timelines and first-article inspection protocols. Do not compromise on quality when your reputation hinges on flawless execution. Choose Wuxi Lead Precision Machinery: where micron-level accuracy meets industrial-scale reliability.

Precision without compromise starts with a single email. Reach out now.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.