Technical Contents

Engineering Guide: Metal Milling Bits

Engineering Insight: The Critical Role of Precision in Metal Milling Bits

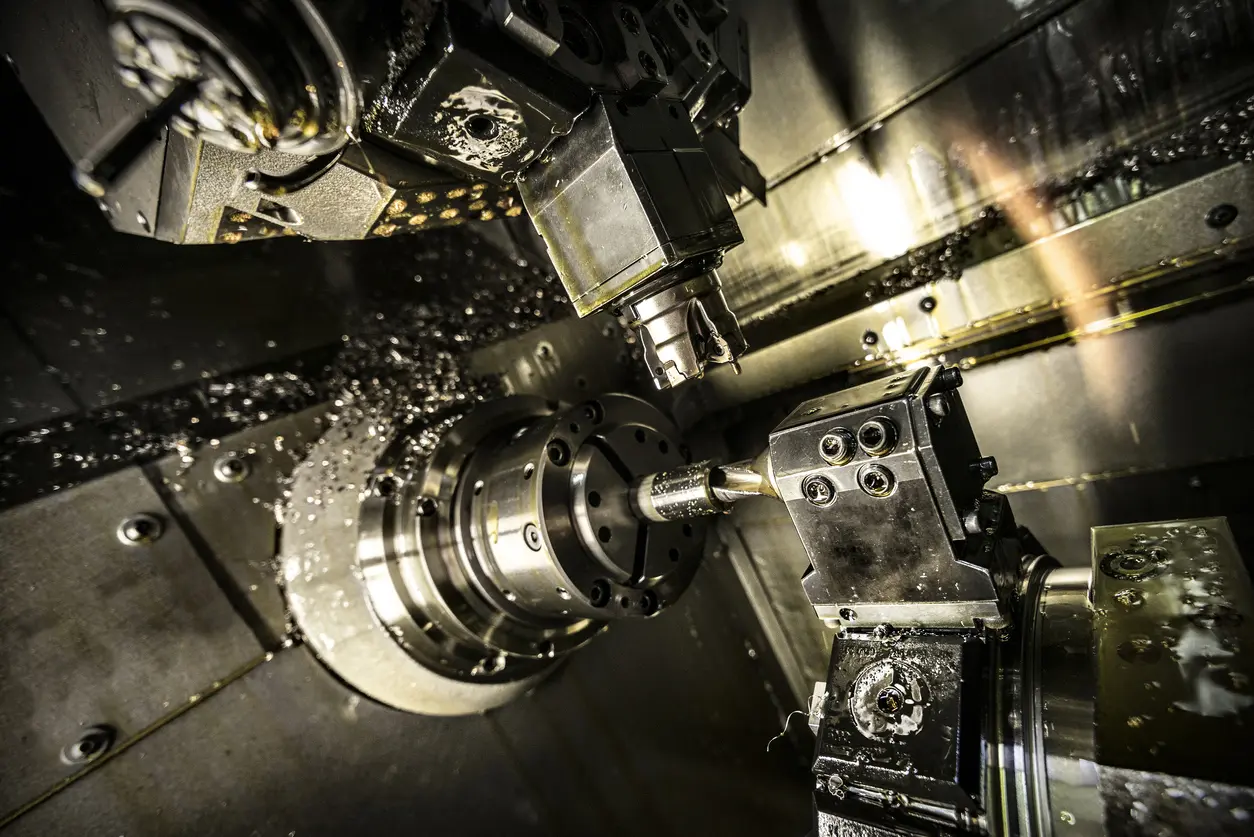

In the realm of high-performance CNC machining, metal milling bits are far more than cutting tools—they are precision instruments that define the integrity, accuracy, and surface quality of machined components. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in tool geometry or material consistency can result in compromised tolerances, increased tool wear, or catastrophic part failure—especially in mission-critical industries such as aerospace, defense, and high-end automotive manufacturing.

Precision in metal milling bits begins with material selection. High-grade tungsten carbide substrates, often reinforced with nano-coatings such as TiAlN or AlCrN, deliver superior hardness, thermal resistance, and wear performance. These properties are essential when machining hardened steels, titanium alloys, or exotic composites where heat generation and mechanical stress are significant. However, material excellence alone is insufficient without micron-level control in flute geometry, helix angle, and edge preparation.

Our engineering team at Lead Precision employs advanced CNC grinding technologies and laser-assisted inspection systems to ensure each milling bit meets stringent geometric tolerances. We maintain ±2µm accuracy on critical dimensions, including diameter, corner radius, and runout. This level of repeatability is not merely a technical benchmark—it is a necessity for achieving consistent chip formation, minimizing vibration, and extending tool life. In applications such as 5-axis contouring or deep cavity milling, such precision directly translates into reduced cycle times and higher first-pass yield rates.

Our experience in supplying precision tooling for Olympic-standard equipment and military-grade components underscores our commitment to reliability under extreme conditions. Whether producing turbine blades for jet engines or structural components for armored vehicles, the milling bits we engineer are designed to perform under sustained high-load operations without dimensional drift.

Below are key specifications that define our high-precision metal milling bits:

| Parameter | Specification |

|---|---|

| Material Substrate | Ultra-fine grain tungsten carbide |

| Coating Options | TiAlN, AlCrN, DLC, Multi-layer PVD |

| Diameter Tolerance | h6 (±2µm) |

| Runout Accuracy | < 3µm at 3xD |

| Helix Angles | 30°, 35°, 45° (customizable) |

| Flute Count | 2 to 6 (application-specific) |

| Corner Radius Tolerance | ±5µm |

| Surface Roughness (Ra) | ≤ 0.2 µm (after coating) |

| Shank Tolerance | g6 |

| Application Range | Steel, Stainless, Titanium, Inconel, Aluminum |

Every milling bit produced at Wuxi Lead undergoes 100% post-production inspection using coordinate measuring machines (CMM) and optical profilometry. This ensures full traceability and compliance with ISO 13399 and AS9100 standards. Our integration of precision engineering with rigorous quality control reflects our mission: to deliver not just tools, but performance assurance.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Milling Bits

Wuxi Lead Precision Machinery delivers exceptional precision in the manufacture of high-performance metal milling bits, serving demanding sectors including aerospace, medical device manufacturing, and advanced energy systems. Our core strength lies in the seamless integration of advanced multi-axis machining technology with rigorous, metrology-grade quality control processes. This ensures every milling bit meets the exacting geometric and surface integrity requirements critical for optimal cutting performance, tool life, and component finish in your most challenging applications.

Central to our capability is a modern fleet of 5-axis CNC machining centers from industry leaders such as DMG MORI and Makino. These systems enable the simultaneous, coordinated movement of the cutting tool across five distinct axes. This capability is essential for producing the complex helical flutes, precise cutting edge geometries, intricate chip gullets, and specialized tip forms required in premium solid carbide and indexable milling bits. The elimination of multiple setups inherent in 5-axis machining significantly reduces cumulative error, ensures superior feature-to-feature positional accuracy, and achieves consistent surface finishes unattainable with lower-axis machines. We expertly machine a wide range of substrates, including micro-grain tungsten carbide, high-speed steel (HSS), and advanced ceramic composites, utilizing optimized toolpaths and cutting parameters specific to each material’s properties.

Quality assurance is not a final step but an integrated discipline embedded throughout our production workflow. Every critical dimension and geometric feature of our milling bits undergoes verification using state-of-the-art Coordinate Measuring Machines (CMMs), primarily from Zeiss and Hexagon. These systems, operating within a certified Class 10,000 cleanroom environment, provide micron-level measurement accuracy traceable to national standards. Our inspection protocols cover comprehensive profile analysis, flute geometry verification, concentricity, runout, cutting edge preparation, and overall dimensional conformance. Full inspection reports, including detailed CMM data, are standard for all production batches, providing absolute traceability and confidence in the dimensional integrity of every bit shipped. This commitment to metrology excellence ensures consistent adherence to even the most stringent aerospace (AS9100) and medical (ISO 13485) specifications.

The following table details our standard and high-precision tolerance capabilities for critical milling bit features, reflecting the performance achievable through our integrated 5-axis machining and CMM inspection processes:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ± 0.005 | ± 0.001 |

| Diameter Tolerance (mm) | H6 (e.g., +0.006/0) | H5 (e.g., +0.004/0) |

| Flute Profile Accuracy | ± 0.008 | ± 0.002 |

| Angular Features (°) | ± 0.05 | ± 0.001 |

| Concentricity (mm) | 0.008 | 0.002 |

| Surface Roughness Ra (µm) | 0.4 | 0.1 |

Wuxi Lead Precision Machinery’s technical capabilities provide the foundation for reliable, high-performance milling bits. Our investment in 5-axis technology and uncompromising CMM-based quality control directly translates to tools that deliver superior cutting efficiency, extended tool life, and exceptional part quality in your production environment. Contact our engineering team to discuss how our precision manufacturing solutions can optimize your specific metal milling processes.

Material & Finish Options

Material Selection for Precision Metal Milling Applications

Selecting the appropriate material for metal milling operations is critical to achieving optimal performance, tool life, and part functionality. At Wuxi Lead Precision Machinery, we specialize in high-precision CNC machining services tailored to demanding industrial applications. Our expertise in machining aluminum, steel, and titanium ensures clients receive components with tight tolerances, superior surface finishes, and long-term reliability. Each material presents unique characteristics that influence machinability, strength, weight, and corrosion resistance—factors that must be evaluated based on the end-use environment and functional requirements.

Aluminum is a preferred choice in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio and thermal conductivity. It mills quickly with minimal tool wear, allowing for high-speed machining and complex geometries. However, aluminum’s softness can lead to built-up edge formation if cutting parameters are not optimized. The 6061 and 7075 alloys are commonly used for structural and load-bearing components, with 7075 offering higher strength at the cost of reduced corrosion resistance.

Steel, particularly in grades such as 4140 and 1018, provides high tensile strength and durability, making it suitable for heavy-duty mechanical and industrial applications. While more challenging to mill than aluminum, modern carbide tooling and controlled feed rates enable precise results. Steel’s wear resistance and ability to withstand high stress make it ideal for tooling, shafts, and machinery parts. Post-machining heat treatments are often applied to enhance hardness and structural integrity.

Titanium, notably Grade 5 (Ti-6Al-4V), is widely used in aerospace and medical sectors where strength, corrosion resistance, and biocompatibility are paramount. Despite its low density, titanium offers strength comparable to many steels. However, its low thermal conductivity leads to heat concentration at the cutting edge, accelerating tool wear. Successful titanium milling requires rigid setups, sharp tools, and conservative cutting speeds with adequate cooling. Proper chip evacuation is also essential to prevent re-cutting and work hardening.

For aluminum components, anodizing is a recommended surface finish to improve wear and corrosion resistance. Anodizing creates a durable oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) anodizing is standard for general protection, while Type III (hardcoat) anodizing delivers enhanced surface hardness for high-wear environments.

The following table outlines key material properties and machining considerations:

| Material | Typical Alloy | Tensile Strength (MPa) | Machinability Rating | Recommended Tooling | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | Excellent | Carbide, high rake angle | Aerospace, electronics |

| Steel | 4140 | 655 | Moderate | Coated carbide, HSS | Machinery, tooling |

| Titanium | Ti-6Al-4V | 900 | Poor | Sharp carbide, low feed | Medical, aerospace |

Understanding material behavior during milling ensures efficient production and superior end-product performance. At Wuxi Lead Precision Machinery, we combine advanced CNC technology with deep metallurgical knowledge to deliver precision-machined components that meet the highest industry standards.

Manufacturing Process & QC

Precision Metal Milling Bit Production: From Concept to Zero Defects Fulfillment

At Wuxi Lead Precision Machinery, our production process for high-performance metal milling bits is engineered for uncompromising quality and repeatability, ensuring zero defects reach the customer. This rigorous methodology spans three critical, interdependent phases, each governed by stringent protocols and advanced metrology. We understand that a single tool failure in your high-value machining operation translates directly to costly downtime and scrap; our process eliminates this risk at the source.

The journey begins with Advanced Design & Material Selection. Our engineering team utilizes integrated CAD/CAM/CAE platforms to model tool geometry optimized for specific materials and applications, such as hardened steels or aerospace alloys. Finite Element Analysis (FEA) simulates cutting forces, thermal loads, and stress distribution to refine flute geometry, helix angles, and core strength before any material is cut. Critical material properties—grade carbide substrate composition, nano-coating thickness (TiAlN, AlTiN), and bond integrity—are meticulously specified against ISO 513 standards. Every design parameter undergoes cross-functional review against application data and failure mode analysis, establishing the foundation for inherent reliability.

Rigorous Prototyping & Validation follows design freeze. Prototypes are manufactured on our dedicated high-precision 5-axis grinding cells under controlled environmental conditions. Each prototype batch undergoes exhaustive metrological verification using Zeiss CONTURA CMMs and optical comparators, measuring critical dimensions far beyond standard tolerances. Performance validation occurs on in-house machining centers simulating real-world conditions—testing chip evacuation, edge stability, surface finish, and tool life against benchmark parameters. Only after achieving consistent, documented performance exceeding customer specifications across multiple test runs is the design approved for mass production. This phase is non-negotiable; it catches potential flaws invisible in simulation.

Zero Defects Mass Production leverages the insights from prototyping within a fully controlled manufacturing cell. Production occurs on calibrated CNC tool grinders with real-time process monitoring. In-line sensors track grinding wheel wear, spindle vibration, and coolant pressure, triggering automatic tool compensation or machine hold if parameters deviate. Every single milling bit undergoes 100% automated optical inspection for geometry, coating integrity, and surface defects immediately post-grinding. Final inspection includes mandatory runout verification on precision test arbors and random batch testing for micro-hardness and coating adhesion per ISO 2859-1 AQL 0.65. Statistical Process Control (SPC) charts are maintained for all critical characteristics, enabling proactive process adjustment. Full traceability, from raw carbide lot to final inspection data, is embedded in our ERP system.

This integrated approach ensures every Wuxi Lead milling bit delivers the dimensional accuracy, edge consistency, and longevity demanded by precision manufacturing. Zero defects is not an aspiration; it is the measurable outcome of our disciplined process.

Critical Production Specifications for Wuxi Lead Precision Milling Bits

| Parameter | Standard Tolerance | Verification Method | Compliance Standard |

|---|---|---|---|

| Diameter Tolerance | ±0.002 mm | Laser Micrometer | ISO 13399 |

| Total Runout (TIR) | ≤ 0.003 mm | Precision Test Arbor | DIN 6535 HA |

| Flute Profile Accuracy | ±0.005 mm | Optical Comparator | ISO 16610 |

| Coating Thickness | ±0.5 µm | XRF Spectrometry | ISO 26443 |

| Surface Roughness (Ra) | ≤ 0.2 µm | Stylus Profilometer | ISO 4287 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Metal Milling Solutions

At Wuxi Lead Precision Machinery, we understand that precision, durability, and performance are non-negotiable in high-end CNC machining. As a trusted leader in the design and manufacture of advanced metal milling bits, we specialize in delivering cutting tools engineered to meet the rigorous demands of aerospace, automotive, medical device manufacturing, and industrial equipment production. Our commitment to innovation and quality ensures that every milling bit we produce enhances your machining efficiency, extends tool life, and reduces downtime.

Choosing the right partner in precision machining goes beyond product supply—it’s about collaboration, technical support, and shared success. At Lead Precision, we don’t just sell tools; we deliver tailored solutions. Our engineering team works closely with your operations to analyze material compatibility, optimize cutting parameters, and recommend the ideal milling bit configuration for your specific application. Whether you’re machining hardened steel, titanium alloys, or high-strength aluminum, our expertise ensures peak performance and consistent repeatability.

Our state-of-the-art manufacturing facility in Wuxi, China, integrates advanced CNC grinding technology with stringent quality control protocols. Each metal milling bit undergoes comprehensive inspection for dimensional accuracy, surface finish, and coating integrity. We utilize premium-grade carbide substrates and apply proprietary nano-coating technologies to maximize wear resistance and thermal stability. The result is a product line that delivers superior edge retention, reduced chipping, and extended service life under the most demanding conditions.

To support global clients, we offer rapid prototyping, custom geometry development, and scalable production runs—all backed by responsive technical service and on-time delivery. Our quality management system is ISO 9001 certified, ensuring every product meets international standards for reliability and performance.

Below are key specifications of our standard high-performance metal milling bit series:

| Specification | Value / Description |

|---|---|

| Tool Diameter Range | 3 mm – 25 mm |

| Shank Type | Straight, Weldon, or Custom Taper |

| Flute Count | 2, 3, 4, or 6 flutes (application-specific) |

| Cutting Material | Ultra-Fine Grain Carbide (ISO K10-K20) |

| Coating Options | TiAlN, AlCrN, DLC, or Custom Multi-Layer |

| Helix Angle | 30°, 35°, 40° (optimized for material type) |

| Recommended RPM Range | 6,000 – 25,000 (depending on diameter) |

| Compatible Materials | Steel, Stainless Steel, Titanium, Aluminum, Inconel |

| Tolerance | h6 (±0.009 mm) |

| Application | Slotting, Profiling, Contouring, High-Speed Machining |

Partnering with Wuxi Lead Precision Machinery means gaining access to a team dedicated to your operational success. We invite you to contact us today to discuss your milling challenges and discover how our precision-engineered metal milling bits can elevate your production capabilities. For technical inquiries, custom tool requests, or pricing information, reach out to our global support team at [email protected]. Let Lead Precision be your trusted partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.