Technical Contents

Engineering Guide: Metal Machinery Service

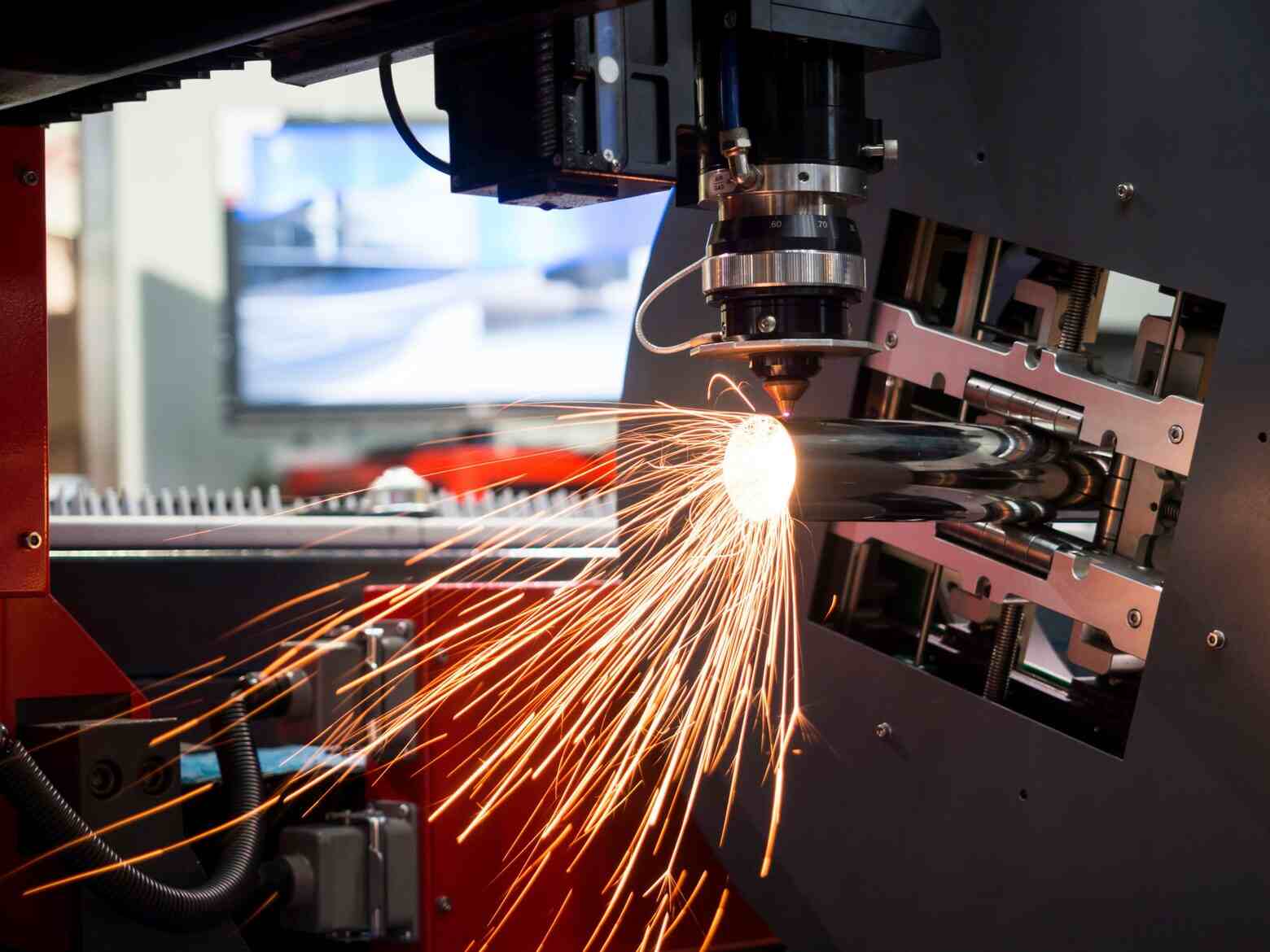

Engineering Insight: The Critical Role of Precision in Metal Machinery Services

In the realm of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. For industries ranging from aerospace and defense to high-performance sports infrastructure, the margin for error is not measured in millimeters but in microns. At Wuxi Lead Precision Machinery, we understand that the integrity of a final product is directly tied to the accuracy and consistency of every machining operation performed during its creation.

Our engineering philosophy centers on achieving micron-level tolerances through advanced CNC technologies, rigorous quality control, and decades of accumulated expertise. This commitment to precision enables us to deliver components and assemblies that meet the most demanding specifications, particularly for clients operating in mission-critical environments. Our proven track record includes supplying precision-engineered parts for Olympic-grade sports facilities and contributing to defense-related infrastructure projects, where failure is not an option.

These high-profile applications demand more than just advanced machinery—they require a deep understanding of material behavior, thermal stability, and structural dynamics under real-world conditions. For example, components used in Olympic timing systems or military-grade deployment mechanisms must function flawlessly under extreme stress, temperature fluctuations, and long operational cycles. Achieving this level of performance begins with precise machining and extends through every stage of design validation, material selection, and post-processing.

At Lead Precision, our engineers leverage state-of-the-art 5-axis CNC machining centers, coordinate measuring machines (CMM), and real-time in-process inspection systems to maintain dimensional accuracy across high-volume and prototype production runs. We specialize in working with challenging materials such as titanium alloys, high-strength stainless steels, and aerospace-grade aluminum, ensuring that each component meets or exceeds international standards including ISO 2768-mK and AS9100.

The following table outlines key precision capabilities that define our metal machinery services:

| Specification | Performance Level |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.4 μm (standard), down to Ra 0.1 μm (polished) |

| Maximum Work Envelope | 2,500 mm × 1,200 mm × 800 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Materials Supported | Aluminum 7075-T6, Titanium Grade 5, Stainless Steel 316L, Inconel 718, Tool Steels |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (compliant processes) |

Precision in metal machining is not a singular achievement but a continuous discipline. It reflects a company’s engineering rigor, investment in technology, and dedication to client success. For Wuxi Lead Precision Machinery, every project—whether supporting national defense initiatives or enabling world-class athletic competition—is approached with the same uncompromising standard: absolute precision, without exception.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

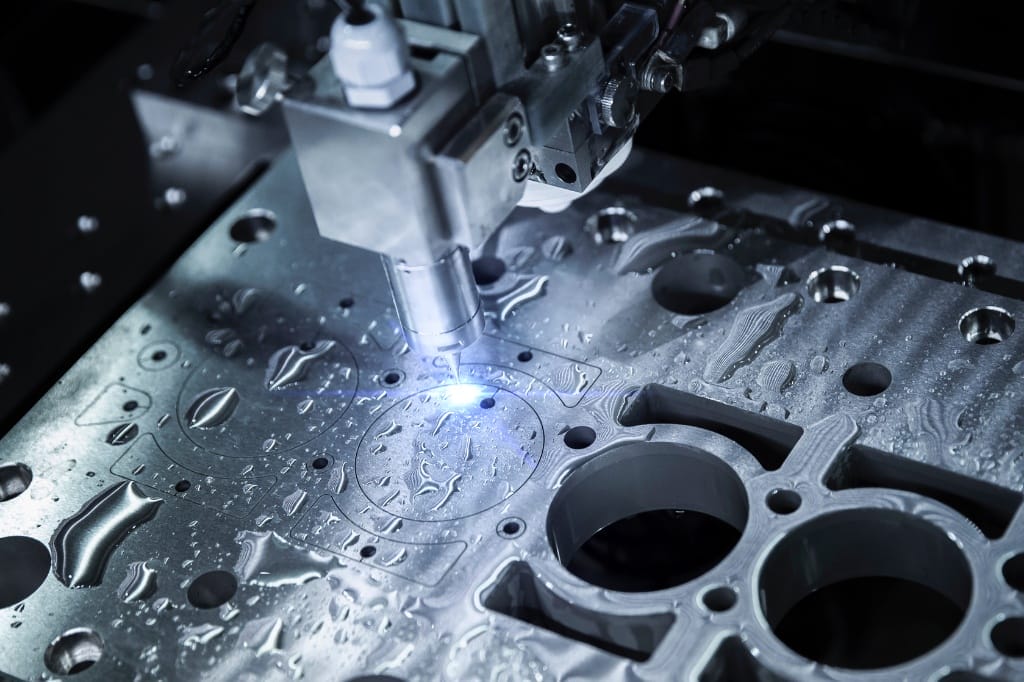

At Wuxi Lead Precision Machinery, our technical foundation centers on advanced multi-axis CNC machining and rigorous quality validation. We specialize in transforming complex metal components from prototype to high-volume production, ensuring dimensional integrity and functional performance for aerospace, medical, and energy sector applications. Our facility integrates cutting-edge 5-axis CNC technology with metrology-grade inspection systems, enabling us to consistently meet the most stringent engineering specifications.

Our 5-axis CNC machining centers feature simultaneous 5-axis movement, eliminating manual repositioning and minimizing cumulative error. Equipped with high-torque spindles (15,000 RPM standard, 24,000 RPM optional) and thermal compensation systems, these machines handle intricate geometries in materials ranging from aluminum alloys and titanium to Inconel and hardened tool steels. Work envelopes accommodate parts up to Ø800 mm x 1,200 mm, with sub-micron linear scale feedback ensuring positional accuracy. This capability allows us to machine organic contours, deep cavities, and compound angles in a single setup—reducing lead times by 30–50% compared to 3-axis alternatives while enhancing part consistency.

Quality control is non-negotiable. Every critical dimension undergoes validation via Zeiss CONTURA G3 CMM systems, calibrated to ISO 17025 standards. Our inspection protocol includes first-article reporting (FAI), in-process checks, and full-surface scanning for GD&T compliance. Statistical process control (SPC) data is documented per AS9102 requirements, providing traceability from raw material to final shipment. This closed-loop methodology ensures tolerances are not merely claimed but empirically verified.

The table below details our standard and tight-tolerance capabilities across common material categories. All values assume standard machining conditions; tighter tolerances are achievable with engineered process adjustments and extended cycle times.

| Material Category | Feature Type | Standard Tolerance (mm) | Tight Tolerance (mm) |

|---|---|---|---|

| Aluminum Alloys | Linear Dimensions | ±0.025 | ±0.005 |

| Hole Diameter | ±0.015 | ±0.003 | |

| Surface Profile | ±0.05 | ±0.01 | |

| Steel & Stainless | Linear Dimensions | ±0.03 | ±0.008 |

| Hole Diameter | ±0.02 | ±0.005 | |

| Surface Profile | ±0.08 | ±0.015 | |

| Titanium/Exotics | Linear Dimensions | ±0.035 | ±0.01 |

| Hole Diameter | ±0.025 | ±0.008 | |

| Surface Profile | ±0.1 | ±0.02 |

Note: Tight tolerances require pre-approval and may impact cost/schedule. Environmental controls (20±1°C) maintain stability during critical operations.

Beyond equipment specs, our value lies in process intelligence. Our engineers collaborate early in the design phase to optimize manufacturability—suggesting geometric refinements that preserve function while reducing cycle time. This proactive approach, combined with real-time machine monitoring and CMM-validated outputs, delivers components that assemble flawlessly and perform reliably in mission-critical environments. For industries where failure is not an option, Wuxi Lead provides precision you can measure and trust.

Material & Finish Options

Material Selection for High-Precision Metal Components

Selecting the appropriate material is a critical step in custom metal manufacturing, directly influencing component performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered solutions tailored to the mechanical, thermal, and environmental demands of your application. Our expertise spans aluminum, steel, and titanium—three of the most widely used metals in high-end industrial sectors including aerospace, medical devices, and automation.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications requiring lightweight components without sacrificing structural integrity. Grade 6061-T6 is commonly used for general-purpose parts, while 7075-T6 offers higher strength for more demanding environments. Aluminum’s natural oxide layer provides inherent corrosion protection, but for enhanced surface performance, anodizing is recommended.

Steel remains the backbone of industrial machinery due to its high tensile strength, wear resistance, and versatility. We work with a range of steel alloys, including 4140, 1018, and stainless steels such as 304 and 316. Stainless variants are particularly suitable for environments requiring resistance to moisture, chemicals, and high temperatures. While heavier than aluminum, steel delivers unmatched durability in load-bearing and high-stress applications.

Titanium, particularly Grade 5 (Ti-6Al-4V), offers an exceptional balance of strength, corrosion resistance, and biocompatibility. It is widely used in aerospace and medical implant manufacturing. Though more challenging to machine and higher in cost, titanium’s performance in extreme conditions justifies its use in mission-critical components. Its low density and high melting point make it ideal for high-temperature and weight-sensitive applications.

Surface finishing plays a pivotal role in enhancing both functionality and aesthetics. Anodizing is a key process for aluminum components, creating a durable, non-conductive oxide layer that improves wear and corrosion resistance. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) provides thicker, harder coatings for industrial use. Anodized layers can also be dyed in various colors for identification or branding purposes.

Below is a comparative overview of key material properties to guide selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | High | 6061, 7075 | Enclosures, heat sinks, frames |

| Steel | 7.8 | 600–900 (varies) | Moderate to High | 1018, 4140, 304, 316 | Shafts, brackets, structural parts |

| Titanium | 4.5 | 900–1000 (Ti-6Al-4V) | Excellent | Gr2, Gr5 | Aerospace, medical implants |

At Wuxi Lead Precision Machinery, we support material selection with in-house engineering consultation, ensuring optimal performance and manufacturability. Our advanced CNC capabilities and strict quality controls guarantee components meet exacting industry standards.

Manufacturing Process & QC

Precision Metal Manufacturing: The Zero Defects Production Process at Wuxi Lead

At Wuxi Lead Precision Machinery, our commitment to Zero Defects begins long before metal meets tool. We execute a rigorously controlled production process spanning Design, Prototyping, and Mass Production, ensuring every component meets exacting aerospace, medical, and industrial specifications. This integrated approach eliminates costly errors and guarantees consistent, flawless output for our global clientele.

The foundation is our collaborative Design for Manufacturability (DFM) phase. Our engineering team works directly with client CAD models, conducting comprehensive feasibility analysis using Siemens NX and Mastercam software. We scrutinize geometric dimensioning and tolerancing (GD&T), material selection, and toolpath optimization to preempt potential production flaws. This proactive engineering review identifies and resolves conflicts in assembly, thermal distortion, or surface finish requirements before physical work commences, establishing the blueprint for defect prevention.

Prototyping transforms validated designs into tangible proof. Utilizing our state-of-the-art 5-axis CNC machining centers and multi-spindle turning centers, we produce functional prototypes under full production conditions. This stage is not merely a sample check; it is a critical validation loop. Every prototype undergoes exhaustive metrology, verifying conformance to the most stringent tolerances. Our inspection capabilities are detailed below.

| Inspection Parameter | Capability | Equipment Used | Accuracy Level |

|---|---|---|---|

| Dimensional Verification | Full 3D Geometry | Zeiss CONTURA CMM | ±0.0001″ (2.5µm) |

| Surface Finish | Ra, Rz, Rq Analysis | Mitutoyo Surftest SJ-410 | Ra 0.025µm |

| Material Verification | Composition & Hardness | SpectroMAXx OES, Wilson Hardness | ASTM E407/E384 |

| Geometric Tolerances | Position, Profile, Runout | Custom Gauges, Vision Systems | Per ASME Y14.5 |

Only upon achieving 100% conformance across all inspection criteria does the approved prototype greenlight Mass Production. Our high-volume manufacturing leverages automated pallet systems, robotic loading, and in-process gauging on Haas and DMG MORI platforms. Crucially, Zero Defects is maintained through real-time statistical process control (SPC). Machine sensors continuously monitor cutting forces, vibration, and tool wear, triggering automatic adjustments or tool changes before deviations occur. Every critical dimension is verified at defined intervals using calibrated CMMs and optical comparators, with data logged for full traceability per ISO 9001:2015 standards. This closed-loop system ensures the first part, the hundredth part, and the ten-thousandth part are identical, delivering uncompromised quality and eliminating scrap or rework.

Wuxi Lead’s integrated process transforms complex metal manufacturing challenges into guaranteed success. By embedding precision engineering and relentless validation at every stage, we deliver true Zero Defects performance, making us the trusted precision engineering partner for discerning global industries.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture metal components—we engineer solutions that drive performance, reliability, and long-term value for global industrial leaders. As a trusted name in high-precision custom metal manufacturing, we specialize in delivering complex, mission-critical parts and assemblies that meet the exacting demands of aerospace, energy, automation, and advanced industrial equipment sectors. When you partner with us, you’re not selecting a vendor—you’re securing a precision engineering ally with deep technical expertise and a relentless commitment to quality.

Our advanced CNC machining centers, multi-axis turning systems, and robotic automation platforms are backed by rigorous quality control protocols and a team of senior engineers with over two decades of experience in solving intricate manufacturing challenges. From prototype development to high-volume production runs, we maintain tight tolerances, superior surface finishes, and full traceability across every stage of production. Our ISO 9001 and IATF 16949 certifications reflect our adherence to international standards, ensuring every component meets or exceeds your specifications.

We understand that in high-end manufacturing, performance is non-negotiable. That’s why we invest continuously in cutting-edge technology and workforce development to stay ahead of evolving industry demands. Whether you require titanium aerospace housings, stainless steel fluid system components, or hardened alloy gears for industrial drives, our facility in Wuxi, China, is equipped to deliver with precision, speed, and scalability.

Our customer-centric approach means we engage early in your design phase, offering Design for Manufacturability (DFM) analysis, material optimization guidance, and rapid prototyping to accelerate time-to-market. With in-house capabilities spanning CNC milling, turning, grinding, welding, and finishing, we minimize supply chain dependencies and ensure consistent quality under one roof.

Below are key capabilities that define our manufacturing excellence

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis to 5-axis milling, turning with Y-axis and live tooling |

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, Tool Steels, Brass, Plastics |

| Tolerances | ±0.005 mm (±0.0002″) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finish | Down to Ra 0.4 µm (16 µin) |

| Quality Standards | ISO 9001, IATF 16949, Full First Article Inspection (FAI) reporting |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

When performance, precision, and partnership matter most, choose Wuxi Lead Precision Machinery. Contact us today at [email protected] to discuss your next project with our engineering team. Let us help you turn precision into progress.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.