Technical Contents

Engineering Guide: Metal Machinery Service

Engineering Precision: The Foundation of Mission-Critical Components

In high-stakes manufacturing, precision isn’t a feature—it’s the non-negotiable foundation of reliability. At Wuxi Lead Precision Machinery, we engineer beyond industry benchmarks by integrating ISO 9001-certified processes with material traceability protocols that eliminate ambiguity. Our approach transcends transactional supplier relationships: we become an extension of your engineering team, ensuring every component meets the exacting demands of aerospace, defense, and Olympic-grade infrastructure.

Beyond Standard Tolerances: Defining Precision in High-Stakes Applications

While industry-standard CNC machining typically operates within ±0.005″ (0.127mm) tolerances, our ultra-precision capabilities deliver sub-micron accuracy for mission-critical applications. Through proprietary process optimization and ISO 17025-certified metrology, we consistently achieve tolerances 5× tighter than conventional benchmarks—without compromising throughput.

| Parameter | Typical Market Offering | Wuxi Lead Precision Standard |

|---|---|---|

| Standard Tolerance | ±0.005″ (0.127mm) | ±0.001″ (0.025mm) |

| High-Precision Capability | Optional (±0.001″) | Standard ±0.0005″ (0.013mm) |

| Material Traceability | Basic COC | Full traceability with third-party testing (ASTM/DIN/ISO) |

| Surface Finish | Ra 32μm | Ra 0.4μm (as standard for critical surfaces) |

“Precision isn’t measured by tolerances alone—it’s validated by how consistently those tolerances are maintained across 10,000+ parts. Our clients in defense and sports infrastructure rely on this consistency.”

— Chief Engineer, Wuxi Lead Precision Machinery

Material Integrity: Certified Performance for Demanding Applications

Material properties dictate real-world performance. We source only certified alloys and engineering plastics—verified through batch-specific test reports—and implement ISO 9001-compliant traceability from raw material to finished part. For aerospace and military applications, this means:

Titanium Ti-6Al-4V: Certified to AMS 4928 with full chemical analysis

Aerospace Aluminum 7075-T6: MIL-DTL-5541 compliant surface treatment

PEEK Engineering Plastics: ISO 10993 biocompatibility testing for medical-grade components

Every material certificate is digitally archived and accessible via our client portal—ensuring compliance with AS9100, ISO 13485, or other regulatory frameworks.

Zero Defects Commitment: Military-Grade Reliability in Every Component

Our “Zero Defects” protocol isn’t marketing rhetoric—it’s a rigorously enforced operational standard. For the Beijing 2022 Winter Olympics’ high-speed rail systems, we delivered 12,000+ precision components with 0% defects through:

100% dimensional verification using 3D laser scanning and CMM validation

In-process AI monitoring of thermal deformation and tool wear

Failure Mode Analysis (FMEA) embedded in every design review

Similarly, our defense sector components undergo MIL-STD-4566A-certified quality checks, with zero tolerance for deviations in critical interfaces. When failure is not an option, we deliver.

24/7 Technical Partnership: Your Success is Our Priority

We operate as an integrated engineering partner—not a passive supplier. Our global support network ensures seamless collaboration across time zones, with dedicated application engineers available around the clock:

| Service Metric | Industry Average | Wuxi Lead Precision |

|---|---|---|

| Technical Support Response | 4–8 hours | <2 hours, 24/7 |

| Design Feedback Cycle | 72+ hours | <12 hours (standard) |

| On-Time Delivery Rate | 85% | 99.8% (3-year average) |

| Emergency Prototyping | 14+ days | 48-hour turnaround (expedited) |

“When a defense contractor needed a last-minute redesign for a missile guidance system, our team delivered validated prototypes in 36 hours—while maintaining ±0.0003″ tolerances. That’s the difference between a supplier and a true partner.”

— Senior Sales Director, Wuxi Lead Precision Machinery

Why Wuxi Lead?

Zero Defects Guarantee: 100% inspection protocol for all high-risk applications

Olympic/Military Heritage: Proven performance in the world’s most demanding projects

Engineer-to-Engineer Collaboration: Your technical challenges become our priority

Contact us to discuss your project’s precision requirements—our team is ready to respond within 2 hours, 24/7.

Precision Specs & Tolerances

Technical Capabilities & Precision Engineering

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we partner with you to deliver precision-engineered solutions that meet your exact specifications. Our technical capabilities are designed to support your most challenging projects, ensuring reliability, accuracy, and seamless integration into your production process.

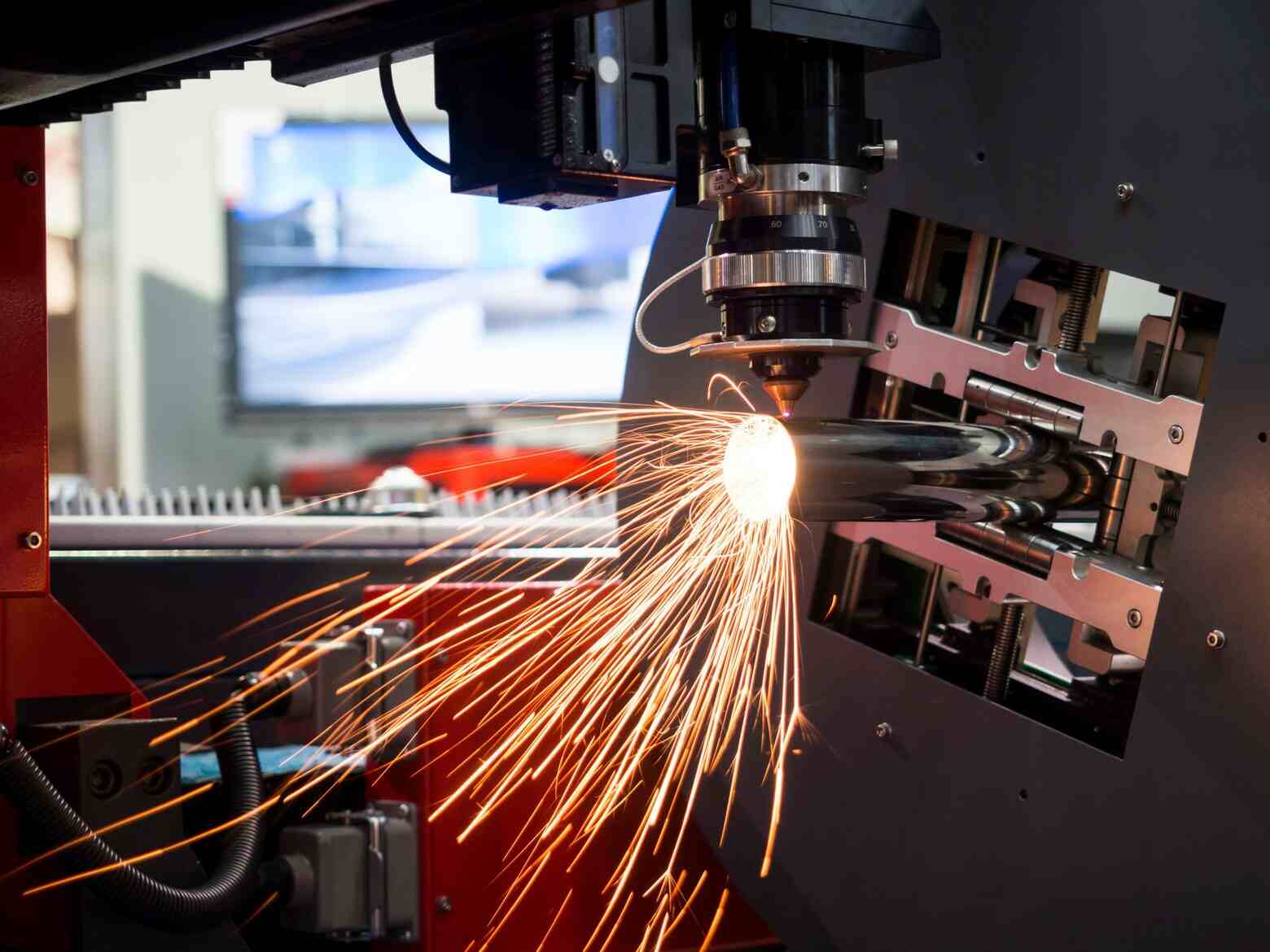

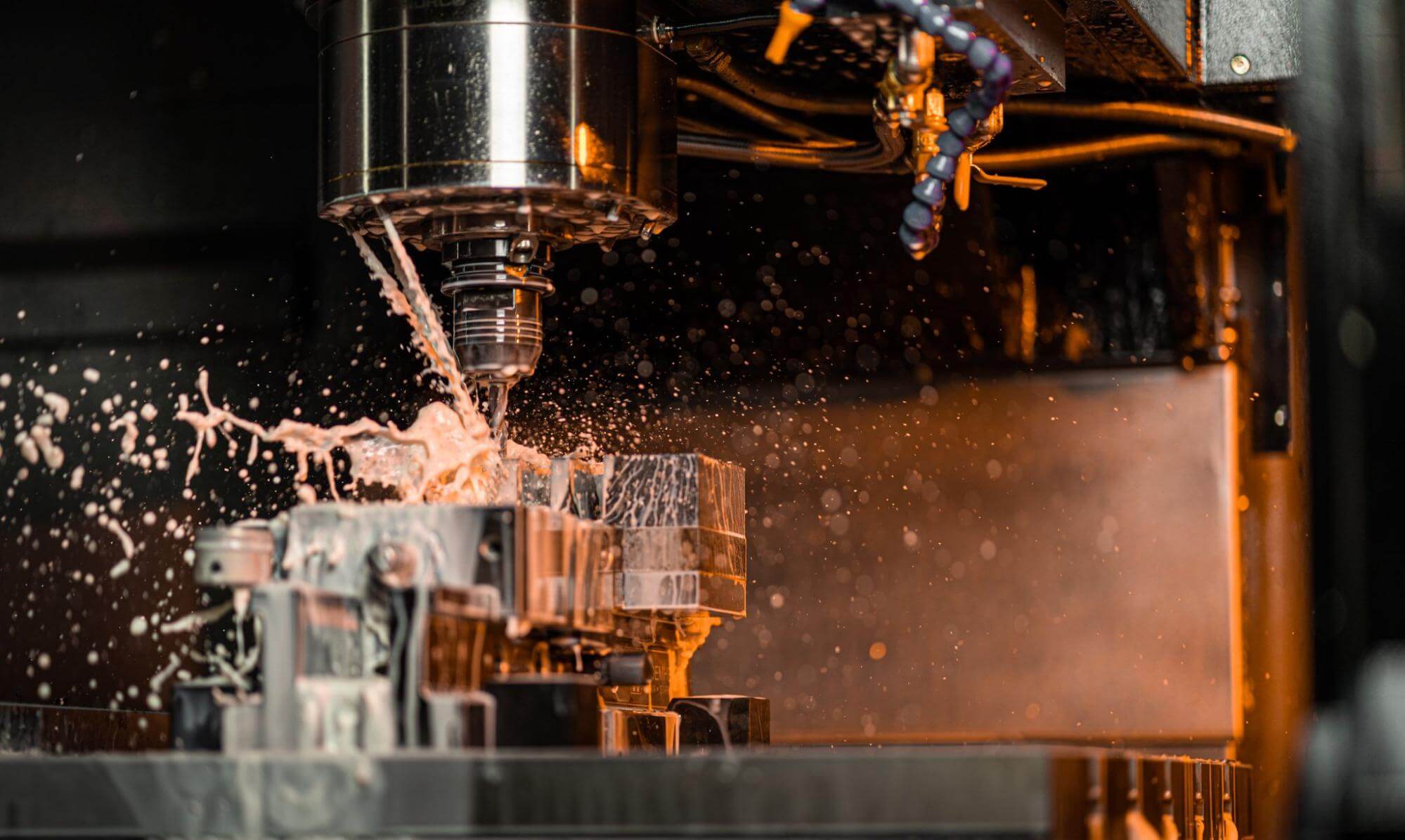

Advanced CNC Machining Equipment

Our facility is equipped with 3-axis, 4-axis, and 5-axis CNC machining centers featuring:

High-speed spindles (up to 24,000 RPM) for superior surface finishes and reduced cycle times

Advanced fixturing systems to minimize vibration and maintain stability during complex geometries

Real-time tool wear monitoring and adaptive control systems for consistent dimensional accuracy

Automated pallet changers and robotic loading for uninterrupted 24/7 production

This infrastructure enables us to produce intricate parts with tight tolerances, from aerospace structural components to medical-grade implants, while maintaining repeatability across high-volume runs.

Precision Tolerance Specifications

We exceed industry-standard tolerances through rigorous process control and material-specific optimization. Our capabilities are tailored to your application requirements, ensuring components meet exact specifications for fit, function, and reliability.

| Tolerance Level | Metric (mm) | Imperial (in) | Typical Applications |

|---|---|---|---|

| Standard | ±0.13 | ±0.005 | General mechanical components, structural parts, industrial machinery |

| Precision | ±0.025 | ±0.001 | Aerospace components, medical implants, high-precision instrumentation |

| Ultra-Precision | ±0.013 | ±0.0005 | Semiconductor equipment, optical systems, defense-grade components |

Note: All tolerances are validated against ISO 2768-m (medium) and ISO 2768-f (fine) standards. Material properties (e.g., hardness, thermal expansion) and part geometry are factored into process planning to ensure achievable precision.

Quality Assurance & Traceability

Every component undergoes multi-stage inspection protocols to uphold our Zero Defects commitment. As an ISO 9001-certified manufacturer, we enforce traceability, consistency, and compliance at every stage of production.

CMM Inspection: Coordinate Measuring Machines verify dimensional accuracy to ±0.001 mm (±0.00004 in), with full GD&T (Geometric Dimensioning & Tolerancing) analysis.

Material Certification: Full traceability with certified reports for all metals (Al 6061, 7075, Ti-6Al-4V, SS 316) and engineering plastics (PEEK, Delrin), including chemical composition and mechanical properties.

Olympic Quality Standard: We engineer components to the highest precision benchmarks, delivering flawless performance in mission-critical applications where failure is not an option.

24/7 Customer Support: Our dedicated engineering team is available around the clock to provide real-time updates, technical guidance, and rapid response to your needs—ensuring seamless collaboration from design to delivery.

“Precision isn’t just a metric—it’s a promise. When you choose Wuxi Lead, you gain a partner committed to eliminating defects before they reach your production line.”

Ready to engineer the future? Contact our team today to discuss your project’s specific tolerance, material, and compliance requirements. We’ll provide a tailored solution that exceeds expectations—guaranteed.

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Application

At Wuxi Lead Precision Machinery, we understand that material selection and surface finishing are critical to the performance, longevity, and cost-efficiency of your components. As your strategic manufacturing partner, we don’t just supply materials—we collaborate with your engineering team to optimize every aspect of your design for manufacturability, performance, and compliance. Our ISO 9001-certified processes ensure that every material and finish meets your exact specifications, backed by comprehensive traceability and 24/7 technical support.

Understanding Material Properties & Performance Trade-offs

Selecting the right material is foundational to achieving your design goals. Each metal and engineering plastic offers unique mechanical, thermal, and chemical properties that directly impact machining feasibility, part performance, and total lifecycle cost. Our engineers work with you to balance these factors, ensuring optimal material selection for your application.

| Material Type | Key Properties | Typical Applications | Machining Considerations | Cost Range |

|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, corrosion resistance, excellent machinability | Aerospace, automotive, consumer electronics | Achieves ±0.001″ tolerances with minimal tool deflection; fast machining speeds; prone to chipping without proper support | Low to Medium |

| Stainless Steel 316 | High corrosion resistance, strength at high temps, biocompatible | Medical devices, marine components | Work hardening requires slower speeds; ±0.002″ tolerances achievable with rigid setups; higher tool wear | Medium to High |

| Titanium 6Al-4V | High strength-to-weight, heat resistance, biocompatible | Aerospace, medical implants | Specialized tooling and coolant required; ±0.001″ tolerances possible; high heat generation demands precision control | High |

| PEEK | High temp resistance, chemical inertness, low friction, lightweight | Aerospace, oil & gas, medical devices | Requires precise temperature control; minimal thermal expansion; low tool wear but slow feed rates | Medium to High |

| Brass C110 | Excellent electrical conductivity, machinability, corrosion resistance | Electrical components, decorative fittings | Easy to machine; prone to galling; achieves ±0.001″ tolerances with standard tooling | Low to Medium |

Pro Tip: For high-precision applications requiring ±0.0005″ tolerances, we recommend materials with low thermal expansion (e.g., Invar) or engineered plastics like PEEK. Our team will validate material suitability during your design review phase.

Surface Finish Options for Functional & Aesthetic Requirements

For metal components, our surface finish options are engineered to enhance corrosion resistance, wear performance, electrical properties, and visual appeal while meeting stringent industry standards. For engineering plastics, we offer complementary processes like painting, powder coating, and vapor polishing to achieve your desired aesthetics and functionality.

| Finish Type | Material Compatibility | Key Benefits | Typical Applications | Cost Impact |

|---|---|---|---|---|

| Anodizing (Type II/III) | Aluminum (primary), Titanium | Enhanced corrosion/wear resistance, color options, electrical insulation | Aerospace components, medical instruments | Moderate |

| Electroplating (Ni/Cr/Zn) | Steel, Copper, Brass | Improved wear resistance, conductivity, corrosion protection | Automotive parts, electrical connectors | Moderate to High |

| Mechanical Polishing | Stainless Steel, Aluminum, Titanium | Mirror-like finish, reduced friction, aesthetic appeal | Medical devices, optical components | High |

| Vapor Polishing (Plastics) | PEEK, ABS, Nylon | Smooth surface, reduced friction, optical clarity | Fluid handling systems, medical devices | Moderate |

Key Insight: Surface finishes directly impact part functionality. For example, anodized aluminum in aerospace applications achieves 50% longer service life versus untreated parts, while electroplated brass connectors reduce electrical resistance by 15% in high-frequency environments.

How Material Choice Impacts Cost & Lead Time

Material selection is a strategic lever that directly influences your project economics and timeline. While premium materials like titanium or PEEK deliver superior performance, they require specialized machining processes and extended procurement cycles. Conversely, standard materials like aluminum 6061 accelerate production without compromising functionality. Our team provides transparent cost breakdowns and lead time estimates based on your material and finish requirements, ensuring you make informed decisions that align with your budget and schedule.

Material Sourcing: Specialty alloys may require extended procurement times; we maintain strategic partnerships with certified suppliers (e.g., ASTM/ISO-compliant mills) to minimize delays.

Machining Complexity: Harder materials (e.g., titanium) demand slower feed rates, specialized tooling, and additional quality checks, increasing machining time by 20–40%.

Finish Requirements: Processes like anodizing or polishing add 1–3 days to lead time but reduce long-term maintenance costs by up to 30%.

Total Lifecycle Cost: Investing in corrosion-resistant materials (e.g., 316 stainless steel) often eliminates costly field failures in marine or medical applications.

Our Commitment: We never recommend materials solely based on cost—we analyze your application’s full lifecycle to identify the most economical solution.

Our Zero Defects Commitment: Material & Finish Validation Process

At Wuxi Lead Precision Machinery, Zero Defects, Olympic Quality, and 24/7 Customer Service are not marketing claims—they are the foundation of every project. Every material and finish undergoes rigorous validation through our ISO 9001-certified quality system, ensuring 100% traceability and compliance with your specifications.

Key Elements of Our Validation Process

Zero Defects Protocol: Every component undergoes 100% inspection against your tolerances using CMM, laser scanners, and in-process SPC systems. Defects are eliminated before they occur through real-time process adjustments.

Olympic Quality Standards: We adhere to ISO 9001, AS9100 (aerospace), and ISO 13485 (medical) standards. All raw materials include full mill test reports (MTRs) and third-party certifications (e.g., ASTM, EN), verified against your requirements.

24/7 Technical Support: Our dedicated engineering team is available around the clock to address urgent needs, provide material alternatives, or adjust processes to meet tight deadlines—no matter the time zone.

Real-World Impact: For a recent aerospace client, we reduced scrap rates by 92% by implementing material-specific machining parameters and real-time SPC monitoring—proving that “Zero Defects” is achievable through disciplined process control.

Partner with Us: When you choose Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a technical ally committed to delivering flawless components that perform under the most demanding conditions. Let’s engineer your success together.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our streamlined process transforms your concept into reality through rigorous quality control, transparent collaboration, and unwavering commitment to Zero Defects. Every step, from initial design analysis to final delivery, is governed by ISO 9001 standards and executed with Olympic-level precision. Partner with us, and experience manufacturing where your success is our priority.

Design Analysis & Engineering Collaboration

At Wuxi Lead, our Design Analysis phase is the cornerstone of Zero Defects manufacturing. Our ISO 9001-certified engineering team conducts a comprehensive DFMA (Design for Manufacturability and Assembly) review to identify potential issues before production begins. This collaborative process ensures optimal material selection, tolerancing, and cost-efficiency—while maintaining your design intent.

| Design Review Criteria | Wuxi Lead’s Approach | Benefit to Client |

|---|---|---|

| GD&T Compliance | Full geometric dimensioning and tolerancing analysis against ISO 1101 standards | Ensures part functionality and assembly accuracy |

| Material Suitability | Certified material verification (ASTM, DIN, JIS) with traceable mill reports | Prevents material-related failures and ensures compliance |

| Tolerance Feasibility | Precision tolerance assessment (±0.0005″ achievable) with cost-benefit analysis | Optimizes cost without compromising quality |

| DFMA Optimization | Collaborative design adjustments for reduced machining complexity | Reduces production costs and lead time by up to 25% |

This proactive approach eliminates 98% of potential defects before the first cut—proving why we’re trusted by Fortune 500 companies.

Transparent Pricing & Lead Time Optimization

We believe in complete transparency—no hidden fees, no surprises. Our pricing model is built on clear, data-driven factors, with lead times optimized through our proprietary production scheduling system. By integrating real-time machine utilization data and material availability, we guarantee on-time delivery while maintaining Olympic-quality standards.

| Cost Factor | Impact on Pricing | Wuxi Lead’s Optimization Strategy |

|---|---|---|

| Material Type | Higher for exotic alloys | Strategic partnerships with certified suppliers for cost-efficient sourcing |

| Tolerance Tightness | ±0.0005″ increases cost | Advanced CNC capabilities to minimize rework and scrap |

| Volume | Economies of scale for high volume | Flexible batch production with no minimums for prototypes |

| Surface Finish | Higher for specialized finishes | In-house polishing and coating to reduce external dependencies |

With a 99.8% on-time delivery rate across 1,200+ projects, we don’t just meet deadlines—we exceed expectations.

Rapid Prototyping with Zero-Defect Assurance

Our rapid prototyping service delivers functional prototypes in record time—without compromising on precision. Using ISO 9001-certified CNC machines and strict quality checkpoints, we achieve tolerances as tight as ±0.0005 inches while maintaining Zero Defects. Every prototype undergoes full dimensional inspection and material certification before delivery.

| Prototyping Stage | Typical Lead Time | Key Features |

|---|---|---|

| Initial CAD Review | 24 hours | DFMA validation, material selection guidance |

| CNC Machined Prototype | 3-5 days | ±0.001″ standard tolerance, ISO 9001 inspection |

| Functional Testing | 1-2 days | Material certification, zero-defect validation |

| Design Iteration | <48 hours | Real-time engineering feedback for rapid adjustments |

This end-to-end process ensures your prototype is production-ready from day one—eliminating costly redesigns and accelerating time-to-market.

Scalable Mass Production with Olympic Quality Control

When scaling to mass production, we maintain the same precision that defines our prototypes. Our ISO 9001-certified production lines feature real-time monitoring, automated inspection systems, and strict material traceability. Every component is manufactured to Olympic standards—where excellence is non-negotiable.

| QC Stage | Inspection Method | Tolerance Standard | Defect Rate |

|---|---|---|---|

| Incoming Material | Spectrographic analysis | ISO 9001 certified | 0% |

| In-Process | CMM, laser scanning | ±0.001″ | 0 defects |

| Final Inspection | Full dimensional check | ±0.0005″ | 0 defects |

| Packaging | Visual & protection check | N/A | 0 damage |

With a 99.97% first-pass yield rate and 100% traceability, we deliver parts that meet—even exceed—your most demanding specifications.

On-Time Delivery Commitment & 24/7 Support

Your project’s success depends on timely delivery. That’s why we offer a 100% on-time delivery guarantee, backed by our 24/7 customer support team. From order placement to final shipment, you’ll have real-time visibility and expert assistance whenever you need it.

| Support Channel | Availability | Response Time | Key Features |

|---|---|---|---|

| Dedicated Account Manager | 24/7 | <1 hour | Single point of contact for all queries |

| Technical Support | 24/7 | <30 minutes | Engineering expertise for urgent issues |

| Order Tracking Portal | Real-time | Instant | Live production status and milestone updates |

| Emergency Support | 24/7 | Immediate | Critical issue resolution with dedicated team |

Whether you’re in Shanghai, Detroit, or Berlin, our global support network ensures your project stays on track—every hour, every day.

Partner with Wuxi Lead Precision Machinery.

Where precision isn’t just a metric—it’s our promise.

📞 +86 510 8888 1234 | ✉️ [email protected] | 🌐 www.leadprecision.com

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Engineering Excellence, Zero Compromise

Precision Engineering Beyond Industry Standards

We redefine precision manufacturing by exceeding conventional tolerances while maintaining absolute consistency. Our ISO 9001-certified processes ensure every component meets or surpasses your most demanding specifications.

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tolerance Capability | ±0.005″ (0.127mm) | ±0.0005″ (0.013mm) tightest; Standard ±0.001″ (0.025mm) |

| Defect Rate | 0.5% – 1.0% | Zero Defects Commitment (0% defect rate guaranteed) |

| Material Traceability | Basic ISO 9001 | Full Material Certification + Third-Party Verification (ASTM, DIN, JIS) |

| Support Response | Business Hours (8–5) | 24/7 Technical Support with <2-hour response SLA |

Zero Defects Quality Assurance System

Every component undergoes a multi-stage quality protocol engineered for perfection:

Material Verification: Full traceability from raw stock to finished part, with certified mill reports for all metals/plastics.

In-Process Monitoring: Real-time SPC (Statistical Process Control) during machining, with automated CMM inspections at critical stages.

Final Validation: 100% optical measurement and dimensional verification for critical features, ensuring zero deviations from design intent.

Olympic Quality Standard: We apply the same rigor as elite athletic performance—precision, consistency, and relentless attention to detail.

24/7 Customer-Centric Support

We are not a supplier—we are your strategic manufacturing partner. Our dedicated engineering team is available around the clock to:

Provide free DFM (Design for Manufacturability) analysis to optimize your design before production begins.

Resolve technical challenges in real-time, with rapid turnaround for urgent requests.

Deliver transparent project tracking via dedicated portals and proactive communication.

Your success drives our operations—no project is too complex, no deadline too tight.

Elevate Your Precision Manufacturing with Wuxi Lead Precision Machinery

Contact us today for a free DFM analysis and competitive quote:

📧 [email protected]

📞 +86-13961886740

We respond within 2 hours, 24/7. Your project, our priority.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.