Technical Contents

Engineering Guide: Metal Laser Cutting Service

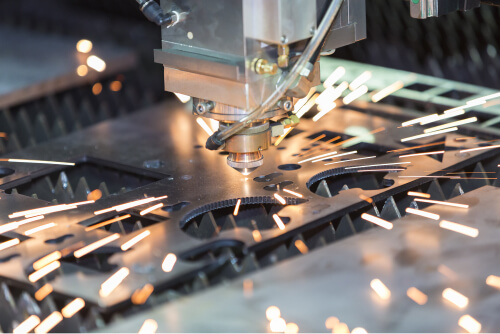

Engineering Insight: The Critical Role of Precision in Metal Laser Cutting Services

In the realm of advanced sheet metal fabrication, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and safety are built. At Wuxi Lead Precision Machinery, we understand that the success of high-stakes industrial applications hinges on micron-level accuracy, repeatability, and material integrity. This understanding drives our approach to metal laser cutting services, where engineering excellence meets cutting-edge technology.

Laser cutting has revolutionized modern manufacturing by enabling intricate geometries, tight tolerances, and clean edge finishes that traditional methods cannot achieve. However, the true value of laser cutting lies not in its capability alone, but in its consistent execution under demanding conditions. Whether producing components for aerospace systems, defense platforms, or critical infrastructure, deviations of even a few microns can lead to assembly failures, performance degradation, or safety risks.

Our expertise in precision laser cutting is validated through our involvement in projects of national and global significance. Wuxi Lead Precision Machinery has delivered components for Olympic-standard sporting infrastructure and supplied mission-critical parts to military-grade specifications. These engagements demand more than advanced machinery—they require a culture of precision engineering, rigorous quality control, and deep material science knowledge. Each cut is optimized for thermal dynamics, kerf width, and edge perpendicularity, ensuring that every part meets exact design intent.

We utilize fiber laser technology with intelligent motion control systems, allowing for high-speed processing without compromising accuracy. Our machines are calibrated daily, and our operators follow ISO-compliant workflows to maintain traceability and consistency across production batches. From thin-gauge stainless steel to thick-section carbon steel, our process adapts to material behavior, minimizing distortion and maximizing dimensional stability.

The following table outlines the core specifications of our metal laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Maximum Power | 12,000 W |

| Cutting Thickness Range | 0.5 mm – 25 mm (steel) |

| Positioning Accuracy | ±0.03 mm/m |

| Repeatability | ±0.02 mm |

| Minimum Feature Size | 0.8 mm (holes), 1.0 mm (slots) |

| Edge Roughness (Ra) | ≤ 6.3 µm (depending on material & thickness) |

| Supported Materials | Mild Steel, Stainless Steel, Aluminum, Galvanized Steel, Brass |

| Standard Tolerances | ±0.1 mm (IT7–IT9 per ISO 2768) |

At Wuxi Lead Precision Machinery, precision is not an outcome—it is engineered into every stage of production. Our clients trust us not only for our technical capabilities, but for our unwavering commitment to delivering components that perform flawlessly in the most demanding environments. When precision matters, experience, technology, and discipline must align. That is the standard we uphold.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Laser Cutting at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers advanced metal laser cutting services engineered for the demanding requirements of high-end industrial manufacturing. Our core strength lies in integrating cutting-edge multi-axis laser technology with rigorous metrology protocols, ensuring exceptional dimensional accuracy and repeatability across complex sheet metal components. We specialize in transforming raw sheet metal into precision-engineered parts that meet the stringent tolerances demanded by aerospace, medical device, and advanced automation sectors. Our facility is purpose-built for efficiency without compromising on the quality essential for mission-critical applications.

Our primary production platform consists of state-of-the-art 5-axis CNC fiber laser cutting systems. These advanced machines provide unparalleled flexibility for processing complex geometries, including intricate contours, beveled edges, and three-dimensional forms directly from flat sheet stock. This capability eliminates secondary operations for many part features, significantly reducing lead times and potential error sources. We routinely process a wide spectrum of engineering metals, including carbon steel, stainless steel (grades 304, 316, 430), aluminum alloys (6061, 5052, 7075), and specialty alloys. Material thickness capabilities span from ultra-thin foils starting at 0.5mm up to robust plates of 25mm, accommodating diverse project scales while maintaining consistent edge quality and minimal heat-affected zones.

Precision is non-negotiable in critical applications. Every component undergoes comprehensive verification through our integrated Coordinate Measuring Machine (CMM) inspection process. Parts are measured against the original CAD model using calibrated Renishaw probes, capturing critical dimensions, hole locations, form tolerances, and complex profile deviations. This data-driven QC methodology provides objective evidence of conformance, generating detailed inspection reports traceable to international standards. Our quality management system ensures that measurement uncertainty is rigorously controlled and documented, providing clients with absolute confidence in part integrity before shipment.

The achievable dimensional accuracy of laser-cut parts depends on material type, thickness, and feature complexity. Wuxi Lead consistently meets or exceeds the following industry benchmarks under controlled production conditions:

| Material Type | Thickness Range | Dimensional Tolerance (Typical) |

|---|---|---|

| Carbon Steel | 0.5mm – 10mm | ±0.05 mm |

| Carbon Steel | 10mm – 25mm | ±0.10 mm |

| Stainless Steel | 0.5mm – 12mm | ±0.05 mm |

| Stainless Steel | 12mm – 20mm | ±0.10 mm |

| Aluminum Alloys | 0.5mm – 8mm | ±0.05 mm |

| Aluminum Alloys | 8mm – 15mm | ±0.10 mm |

These tolerances reflect our standard production capability for features within standard design parameters. For applications requiring micron-level precision or complex form tolerances, our engineering team collaborates directly with clients during the design phase to optimize manufacturability and implement enhanced process controls. Wuxi Lead Precision Machinery combines advanced 5-axis laser technology with uncompromising metrology to deliver metal fabrication solutions where precision, reliability, and technical expertise are fundamental requirements. Partner with us to transform your most challenging sheet metal designs into reality. Wuxi Lead Precision Machinery: Engineered Precision, Delivered.

Material & Finish Options

Material Selection for Precision Metal Laser Cutting Services

Selecting the appropriate material is critical when commissioning high-precision metal laser cutting services. At Wuxi Lead Precision Machinery, we specialize in processing a range of industrial-grade metals, with aluminum, steel, and titanium being the most frequently requested due to their distinct mechanical properties and application suitability. Understanding the characteristics of each material ensures optimal performance, cost-efficiency, and longevity in end-use environments.

Aluminum is widely favored in aerospace, electronics, and transportation industries for its excellent strength-to-weight ratio and natural corrosion resistance. It is highly reflective and thermally conductive, which requires precise laser parameter control during cutting to avoid beam reflection and thermal distortion. Our fiber laser systems are calibrated to handle aluminum grades such as 5052, 6061, and 7075, supporting thicknesses from 0.5 mm to 12 mm with clean, burr-free edges. Aluminum’s compatibility with anodizing makes it ideal for components requiring enhanced surface durability and aesthetic finish.

Steel, particularly mild steel and stainless steel, remains a cornerstone in industrial fabrication. Mild steel (e.g., Q235, ASTM A36) offers high tensile strength and weldability, making it suitable for structural enclosures, machinery frames, and heavy-duty components. Stainless steel (grades 304 and 316) provides superior corrosion resistance and a clean aesthetic, often used in medical devices, food processing equipment, and architectural applications. Our laser cutting systems achieve tight tolerances of ±0.1 mm on steel up to 25 mm thick, ensuring dimensional accuracy and smooth edge quality ideal for subsequent forming or welding operations.

Titanium and its alloys, such as Grade 2 and Ti-6Al-4V, are employed in high-performance sectors like aerospace, defense, and biomedical engineering. Titanium offers exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments. However, its low thermal conductivity and high reactivity at elevated temperatures demand specialized cutting protocols, including inert gas shielding (typically argon or nitrogen) to prevent oxidation. Our advanced laser platforms are equipped to process titanium sheets up to 10 mm, delivering precise cuts with minimal heat-affected zones.

For aluminum components, anodizing is a recommended post-processing finish. This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and surface hardness. Decorative anodizing in various colors is also available for branding or identification purposes. We coordinate closely with trusted surface treatment partners to ensure seamless integration of anodized finishes without compromising dimensional integrity.

The following table outlines key material specifications supported in our laser cutting processes:

| Material | Common Grades | Thickness Range (mm) | Max Tolerance | Surface Finish Option |

|---|---|---|---|---|

| Aluminum | 5052, 6061, 7075 | 0.5 – 12 | ±0.1 mm | Anodizing (clear/color) |

| Mild Steel | Q235, ASTM A36 | 1 – 25 | ±0.1 mm | Powder coating, plating |

| Stainless Steel | 304, 316 | 1 – 20 | ±0.1 mm | Passivation, polishing |

| Titanium | Gr 2, Ti-6Al-4V | 0.8 – 10 | ±0.1 mm | Bare, sandblasted |

Material choice directly impacts manufacturability, performance, and lifecycle cost. At Wuxi Lead Precision Machinery, we provide engineering consultation to match your design requirements with the optimal material and finishing solution.

Manufacturing Process & QC

Precision Metal Laser Cutting: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, our metal laser cutting service delivers uncompromising quality through a rigorously controlled three-phase workflow. This integrated approach ensures zero defects are not aspirational but a measurable outcome, directly supporting your production efficiency and product integrity. We begin with foundational Design optimization. Our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis on your CAD files, identifying potential stress points, kerf allowances, and material grain orientation issues before cutting commences. This proactive review eliminates geometry-related defects at the source, optimizing nesting for minimal waste and validating material suitability against your functional requirements. Precise parameter selection—laser power, assist gas type, cutting speed—is finalized during this phase based on the specific alloy and thickness, establishing the baseline for dimensional accuracy.

Prototyping is our critical validation step, not merely a sample run. Using the exact production-grade fiber laser systems and materials destined for your final parts, we produce functional prototypes under controlled conditions. Every cut undergoes 100% dimensional verification against your original CAD model using calibrated CMMs and optical comparators. Edge quality, burr formation, and heat-affected zone characteristics are meticulously assessed. This phase confirms the DFM adjustments and laser parameters, providing tangible evidence of process capability and allowing for micro-adjustments. Only when the prototype meets all geometric and surface finish specifications is the process formally locked for mass production, ensuring scalability without quality compromise.

Mass production executes the validated process with unwavering consistency. Our state-of-the-art automated fiber laser systems, integrated with real-time process monitoring, continuously track critical variables like beam focus, gas pressure, and positional accuracy. Statistical Process Control (SPC) charts are maintained for key characteristics, enabling immediate intervention should any parameter drift. Each sheet undergoes in-process inspection at defined intervals, while final parts receive 100% visual and dimensional verification per your acceptance criteria. This closed-loop system, combined with operator expertise and rigorous material traceability, guarantees every component shipped meets the zero-defect standard, minimizing your rework costs and assembly line disruptions. Our commitment extends beyond the cut; we provide full documentation for seamless integration into your assembly process.

Key laser cutting capabilities enabling this precision workflow are detailed below:

| Parameter | Specification |

|---|---|

| Material Types | Carbon Steel, Stainless Steel, Aluminum, Brass, Copper |

| Thickness Range | 0.5 mm – 25 mm |

| Positional Tolerance | ±0.05 mm |

| Max Sheet Size | 3000 mm x 1500 mm |

| Edge Quality | Burr-free (Ra < 3.2 µm) achievable on critical surfaces |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Metal Laser Cutting Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and engineering excellence. As a global leader in high-end sheet metal fabrication, we specialize in advanced metal laser cutting services that meet the exacting demands of aerospace, automotive, medical, and industrial equipment manufacturers. Our commitment to quality, innovation, and on-time delivery makes us the preferred partner for OEMs and Tier-1 suppliers worldwide.

Our state-of-the-art laser cutting facilities are equipped with high-power fiber laser systems capable of processing a wide range of conductive and non-conductive metals with micron-level accuracy. Whether you’re prototyping a new design or scaling up for high-volume production, our team of CNC engineers and manufacturing specialists ensures every cut meets your dimensional tolerances, material specifications, and surface finish requirements.

We understand that in precision manufacturing, consistency is non-negotiable. That’s why every project undergoes rigorous quality control, including first-article inspection, in-process monitoring, and final dimensional verification using coordinate measuring machines (CMMs). Our ISO 9001:2015-certified processes guarantee repeatability and traceability across batches, giving you confidence in every component we produce.

Beyond cutting, we offer integrated fabrication solutions—bending, welding, surface treatment, and assembly—streamlining your supply chain and reducing lead times. Our agile manufacturing model supports low-volume custom runs and high-mix production with the same level of precision and responsiveness.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic manufacturing ally. We work closely with your engineering team to optimize designs for manufacturability, reduce material waste, and accelerate time-to-market. From DFM feedback to real-time production updates, our customer-centric approach ensures transparency and collaboration at every stage.

Explore the full potential of your next metal fabrication project with a team that combines cutting-edge technology with decades of industrial expertise. Let us help you achieve tighter tolerances, faster turnaround, and superior part quality—every time.

Contact us today to discuss your requirements. Email us at [email protected] and receive a personalized consultation, free quote, and technical support tailored to your application. Whether you’re sourcing complex enclosures, structural components, or precision chassis, we’re ready to deliver the performance you demand.

| Specification | Detail |

|---|---|

| Laser Type | Fiber Laser |

| Power Range | Up to 12 kW |

| Material Thickness Range | 0.5 mm – 25 mm (steel), up to 20 mm (aluminum, stainless) |

| Max Cutting Area | 4000 mm × 2000 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Supported Materials | Mild steel, stainless steel, aluminum, brass, copper |

| Standard Tolerances | ±0.1 mm (per ISO 2768) |

| Surface Finish | Burr-free edges, minimal dross |

| Certifications | ISO 9001:2015 |

Start your next project with confidence. Reach out to Wuxi Lead Precision Machinery—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.