Technical Contents

Engineering Guide: Metal Fabrication Minneapolis

Engineering Insight: The Critical Role of Precision in Metal Fabrication – A Global Perspective

In the competitive landscape of modern manufacturing, precision in sheet metal fabrication is not merely a quality benchmark—it is a foundational requirement for performance, safety, and long-term reliability. Whether serving the aerospace, defense, or high-performance commercial sectors, the margin for error in metal fabrication is measured in thousandths of an inch. This level of accuracy is what separates functional components from mission-critical failures. In cities like Minneapolis, where advanced manufacturing and engineering innovation converge, the demand for precision-driven fabrication has never been higher.

At Wuxi Lead Precision Machinery, we understand that precision begins long before the first cut is made. It starts with material selection, continues through laser cutting, bending, welding, and culminates in rigorous quality assurance. Our engineering protocols are built on decades of experience delivering components for applications where failure is not an option. This includes supplying precision-fabricated parts for Olympic-standard equipment and military-grade systems, where structural integrity and dimensional accuracy are non-negotiable.

The processes we employ—such as fiber laser cutting with ±0.1 mm tolerance, CNC press braking with real-time feedback systems, and robotic welding under inert gas shielding—are designed to eliminate variability. In Minneapolis, a hub for medical device manufacturing and industrial automation, these capabilities align directly with the region’s demand for repeatable, high-integrity metal components. Our clients in North America rely on our ability to meet stringent ASME, ISO, and MIL-STD specifications, ensuring seamless integration into their final assemblies.

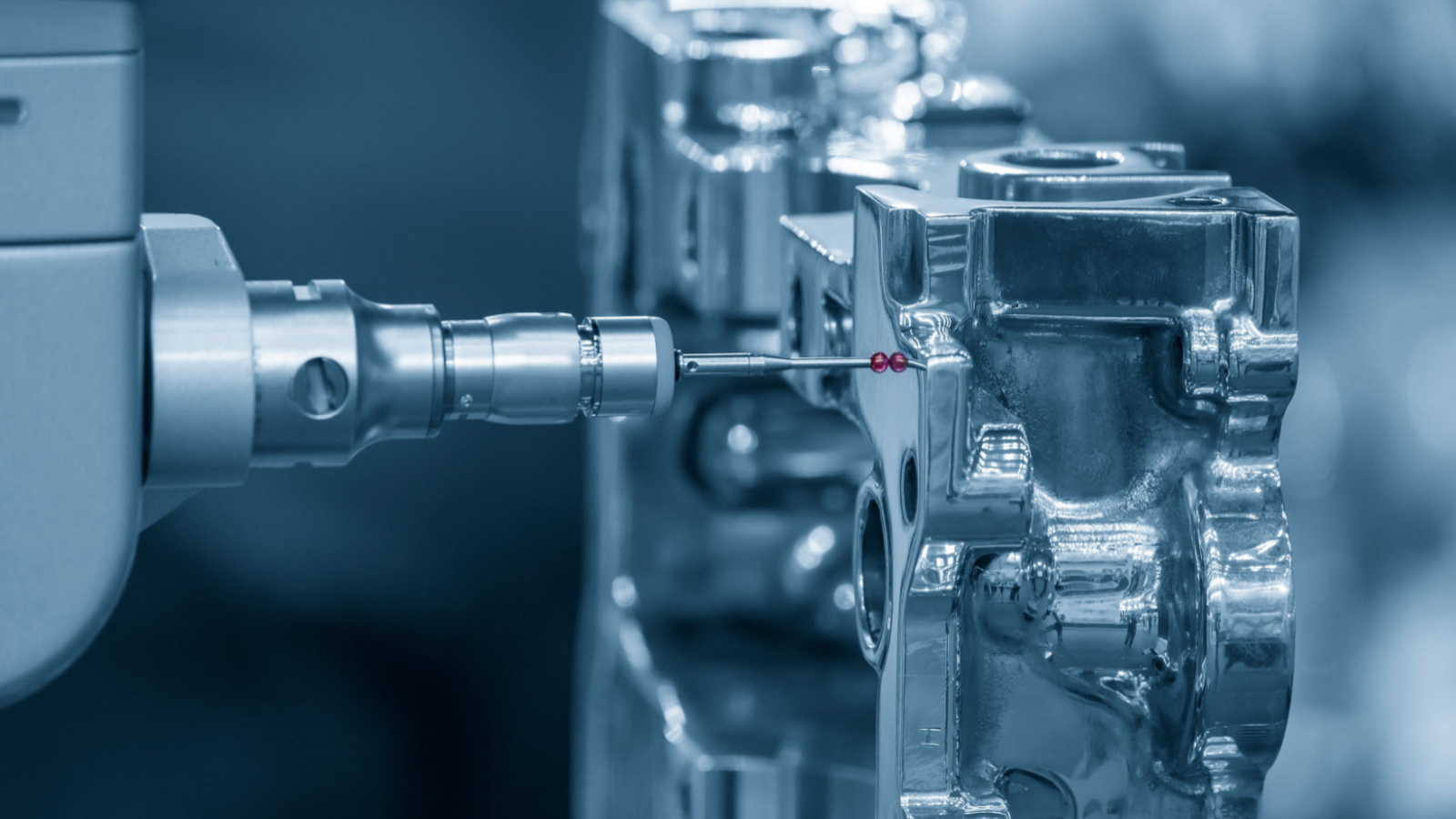

Precision also extends beyond machinery—it is embedded in our engineering culture. Every design is subjected to finite element analysis (FEA) and manufacturability review. We utilize 3D metrology systems, including coordinate measuring machines (CMM), to validate each batch against original CAD models. This closed-loop quality process ensures that every fabricated part meets the exacting standards required by high-end industrial clients.

Below are key technical specifications that define our precision fabrication capabilities:

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Laser Cutting Tolerance | ±0.1 mm |

| CNC Bending Accuracy | ±0.25° angular, ±0.1 mm linear |

| Welding Processes | TIG, MIG, Robotic Pulsed GMAW |

| Surface Roughness (Ra) | Up to 0.8 µm (polished finishes) |

| Quality Standards | ISO 9001, ASME BPVC, MIL-STD-276, RoHS |

| Inspection Tools | CMM, Laser Scanning, Ultrasonic Testing |

Our experience with high-stakes projects has taught us that consistency is as vital as accuracy. In metal fabrication, especially for clients in Minneapolis and across the Midwest, supply chain reliability and technical transparency are paramount. Wuxi Lead Precision Machinery bridges the gap between Chinese manufacturing scale and German-level precision, offering a globally competitive solution without compromising on quality.

Precision is not a feature—it is the standard. And for industries where performance is measured under extreme conditions, that standard is what defines success.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding sheet metal fabrication projects, directly addressing the stringent requirements of Minneapolis aerospace, medical device, and industrial equipment manufacturers. Our integrated technical infrastructure centers on state-of-the-art 5-axis CNC machining technology, enabling the production of complex geometries impossible with conventional 3-axis systems. These multi-axis platforms execute simultaneous contouring and feature machining in a single setup, eliminating cumulative error from multiple fixtures and drastically reducing lead times for intricate components. High-torque spindles and advanced kinematic stability ensure exceptional surface finishes and dimensional accuracy across challenging materials including aerospace-grade aluminum alloys, medical stainless steels, and hardened tool steels, even at thicknesses up to 25mm.

Rigorous quality control is non-negotiable in high-integrity applications. Every critical component undergoes comprehensive dimensional validation using industry-standard Coordinate Measuring Machine (CMM) inspection. Our Zeiss CONTURA and Mitutoyo CRYSTA-Apex systems, operating within a certified ISO 17025 metrology lab, provide traceable, sub-micron measurement accuracy. This process verifies complex 3D profiles, positional tolerances, and geometric dimensioning and tolerancing (GD&T) callouts against original CAD models, ensuring absolute conformity before shipment. Real-time SPC data analysis from both machining centers and CMMs allows for immediate process correction, guaranteeing consistent batch-to-batch repeatability essential for regulated industries.

Our commitment to precision is quantified through demonstrable tolerance performance across standard fabrication processes. The following table details achievable capabilities under controlled production conditions for common materials:

| Process | Material Range | Thickness Range | Standard Tolerance | Tight Tolerance Option |

|---|---|---|---|---|

| 5-Axis CNC Milling | Aluminum 6061/7075 | 1.0 – 25.0 mm | ±0.010 mm | ±0.005 mm |

| Stainless Steel 304/316 | 1.0 – 20.0 mm | ±0.012 mm | ±0.008 mm | |

| Carbon Steel 1018 | 1.5 – 25.0 mm | ±0.015 mm | ±0.010 mm | |

| Laser Cutting | All Sheet Metals | 0.5 – 12.0 mm | ±0.050 mm | ±0.025 mm |

| Precision Bending | All Sheet Metals | 0.8 – 6.0 mm | ±0.1° / ±0.05 mm | ±0.05° / ±0.02 mm |

| CMM Final Inspection | All Machined Parts | N/A | ISO 2768-mK | ISO 2768-fK |

These specifications reflect our baseline performance for production runs exceeding 50 pieces, utilizing optimized toolpaths, in-process gaging, and thermally stable machining environments. For Minneapolis clients requiring mission-critical components, Wuxi Lead implements enhanced process controls including 100% CMM reporting, first-article inspection to AS9102 standards, and material certification traceability to mill test reports. Our technical team collaborates directly with your engineering staff during DFM analysis to validate manufacturability against your specific tolerance stack-ups, ensuring seamless integration into your final assemblies. This disciplined approach to capability and verification establishes Wuxi Lead as a reliable extension of your precision manufacturing supply chain.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material is a critical step in the sheet metal fabrication process, particularly for high-performance industrial applications. At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered components using top-tier materials including aluminum, steel, and titanium. Each material offers distinct mechanical, thermal, and chemical properties that influence its suitability for specific environments and functional requirements.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is ideal for aerospace, transportation, and electronics enclosures where weight reduction and durability are paramount. Grade 6061-T6 is commonly used for structural components due to its weldability and machinability, while 5052-H32 excels in marine and chemical exposure environments.

Steel remains the backbone of industrial fabrication due to its high tensile strength, affordability, and versatility. Mild steel (A36) is frequently used in general-purpose applications such as chassis frames and brackets. For enhanced durability and resistance to wear, stainless steel grades like 304 and 316 are preferred—especially in food processing, medical devices, and outdoor installations. 316 stainless steel contains molybdenum, offering superior resistance to chlorides and pitting corrosion.

Titanium, though more costly, delivers unmatched performance in extreme conditions. Its exceptional strength-to-density ratio, resistance to high temperatures, and immunity to seawater and chemical corrosion make it the material of choice for aerospace, defense, and high-end medical applications. Grade 2 is commonly used for general corrosion resistance, while Grade 5 (Ti-6Al-4V) is selected for high-stress structural components.

Surface finishing plays a vital role in enhancing both performance and aesthetics. Anodizing is a highly effective electrochemical process primarily applied to aluminum. It increases surface hardness, improves wear resistance, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and moderate protective needs, while Type III (hardcoat anodizing) provides a thicker, more durable layer suitable for industrial machinery and military-grade equipment.

At Wuxi Lead, we integrate material science with advanced CNC fabrication to ensure each component meets exacting specifications. Our engineering team collaborates with clients to match material and finish choices with operational demands, environmental exposure, and lifecycle expectations.

The following table outlines key mechanical and fabrication properties of commonly used materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Key Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum | 180–310 | 2.7 | 6061-T6, 5052-H32 | Aerospace, Electronics | Anodizing, Powder Coating |

| Mild Steel | 370–500 | 7.85 | A36, 1018 | Frames, Brackets | Zinc Plating, Painting |

| Stainless Steel | 505–860 | 8.0 | 304, 316 | Medical, Food Processing | Passivation, Polishing |

| Titanium | 345–900 | 4.5 | Grade 2, Grade 5 | Aerospace, Defense | Bead Blasting, Anodizing (Ti) |

Material and finish selection directly impacts product longevity, performance, and cost-efficiency. By combining technical expertise with precision manufacturing, Wuxi Lead ensures optimal outcomes for every fabrication project.

Manufacturing Process & QC

Precision Sheet Metal Fabrication: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our global sheet metal fabrication process delivers the uncompromising quality Minneapolis manufacturers demand. We integrate advanced engineering with rigorous quality control across three critical phases: Design, Prototyping, and Mass Production. This structured approach ensures seamless transition from concept to flawless high-volume output, eliminating costly errors before they reach your production floor.

The Design phase is foundational. Our engineering team conducts thorough Design for Manufacturability (DFM) analysis on every Minneapolis client’s CAD model. We identify potential fabrication conflicts early—material suitability, bend allowances, weld accessibility, and tolerance stack-ups—preventing defects at the source. Our engineers collaborate directly with your design team, providing actionable feedback to optimize the part for precision laser cutting, CNC punching, and forming. This proactive review ensures the design is not only functional but inherently manufacturable to exacting standards, significantly reducing downstream rework.

Prototyping transforms the validated design into a tangible proof of concept. Utilizing the same production-grade equipment intended for mass production, we fabricate initial units under controlled conditions. Each prototype undergoes comprehensive dimensional inspection against the original CAD data using CMM and optical measurement systems. Critical functional tests, including fit checks, weld integrity verification, and surface finish assessment, are performed. This stage validates the entire process flow and confirms the design meets all Minneapolis project specifications. Only after prototype approval, with zero non-conformances documented, do we proceed to full-scale production.

Mass Production leverages the perfected process blueprint established in prior phases. Our automated production lines, featuring state-of-the-art Bystronic and Amada equipment, operate under stringent Statistical Process Control (SPC). Real-time monitoring tracks key parameters like laser power, bend angle consistency, and weld penetration depth. Every component undergoes in-process inspection at predefined checkpoints, with final 100% inspection verifying critical dimensions and overall conformance. Material traceability is maintained from raw stock to finished part, meeting all Minneapolis industry compliance requirements. This systematic execution, rooted in the Zero Defects philosophy, ensures consistent output where near-zero defect rates are the measurable outcome, not an aspiration.

Our core production capabilities consistently achieve the tolerances and throughput Minneapolis clients require:

| Process | Typical Tolerance | Material Thickness Range | Max. Part Size (L x W) | Key Technology |

|---|---|---|---|---|

| Fiber Laser Cutting | ±0.1 mm | 0.5 – 25 mm Steel | 4000 x 2000 mm | 12kW Bystronic BySprint |

| CNC Bending | ±0.25° / ±0.1 mm | 0.5 – 6 mm Steel | 3000 x 2000 mm | Amada HG-1003 AR |

| Robotic Welding | ±0.5 mm | 0.8 – 8 mm Steel | Custom Fixturing | FANUC ARC Mate 100iD |

This integrated methodology—grounded in engineering rigor, validated prototyping, and statistically controlled mass production—guarantees that every sheet metal component shipped from Wuxi Lead meets the highest standards of precision expected by Minneapolis industry leaders, driving your operational efficiency and product reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Excellence

When your manufacturing operations demand precision, consistency, and scalability, partnering with a globally trusted leader in sheet metal fabrication is not just an advantage—it’s a necessity. At Wuxi Lead Precision Machinery, we specialize in delivering high-end, custom sheet metal solutions engineered to meet the rigorous standards of advanced industrial sectors. From complex prototypes to high-volume production runs, our capabilities are built on decades of technical mastery, cutting-edge infrastructure, and a relentless commitment to quality.

Located in Wuxi, China, we serve as a strategic offshore partner for leading manufacturers across North America, including key industrial hubs such as Minneapolis. Our clients rely on us not only for our technical expertise but also for our ability to integrate seamlessly into global supply chains—offering competitive pricing without compromising on precision or delivery timelines. Whether you are in aerospace, medical device manufacturing, industrial automation, or advanced electronics, our team collaborates closely with your engineers to ensure every component meets exact specifications and performance requirements.

Our state-of-the-art facility is equipped with advanced CNC punching, laser cutting, bending, and welding systems, enabling us to process a wide range of materials—including stainless steel, aluminum, carbon steel, and specialty alloys—with tolerances as tight as ±0.1 mm. Every stage of production is governed by strict quality control protocols, including ISO 9001-certified processes and comprehensive in-process inspection systems. This ensures that every fabricated part is consistent, traceable, and ready for immediate integration into your assembly line.

We understand that in high-stakes manufacturing environments, time is critical. That’s why we offer rapid prototyping, fast turnaround times, and agile production scaling to support both short-run customization and long-term volume contracts. Our logistics network ensures reliable, on-time delivery to Minneapolis and beyond, with full documentation and packaging tailored to your operational needs.

To learn how Wuxi Lead Precision Machinery can become your trusted partner in precision sheet metal fabrication, contact us today. Let us help you reduce costs, improve quality, and accelerate time to market.

Contact us at:

Email: [email protected]

Let’s discuss your next project and explore how we can deliver precision that leads.

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 – 6.0 mm |

| Maximum Processing Size | 1500 x 3000 mm |

| Tolerance | ±0.1 mm |

| Laser Cutting Accuracy | ±0.05 mm |

| Bending Tolerance | ±0.2° |

| Supported Materials | Stainless Steel, Aluminum, Carbon Steel, Galvanized Steel, Copper |

| Production Capacity | Up to 500,000 units/month |

| Certifications | ISO 9001:2015, RoHS Compliant |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.