Technical Contents

Engineering Guide: Metal Fabrication Boston

Engineering Insight: Precision as the Non-Negotiable Foundation in Boston Metal Fabrication

In Boston’s competitive advanced manufacturing ecosystem, where aerospace components, medical devices, and defense systems demand absolute reliability, precision in sheet metal fabrication transcends mere quality control—it becomes the core determinant of product success and operational safety. Marginal deviations in critical dimensions, surface finish, or material integrity can cascade into catastrophic field failures, regulatory non-compliance, or costly recalls. For Boston-based OEMs and tier suppliers operating under stringent AS9100 or ITAR frameworks, partnering with a fabrication provider possessing demonstrable, uncompromising precision capabilities is not optional; it is a fundamental requirement for market access and sustained competitiveness. The high cost of rework or failure in these sectors makes upfront precision engineering the most economical and strategic choice.

Wuxi Lead Precision Machinery brings this rigor to global clients, including demanding Boston projects. Our engineering discipline is forged through direct experience fabricating mission-critical components for the Beijing Olympic infrastructure and certified military supply chains. These engagements demanded tolerances and documentation far exceeding standard industrial practices, operating under relentless scrutiny where zero defects were the only acceptable outcome. This heritage instills a systematic approach: from advanced FEA-backed flat pattern development and laser-probe verified forming simulations to in-process CMM checks and final first-article inspections per ASME Y14.5. We treat every Boston client project with the same uncompromising standards applied to defense contracts, ensuring dimensional stability and repeatability are engineered in, not inspected in.

Our technical capabilities are structured to meet and exceed the precision expectations of Boston’s advanced manufacturing sector. Key specifications include:

| Parameter | Capability | Industry Standard Benchmark |

|---|---|---|

| Linear Tolerance | ±0.005 mm (0.0002″) | ±0.1 mm (0.004″) |

| Hole Position Tolerance | ±0.01 mm (0.0004″) | ±0.05 mm (0.002″) |

| Surface Roughness (Ra) | 0.4 µm (16 µin) | 1.6 µm (63 µin) |

| Material Thickness Range | 0.5 mm – 6.0 mm (0.02″ – 0.24″) | 0.8 mm – 3.0 mm (0.03″ – 0.12″) |

| Supported Materials | Aerospace Al 6061/7075, SS 304/316, Titanium | Mild Steel, Basic Alloys |

Precision fabrication is the invisible backbone of Boston’s innovation engine. When your next project requires components that must perform flawlessly under extreme conditions—whether in a surgical robot, satellite subsystem, or naval platform—partner with an engineering team whose precision pedigree is proven where failure is not an option. Wuxi Lead Precision Machinery delivers the dimensional integrity, material consistency, and traceable quality processes Boston’s high-stakes industries demand, ensuring your design intent becomes flawless physical reality. Let our Olympic and military-grade precision standards become your competitive advantage.

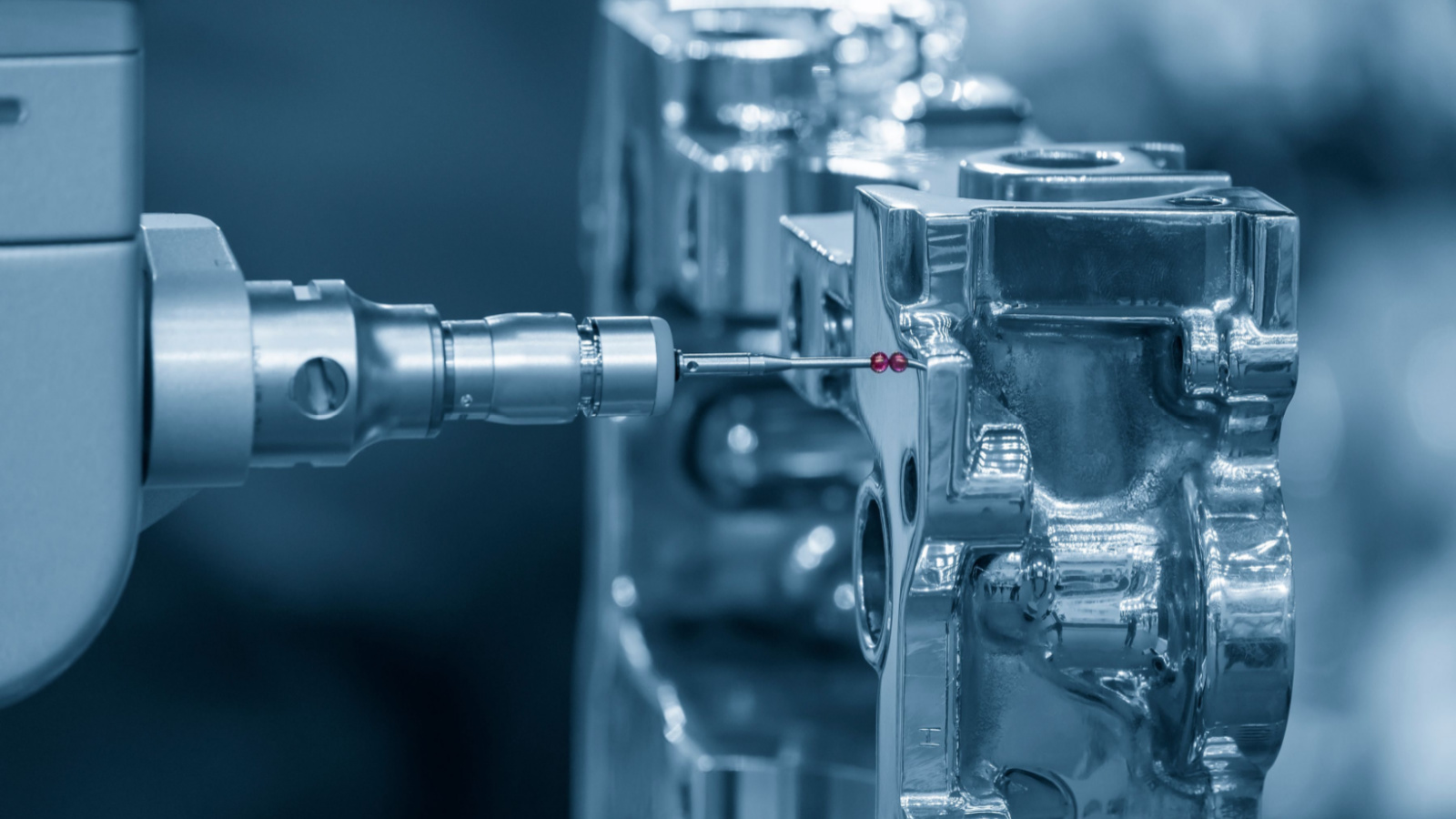

Precision Specs & Tolerances

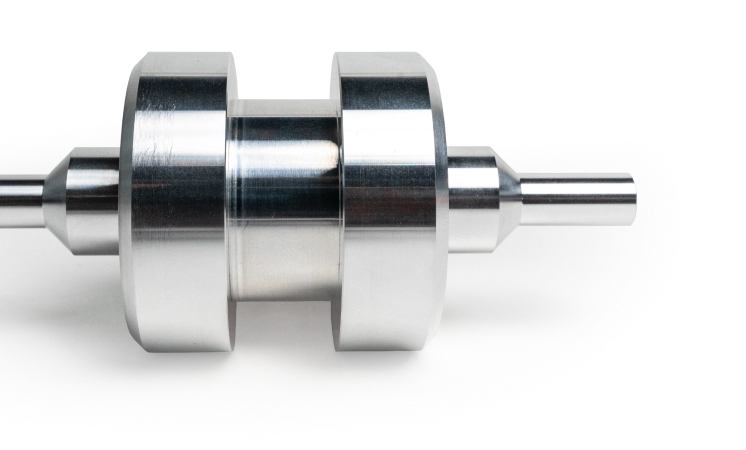

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored to meet the exacting demands of high-performance industries, including aerospace, medical, and industrial automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, enabling us to produce complex geometries with exceptional precision and repeatability. These multi-axis platforms allow for simultaneous cutting, drilling, and contouring from multiple angles, minimizing setup changes and reducing cumulative error—critical advantages when producing intricate sheet metal components with tight tolerances and high consistency.

Our 5-axis CNC technology supports a broad range of materials, including stainless steel, aluminum, titanium, and specialty alloys, ensuring compatibility with diverse engineering requirements. The integration of high-speed spindles and dynamic toolpath algorithms enhances machining efficiency while maintaining surface integrity and dimensional accuracy. This level of control is essential for components used in mission-critical environments where fit, function, and reliability are non-negotiable.

Complementing our machining expertise is a comprehensive quality control infrastructure centered around Coordinate Measuring Machine (CMM) inspection. Each fabricated part undergoes rigorous dimensional validation using calibrated CMM systems, providing micron-level verification of critical features. Our inspection protocols conform to ISO 9001 standards, ensuring traceability, repeatability, and full compliance with customer specifications. Data from CMM reports can be provided with each shipment, offering full transparency and supporting downstream assembly and certification processes.

To further ensure consistency and client confidence, we maintain detailed tolerance benchmarks across key fabrication parameters. These tolerances reflect our commitment to precision and are validated through continuous process monitoring and equipment calibration.

| Parameter | Standard Tolerance | High-Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.02 mm | Up to 500 mm; beyond requires special fixturing |

| Angular Features | ±0.1° | ±0.05° | Verified via CMM and optical alignment |

| Hole Positioning | ±0.03 mm | ±0.01 mm | Relative to datum; includes reamed and tapped holes |

| Surface Flatness | 0.05 mm | 0.02 mm | Over 100 x 100 mm area |

| Feature-to-Feature Distance | ±0.04 mm | ±0.015 mm | Critical for mating components |

| Thread Accuracy | 6H / 6g | 4H / 4g | Per ISO 965; includes M2 and larger |

All tolerances are achievable across our production volumes, from rapid prototyping to high-volume runs. Our engineering team collaborates directly with clients during the design-for-manufacturability phase to optimize part geometry, material selection, and tolerance allocation—ensuring cost efficiency without compromising performance.

At Wuxi Lead Precision Machinery, we combine advanced 5-axis CNC capabilities with metrology-grade inspection to deliver sheet metal components that meet the highest standards of precision and reliability. Our technical infrastructure supports global clients who demand consistency, quality, and engineering excellence in every part produced.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication in Boston

Material selection fundamentally dictates performance, longevity, and cost-effectiveness in high-precision sheet metal fabrication projects. For Boston-area manufacturers serving demanding sectors like aerospace, medical devices, and defense, understanding the nuanced properties of Aluminum, Steel, and Titanium is non-negotiable. Wuxi Lead Precision Machinery leverages advanced CNC capabilities to process these materials to exacting tolerances, ensuring your final component meets critical application requirements. Choosing incorrectly risks premature failure, excessive maintenance, or unnecessary expenditure.

Aluminum alloys, particularly 5052 and 6061, dominate applications requiring an optimal strength-to-weight ratio and superior corrosion resistance. These materials are ideal for enclosures, structural components in transportation, and marine hardware common in New England’s coastal environment. Their excellent machinability and weldability streamline production, while inherent non-magnetic properties suit sensitive electronic housings. Aluminum’s natural oxide layer provides baseline protection, but anodizing significantly enhances surface durability and aesthetics for Boston clients demanding both function and finish.

Steel remains the backbone for structural integrity where maximum strength and wear resistance are paramount. Low-carbon steels like 1008/1010 offer exceptional formability for complex enclosures and chassis, while stainless grades (304, 316) provide essential corrosion resistance for medical instruments or marine applications exposed to Boston’s harsh winters and salt air. High-strength low-alloy (HSLA) steels deliver enhanced yield strength for load-bearing components without excessive weight penalties. Precise laser cutting and bending are critical to maintain steel’s structural properties during fabrication.

Titanium, specifically Grade 2 and 5 (Ti-6Al-4V), is the solution for extreme environments demanding unparalleled strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. Essential in Boston’s aerospace and high-end medical device sectors, titanium withstands aggressive chemicals, high temperatures, and constant stress. Its work-hardening nature requires specialized CNC tooling and processes – a capability Wuxi Lead Precision Machinery has mastered to prevent tool wear and ensure dimensional accuracy in critical components.

Anodizing is the premier surface treatment for aluminum, transforming the natural oxide layer into a dense, corrosion-resistant, and electrically insulating barrier. Type II (sulfuric acid) anodizing is standard for enhanced wear resistance and dye acceptance for color coding. Type III (hardcoat) anodizing delivers extreme surface hardness for components subject to abrasion. Proper pre-treatment and process control, which our facility rigorously maintains, are vital for uniform thickness, adhesion, and meeting stringent Boston industry specs like MIL-A-8625.

Key material properties guide optimal selection for Boston fabrication projects:

| Material | Key Alloys | Tensile Strength (MPa) | Corrosion Resistance | Primary Boston Applications | Critical Fabrication Note |

|---|---|---|---|---|---|

| Aluminum | 5052, 6061-T6 | 193-310 | Excellent | Enclosures, Marine Hardware, Drones | Anodizing essential for max durability |

| Steel | 1008, 304, 316 | 300-900+ | Good (SS: Excellent) | Structural Frames, Medical Devices | Stainless requires clean tooling paths |

| Titanium | Gr 2, Gr 5 | 345-900 | Exceptional | Aerospace, Surgical Implants | Slow feeds/speeds; avoid contamination |

Selecting the correct material and finish is the first critical engineering decision. Wuxi Lead Precision Machinery provides expert consultation to match your Boston project’s environmental, mechanical, and regulatory demands with the optimal material solution, backed by our precision manufacturing processes and quality assurance protocols. Contact our engineering team for material-specific fabrication guidance.

Manufacturing Process & QC

Design: Precision Engineering from Concept to Blueprint

The foundation of any successful sheet metal fabrication project lies in meticulous design. At Wuxi Lead Precision Machinery, we begin with a collaborative engineering review, ensuring that every design is optimized for manufacturability, structural integrity, and cost-efficiency. Our team leverages advanced CAD/CAM software—SolidWorks, AutoCAD, and Siemens NX—to translate client concepts into precise 3D models and 2D technical drawings. Design for Assembly (DFA) and Design for Manufacturing (DFM) principles are applied rigorously to eliminate potential production bottlenecks. Tolerance analysis, material selection, and bend allowance calculations are conducted at this stage to prevent downstream errors. All designs undergo a formal review and approval process with the client before moving forward, ensuring alignment with functional and aesthetic requirements.

Prototyping: Validating Accuracy and Functionality

Once the design is finalized, we proceed to prototyping—a critical phase for verifying form, fit, and function. Utilizing high-precision laser cutting, CNC punching, and press brake forming, we produce functional prototypes that mirror the final product. These prototypes are subjected to rigorous dimensional inspection using coordinate measuring machines (CMM) and optical comparators to validate geometric accuracy. We also perform material testing and, when required, environmental and stress testing to assess durability. Feedback from prototype evaluation is integrated quickly, allowing for design refinements before mass production. This iterative approach minimizes risk and ensures that the final product meets all technical and quality standards. Our prototyping cycle typically delivers first-article samples within 7–10 business days, accelerating time-to-market for our clients.

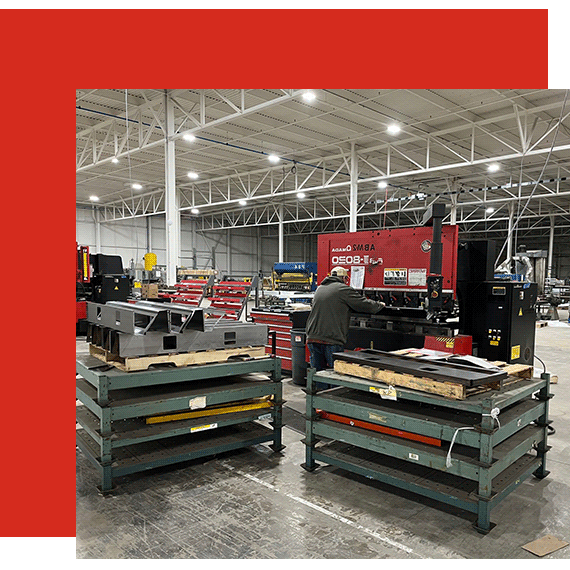

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we transition seamlessly into mass production. Our automated production lines integrate laser cutting, CNC turret punching, robotic bending, and automated welding systems to ensure consistency and efficiency. Each stage of production is governed by a comprehensive Quality Management System compliant with ISO 9001:2015 standards. In-process inspections, statistical process control (SPC), and real-time monitoring are employed to maintain dimensional accuracy and detect deviations instantly. Our zero-defect philosophy is enforced through a multi-tiered inspection protocol, including first-article inspection, in-line checks, and final 100% functional and visual inspection. Traceability is maintained through batch coding and digital production logs, enabling full accountability.

The following table outlines key capabilities and tolerances achievable across our production process:

| Parameter | Capability | Tolerance Range |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm | ±0.1 mm |

| Laser Cutting Accuracy | Up to 4000W fiber laser | ±0.05 mm |

| CNC Punching | Max 2.5 m x 1.5 m sheet | ±0.1 mm |

| Press Brake Forming | Up to 1000-ton capacity | ±0.2° angular, ±0.1 mm |

| Welding Processes | MIG, TIG, Spot, Robotic | AWS D1.1 compliant |

| Surface Finishes | Powder coating, anodizing, plating, passivation | Per customer specification |

From design to delivery, Wuxi Lead ensures every fabricated component meets the highest standards of precision and reliability—enabling Boston’s advanced manufacturing sector to build with confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Sheet Metal Excellence in Boston

Boston’s advanced manufacturing sector demands precision, reliability, and seamless supply chain integration. As your dedicated sheet metal fabrication partner, Wuxi Lead Precision Machinery bridges global capability with localized responsiveness. We specialize in high-tolerance components for aerospace, medical device, and defense applications—sectors where Boston thrives. Our ISO 9001-certified facility in China operates under stringent U.S. quality standards, ensuring every bracket, housing, or enclosure meets your exact engineering specifications. Unlike regional vendors constrained by capacity or technology, we deploy cutting-edge Amada and Trumpf systems to deliver complex geometries at scale, without compromising on lead times or cost efficiency. This global scale with precision focus eliminates the trade-offs Boston engineers often face.

Our technical capabilities are engineered for Boston’s most demanding projects. The table below outlines our core sheet metal specifications:

| Specification | Detail |

|---|---|

| Material Types | Aluminum 5052/6061, Stainless 304/316, Cold Rolled Steel, Brass |

| Tolerance Range | ±0.005 mm (0.0002″) for critical features |

| Max Sheet Size | 2000 x 4000 mm (78.7 x 157.5 inches) |

| Equipment | Amada Pega 367, Trumpf TruLaser 5030, CNC Press Brakes |

| Lead Time | 2–4 weeks (varies by complexity) |

| Finishing Options | Anodizing, Powder Coating, Passivation, Welding |

We understand Boston manufacturers prioritize supply chain transparency. Our dedicated U.S.-based project managers—fluent in English and engineering terminology—provide real-time production updates via cloud-based tracking. Every component undergoes first-article inspection per AS9102 or ISO 13485 protocols, with full documentation delivered digitally. This eliminates import delays and quality ambiguities common with offshore partners. For time-sensitive medical or defense contracts, we maintain buffer stock for critical components, ensuring your assembly lines never stall.

Partnering with Lead Precision means accessing Tier-1 aerospace-grade fabrication without geographic constraints. We absorb all international logistics complexity, delivering DDP (Delivered Duty Paid) to your Boston facility. Our engineers collaborate during your design phase to optimize manufacturability, reducing material waste by up to 18% while enhancing structural integrity. This proactive approach has helped Boston-based clients like robotics innovators and satellite subsystem makers accelerate time-to-market by 22% on average.

Do not let supply chain limitations hinder your next breakthrough. Contact us today to discuss how our precision sheet metal solutions can elevate your Boston operations. Email [email protected] with your project specifications and timeline. Our engineering team will respond within 4 business hours with a feasibility assessment and competitive quotation. Let us prove why leading Boston manufacturers trust Lead Precision for components where tolerance consistency is non-negotiable. Your vision, engineered to perfection—without borders.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.