Technical Contents

Engineering Guide: Metal Enclosures For Electronics

Engineering Insight: Metal Enclosures for Electronics

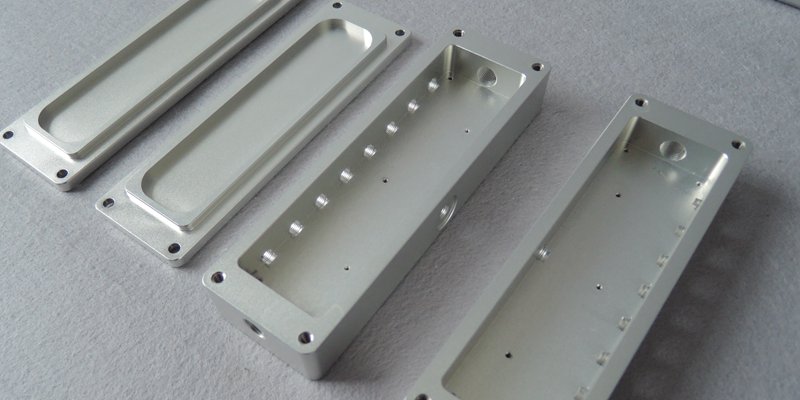

In the realm of advanced electronics, the enclosure is far more than a protective shell—it is a critical engineering component that ensures performance, reliability, and longevity. At Wuxi Lead Precision Machinery, we recognize that precision in metal enclosure manufacturing is not optional; it is foundational. Even micron-level deviations can compromise electromagnetic shielding, thermal management, or mechanical integration, leading to system failure in high-stakes environments.

Our approach to metal enclosures for electronics is rooted in aerospace-grade standards and military-grade tolerances. With over 15 years of specialized experience in custom metal manufacturing, we have engineered enclosures for applications ranging from onboard defense systems to critical infrastructure in Olympic broadcast networks. These projects demand absolute precision, not only in dimensional accuracy but also in material consistency, weld integrity, and surface finish. Our CNC fabrication processes are calibrated to maintain tolerances as tight as ±0.02 mm, ensuring seamless fit and function across complex electronic assemblies.

Precision begins at the design stage. We employ advanced 3D modeling and finite element analysis (FEA) to simulate thermal expansion, vibration resistance, and structural load under real-world conditions. This predictive engineering allows us to optimize wall thickness, mounting configurations, and aperture placements before a single cut is made. Our multi-axis laser cutting, precision bending, and automated welding systems then translate these designs into physical enclosures with repeatable accuracy.

Material selection is equally critical. For electronic enclosures, we commonly utilize aluminum alloys (such as 5052 and 6061) for their excellent strength-to-weight ratio and inherent corrosion resistance, or cold-rolled steel (SPCC) when enhanced EMI shielding is required. All materials are sourced from certified suppliers and undergo rigorous incoming inspection to ensure compliance with international standards.

Surface treatment plays a pivotal role in both performance and durability. Our standard finishes include electrostatic powder coating for superior insulation and abrasion resistance, as well as anodizing for aluminum enclosures used in outdoor or high-humidity environments. Custom grounding points, EMI gasket integration, and precision-threaded inserts are added with exacting control to support reliable electrical continuity and modular assembly.

The following table outlines key specifications achievable through our manufacturing process:

| Parameter | Capability | Standard Tolerance |

|---|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm | ±0.1 mm |

| Dimensional Accuracy | Up to ±0.02 mm | ISO 2768-m |

| Bend Tolerance | ±0.2° | Per DIN 6930 |

| Welding Precision | TIG/MIG with distortion control | < 0.3 mm deviation |

| Surface Roughness (post-treat) | Ra ≤ 1.6 µm | Measured per ISO 4287 |

| Coating Thickness | 60–80 µm (powder coat) | ASTM D7091 compliant |

At Wuxi Lead Precision Machinery, we treat every enclosure as a mission-critical component. Our experience in serving defense and high-profile international events has instilled a culture of zero-defect manufacturing. When electronics operate at the edge of performance, their metal enclosures must meet no less than perfection.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Metal Enclosures

At Wuxi Lead Precision Machinery, we engineer mission-critical metal enclosures for demanding electronics applications where dimensional stability, EMI shielding, and thermal management are non-negotiable. Our integrated manufacturing ecosystem combines cutting-edge hardware with rigorous process control to deliver enclosures that meet aerospace, medical, and industrial automation standards. Central to our capability is a dedicated fleet of 5-axis CNC machining centers featuring high-torque spindles, sub-micron linear encoders, and collision-avoidance systems. This technology enables single-setup machining of complex geometries—including integrated heat sinks, threaded inserts, and hermetic sealing surfaces—eliminating cumulative errors from multiple fixtures. Material utilization is optimized through dynamic toolpath simulation, reducing waste in costly aluminum alloys, stainless steels, and copper-beryllium composites.

Precision is validated through our multi-stage quality assurance protocol. Every enclosure undergoes 100% CMM inspection using Zeiss CONTURA systems with temperature-stabilized granite beds, ensuring measurements adhere to ISO 10360-2 standards. Critical features are verified against 3D CAD models with GD&T callouts, while surface finishes are quantified via profilometry to meet Ra 0.4–1.6 μm requirements. Material certifications, first-article reports, and full CMM datasets are provided with each shipment, enabling full traceability from raw billet to finished component.

Our tolerance execution reflects decades of refinement in electronics enclosure production. The following table details achievable specifications across common materials and feature types:

| Feature Type | Typical Tolerance | Tight Tolerance Capability | Material Constraints |

|---|---|---|---|

| Overall Dimensions | ±0.05 mm | ±0.01 mm | Aluminum, Steel ≤ 600 mm |

| Critical Holes (Ø) | ±0.025 mm | ±0.005 mm | All metals |

| Flatness (per 100 mm) | 0.05 mm | 0.01 mm | Max area 300×300 mm |

| Threaded Inserts | Position ±0.03 mm | Position ±0.01 mm | Requires pre-tapped holes |

| Mating Surface Gap | ≤ 0.05 mm | ≤ 0.02 mm | Critical for EMI shielding |

Beyond machining, we implement stress-relief cycles for thin-walled structures and perform in-process deburring to eliminate micro-burrs that compromise gasket sealing. Our engineers collaborate early in your design phase to optimize manufacturability—suggesting strategic ribbing for rigidity or adjusting draft angles for seamless anodizing. This proactive approach prevents costly revisions while ensuring enclosures withstand vibration, thermal cycling, and corrosive environments.

Wuxi Lead transforms enclosure specifications into field-proven reliability. By merging 5-axis precision with uncompromising metrology, we deliver components where every micron contributes to system integrity. Contact our engineering team to discuss tolerance-critical applications—we’ll provide a feasibility assessment within 48 hours.

Material & Finish Options

Material Selection for High-Performance Metal Enclosures in Electronics

Selecting the appropriate material for electronic enclosures is critical to ensuring long-term reliability, environmental resistance, and structural integrity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the demanding requirements of advanced electronics applications. The most commonly used materials in our production—aluminum, steel, and titanium—each offer distinct advantages depending on the operational environment, weight constraints, and performance expectations.

Aluminum is the preferred choice for a broad range of electronic enclosures due to its excellent strength-to-weight ratio, natural corrosion resistance, and high thermal and electrical conductivity. It is particularly well-suited for applications requiring lightweight construction without sacrificing durability, such as portable medical devices, aerospace systems, and industrial control units. When enhanced surface protection is needed, aluminum responds exceptionally well to anodizing, a controlled electrochemical process that increases surface hardness and wear resistance while allowing for color coding and improved aesthetics.

Steel, especially in its stainless or cold-rolled forms, provides superior mechanical strength and electromagnetic interference (EMI) shielding. It is ideal for heavy-duty industrial environments where impact resistance and long-term structural stability are paramount. While heavier than aluminum, steel offers excellent protection against physical damage and harsh chemical exposure, making it suitable for outdoor enclosures, power distribution units, and military-grade electronics.

Titanium, though more costly, delivers unmatched performance in extreme conditions. With exceptional corrosion resistance—even in saltwater environments—and a strength-to-density ratio superior to both aluminum and steel, titanium is used in mission-critical applications such as deep-sea instrumentation, aerospace avionics, and high-reliability defense systems. Its biocompatibility also makes it a candidate for implantable medical electronics.

Surface finishing plays a vital role in enhancing both functionality and appearance. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that resists abrasion and environmental degradation. This finish can be dyed in various colors for branding or coding purposes and is available in different thicknesses to meet MIL-STD or industrial standards.

Below is a comparative overview of key material properties to guide selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Electrical Conductivity | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 200–300 | High | High | Anodizing, Powder Coating |

| Steel (Stainless) | 7.9 | 500–700 | Very High | Moderate | Passivation, Plating |

| Titanium | 4.5 | 900–1,100 | Exceptional | Low | Bead Blasting, Anodizing |

At Wuxi Lead Precision Machinery, we support material and finish selection with in-house engineering consultation, prototyping, and full-scale precision fabrication. Our expertise ensures that every enclosure meets the exact mechanical, thermal, and environmental demands of your application.

Manufacturing Process & QC

Precision Metal Enclosure Production: Design to Zero Defects Execution

At Wuxi Lead Precision Machinery, our end-to-end production process for custom electronic metal enclosures integrates rigorous engineering discipline with advanced manufacturing to guarantee zero-defect deliverables. This systematic approach spans three critical phases, ensuring your enclosure meets exact functional, environmental, and aesthetic requirements while maintaining cost efficiency at scale.

The Design phase begins with collaborative engineering workshops. Our team conducts in-depth Design for Manufacturability (DFM) analysis on your CAD models, identifying potential stress points, weld accessibility issues, or tolerance stack-ups before metal is cut. We optimize material selection—aluminum alloys like 6061-T6 or 5052, stainless steel 304/316, or cold-rolled steel—based on your environmental demands (IP67 sealing, EMI shielding, thermal management). Critical features such as mounting bosses, cable glands, and grounding points are validated through FEA simulation, ensuring structural integrity under operational loads. This phase culminates in a finalized, production-ready drawing package with explicit Geometric Dimensioning and Tolerancing (GD&T) callouts.

Prototyping transforms validated designs into physical reality using our 5-axis CNC milling and laser cutting centers. We produce 1-5 functional units for comprehensive validation. Dimensional accuracy is verified via Coordinate Measuring Machine (CMM) inspection against the master CAD model, with deviations documented in First Article Inspection (FAI) reports per AS9102 standards. Enclosures undergo functional testing: thermal cycling, vibration analysis, and ingress protection validation. Surface finish quality—whether anodized, powder-coated, or bead-blasted—is assessed against RAL or Pantone references. Client feedback on these prototypes drives final micro-adjustments, eliminating downstream rework risks.

Mass Production leverages our automated production cells under real-time Statistical Process Control (SPC). Each batch begins with material certification checks against ASTM/EN standards. CNC machining centers operate with tool-wear monitoring and in-process probing, ensuring micron-level consistency. Automated welding cells use gas-shielded TIG or laser processes with post-weld CMM verification of critical seams. Final assembly includes precision insertion of EMI gaskets, captive fasteners, and nameplates under ISO Class 8 cleanroom conditions where required. Every enclosure undergoes 100% functional testing and final dimensional audit before shipment, with full traceability of materials, processes, and inspection data.

Our commitment to zero defects is quantifiable through these controlled specifications:

| Parameter | Standard Tolerance | Precision Option | Measurement Method |

|---|---|---|---|

| Material Thickness | ±0.1 mm | ±0.05 mm | Ultrasonic Gauge |

| Dimensional Tolerance | ±0.05 mm | ±0.02 mm | CMM (ISO 10360-2) |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | Profilometer (ISO 4287) |

| Coating Thickness | 25-40 μm | 50-70 μm | Eddy Current (ASTM B244) |

This closed-loop process—from engineering validation through to certified mass production—ensures your electronic enclosure performs flawlessly in the field, backed by Wuxi Lead’s decades of aerospace-grade manufacturing excellence. We deliver not just parts, but guaranteed operational readiness.

Why Choose Wuxi Lead Precision

When it comes to high-performance metal enclosures for electronics, precision, durability, and customization are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering engineered metal solutions tailored to the exacting demands of advanced electronics integration. As a trusted partner in custom metal manufacturing, we combine decades of industrial expertise with state-of-the-art fabrication technology to ensure your enclosures meet the highest standards of performance and reliability.

Our advanced production capabilities include laser cutting, CNC bending, robotic welding, and precision surface finishing—all conducted under strict quality control protocols. Whether you require compact housings for sensitive control modules or large-scale enclosures for industrial automation systems, our team works closely with your engineering staff from concept to completion. We understand that every application presents unique challenges, from thermal management and EMI shielding to ingress protection and structural integrity. That’s why every enclosure we produce is not just manufactured—it’s engineered.

Partnering with Wuxi Lead Precision means gaining access to a flexible, responsive, and scalable manufacturing partner. We support low-volume prototyping and high-volume production with equal efficiency, ensuring rapid turnaround without compromising quality. Our facility in Wuxi, China, is equipped to handle a wide range of materials, including aluminum, stainless steel, and galvanized steel, allowing us to match your specific environmental and functional requirements.

We pride ourselves on transparency, technical accountability, and long-term collaboration. Our engineering team provides DFM analysis, 3D modeling support, and material optimization recommendations to streamline your product development cycle and reduce total cost of ownership. With full traceability, ISO-compliant processes, and in-house quality inspection, we ensure every component meets international standards and your internal specifications.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Material Options | Aluminum (5052, 6061), Stainless Steel (304, 316), Galvanized Steel, Cold-Rolled Steel |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance | ±0.1 mm (laser cutting), ±0.2° (bending) |

| Max Working Area | 3000 mm × 1500 mm (laser cutting) |

| Surface Finishes | Powder coating, anodizing, zinc plating, passivation, brushed, sandblasting |

| Certifications | ISO 9001:2015, RoHS compliant |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

Your electronics deserve enclosures built with precision, integrity, and forward-thinking engineering. At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver solutions that enhance your product’s performance and market competitiveness.

Take the next step toward a smarter, more reliable manufacturing partnership. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation. Let us help you turn your design challenges into engineered success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.