Technical Contents

Engineering Guide: Metal Bending Shop

Engineering Insight: The Critical Role of Precision in Metal Bending Operations

In high-end custom metal manufacturing, the bending process is far more than a simple forming operation—it is a decisive phase where material integrity, dimensional accuracy, and structural performance converge. At Wuxi Lead Precision Machinery, we treat metal bending not as a standalone task but as a precision engineering discipline, where tolerances measured in fractions of a millimeter directly influence the functionality and reliability of the final product. This level of control is non-negotiable in industries such as aerospace, defense, and advanced industrial equipment, where failure is not an option.

Precision in metal bending begins with material understanding. Different alloys respond uniquely to stress, spring-back, and forming forces. Our engineering team conducts comprehensive material analysis prior to any bending operation, ensuring that tooling, bend angles, and sequence are optimized for the specific grade and thickness. This preemptive approach eliminates guesswork and ensures repeatability across production runs.

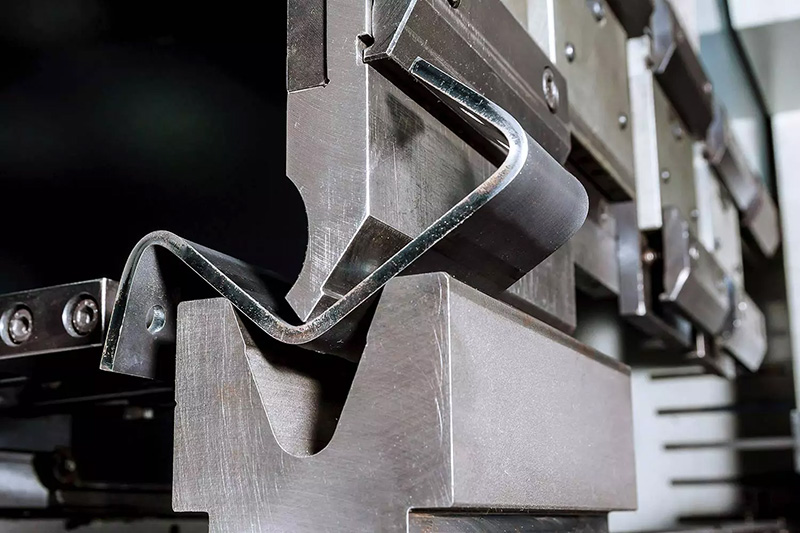

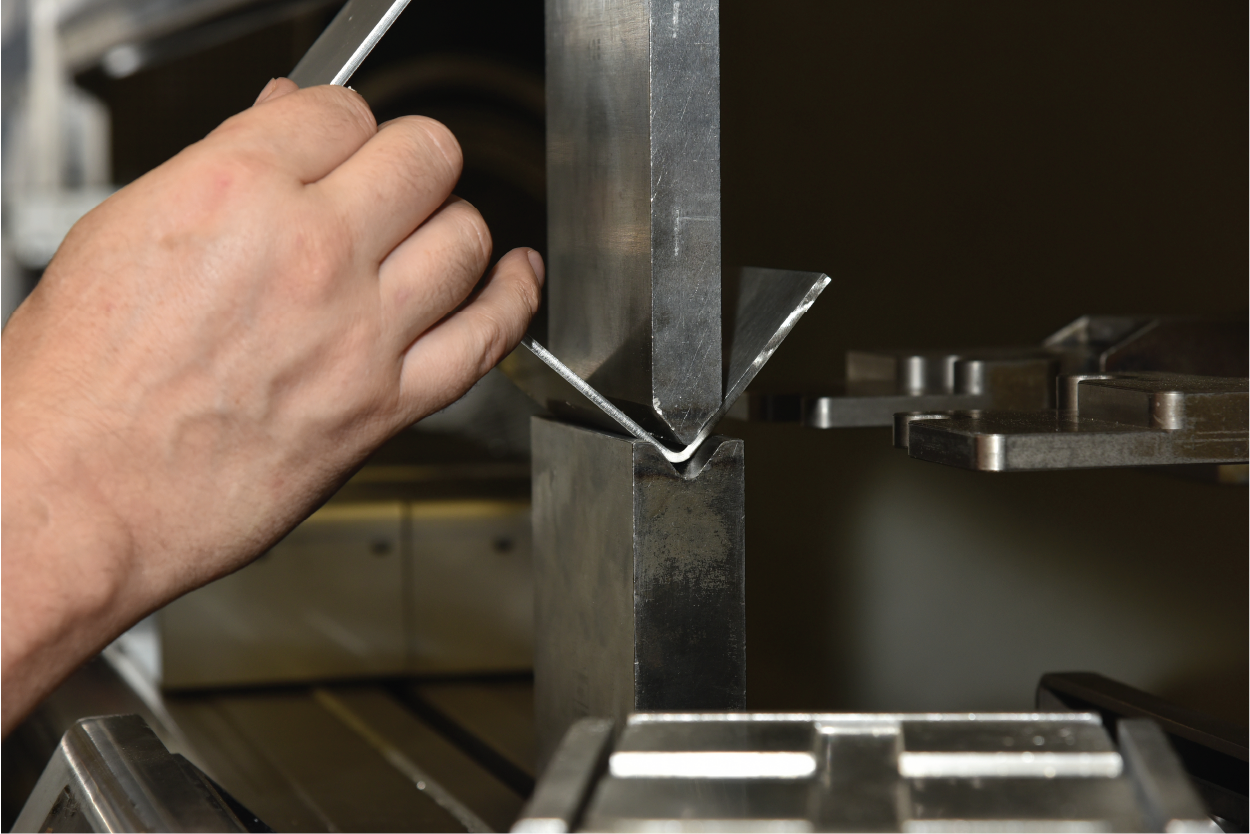

Our CNC-controlled press brakes, equipped with real-time feedback systems and laser-guided positioning, deliver consistent accuracy down to ±0.1 degrees in angular tolerance and ±0.05 mm in linear dimension. These systems are calibrated daily and operate within ISO 9001-certified processes, ensuring that every bend meets the exact specifications of the design. But technology alone does not guarantee excellence. At Lead Precision, decades of hands-on experience—forged through projects for Olympic-standard equipment and military-grade components—inform every decision on the shop floor. These high-stakes applications demanded zero-defect performance, teaching us how to anticipate and mitigate risks before they manifest.

One of the most critical aspects of precision bending is the management of spring-back—the elastic recovery of metal after bending. Without accurate compensation, even the most advanced machine can produce out-of-spec parts. Our proprietary algorithms, developed through years of empirical testing, dynamically adjust punch depth and pressure to counteract material behavior, ensuring the final angle matches the design intent.

We also emphasize fixturing and support tooling. Improper support during bending leads to distortion, especially in long or thin workpieces. Custom clamping systems and precision-ground tooling blocks are deployed as needed to maintain part stability and surface integrity.

At the heart of our metal bending capability is a culture of accountability and continuous improvement. Every operator is trained not just to run machines, but to understand the engineering principles behind them. This integration of skill, technology, and process discipline is what allows us to deliver components that meet the most stringent international standards.

Below are key specifications representative of our metal bending capabilities:

| Parameter | Specification |

|---|---|

| Maximum Bending Force | 1250 tons |

| Angular Accuracy | ±0.1 degrees |

| Length Tolerance | ±0.05 mm per 300 mm |

| Material Thickness Range | 0.5 mm – 25 mm |

| Maximum Bending Length | 6000 mm |

| CNC Control System | Delem DA-66T with 3D simulation |

| Tooling Compatibility | Standard and custom segmented tooling |

| Quality Standards | ISO 9001, MIL-STD-810, GB/T 19001 |

Precision in metal bending is not an outcome—it is engineered. At Wuxi Lead Precision Machinery, we bring together advanced technology, rigorous process control, and deep domain expertise to ensure every bend meets the highest standard of performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Bending & Fabrication

Wuxi Lead Precision Machinery delivers advanced metal bending solutions engineered for complex, high-tolerance components demanded by aerospace, medical, and industrial OEMs. Our integrated manufacturing cell centers on state-of-the-art 5-axis CNC press brakes, enabling intricate geometries and tight tolerances unattainable with conventional 3-axis systems. This capability allows simultaneous bending along multiple vectors within a single setup, significantly reducing handling errors and secondary operations for parts requiring compound angles, offsets, or nested features. All equipment undergoes rigorous daily calibration and preventive maintenance per ISO 9001 protocols, ensuring consistent machine performance and longevity critical for high-mix, low-volume production.

Material versatility is fundamental to our service. We process a comprehensive range of metals including carbon steel, stainless steel (304, 316), aluminum alloys (5052, 6061, 7075), copper, and brass, accommodating thicknesses from 0.5 mm to 12.7 mm (0.020″ to 0.500″). Our CNC bending cells feature advanced adaptive control systems that dynamically adjust tonnage and stroke based on real-time material feedback, minimizing springback and ensuring dimensional repeatability across diverse alloys and gauges. This precision is further guaranteed through our comprehensive quality control framework, anchored by Zeiss CONTURA G2 Coordinate Measuring Machine (CMM) inspection. Every critical feature undergoes 100% first-article inspection and periodic in-process verification against CAD models, validating form, fit, and positional accuracy to the most stringent customer specifications.

The foundation of our capability is quantifiable precision. The following table details our standard achievable tolerances for bent components, validated through CMM measurement and statistical process control (SPC) data:

| Feature | Material Range | Standard Tolerance | Reference Standard |

|---|---|---|---|

| Linear Dimension (Bend) | 0.5 mm – 12.7 mm | ±0.10 mm | ISO 2768-mK |

| Bend Angle | All Materials | ±0.1° | ISO 2768-f |

| Hole to Bend Position | All Materials | ±0.05 mm | ISO 2768-mK |

| Flatness | < 600 mm Length | 0.05 mm/m | ISO 2768-mK |

| Hole to Hole Position | All Materials | ±0.03 mm | ISO 2768-k |

These tolerances represent routine production capability under controlled conditions using certified tooling and validated processes. For mission-critical applications exceeding standard specifications, our engineering team collaborates directly with clients during DFMA reviews to implement enhanced process controls, specialized tooling, or additional inspection protocols. This commitment to measurable precision ensures components integrate seamlessly into final assemblies, reducing scrap rates and accelerating time-to-market for our global partners. Wuxi Lead’s technical infrastructure transforms complex design intent into reliably manufactured reality.

Material & Finish Options

Material Selection for Precision Metal Bending Applications

Selecting the appropriate material is critical in custom metal manufacturing, particularly when high precision, durability, and performance under stress are required. At Wuxi Lead Precision Machinery, we specialize in bending complex geometries from high-grade aluminum, steel, and titanium—each offering distinct mechanical properties and suitability for specific industrial applications. Understanding the behavior of these materials during and after the bending process ensures optimal performance, cost efficiency, and longevity of the final component.

Aluminum is widely used in aerospace, transportation, and electronics due to its excellent strength-to-weight ratio and corrosion resistance. It bends easily under controlled conditions and responds well to precision tooling. However, aluminum’s lower yield strength compared to steel requires careful handling to avoid cracking, especially in tight bend radii. Grade 6061-T6 is a common choice for structural components, offering good weldability and machinability post-forming.

Steel remains the backbone of heavy-duty manufacturing, favored for its high tensile strength, durability, and cost-effectiveness. Mild steel (e.g., ASTM A36) is highly formable and ideal for general fabrication, while high-strength low-alloy (HSLA) steels provide enhanced performance in demanding environments. Steel’s predictable springback behavior allows for accurate compensation during CNC bending, ensuring dimensional accuracy. For applications requiring superior wear resistance or structural integrity, steel is often the default choice.

Titanium, though more expensive and challenging to process, delivers unmatched performance in extreme conditions. Its exceptional strength-to-density ratio, coupled with outstanding resistance to corrosion and high temperatures, makes it ideal for aerospace, medical, and defense applications. Titanium requires specialized tooling and slower bending speeds due to its tendency to gall and work-harden rapidly. However, when precision and reliability are non-negotiable, titanium offers unparalleled value.

Post-bending surface finishes further enhance material performance. Anodizing, particularly for aluminum, increases surface hardness, improves corrosion resistance, and allows for color coding or aesthetic customization. Type II (sulfuric acid) anodizing is commonly used for decorative and protective finishes, while Type III (hardcoat anodizing) delivers thick, wear-resistant layers suitable for industrial components.

Below is a comparative overview of key material properties relevant to the bending process:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Bend Radius (Min. Recommended) | Common Grades |

|---|---|---|---|---|---|

| Aluminum | 310 | 275 | 12 | 1.5 x thickness | 6061-T6, 5052-H32 |

| Mild Steel | 400–550 | 250 | 20 | 1.0 x thickness | ASTM A36, Q235 |

| HSLA Steel | 550–700 | 350–500 | 15 | 1.5 x thickness | ASTM A572, Q355 |

| Titanium | 900 | 830 | 10 | 3.0 x thickness | Grade 5 (Ti-6Al-4V) |

At Wuxi Lead Precision Machinery, we combine advanced CNC press brakes with material science expertise to ensure every bend meets exact specifications. Our engineering team supports clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and production volume.

Manufacturing Process & QC

Precision Metal Bending: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, our production process for custom metal bending is engineered for uncompromising quality and efficiency, ensuring zero defects from initial concept to final shipment. We understand that high-end manufacturing demands absolute reliability; our integrated workflow eliminates guesswork and mitigates risk at every stage.

The journey begins with meticulous Design engineering. Our team collaborates closely with clients using advanced CAD/CAM software to translate specifications into optimized bending sequences. Crucially, we conduct rigorous Design for Manufacturability (DFM) analysis upfront. This proactive step identifies potential material stress points, tooling conflicts, or geometric complexities before physical work commences, preventing costly revisions later. Client approval of the finalized digital model and bending plan is mandatory, establishing a clear, defect-proof baseline for all subsequent phases.

Prototyping follows immediately, utilizing the exact production-grade materials and tooling intended for full-scale manufacturing. This is not merely a sample check; it is a critical validation step. Every bend angle, hole placement, and surface finish undergoes metrology-grade inspection against the approved design. Any micro-discrepancy triggers immediate process refinement. Only when the prototype meets or exceeds all dimensional and functional tolerances—verified by our CMM and laser scanning systems—does the project advance. This stage transforms theoretical design into proven manufacturability.

Mass production leverages the validated process with industrial-scale precision. Our state-of-the-art press brakes, featuring CNC control and real-time angle monitoring, execute bending sequences with micron-level repeatability. Automated material handling minimizes human error, while integrated Statistical Process Control (SPC) systems continuously analyze key parameters like tonnage, backgauge position, and bend angle. Any deviation beyond our stringent control limits triggers instant machine correction or halts production. Final inspection employs 100% critical dimension checks and batch sampling for non-critical features, guaranteeing every component shipped meets the zero-defect standard demanded by aerospace, medical, and high-tech industries.

Our equipment capabilities underpin this rigorous methodology. The following table details core specifications ensuring consistent output:

| Parameter | Capability | Tolerance Range |

|---|---|---|

| Max. Bending Force | 3000 Tons | N/A |

| Material Thickness | 0.5 mm – 25 mm | ±0.1 mm |

| Max. Bend Length | 6000 mm | ±0.5 mm over length |

| Angular Accuracy | CNC-controlled with feedback | ±0.25° |

| Repeatability | SPC-monitored production runs | ±0.1° |

Zero defects is not an aspiration at Wuxi Lead; it is the non-negotiable outcome of our disciplined Design-Prototyping-Production protocol. We deliver certainty in metal fabrication.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Custom Metal Bending Solutions

When precision, consistency, and engineering excellence define your production standards, partnering with a trusted leader in custom metal manufacturing is not just an advantage—it’s a necessity. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance metal bending solutions tailored to the exacting demands of global industries, from aerospace and automotive to industrial equipment and energy infrastructure. Our advanced manufacturing capabilities, combined with decades of engineering experience, position us as the ideal strategic partner for businesses seeking reliable, scalable, and precision-driven metal fabrication.

Our state-of-the-art facility in Wuxi, China, is equipped with next-generation CNC press brakes, automatic panel benders, and robotic handling systems, enabling us to achieve tight tolerances, complex geometries, and repeatable quality across high-volume and low-volume production runs. Every component we produce is subject to rigorous quality control protocols, including laser measurement, material traceability, and in-process inspections, ensuring full compliance with international standards such as ISO 9001 and IATF 16949.

We understand that no two projects are the same. That’s why our engineering team works closely with clients from the design phase through final delivery, offering DFM (Design for Manufacturability) analysis, prototype development, and rapid turnaround times. Whether you require simple bends or multi-stage forming of high-strength steel, aluminum, or specialty alloys, our processes are calibrated to meet your specifications with zero compromise.

Our commitment extends beyond manufacturing. We offer end-to-end supply chain support, including just-in-time delivery, kitting, and global logistics coordination, helping you reduce lead times and inventory costs. With a production capacity exceeding 10,000 tons annually and a flexible production model, we scale with your business—whether you’re launching a pilot project or ramping up for mass production.

Below are key technical capabilities that define our metal bending expertise:

| Specification | Detail |

|---|---|

| Bending Capacity | Up to 300 tons |

| Maximum Bending Length | 3,200 mm |

| Material Thickness Range | 0.5 mm – 12 mm |

| Tolerance Accuracy | ±0.1 mm |

| Minimum Bend Radius | 1x material thickness (depending on alloy) |

| CNC Press Brakes | 15+ units with 3D backgauging and laser alignment |

| Supported Materials | Carbon steel, stainless steel, aluminum, copper, brass |

| Finishing Options | Deburring, grinding, powder coating coordination |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally focused on precision, reliability, and long-term value. We don’t just meet specifications—we anticipate challenges and engineer solutions before they arise.

For immediate assistance or to discuss your next project, contact us at [email protected]. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.