Technical Contents

Engineering Guide: Medical Precision Machining

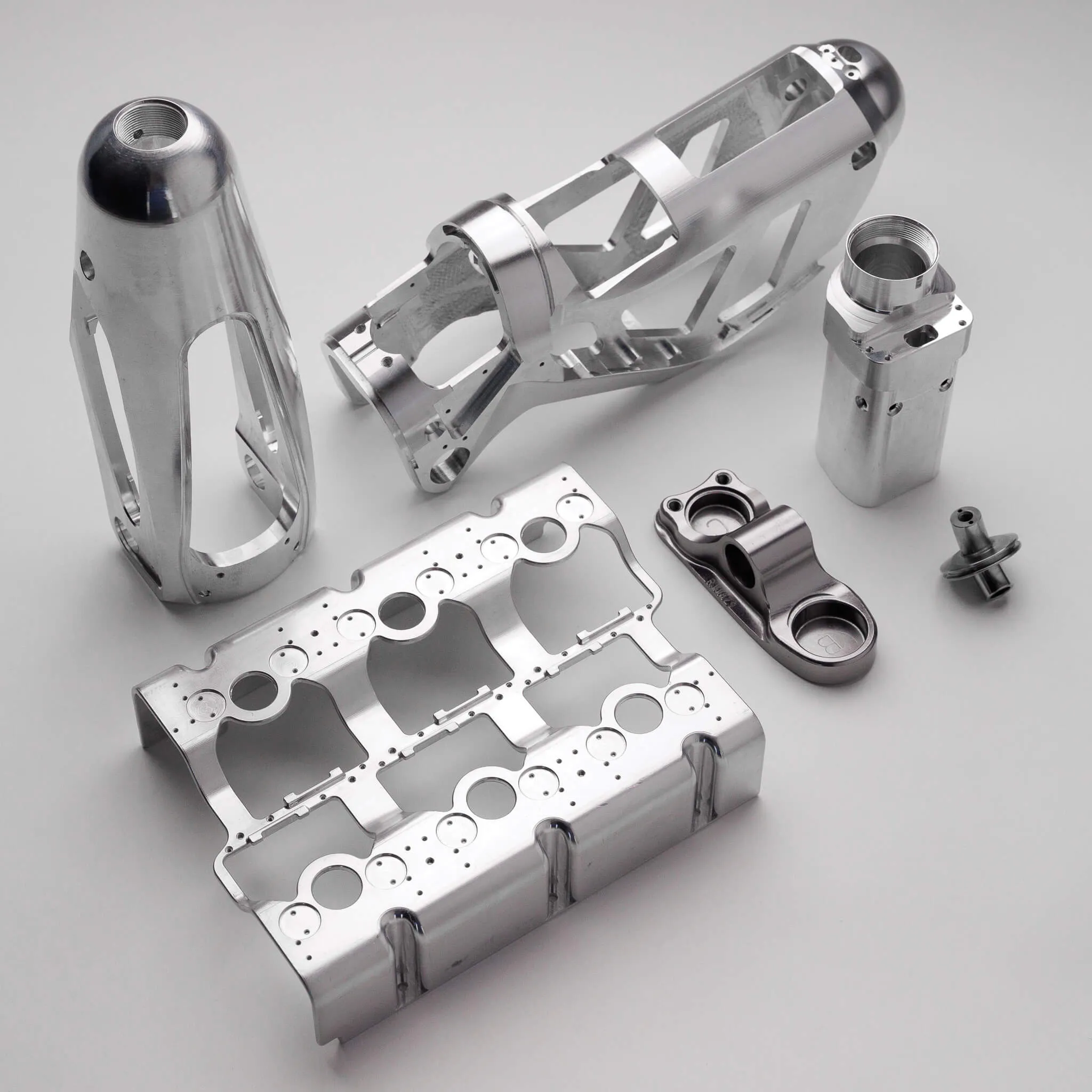

Engineering Insight Precision as the Non-Negotiable Standard in Medical Device Manufacturing

In the realm of medical device manufacturing, precision transcends mere specification; it is the fundamental pillar upon which patient safety, device efficacy, and regulatory compliance rest. Components for surgical instruments, orthopedic implants, neurostimulators, and diagnostic equipment demand tolerances measured in microns. A variance of even 0.0002 inches can compromise biocompatibility, induce premature wear, alter fluid dynamics in microfluidic channels, or render an implant unstable within the human body. The consequences of imprecision are not operational inefficiencies but potential patient harm and catastrophic device failure. This uncompromising requirement necessitates machining capabilities operating at the absolute edge of technological possibility, where thermal stability, vibration control, and sub-micron measurement repeatability are not optional features but baseline expectations. Material integrity must be preserved throughout the process, as secondary operations or residual stress can introduce weaknesses invisible to standard inspection but critical in vivo.

Wuxi Lead Precision Machinery operates within this zero-failure environment daily. Our engineering philosophy is forged in sectors where absolute reliability is paramount: Olympic timing systems demanding microsecond synchronization and military aerospace components subjected to extreme operational stresses. This heritage directly translates to medical manufacturing. We understand that the titanium acetabular cup destined for a hip replacement or the platinum-iridium electrode array for a neural implant requires the same rigorous process validation, material traceability, and dimensional scrutiny as a guidance system component. Our CNC platforms, maintained within ISO Class 7 cleanroom environments where required, are calibrated and monitored to achieve and verify tolerances consistently below ±0.0001 inches. Advanced metrology, including multi-sensor CMMs and optical comparators, is integrated into every production phase, not merely as final inspection, but as a continuous feedback loop ensuring process stability. Material expertise spans medical-grade stainless steels (316LVM, 17-4PH), titanium alloys (Ti-6Al-4V ELI), cobalt-chromium, and specialized alloys, processed under strict protocols to maintain biocompatibility and mechanical properties.

Our experience demonstrates that achieving medical-grade precision requires more than advanced machinery; it demands an ingrained culture of quality and deep process understanding. The following table outlines core capabilities essential for critical medical applications:

| Parameter | Capability | Application Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.0001 inches (2.5 μm) | Ensures perfect fit of implants, instrument articulation |

| Surface Finish | Ra 0.2 μm (8 μin) and below | Critical for biocompatibility, reduces tissue irritation |

| Material Expertise | Medical Ti, CoCr, Stainless Steels, Nitinol | Meets ASTM/ISO standards for implant safety |

| Process Validation | Full PPAP, ISO 13485 compliant | Mandatory for regulatory submissions (FDA, CE) |

| Cleanroom Machining | ISO Class 7 available | Prevents contamination for sterile devices |

Precision in medical machining is not a technical detail; it is the absolute prerequisite for trust. At Wuxi Lead Precision Machinery, our proven execution in the world’s most demanding precision environments provides the engineering certainty medical device innovators require. Partner with us to transform your most complex medical component designs into reality, manufactured to the exacting standards where human health is the ultimate metric. Consult our engineering team to discuss your specific tolerance challenges and validation requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the field of medical precision machining, engineered to meet the stringent demands of the global healthcare industry. Our expertise lies in producing complex, high-integrity metal components for surgical instruments, implantable devices, diagnostic equipment, and minimally invasive technologies. Every process is executed under strict ISO 13485-certified protocols, ensuring full compliance with medical device manufacturing standards.

At the core of our precision machining capability is a modern fleet of 5-axis CNC machining centers. These multi-axis systems enable simultaneous movement across five planes, allowing for the production of geometrically intricate parts in a single setup. This eliminates cumulative error from multiple fixturing stages and ensures superior dimensional accuracy. Our machines support a wide range of medical-grade alloys, including titanium (Ti-6Al-4V), stainless steel (316L, 17-4 PH), cobalt-chrome, and specialized aluminum alloys. The 5-axis platform also allows for optimal tool approach angles, improving surface finish and reducing cycle times—critical factors in high-mix, low-volume medical production.

Our machining processes are supported by a comprehensive quality control infrastructure centered on Coordinate Measuring Machine (CMM) inspection. Each component undergoes full dimensional verification using Zeiss and Mitutoyo CMM systems, programmed to inspect complex contours, thread forms, hole patterns, and critical datum relationships. These systems provide traceable, high-resolution data that is documented in detailed First Article Inspection (FAI) reports and batch-specific quality dossiers. In addition to CMM, we employ optical comparators, surface roughness testers, and metallurgical analysis tools to validate material properties and process consistency.

To ensure repeatability and process stability, we utilize Statistical Process Control (SPC) methodologies across all production runs. Real-time monitoring of tool wear, spindle load, and environmental conditions ensures that deviations are detected and corrected before impacting output quality. Our engineers work closely with clients during the Design for Manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance allocation—reducing cost and accelerating time to market.

The following table outlines our standard precision machining tolerances, which can be further refined based on application requirements:

| Feature | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.005 |

| Hole Diameter (mm) | ±0.012 | ±0.003 |

| Positional Tolerance (mm) | ±0.015 | ±0.008 |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Angular Tolerance (°) | ±0.1 | ±0.05 |

| Flatness (mm) | 0.01 per 100 mm | 0.005 per 100 mm |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade inspection to deliver medical components that meet the highest benchmarks in precision and reliability. Our technical capabilities are designed not only to meet specifications but to ensure long-term performance in life-critical applications.

Material & Finish Options

Material Selection for Medical Precision Machining

Selecting optimal materials and finishes is critical in medical device manufacturing where biocompatibility, corrosion resistance, and dimensional stability directly impact patient safety and regulatory compliance. At Wuxi Lead Precision Machinery, we prioritize materials meeting ASTM F86 surface preparation standards and ISO 13485 requirements to ensure traceability and performance in sterile environments. Aluminum alloys like 6061-T6 offer lightweight strength for non-implant surgical instruments and housings but require protective finishes due to limited corrosion resistance. Stainless steel 316L remains the industry benchmark for implants and reusable instruments, leveraging molybdenum-enhanced pitting resistance against saline and chemical sterilants. Titanium Grade 5 (Ti-6Al-4V) excels in permanent implants owing to its bone-osseointegration properties and exceptional strength-to-weight ratio, though its low thermal conductivity demands specialized CNC toolpaths to prevent galling.

Each material presents unique machining challenges. Aluminum necessitates sharp carbide tools and high-speed parameters to avoid burring on thin-walled components. 316L stainless requires rigid setups and controlled feeds to minimize work hardening during complex geometries like bone screws. Titanium machining demands reduced cutting speeds, consistent coolant flow, and anti-galling coatings to manage heat buildup during deep cavity milling. Surface integrity is non-negotiable; Ra values must consistently achieve ≤0.8 μm to prevent bacterial adhesion per FDA guidance.

Anodizing transforms aluminum’s surface for medical use. Type II (sulfuric acid) anodizing provides moderate wear resistance for external device housings, while Type III (hardcoat) anodizing delivers 50–70 μm thickness with Rockwell C60+ hardness for instrument trays subjected to repeated autoclaving. Both processes must exclude dyes containing heavy metals and include rigorous sealing per AMS 2469 to eliminate porosity. Critical validation includes adhesion testing via ASTM D3359 and biocompatibility screening per ISO 10993-5.

Material specifications guide critical decisions:

| Material | Key Properties | Medical Applications | Critical Machining Notes |

|---|---|---|---|

| Aluminum 6061-T6 | 310 MPa tensile strength, 35% IACS conductivity | Surgical tool handles, imaging frames | High-speed machining; avoid chloride coolants |

| Stainless 316L | 700 MPa yield strength, PREN 24–26 | Bone screws, implantable pumps | Low-RPM finishing; manage chip evacuation |

| Titanium Ti-6Al-4V | 925 MPa tensile strength, 4.5 g/cm³ density | Hip stems, dental implants | Flood coolant mandatory; sharp insert geometry |

Wuxi Lead Precision Machinery combines Swiss CNC technology with ISO 13485-certified processes to machine these materials within ±2μm tolerances. Our material traceability system logs every batch from mill certificate to final inspection, mitigating contamination risks. Partner with us to transform material science into regulatory-compliant medical solutions where precision isn’t optional—it’s a patient imperative.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every medical precision machining project begins with meticulous design engineering. Our team collaborates closely with OEMs and R&D departments to transform conceptual requirements into actionable, manufacturable designs. Utilizing advanced CAD/CAM software—such as Siemens NX, SolidWorks, and Autodesk Fusion—we ensure geometric accuracy, material compatibility, and compliance with ISO 13485 and FDA standards. Each design undergoes rigorous simulation for stress analysis, thermal behavior, and tolerance stack-up, minimizing risks before physical production. This phase includes Design for Manufacturability (DFM) reviews, where our engineers optimize part geometry, wall thickness, and feature complexity to enhance machinability while maintaining clinical performance.

Prototyping: Validating Performance with Zero Tolerance for Error

Once the design is finalized, we proceed to precision prototyping—a critical stage for medical components where functionality, biocompatibility, and dimensional accuracy are non-negotiable. Using 5-axis CNC milling, wire EDM, and micro-turning technologies, we produce functional prototypes in the actual production-grade materials, including titanium alloys, medical-grade stainless steel (316L, 17-4 PH), and high-performance polymers such as PEEK. Each prototype is subjected to full metrological validation using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports, material certifications, and first-article inspection (FAI) documentation are provided to ensure complete traceability. This iterative process allows for design refinement and regulatory verification, ensuring the final product meets stringent medical device requirements.

Mass Production: Scalable Excellence with Zero Defects

With prototype approval, we transition seamlessly into high-volume, zero-defect mass production. Our automated CNC cells operate under strict Statistical Process Control (SPC), with real-time monitoring of tool wear, cutting parameters, and environmental conditions. Every component is machined with tolerances as tight as ±0.001 mm, supported by in-process gauging and automated vision inspection systems. We enforce a comprehensive Quality Management System (QMS) that integrates root cause analysis, corrective action protocols (CAPA), and 100% inspection for critical features. Our cleanroom machining environment (Class 10,000) ensures particulate control, essential for implantable and surgical devices.

| Specification | Capability |

|---|---|

| Materials | Stainless Steel (316L, 17-4 PH), Titanium (Gr 2, Gr 5), PEEK, Inconel, Aluminum |

| Tolerances | ±0.001 mm to ±0.005 mm |

| Surface Finish | Ra 0.1 µm to Ra 0.8 µm (customizable) |

| Maximum Part Size | Ø300 mm x 400 mm |

| Production Capacity | 10,000+ units/month (automated lines) |

| Certifications | ISO 9001, ISO 13485, FDA Registered Facility |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers medical components with uncompromised quality, traceability, and reliability.

Why Choose Wuxi Lead Precision

Elevate Medical Device Manufacturing Through Precision Partnership

In the medical device sector, component failure is not an option. Every implant, surgical instrument, and diagnostic component demands micron-level accuracy, biocompatible material integrity, and uncompromising regulatory adherence. Wuxi Lead Precision Machinery exists to transform these demands into guaranteed outcomes. As your dedicated precision machining partner, we merge 15 years of specialized medical manufacturing expertise with ISO 13485-certified processes and cutting-edge Swiss CNC technology. Our facility in Wuxi operates under stringent cleanroom protocols, ensuring zero contamination risk for life-critical applications. We do not merely produce parts—we engineer reliability into every micron of your design, from prototyping through high-volume production.

Core Capabilities for Medical Excellence

| Specification | Capability | Relevance to Medical Manufacturing |

|---|---|---|

| Tolerance Range | ±0.0002″ (5μm) | Ensures perfect fit for micro-implants and sensors |

| Surface Finish | Ra 0.2μm (optical grade) | Critical for biocompatibility and fluid dynamics |

| Materials Expertise | Titanium Ti-6Al-4V, MP35N, PEEK, 316LVM | Full traceability for ASTM F136/F1586 compliance |

| Certifications | ISO 13485, FDA Registered Facility | Streamlines your 510(k) submissions |

| Process Validation | IQ/OQ/PQ documentation per device lifecycle | Eliminates regulatory roadblocks |

Our engineering collaboration begins with your design intent. We deploy DFM analysis to identify manufacturability risks early—reducing costs while enhancing performance. Unlike commodity suppliers, we assign a dedicated project engineer to your account, providing real-time GD&T feedback and material certification traceability down to the ingot level. This proactive partnership prevents costly redesigns and accelerates time-to-market. Our multi-axis milling and turning centers achieve sub-5μm repeatability on complex geometries, including thin-walled catheter components and porous-coated orthopedic structures. Every batch undergoes 100% CMM inspection with calibrated Mitutoyo equipment, generating full FAI reports for your quality dossiers.

Wuxi Lead operates at the intersection of innovation and compliance. We understand that your reputation hinges on component performance. That is why we enforce dual-stage material verification—certifying both supplier documentation and in-house spectrographic analysis. Our statistical process control (SPC) systems monitor tool wear and environmental variables in real time, ensuring batch-to-batch consistency demanded by Class II and III devices. When machining nitinol for self-expanding stents or cobalt-chrome for joint replacements, we apply proprietary thermal management techniques to prevent microstructural distortion. This precision is non-negotiable in medical manufacturing.

Initiate your precision project with a partner who treats your specifications as sacred. Contact our medical engineering team directly at [email protected] to submit your RFQ with CAD files. Include your target tolerance stack-up and material certification requirements for a guaranteed 72-hour technical feasibility assessment. We will provide a detailed process plan with risk-mitigation strategies—no generic quotes. Let Wuxi Lead Precision Machinery become the silent guardian of your device’s performance, where every micron machined translates to patient safety achieved. Your next breakthrough component starts with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.