Technical Contents

Engineering Guide: Medical Plastic Injection Molding Companies

Engineering Insight Precision Imperatives in Medical Plastic Injection Molding

Medical plastic injection molding operates under constraints where microscopic deviations translate to critical failures. Unlike consumer applications, tolerances measured in microns directly impact patient safety, drug efficacy, and regulatory compliance. A syringe plunger with inconsistent wall thickness risks dose inaccuracy; an inhaler component with surface imperfections can compromise drug particle dispersion. These components demand absolute dimensional stability across millions of cycles, requiring mold tooling engineered to withstand extreme polymer pressures while maintaining sub-5-micron repeatability. The consequences of imprecision extend beyond scrap rates—they trigger costly regulatory delays, recalls, and reputational damage in a sector where ISO 13485 and FDA 21 CFR Part 820 compliance is non-negotiable.

Achieving this level of precision begins with the mold’s foundational metal components. Core pins, cavities, and ejection systems must exhibit thermal stability under repeated thermal cycling and resist microscopic wear from abrasive medical-grade resins like PEEK or implantable silicones. This necessitates CNC machining capabilities exceeding standard industrial practices. At Wuxi Lead Precision Machinery, we apply aerospace-grade metrology protocols honed through verified production for Olympic Games timing systems and naval defense components. These projects demanded tolerances of ±2μm under dynamic load conditions—rigorous standards directly transferable to medical mold manufacturing. Our 5-axis milling centers, operating within ISO Class 7 cleanroom environments, utilize in-process laser probing to compensate for thermal drift, ensuring cavity geometries remain within specification during extended production runs. Material selection is equally critical; we specify hardened tool steels like AISI H13 or corrosion-resistant stainless variants, heat-treated to 52-54 HRC, then polished to optical-grade finishes that prevent polymer adhesion and microbial retention.

The following specifications represent baseline capabilities for medical mold tooling where precision is non-negotiable:

| Critical Parameter | Performance Standard | Measurement Method | Relevance to Medical Molding |

|---|---|---|---|

| Cavity Pressure Tolerance | ≤ ±0.5% | Piezoelectric Sensors | Ensures consistent fill for thin-walled drug delivery components |

| Surface Finish (Cavity) | Ra ≤ 0.025 μm | Atomic Force Microscopy | Eliminates micro-crevices for USP Class VI biocompatibility |

| Thermal Stability (ΔT) | ≤ ±0.5°C | Infrared Thermography | Prevents warpage in high-precision optics like lens housings |

| Geometric Repeatability | ≤ 2 μm | CMM (ISO 10360-2) | Guarantees mating part alignment in multi-component assemblies |

Partnering with a metal manufacturing specialist possessing demonstrable high-stakes precision experience mitigates risk at the earliest stage of the medical device lifecycle. Wuxi Lead Precision Machinery’s engineering discipline—forged in environments where failure is unacceptable—ensures your mold tooling becomes a reliability asset, not a validation vulnerability. We integrate material science, thermal dynamics, and micron-level machining to deliver molds that consistently produce components meeting the exacting demands of life-critical applications. This foundational precision enables medical molders to focus on process optimization rather than defect remediation, accelerating time-to-market for innovations that save lives.

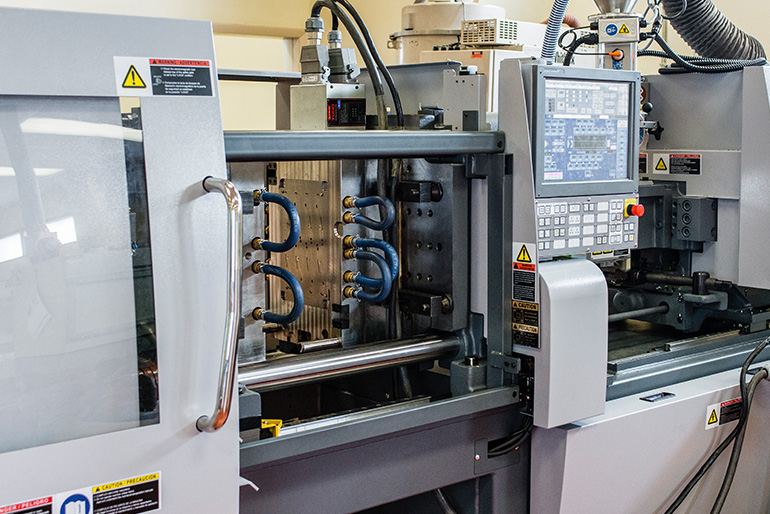

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered specifically to support high-performance applications within the medical plastic injection molding industry. Our precision machining services are built around a foundation of 5-axis CNC technology, enabling us to produce complex, high-integrity components with exceptional accuracy and repeatability. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled access to intricate geometries and tight-tolerance features that are critical in mold bases, cavities, cores, and other tooling elements used in medical-grade injection molding.

Our 5-axis CNC machining centers are operated by certified engineers with extensive experience in medical sector requirements, ensuring that every component meets the stringent demands of biocompatibility, sterilization resistance, and long-term reliability. The integration of high-speed machining with dynamic toolpath strategies results in superior surface finishes and reduced cycle times, directly contributing to faster mold development and improved part consistency. Materials commonly processed include hardened steels, stainless alloys, aluminum, and specialty tool steels—all selected and treated to meet medical industry standards.

Quality assurance is embedded throughout our manufacturing workflow. Every critical component undergoes comprehensive dimensional verification using a Coordinate Measuring Machine (CMM), ensuring full compliance with design specifications. Our CMM inspection process is ISO 10360-certified and supports both first-article inspection reports (FAIR) and production batch validation. This metrology-backed approach guarantees traceability and accountability across every production run, satisfying the regulatory expectations of medical device OEMs and contract manufacturers.

In addition to hardware precision, we utilize advanced CAD/CAM software to simulate machining processes prior to production, minimizing errors and optimizing tool engagement. This digital-first methodology enhances predictability and reduces material waste, supporting sustainable manufacturing practices without compromising quality.

The following table outlines our standard and achievable tolerances across common feature types, reflecting our commitment to precision in support of medical injection molding applications.

| Feature Type | Standard Tolerance | Achievable Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.01 mm | ±0.003 mm | CMM, Air Gaging |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM |

| Flatness | 0.01 mm | 0.005 mm | CMM, Surface Plate |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm | Profilometer |

| Angular Tolerance | ±0.05° | ±0.02° | CMM, Optical Comparator |

| Profile of Surface | ±0.02 mm | ±0.01 mm | CMM |

All tolerances are verified under controlled environmental conditions to eliminate thermal drift and ensure measurement integrity. At Wuxi Lead Precision Machinery, our technical capabilities are aligned with the exacting standards of the global medical device supply chain, delivering precision metal components that enable reliable, high-quality plastic injection molding.

Material & Finish Options

Material Selection for Medical Injection Molding Tooling: Precision Engineering Imperatives

Material selection for molds and components in medical plastic injection molding is a critical determinant of part quality, regulatory compliance, and production economics. Medical applications demand exceptional dimensional stability, resistance to aggressive sterilization methods (autoclave, gamma, EtO), and absolute biocompatibility. At Wuxi Lead Precision Machinery, we engineer solutions where material properties directly address the stringent requirements of medical device manufacturing, ensuring mold longevity, surface finish integrity, and seamless adherence to ISO 13485 pathways. Understanding the interplay between base metal and surface finish is paramount.

Aluminum alloys, particularly 7075-T6 and 6061-T6, offer significant advantages for prototyping and lower-volume production of complex medical geometries. Their high thermal conductivity enables rapid cooling cycles, crucial for thermally sensitive biocompatible polymers like PEEK or resorbable PLGA. While lacking the ultimate hardness of steel, modern aluminum grades achieve sufficient wear resistance for tens of thousands of cycles when paired with appropriate coatings. Aluminum’s machinability allows for intricate cooling channel designs, directly impacting part warpage and cycle time – critical factors for precision medical components such as surgical instrument housings or diagnostic device parts.

For high-volume production of demanding medical devices (e.g., syringe barrels, implant components), tool steels like H13, S136, or 420 Stainless Steel are indispensable. These materials provide the necessary hardness (typically 48-54 HRC after heat treatment) and exceptional resistance to wear and corrosion induced by repeated exposure to cleaning agents and sterilization. Stainless variants are essential for molds processing highly corrosive polymers or where direct contact with sensitive biological materials occurs. The investment in premium tool steel pays dividends through extended mold life exceeding millions of cycles and consistent part quality meeting tight medical tolerances.

Titanium alloys (primarily Grade 5, Ti-6Al-4V, ASTM F136) serve specialized medical molding needs where extreme corrosion resistance is non-negotiable, such as molds for highly aggressive polymers or applications requiring direct biocompatibility of the tool surface itself. While costlier and more challenging to machine, titanium’s inert nature and strength-to-weight ratio make it viable for niche, high-value implant molding where zero metallic contamination is mandated.

Surface finishing, particularly anodizing, is not merely cosmetic but a functional necessity. Type II (Sulfuric Acid) anodizing provides a robust, non-conductive, and corrosion-resistant layer on aluminum molds, enhancing release properties for sticky medical polymers and improving wear resistance. For the most demanding medical environments requiring maximum hardness and chemical inertness, Type III (Hardcoat) anodizing creates a thick, dense oxide layer significantly extending mold life in abrasive polymer applications. Crucially, all anodizing processes for medical tooling must utilize chromium-free electrolytes to ensure biocompatibility and meet stringent environmental regulations.

The optimal material and finish choice hinges on polymer type, production volume, part complexity, and sterilization requirements. Wuxi Lead Precision Machinery leverages decades of empirical evidence in medical tooling to specify and manufacture solutions that guarantee performance and regulatory success.

| Material Type | Typical Hardness Range | Corrosion Resistance | Primary Medical Applications | Critical Medical Relevance |

|---|---|---|---|---|

| Aluminum Alloys | 15-30 HB (As Machined) | Moderate | Prototypes, Low/Medium Volume Complex Parts | Rapid cooling, Complex geometries, Cost-effective |

| Tool Steels (H13/S136) | 48-54 HRC (HT) | High (Stainless: V.High) | High-Volume Production, Critical Components | Longevity, Wear Resistance, Sterilization Cycles |

| Titanium Alloys | 36-42 HRC (HT) | Exceptional | Extreme Corrosion Environments, Direct Biocompatibility | Zero Contamination, Aggressive Polymer Processing |

Manufacturing Process & QC

Design: Precision Engineering for Medical Applications

At Wuxi Lead Precision Machinery, the foundation of every successful medical plastic injection molding project begins with meticulous design engineering. Our team of senior CNC engineers and industrial designers collaborates closely with medical device manufacturers to translate complex functional requirements into manufacturable, high-precision metal components. Utilizing advanced CAD/CAM software such as Siemens NX and SolidWorks, we conduct comprehensive design validation, including mold flow analysis, thermal stress simulation, and tolerance stack-up evaluation. This ensures that every mold and tooling component meets ISO 13485 standards and complies with FDA regulatory expectations for medical device production. Design for manufacturability (DFM) reviews are conducted in real time, minimizing risks of post-production defects and ensuring seamless transition to prototyping.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move into the prototyping phase, where precision metal components are manufactured using state-of-the-art 5-axis CNC machining, wire EDM, and micro-milling technologies. These prototypes serve as functional test units for mold trials and are used to validate dimensional accuracy, surface finish, and material integrity under real-world injection molding conditions. All prototype parts are inspected using Zeiss coordinate measuring machines (CMM) and optical profilometers to confirm adherence to tolerances as tight as ±0.002 mm. This phase is critical for identifying potential defects such as warpage, sink marks, or gate vestige in the molded plastic parts—issues that originate from subtle imperfections in the metal tooling. Feedback from prototype testing is integrated into design refinements, ensuring zero-defect readiness before mass production launch.

Mass Production: Consistency, Control, and Zero Defects

Our mass production process is engineered for repeatability, traceability, and uncompromising quality. Each metal component—whether mold cores, cavities, or inserts—is manufactured under strict environmental controls in a Class 10,000 cleanroom environment. Automated CNC cells operate under SPC (Statistical Process Control) monitoring, with real-time data logging for every critical dimension. We implement a full first-article inspection (FAI) protocol and ongoing in-process inspections at defined intervals. All materials used are certified and traceable, with documentation including material test reports (MTRs) and heat lot tracking. Our quality management system is ISO 13485 and IATF 16949 certified, ensuring compliance with the highest standards in medical manufacturing.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished to mirror finish if required) |

| Materials | 420 Stainless Steel, H13, S136, Titanium Alloys, Inconel 718 |

| Machining Capabilities | 5-Axis CNC, Wire EDM, Micro Milling, Grinding |

| Quality Standards | ISO 13485, IATF 16949, FDA 21 CFR Part 820 |

| Inspection Equipment | Zeiss CMM, Optical Comparator, Laser Scanning, Roughness Tester |

Through integrated design, rigorous prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers custom metal components that enable zero-defect plastic injection molding for the most demanding medical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Medical Molding Success

In the tightly regulated medical device sector, your plastic injection molding outcomes depend entirely on the precision and reliability of your tooling. Substandard molds introduce unacceptable risks: part inconsistency, material degradation, production downtime, and potential regulatory non-compliance. Wuxi Lead Precision Machinery delivers engineered metal solutions that transform these risks into competitive advantages. We specialize in custom CNC-machined molds, inserts, and precision components engineered to the exacting standards demanded by Class I, II, and III medical devices. Our ISO 13485-certified processes ensure every cavity, core, and ejector system meets micron-level tolerances while maintaining biocompatibility and sterilization integrity. When your application requires zero-defect performance for syringes, surgical housings, or diagnostic components, our expertise in hardened tool steels, corrosion-resistant alloys, and cleanroom-compatible surface finishes becomes your operational safeguard.

Our technical partnership begins with deep engagement in your design phase. We collaborate to optimize mold geometry for complex medical resins like PEEK, PPSU, and liquid silicone rubber, ensuring balanced thermal management and stress-free part ejection. Unlike generic manufacturers, we validate every critical feature through in-process CMM inspection and first-article reporting aligned with your FDA 21 CFR Part 820 or ISO 13485 protocols. This proactive approach eliminates costly iterations and accelerates time-to-market for life-critical products. Below are core capabilities directly impacting medical molding performance:

| Capability | Specification | Relevance to Medical Molding |

|---|---|---|

| Positional Accuracy | ±0.001 mm | Ensures hermetic seals and precise fluid pathways |

| Surface Finish (Cavity) | Ra 0.05 µm (Mirror) | Prevents bacterial adhesion; critical for implants |

| Material Certification | ASTM F899, ISO 22067 | Guarantees biocompatibility and chemical resistance |

| Cooling Channel Precision | ±0.002 mm concentricity | Eliminates warpage in thin-walled drug delivery components |

| Validation Documentation | Full FAIR data package | Streamlines regulatory submissions and audits |

Choosing Wuxi Lead Precision Machinery means aligning with a partner who treats your compliance obligations as our own. We understand that a 5-micron deviation isn’t just a tolerance issue—it’s a potential patient safety event. Our facility operates under controlled environmental conditions with dedicated tooling cells for medical projects, preventing cross-contamination and ensuring traceability from raw material to final inspection. When production scales, our molds consistently deliver 500,000+ cycles without degradation, protecting your yield rates and reducing total cost of ownership.

The next step in securing your medical molding excellence requires direct technical collaboration. Contact our engineering team at [email protected] to initiate a confidential review of your current tooling challenges. Specify your target resin, part complexity, and regulatory framework in your inquiry. We will provide a detailed capability assessment within 24 business hours—including feasibility analysis, lead time projection, and sample validation options. Do not compromise on the foundation of your medical device quality. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.