Technical Contents

Engineering Guide: Medical Parts

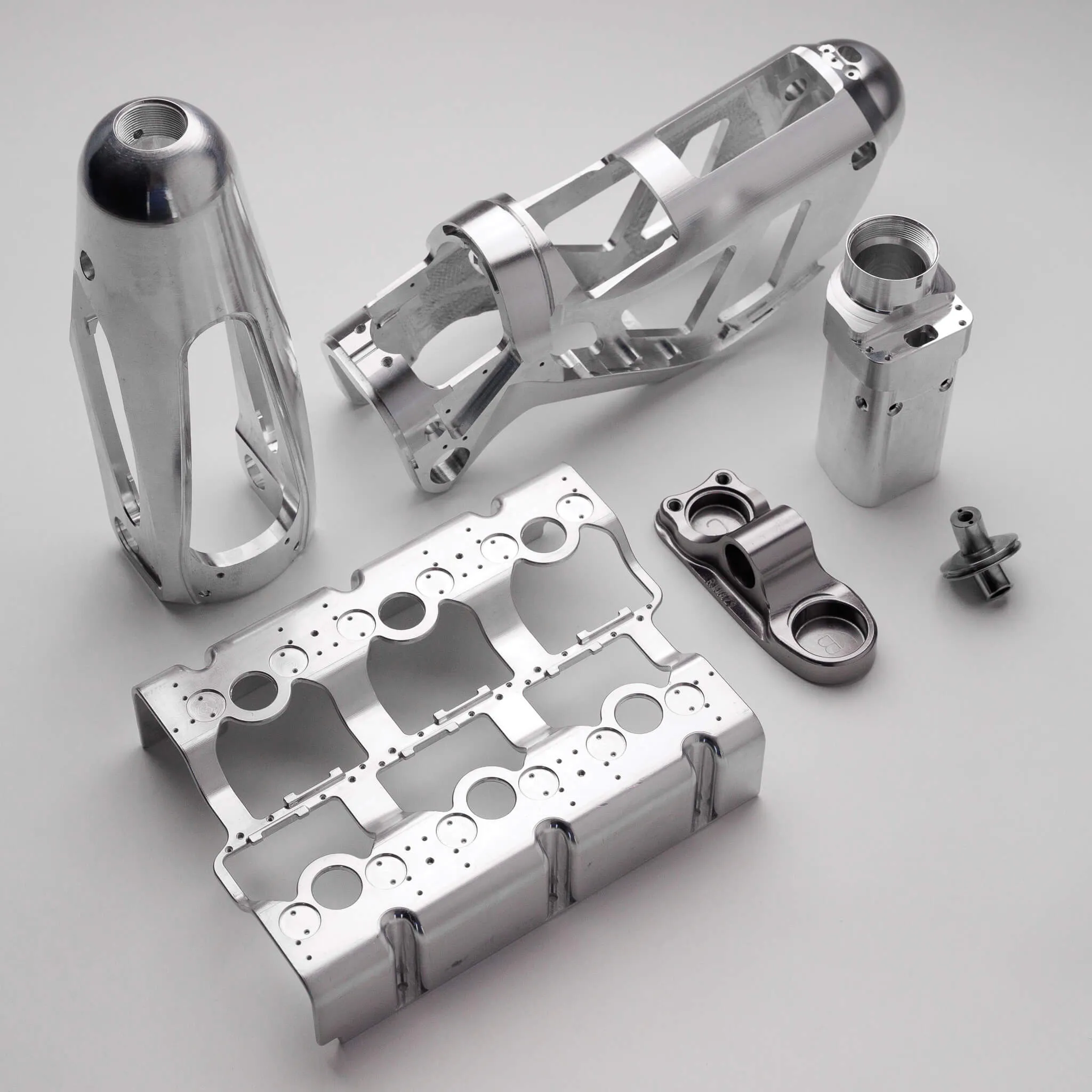

Engineering Insight Precision in Medical Component Manufacturing

In the medical device sector, precision transcends mere manufacturing specification; it is a non-negotiable determinant of patient safety, regulatory compliance, and clinical efficacy. Components such as orthopedic implants, surgical instrument tips, and diagnostic sensor housings operate within unforgiving physiological environments. Tolerances measured in single-digit microns directly influence biocompatibility, structural integrity under cyclic loading, and the flawless integration of complex assemblies. A deviation of 5 microns in a femoral stem taper junction can accelerate wear debris generation, triggering osteolysis and premature implant failure. Similarly, inconsistent surface finish on a micro-surgical clamp risks tissue trauma during delicate procedures. The stakes demand processes validated not only to ISO 13485 but to the implicit standard of human life. This is where engineered precision becomes inseparable from ethical responsibility.

Wuxi Lead Precision Machinery applies rigor forged in mission-critical domains to every medical component. Our foundational experience machining parts for Olympic-caliber sporting equipment taught us the physics of peak performance under extreme stress – knowledge directly transferable to load-bearing orthopedic implants. Subsequent defense sector projects, requiring absolute reliability in harsh operational environments, instilled disciplined traceability and failure-mode anticipation now embedded in our medical workflows. This cross-industry pedigree ensures our CNC machining centers, metrology labs, and quality engineers approach medical projects with a systemic understanding of consequence. We recognize that a hip cup’s geometric accuracy isn’t just a drawing note; it’s the difference between pain-free mobility and revision surgery.

Our technical execution centers on controlled material transformation. Medical-grade titanium alloys (Grade 5, ASTM F136), cobalt-chromium (ASTM F75), and nitinol demand specialized toolpath strategies to prevent thermal distortion or micro-fractures. We deploy 5-axis simultaneous machining with real-time tool deflection compensation, achieving geometric tolerances unattainable through conventional methods. Critical parameters are monitored via integrated in-process gauging, eliminating post-process surprises. The table below outlines capabilities essential for high-risk medical applications:

| Parameter | Capability | Relevance to Medical Parts |

|---|---|---|

| Positional Tolerance | ±0.001 mm (40 μm) | Ensures perfect joint articulation in implants |

| Surface Roughness (Ra) | 0.05 μm (mirror finish) | Minimizes bacterial adhesion on implants |

| Geometric Tolerance (GD&T) | ±0.002 mm (true position) | Critical for mating surfaces in surgical tools |

| Material Traceability | Full lot/barcode tracking | Meets FDA UDI requirements |

| Process Validation | IQ/OQ/PQ per ASTM F2996 | Required for sterile barrier system components |

This precision ecosystem – combining advanced hardware, material science expertise, and military-grade process discipline – allows medical OEMs to mitigate supply chain risk. When your component’s function is measured in human outcomes, tolerances cannot be theoretical. At Lead Precision, we engineer certainty into every micron, ensuring your innovation translates reliably from CAD model to patient impact. Our validation protocols don’t just meet standards; they anticipate the next regulatory evolution, safeguarding your time-to-market.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored specifically for the medical device industry, where precision, reliability, and regulatory compliance are non-negotiable. Our technical capabilities are built around state-of-the-art 5-axis CNC machining centers, enabling us to produce complex, high-integrity components with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in machining intricate geometries commonly found in surgical instruments, implantable devices, and diagnostic equipment housings.

Our 5-axis CNC platforms are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent part quality and reduced cycle times. This technology eliminates the need for multiple setups, minimizing human intervention and reducing the risk of cumulative errors. As a result, we achieve tighter tolerances, improved part repeatability, and faster turnaround—critical factors in meeting the demanding production schedules of medical OEMs.

Quality control is fully integrated into our manufacturing workflow. Every component undergoes rigorous inspection using a Zeiss DuraMax and O-Inspect 553 Coordinate Measuring Machine (CMM), ensuring dimensional accuracy and geometric conformity to design specifications. Our CMM system supports both contact and optical probing, enabling comprehensive metrology for small, complex parts with tight form and position tolerances. All inspection data is documented and traceable, supporting full compliance with ISO 13485 and other medical industry standards.

We specialize in machining a wide range of medical-grade materials, including titanium (Grade 5, ASTM F136), stainless steel (316L, 17-4 PH), cobalt-chrome alloys (ASTM F75), and high-performance nickel-based superalloys. Our process engineers work closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and machining strategy—ensuring cost-effective production without compromising performance or regulatory requirements.

The table below outlines our standard machining tolerances and capabilities for medical components.

| Parameter | Standard Capability | Tight Tolerance (Achievable) | Notes |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.005 mm | ±0.002 mm | Up to 100 mm |

| Positional Tolerance | ±0.008 mm | ±0.003 mm | GD&T controlled |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Achievable with fine finishing |

| Feature Size (Minimum) | 0.3 mm diameter | 0.15 mm diameter | Drilled or milled |

| Geometric Tolerance (Flatness) | 0.01 mm per 50 mm | 0.005 mm per 50 mm | Verified via CMM |

| Repeatability (Batch-to-Batch) | ±0.003 mm | ±0.001 mm | Statistical process control applied |

All processes are supported by full documentation, first-article inspection reports, and material certifications. Wuxi Lead Precision Machinery is committed to delivering medical components that meet the highest standards of precision, quality, and reliability required in today’s advanced healthcare environments.

Material & Finish Options

Material Selection for Critical Medical Components

Selecting the optimal material and surface finish is non-negotiable in medical device manufacturing. Performance, biocompatibility, regulatory compliance, and long-term reliability hinge on precise choices. At Wuxi Lead Precision Machinery, we guide clients through this critical decision process, leveraging deep expertise in CNC machining for demanding medical applications. Understanding the distinct properties of Aluminum, Stainless Steel, and Titanium is fundamental to component success.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio and excellent machinability. They are frequently specified for non-implantable surgical instrument housings, diagnostic equipment frames, and portable medical device enclosures where weight reduction is paramount. However, aluminum lacks inherent biocompatibility for direct patient contact or implantation. Rigorous surface finishing, primarily hard anodizing (Type III), is essential to enhance corrosion resistance, wear properties, and electrical insulation while meeting medical cleanliness standards. Anodizing thickness and sealing processes must be tightly controlled to prevent particle generation.

Stainless Steel, especially grades 316L and 316LVM (Vacuum Melted), remains the workhorse for surgical instruments, implantable components like bone screws and plates, and fluid handling systems. Its superior corrosion resistance in bodily fluids, high strength, and excellent biocompatibility (ASTM F138/F139) are critical. Passivation per ASTM A967 is mandatory post-machining to maximize the protective chromium oxide layer. While highly durable, 316L requires careful machining parameters to avoid work hardening and achieve the stringent surface finishes demanded in medical applications.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V) and Grade 23 (Ti-6Al-4V ELI) compliant with ASTM F136/F1472, are indispensable for permanent implants due to their outstanding biocompatibility, exceptional strength-to-weight ratio, and near-zero modulus of elasticity mismatch with bone. This minimizes stress shielding. Titanium’s corrosion resistance in physiological environments is superior to stainless steel. However, its low thermal conductivity and chemical reactivity necessitate specialized CNC machining techniques and tooling to prevent galling and achieve precise geometries. Surface treatments like acid etching or porous coatings are often applied for osseointegration, but base material purity is paramount.

The following table summarizes key material specifications relevant to medical part production:

| Material | Common Grades | Key Medical Standards | Primary Medical Applications | Critical Processing Notes |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | ASTM B209, AMS 4027 | Non-implant housings, frames, carts | Requires hard anodizing (Type III); not biocompatible raw |

| Stainless Steel | 316L, 316LVM | ASTM F138, F139 | Surgical instruments, implants, fluid systems | Mandatory passivation; prone to work hardening |

| Titanium | Gr 5 (Ti-6Al-4V), Gr 23 | ASTM F136, F1472 | Permanent orthopedic/dental implants | Specialized machining; requires high purity |

Anodizing, specifically hardcoat anodizing (MIL-A-8625 Type III), is the dominant finish for aluminum medical components. It creates a dense, hard, non-conductive ceramic layer significantly improving wear and corrosion resistance. Precise control over electrolyte temperature, current density, and time is vital to achieve the required coating thickness (typically 25-50 μm), uniformity, and pore sealing without compromising dimensional tolerances critical for medical assemblies. Wuxi Lead employs in-process metrology to ensure anodized finishes consistently meet ISO 13485 requirements for medical devices.

Material selection is not merely technical; it directly impacts patient safety, device longevity, and regulatory pathway success. Partner with Wuxi Lead Precision Machinery early in your design phase. Our engineering team provides material certification, process validation support, and machining expertise to ensure your medical components meet the highest global standards from prototype to full production. Contact our medical division for a tailored material assessment.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, the production of custom medical parts follows a rigorously controlled sequence designed to ensure precision, compliance, and zero-defect outcomes. Our process spans from initial design through prototyping to full-scale mass production, with each phase governed by ISO 13485 standards and advanced quality control protocols.

The journey begins with collaborative design engineering. Our team works closely with medical device developers to translate specifications into manufacturable components. Utilizing 3D CAD modeling and finite element analysis (FEA), we optimize geometries for structural integrity, material efficiency, and compatibility with surgical or diagnostic applications. Design for Manufacturability (DFM) reviews are conducted to identify potential risks early, ensuring tight tolerances—down to ±0.002 mm—are achievable without compromising yield.

Following design finalization, we proceed to precision prototyping. This phase employs CNC milling, turning, and wire EDM processes on medical-grade stainless steel (e.g., 316L), titanium (Grade 5), and other biocompatible alloys. Prototypes are machined in controlled cleanroom environments to prevent contamination. Each sample undergoes comprehensive metrology testing using coordinate measuring machines (CMM) and optical profilometers to validate dimensional accuracy and surface finish. Functionality, fit, and sterilization compatibility are also assessed. Feedback from this stage informs any necessary design refinements before launch into series production.

Mass production is executed on automated CNC platforms integrated with real-time process monitoring. Our facility leverages multi-axis machining centers capable of complex geometries required for orthopedic implants, surgical instruments, and diagnostic equipment housings. In-process inspections occur at defined intervals, supported by Statistical Process Control (SPC) to detect deviations before they affect output. Every component is traceable via laser marking, and batch records are maintained for full auditability.

Quality assurance is embedded throughout the workflow. Raw materials are certified and logged upon receipt. Final inspection includes 100% visual checks under magnification and random sampling for destructive and non-destructive testing. Packaging conforms to medical packaging standards (ISO 11607), ensuring sterility maintenance through distribution.

The following table outlines key production specifications for medical part manufacturing at Wuxi Lead Precision Machinery:

| Parameter | Capability |

|---|---|

| Material Options | 316L Stainless Steel, Titanium Gr5, Inconel 718, PEEK (metal-filled) |

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Maximum Part Size | Ø450 mm × 600 mm length |

| Minimum Feature Size | 0.3 mm internal radius |

| Production Capacity | Up to 50,000 units/month (depending on complexity) |

| Quality Standards | ISO 13485, ISO 9001, RoHS, biocompatibility testing available |

Through disciplined execution and advanced manufacturing technology, Wuxi Lead Precision Machinery delivers medical components with uncompromising quality, supporting global clients in bringing safe, reliable devices to market.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineering Medical Excellence Through Precision Manufacturing

In the critically demanding field of medical device manufacturing, component integrity is non-negotiable. A single micron of deviation can compromise patient safety, regulatory compliance, and device functionality. Wuxi Lead Precision Machinery operates at the intersection of uncompromising precision and deep medical industry expertise, delivering custom metal components that meet the exacting standards of global healthcare innovators. We understand that your reputation and patient outcomes depend on partners who treat precision as a scientific imperative, not merely a production target. Our ISO 13485-certified facility in Wuxi, China, is engineered specifically for medical-grade manufacturing, featuring Class 7 and 8 cleanrooms, full material traceability, and processes validated to FDA 21 CFR Part 820 and EU MDR requirements.

Our advanced CNC milling, turning, and multi-axis machining capabilities transform complex geometries in titanium, stainless steel 316L, PEEK, and cobalt-chrome into mission-critical surgical instruments, implant components, and diagnostic device parts. Every process—from initial material certification to final inspection—is documented with aerospace-grade rigor, ensuring seamless audit readiness. We integrate directly with your engineering teams to optimize designs for manufacturability while maintaining strict confidentiality under NDA. This collaborative approach minimizes time-to-market without sacrificing the zero-defect performance your applications demand. Below outlines our core technical capabilities tailored for medical device success.

| Parameter | Capability | Relevance to Medical Applications |

|---|---|---|

| Tolerance Control | ±0.001 mm (±0.00004″) | Ensures flawless fit for implants and micro-surgical tools |

| Surface Finish | Ra ≤ 0.4 μm (16 μin) achievable | Critical for biocompatibility and reduced tissue irritation |

| Materials Expertise | Ti-6Al-4V, 316LVM, CoCr, PEEK, MP35N | Full compliance with ASTM F136, F138, ISO 5832 |

| Inspection | CMM, optical comparators, 100% traceability | Validates conformance to ISO 13485 and custom specifications |

| Cleanroom Standards | ISO Class 7 & 8 certified | Prevents particulate contamination during machining |

Choosing a manufacturing partner for medical components requires confidence in both technical mastery and regulatory vigilance. At Lead Precision, we embed quality into every spindle rotation—not as an afterthought, but as the foundation of our workflow. Our engineers proactively identify potential failure points during prototyping, leveraging decades of experience in orthopedics, cardiovascular, and minimally invasive device manufacturing. This foresight reduces scrap rates, accelerates validation cycles, and delivers components that perform flawlessly in life-critical applications.

The medical technology landscape evolves rapidly, and your manufacturing partner must evolve with it. We invest continuously in next-generation Swiss-type lathes, 5-axis milling centers, and in-process probing systems to tackle emerging design challenges. When you partner with Lead Precision, you gain more than a supplier—you secure a strategic ally committed to advancing healthcare through precision engineering.

Contact Lead Precision Machinery directly at [email protected] to initiate a confidential consultation. Share your design specifications or engineering challenges, and our medical manufacturing specialists will respond within 24 business hours with a detailed capability assessment and prototyping roadmap. Let us demonstrate how precision-engineered components become your competitive advantage. Your next breakthrough in medical innovation starts with a single, perfectly machined part.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.