Technical Contents

Engineering Guide: Medical Device Parts

Engineering Insight: Precision in Medical Device Manufacturing

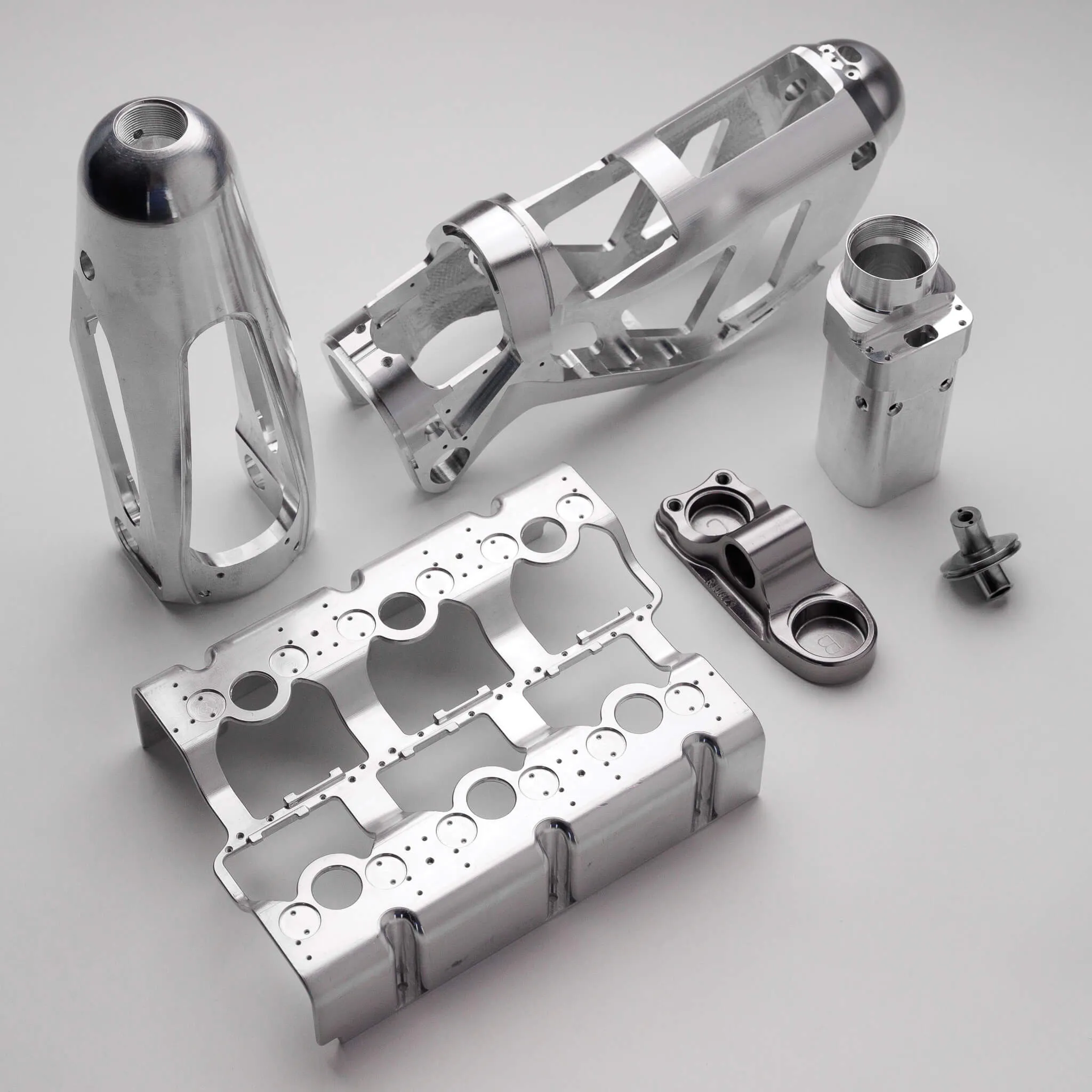

In the production of medical device components, precision is not merely a performance metric—it is a foundational requirement for safety, reliability, and regulatory compliance. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in dimensional accuracy can compromise the functionality of a surgical instrument, implant, or diagnostic device. Our engineering philosophy centers on achieving micron-level tolerances consistently, ensuring that every part meets the stringent demands of the global healthcare industry.

The complexity of modern medical devices—ranging from minimally invasive surgical tools to implantable orthopedic components—demands more than standard machining capabilities. These parts often feature intricate geometries, tight tolerance requirements, and must be manufactured from biocompatible materials such as titanium, stainless steel 316L, and MP35N. At Lead Precision, we utilize advanced 5-axis CNC machining, Swiss-type turning, and automated inspection systems to maintain precision across high-mix, low-volume production runs. Our process control systems are ISO 13485 certified, ensuring traceability, material verification, and full documentation for every component produced.

Our expertise in high-precision manufacturing is not limited to the medical sector. The same engineering rigor that supports life-critical medical applications has been proven in equally demanding environments. Wuxi Lead has contributed precision components for Olympic-grade timing systems, where split-second accuracy is non-negotiable, and for military-grade communication and navigation equipment, where failure is not an option. These cross-industry validations reinforce our capability to deliver under extreme performance and reliability standards.

What sets Lead Precision apart is our integrated approach—combining cutting-edge equipment with deep process knowledge. Our engineers work closely with clients during the design-for-manufacturability (DFM) phase, identifying potential challenges early and optimizing toolpaths, fixturing, and inspection protocols before production begins. This proactive collaboration reduces time-to-market and ensures first-time-right outcomes, even for the most complex parts.

We also recognize that precision extends beyond the machine shop floor. Surface finish, burr-free edges, and repeatable cleaning processes are critical for biocompatibility and device performance. Our post-machining processes—including electropolishing, passivation, and cleanroom packaging—are designed to meet FDA and CE marking requirements, providing full regulatory support for our clients.

Below is a summary of our core manufacturing capabilities relevant to medical device components:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004 in) |

| Surface Finish | Ra 0.1 – 0.8 µm (4–32 µin) |

| Materials | Titanium (Gr 2, Gr 5), Stainless Steel 316L, MP35N, Inconel 718, PEEK |

| Maximum Part Size | Ø200 mm x 300 mm (Ø7.9 in x 11.8 in) |

| Machining Processes | 5-Axis CNC Milling, CNC Turning, Swiss Machining, EDM |

| Quality Standards | ISO 13485, ISO 9001, RoHS Compliant |

| Inspection Equipment | CMM, Optical Comparator, Surface Roughness Tester, Laser Micrometer |

At Wuxi Lead Precision Machinery, we view every medical component as a mission-critical part. Our experience across Olympic, military, and medical applications demonstrates our unwavering commitment to precision—where engineering excellence meets real-world impact.

Precision Specs & Tolerances

Technical Capabilities for Medical Device Component Manufacturing

Precision is non-negotiable in medical device manufacturing, where component integrity directly impacts patient safety and regulatory compliance. At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to meet the exacting demands of orthopedic implants, surgical instrumentation, and diagnostic equipment. We specialize in complex, high-mix metal components using advanced 5-axis CNC machining centers, eliminating the need for multiple setups and minimizing human handling errors. This capability ensures geometric consistency for intricate features such as bone screw threads, implant surface textures, and micro-fluidic channels that define modern medical devices.

Our DMG MORI and MAZAK 5-axis platforms deliver simultaneous multi-axis machining with sub-micron repeatability. This enables single-setup production of geometries requiring tight angular relationships—critical for load-bearing orthopedic components where misalignment compromises structural performance. High-speed spindles (up to 24,000 RPM) and rigid thermal compensation systems maintain dimensional stability during extended production runs of titanium, cobalt-chrome, and medical-grade stainless steel. We routinely machine wall thicknesses below 0.25mm and achieve surface finishes down to Ra 0.4µm without secondary operations, reducing biocompatibility risks from post-processing.

Quality verification is integrated into every production phase through Zeiss and Hexagon CMM systems operating in ISO Class 7 cleanroom environments. All inspections adhere to ASME Y14.5-2018 standards, with full traceability via calibrated probes and temperature-controlled metrology labs. Our process includes first-article inspection reports (FAIR), in-process SPC charting, and final batch certification with GD&T analysis. This rigorous protocol ensures conformity to FDA 21 CFR Part 820 and ISO 13485 requirements, with documentation structured for seamless regulatory audits.

Tolerances achieved consistently across production batches are detailed below:

| Feature Type | Standard Capability | Tight Tolerance Option | Material Constraints |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | All medical alloys |

| Geometric (GD&T) | ±0.015 mm | ±0.008 mm | Critical mating surfaces |

| Hole Position | ±0.008 mm | ±0.003 mm | Multi-hole patterns |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm | Titanium, CoCr, 316L |

| Thin Walls | 0.30 mm | 0.25 mm | Titanium Grade 5 |

This precision foundation is supported by statistical process control (SPC) monitoring of critical parameters like tool wear and coolant concentration. Our engineers collaborate with clients during DFM to optimize manufacturability without compromising design intent—transforming complex CAD models into certified, production-ready components. For medical device OEMs, this translates to reduced time-to-market, minimized scrap costs, and unwavering adherence to clinical performance requirements. Wuxi Lead delivers not just parts, but validated solutions engineered for the operating room.

Material & Finish Options

Material selection is a critical step in the production of medical device components, where performance, biocompatibility, and precision are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-end medical applications, leveraging advanced CNC machining and finishing techniques to meet stringent industry standards. The most commonly used materials in this domain are aluminum, stainless steel, and titanium, each offering distinct mechanical and chemical properties suited to specific medical environments.

Aluminum is favored for its lightweight nature and excellent machinability, making it ideal for portable medical devices and non-implantable equipment housings. While not typically used in direct patient contact applications, aluminum 6061 and 7075 grades provide high strength-to-weight ratios and good corrosion resistance—especially when enhanced with surface treatments such as anodizing. Type II and Type III (hard) anodizing are frequently applied to aluminum parts to improve wear resistance, electrical insulation, and surface durability. These finishes also allow for color coding, which is beneficial in multi-component medical systems.

Stainless steel, particularly grades 316 and 316L, is the material of choice for surgical instruments, implantable devices, and components requiring repeated sterilization. Its high corrosion resistance, mechanical strength, and biocompatibility make it compliant with ISO 10993 and USP Class VI standards. 316L, with its lower carbon content, minimizes carbide precipitation during welding, enhancing its suitability for complex medical assemblies. Passivation is typically performed post-machining to remove free iron and maximize the chromium oxide layer, further improving corrosion resistance.

Titanium, especially Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio and unparalleled biocompatibility, making it the preferred material for long-term implants such as bone screws, dental fixtures, and joint replacements. It is highly resistant to body fluids and does not induce adverse tissue reactions. Although more challenging to machine than aluminum or steel, titanium’s performance in critical applications justifies the added manufacturing complexity.

The following table summarizes key properties and applications of these materials in medical device manufacturing:

| Material | Key Grades | Tensile Strength (MPa) | Corrosion Resistance | Common Medical Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310 – 570 | Moderate to High | Device enclosures, frames | Anodizing (Type II, Type III) |

| Stainless Steel | 316, 316L | 570 – 860 | Very High | Surgical tools, implantable parts | Passivation, electropolishing |

| Titanium | Grade 5 (Ti-6Al-4V) | 900 – 1,170 | Excellent | Orthopedic implants, dental posts | Acid etching, plasma spray |

At Wuxi Lead, we ensure every material selection is aligned with the functional, regulatory, and environmental demands of the end-use application. Our engineering team collaborates closely with clients to optimize material and finish combinations, ensuring reliability, longevity, and compliance in every medical component we produce.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept

Our medical device production begins with rigorous design collaboration. We integrate client specifications with regulatory requirements including ISO 13485 and FDA QSR, ensuring every component meets biocompatibility and functional demands. Advanced CAD/CAM software enables tolerance analysis down to ±0.001mm, while finite element analysis (FEA) validates structural integrity under physiological loads. Material selection strictly adheres to ASTM standards for implant-grade titanium, stainless steel 316L, or cobalt-chrome alloys. Critical features like osseointegration surfaces or fluid pathways undergo DFMEA to eliminate failure modes before prototyping. This phase concludes with design freeze approval, locking specifications for traceability.

Prototyping Phase: Validating Functionality and Compliance

Prototypes are manufactured using the same CNC Swiss lathes and 5-axis milling centers destined for mass production, eliminating process variation risks. Each iteration undergoes accelerated life testing, dimensional CMM verification against CAD models, and surface roughness validation per ASTM F86. Biocompatibility testing per ISO 10993 is coordinated with certified labs. We implement rapid feedback loops: if a catheter hub shows micro-fractures under 10,000-cycle fatigue testing, we adjust toolpaths and re-machine within 72 hours. This phase delivers 3-5 validated units for client clinical trials, with full documentation of material certs, process parameters, and inspection reports. Zero defects are non-negotiable; any deviation triggers root-cause analysis before progression.

Mass Production: Zero-Defect Execution at Scale

Transition to volume production leverages our automated zero-defect framework. CNC cells run under SPC control with real-time tool wear monitoring and in-process laser scanning. Every component undergoes 100% automated optical inspection (AOI) for surface defects and critical dimensions, supplemented by batch CMM validation. Our traceability system logs serial numbers, machine parameters, operator IDs, and material lot numbers into a blockchain-secured database for instant recall management. For orthopedic screws requiring Ra ≤ 0.2µm surface finish, we deploy multi-stage polishing with post-process SEM verification. Final packaging occurs in ISO Class 7 cleanrooms, with sterile barrier validation per ISO 11607. Statistical process capability (Cpk ≥ 2.0) is maintained through daily recalibration and AI-driven anomaly detection, ensuring <10 ppm defect rates.

Key Process Specifications Comparison

| Parameter | Prototype Phase | Mass Production Phase |

|---|---|---|

| Tolerance Capability | ±0.005 mm | ±0.001 mm |

| Surface Roughness | Ra ≤ 0.4 µm (verified) | Ra ≤ 0.2 µm (100% AOI) |

| Material Traceability | Mill cert + batch ID | Full blockchain chain of custody |

| Inspection Coverage | 100% CMM + functional | 100% AOI + batch CMM |

| Process Control | Manual SPC | Real-time AI SPC + laser scanning |

| Cleanroom Standard | ISO Class 8 | ISO Class 7 |

This integrated workflow ensures medical components achieve first-pass yield rates exceeding 99.95%, transforming regulatory challenges into manufacturing excellence. Every part ships with a digital twin dossier for lifelong quality assurance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Quality in Medical Device Component Manufacturing

In the high-stakes world of medical device manufacturing, precision, reliability, and regulatory compliance are non-negotiable. At Wuxi Lead Precision Machinery, we understand the critical nature of your applications. As a trusted partner in custom metal manufacturing, we specialize in delivering high-precision components that meet the exacting standards of the global medical industry. From surgical instruments and implantable devices to diagnostic equipment and minimally invasive tools, our engineering expertise ensures your parts perform flawlessly in the most demanding environments.

Our vertically integrated facility in Wuxi, China, combines advanced CNC machining, Swiss turning, multi-axis milling, and automated inspection systems to produce components with tolerances as tight as ±0.001 mm. Every process is designed and validated under ISO 13485:2016 quality management standards, ensuring full traceability, material certification, and compliance with FDA and CE requirements. We work extensively with medical-grade stainless steel (316L, 17-4 PH), titanium (Grade 5), and specialized alloys such as MP35N and Nitinol, providing biocompatible, corrosion-resistant solutions tailored to your specifications.

What sets Wuxi Lead Precision Machinery apart is our commitment to engineering collaboration. We don’t just manufacture parts—we partner with your design and R&D teams to optimize manufacturability, reduce lead times, and lower total production costs. Our in-house engineering support includes Design for Manufacturability (DFM) analysis, rapid prototyping, and first-article inspection reports (FAIR), ensuring a seamless transition from concept to volume production.

Our clients span North America, Europe, and Asia, serving Tier-1 medical OEMs and innovative startups alike. Whether you require low-volume, high-mix production for clinical trials or scalable, high-volume manufacturing for commercial distribution, our flexible production systems adapt to your needs without compromising on quality or delivery.

Below are key capabilities that define our medical device manufacturing excellence:

| Specification | Detail |

|---|---|

| Materials | 316L SS, 17-4 PH SS, Titanium Grade 5, Nitinol, MP35N, Cobalt-Chrome |

| Tolerances | ±0.001 mm (±0.00004″) |

| Processes | CNC Turning, Multi-Axis Milling, Swiss Machining, Mill-Turning, EDM |

| Secondary Operations | Passivation, Electropolishing, Laser Marking, Clean Room Assembly |

| Quality Standards | ISO 13485:2016, ISO 9001:2015, FDA Registered, RoHS Compliant |

| Inspection | CMM, Optical Comparators, Surface Roughness Testers, In-Process Gauging |

| Production Range | Prototypes to 1,000,000+ annual volumes |

When precision impacts patient outcomes, trust your supply chain to a partner with proven expertise. Contact us today to discuss your next medical device project. Email us at [email protected] and receive a detailed DFM review and quote within 24 hours. Let Wuxi Lead Precision Machinery become your strategic manufacturing partner—where engineering excellence meets medical innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.