Technical Contents

Engineering Guide: Medical Design Components

Engineering Insight: Precision in Medical Design Components

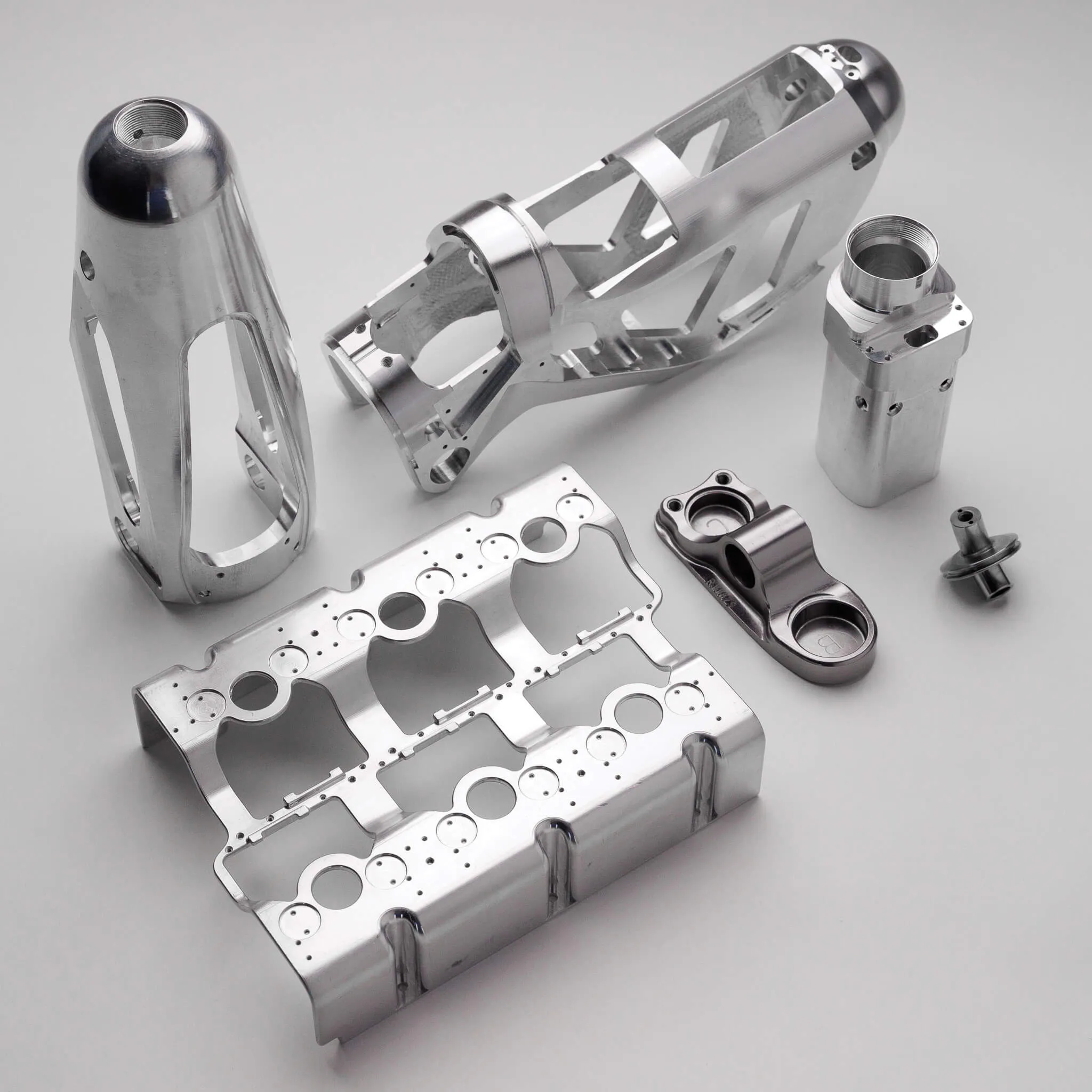

In the field of custom metal manufacturing for medical design components, precision is not merely a performance metric—it is a fundamental requirement for safety, reliability, and regulatory compliance. Medical devices operate within tightly constrained environments, often interfacing directly with human tissue or delivering life-critical therapies. As such, even micron-level deviations in component geometry can compromise functionality, sterility, or biocompatibility. At Wuxi Lead Precision Machinery, we recognize that achieving such levels of accuracy demands more than advanced machinery; it requires deep engineering insight, rigorous process control, and a culture of zero-defect manufacturing.

Our expertise in high-precision machining has been honed through participation in some of the most demanding engineering projects globally, including components for Olympic-standard equipment and mission-critical military systems. These applications share a common thread: absolute reliability under extreme conditions. The same engineering discipline applied to aerospace actuators or high-speed competition mechanisms translates directly to the production of surgical instruments, implantable devices, and diagnostic equipment. Whether machining titanium bone screws or stainless steel fluid control manifolds, our approach integrates material science, geometric dimensioning, and statistical process control to ensure every part meets exacting specifications.

Medical design components frequently involve complex geometries, thin walls, and tight tolerance stacks that challenge conventional machining methods. We employ multi-axis CNC milling, Swiss-type turning, and micro-machining technologies, all calibrated and maintained to sub-micron accuracy. In-process metrology and post-production inspection using coordinate measuring machines (CMM) and optical comparators ensure full traceability and compliance with ISO 13485 standards. Our facility operates under cleanroom protocols for selected assemblies, further safeguarding against contamination in sensitive applications.

Beyond technical capability, our experience in regulated industries enables us to support clients through design for manufacturability (DFM) reviews, risk assessment documentation, and production scalability planning. We collaborate closely with medical device engineers to optimize component designs for both performance and manufacturability—reducing cost without sacrificing quality.

The following table outlines typical precision capabilities for medical-grade components manufactured at our facility:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004 in) |

| Surface Roughness (Ra) | As low as 0.1 µm |

| Minimum Feature Size | 0.05 mm (0.002 in) |

| Materials | 316L Stainless Steel, Titanium (Gr 2, Gr 5), Inconel 718, MP35N, PEEK (metal-filled) |

| Inspection Standards | ISO 9001, ISO 13485, GD&T compliant |

| Production Volume | Prototype to High-Volume Series |

Precision in medical manufacturing is not an endpoint—it is a continuous commitment. At Wuxi Lead Precision Machinery, our legacy in high-stakes engineering disciplines ensures that every medical design component we produce meets the highest standards of performance and integrity.

Precision Specs & Tolerances

Technical Capabilities for Medical Design Component Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision for critical medical design components through integrated advanced manufacturing and quality assurance systems. Our facility operates under strict ISO 13485 standards, ensuring every process aligns with the stringent regulatory demands of the medical device industry. Central to our capability is a dedicated fleet of state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and Makino D200Z models. These systems enable complex geometries—such as implant threads, surgical instrument articulations, and fluidic manifolds—to be produced in a single setup, eliminating cumulative errors from multiple fixtures and ensuring micron-level repeatability. Material expertise spans biomedical titanium (Ti-6Al-4V ELI), stainless steel 316L, PEEK, and cobalt-chrome alloys, all processed under controlled cleanroom environments to maintain biocompatibility and surface integrity.

Precision is validated through a multi-stage quality control protocol. All critical dimensions undergo first-article inspection via Zeiss CONTURA CMM systems with 0.0008 mm volumetric accuracy, generating full GD&T reports traceable to NIST standards. Surface roughness is quantified using Bruker white-light interferometers, while optical comparators verify edge radii and micro-features down to 5 µm. This rigorous approach guarantees dimensional stability across high-mix, low-volume production runs typical of surgical tools, orthopedic implants, and diagnostic equipment housings.

Our tolerance mastery reflects medical industry requirements, as demonstrated below:

| Feature Type | Standard Industrial Tolerance | Medical Grade Tolerance |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Geometric Position | ±0.05 mm | ±0.002 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.2 µm |

| Hole Concentricity | 0.05 mm | 0.008 mm |

| Thread Pitch Accuracy | ±0.025 mm | ±0.005 mm |

These specifications are consistently achieved through adaptive machining strategies, including in-process probing for thermal compensation and closed-loop tool-wear monitoring. For mission-critical components like cranial plates or catheter hubs, we implement full-material traceability and batch-specific certification, including ASTM F86 surface preparation documentation. Our engineering team collaborates directly with client R&D departments during DFM analysis to optimize manufacturability without sacrificing functional requirements—reducing prototyping cycles by up to 40% while ensuring regulatory compliance.

Wuxi Lead’s technical infrastructure transforms complex medical designs into production-ready components with zero compromise on safety or performance. Every process, from raw material validation to final packaging, is engineered for the exacting standards of global healthcare applications. Contact our engineering team to discuss tolerance validation for your next-generation medical device project.

Material & Finish Options

Material selection is a critical step in the development of high-performance medical design components, where precision, biocompatibility, and long-term reliability are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for advanced medical applications, leveraging deep expertise in aluminum, stainless steel, and titanium—three of the most trusted materials in the industry. Each material offers distinct mechanical, thermal, and chemical properties that must align precisely with the functional and regulatory demands of medical devices.

Aluminum is widely used in medical housings, frames, and portable diagnostic equipment due to its excellent strength-to-weight ratio and thermal conductivity. It is particularly advantageous in applications requiring lightweight construction without sacrificing structural integrity. While pure aluminum lacks the corrosion resistance needed for sterilization cycles, specific alloys such as 6061 and 7075 offer enhanced durability and machinability. When paired with anodizing—a controlled electrochemical process that thickens the natural oxide layer—aluminum achieves superior surface hardness, wear resistance, and electrical insulation. Type II and Type III (hard coat) anodizing are commonly applied based on operational stress and environmental exposure.

Stainless steel, especially grades 316L and 17-4 PH, remains the gold standard for surgical instruments, implants, and reusable medical tools. Its exceptional corrosion resistance, high tensile strength, and ability to withstand repeated autoclaving make it ideal for sterile environments. 316L, an austenitic grade with low carbon content, offers excellent weldability and biocompatibility, minimizing the risk of adverse reactions in implantable devices. 17-4 PH, a precipitation-hardening martensitic steel, provides superior strength and can be heat-treated to meet stringent mechanical requirements.

Titanium, particularly Grade 5 (Ti-6Al-4V), is favored in implantable and long-term biomedical applications due to its outstanding strength-to-density ratio, fatigue resistance, and osseointegration capabilities. It is inherently biocompatible, non-magnetic, and highly resistant to body fluids and chlorides. Though more challenging to machine than aluminum or steel, titanium’s performance in critical applications justifies the investment. It is commonly used in orthopedic implants, dental fixtures, and cranial plates.

Surface finish plays a pivotal role in both functionality and compliance. Anodizing not only enhances aluminum’s durability but also allows for color coding—useful in device differentiation and user guidance. For medical components, finishes must meet ISO 13485 standards and support cleanability, sterilization compatibility, and minimal particulate generation.

Below is a comparative overview of key material properties relevant to medical design components:

| Material | Typical Grade | Tensile Strength (MPa) | Corrosion Resistance | Biocompatibility | Common Medical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | Moderate (enhanced with anodizing) | Good | Housings, imaging frames, carts |

| Stainless Steel | 316L | 570 | Excellent | Excellent | Surgical tools, clamps, implants |

| Stainless Steel | 17-4 PH | 1000+ | Excellent | Excellent | Load-bearing instruments, connectors |

| Titanium | Ti-6Al-4V | 950 | Excellent | Excellent | Implants, dental fixtures, prosthetics |

Selecting the right material and finish requires a holistic understanding of the component’s operational environment, regulatory pathway, and lifecycle demands. At Wuxi Lead, we collaborate closely with engineering teams to ensure optimal material performance and manufacturability, delivering precision components that meet the highest standards of medical device excellence.

Manufacturing Process & QC

Precision Manufacturing Process for Medical Design Components

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for medical design components where zero defects are non-negotiable. This high-stakes environment demands absolute precision from initial concept through volume delivery, directly impacting patient safety and device efficacy. Our integrated process eliminates traditional handoffs, embedding quality assurance at every stage to meet stringent ISO 13485 and FDA requirements.

Design Phase: Engineering Perfection from Conception

Collaboration begins immediately with your engineering team. We conduct comprehensive Design for Manufacturability (DFM) and Design for Assembly (DFA) analysis, identifying potential production risks before metal is cut. Advanced CAD/CAM simulation validates toolpaths and detects interference or stress points. Material selection is scrutinized against biocompatibility standards like ASTM F138 or ISO 5832, ensuring compatibility with surgical environments and long-term implantation. This proactive engineering phase prevents 95% of potential defects at the source, establishing a flawless foundation.

Prototyping Phase: Validating Performance Under Real Conditions

Prototypes are manufactured using the exact production-grade CNC equipment and processes intended for volume runs, not simplified methods. Each prototype undergoes full metrological validation against your CAD model using calibrated Coordinate Measuring Machines (CMMs) and optical comparators. Dimensional accuracy, surface integrity, and material properties are verified to micron-level tolerances. Functional testing simulates actual clinical use conditions. This phase confirms design viability and process capability, generating the approved master sample and documented inspection protocols essential for zero-defect mass production.

Mass Production Phase: Sustained Excellence at Scale

Volume manufacturing leverages the validated process parameters and fixtures from prototyping. Our facility employs automated CNC machining centers with sub-micron repeatability, operating under strict environmental controls. Real-time Statistical Process Control (SPC) monitors critical dimensions continuously, triggering immediate corrective action if trends approach tolerance limits. Every component undergoes 100% automated visual inspection and dimensional verification against the master sample. Full material traceability from raw bar stock to finished part is maintained, with comprehensive batch documentation provided. This closed-loop system ensures consistent output meeting the most demanding medical specifications.

Critical dimensional and surface specifications consistently achieved across our medical component portfolio include:

| Parameter | Typical Capability | Medical Industry Standard | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ±0.005 mm – ±0.01 mm | CMM (Calibrated to ISO 17025) |

| Surface Roughness (Ra) | 0.2 µm | 0.8 µm – 1.6 µm | Profilometer |

| Geometric Tolerance | ±0.003 mm | ±0.01 mm | CMM / Optical Comparator |

| Material Certification | Full MTR Traceability | ASTM F86 / ISO 13485 | Certified Mill Reports |

| Biocompatibility | ISO 10993 Compliant | Mandatory for Implants | Third-Party Lab Testing |

This seamless, quality-integrated process—from collaborative design through validated prototyping to rigorously controlled mass production—is how Wuxi Lead delivers medical design components with demonstrable zero-defect performance. We transform complex surgical requirements into manufactured reality, ensuring every part contributes to patient well-being.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Medical Design Component Manufacturing

In the highly regulated and precision-driven world of medical device manufacturing, every component must meet exacting standards for reliability, biocompatibility, and performance. At Wuxi Lead Precision Machinery, we specialize in the custom metal manufacturing of critical medical design components, delivering solutions that meet the stringent demands of global healthcare innovators. Our engineering expertise, combined with advanced CNC machining, Swiss turning, and multi-axis milling capabilities, ensures that your components are not only dimensionally accurate but also compliant with ISO 13485 and other industry-specific certifications.

Choosing the right manufacturing partner is more than a procurement decision—it’s a strategic collaboration that impacts time-to-market, product quality, and patient safety. Lead Precision is built on a foundation of technical precision, responsive engineering support, and a deep understanding of the challenges faced by medical device designers and OEMs. From prototyping to high-volume production, we provide end-to-end manufacturing services tailored to your unique design requirements. Our facility in Wuxi, China, operates under cleanroom conditions where necessary, and we maintain full traceability across every production batch.

We understand that medical components often require complex geometries, tight tolerances, and specialized materials such as titanium, stainless steel 316L, and MP35N. Our team works closely with your engineers during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce assembly complexity, and ensure regulatory compliance from the outset. This proactive collaboration minimizes risk, accelerates development cycles, and reduces long-term production costs.

Our commitment to quality is reflected in every stage of the process. Each component undergoes rigorous in-process and final inspections using high-precision CMMs, optical comparators, and surface finish testers. We support full documentation packages, including first article inspection (FAI) reports, material certifications, and process validation records required for FDA submissions.

Below are key technical capabilities that define our service offering:

| Specification | Detail |

|---|---|

| Tolerance Capability | ±0.001 mm (±0.00004 in) |

| Maximum Part Size | Ø150 mm × 300 mm (Ø5.9 in × 11.8 in) |

| Minimum Feature Size | Ø0.2 mm (Ø0.008 in) micro-machining |

| Materials | Stainless Steel (303, 304, 316L), Titanium (Gr 2, Gr 5), Inconel, MP35N, Aluminum, Brass |

| Processes | CNC Milling (3–5 axis), CNC Turning, Swiss Machining, Mill-Turn, EDM |

| Secondary Operations | Passivation, Electropolishing, Laser Marking, Heat Treatment, Coating |

| Quality Standards | ISO 9001, ISO 13485, RoHS, REACH |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering ally dedicated to advancing medical innovation. Contact us today at [email protected] to discuss your next medical design component project. Let us help you turn precision concepts into life-saving realities.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.