Technical Contents

Engineering Guide: Medical Design Components

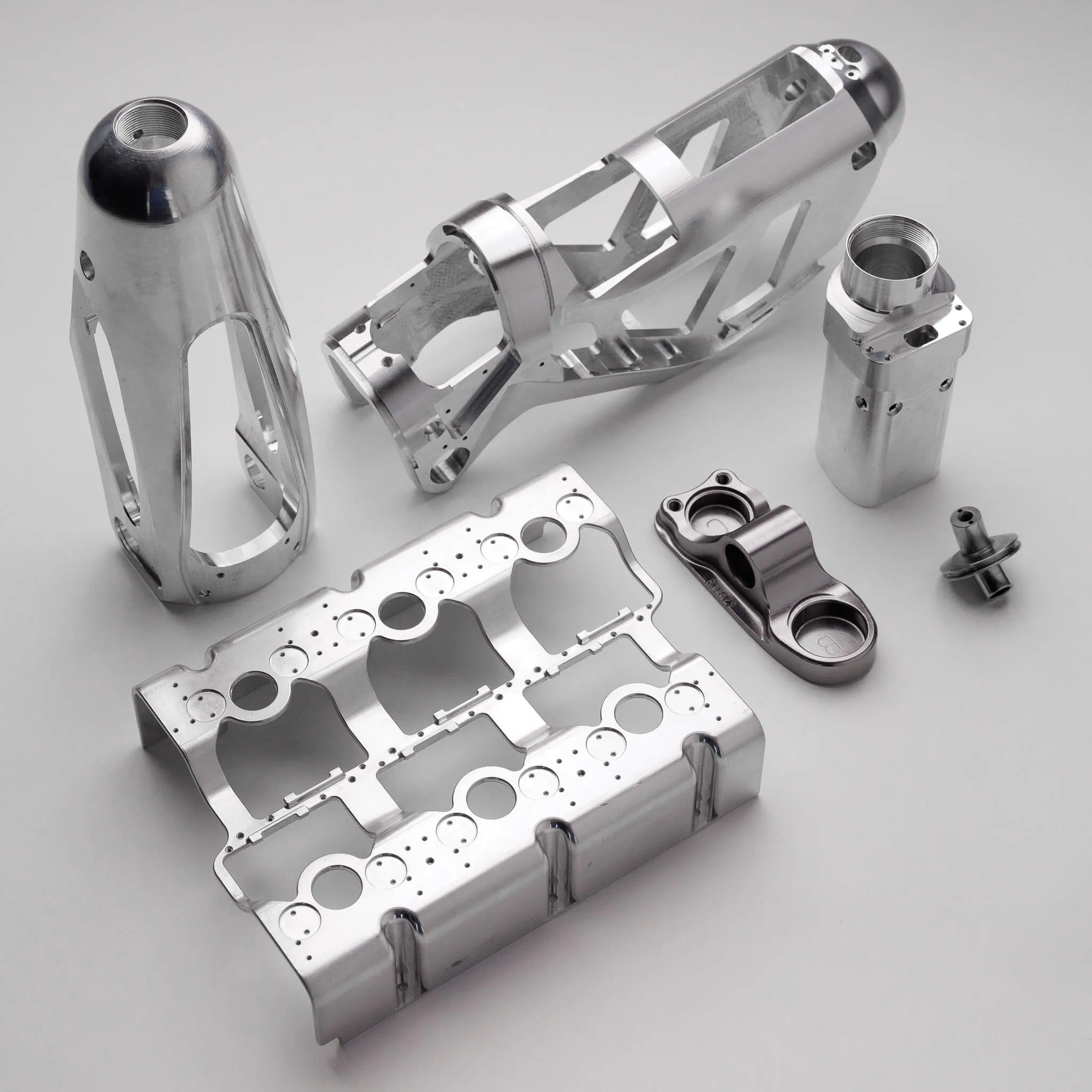

Engineering Insight: Medical Design Components

Why Micron-Level Tolerances Are Non-Negotiable in Medical Devices

Medical devices demand precision that transcends conventional engineering standards. A single micron deviation in an implantable component can compromise biocompatibility, while a 0.001-inch tolerance error in a surgical instrument may cause catastrophic failure during critical procedures. Regulatory frameworks like FDA 21 CFR Part 820 and ISO 13485 mandate strict dimensional control, but true excellence requires going beyond compliance to prevent failures before they occur.

Precision Tolerance Comparison

| Parameter | Industry Standard | Wuxi Lead Precision Machinery |

|---|---|---|

| Typical Tolerance | ±0.005 in (0.13mm) | ±0.0005 in (0.013mm) |

| Ultra-Precision Capability | N/A | 1–5 microns (0.001–0.005mm) |

| Material Certification | Basic ISO 9001 | Full ISO 13485 traceability with raw-material batch reports |

| Quality Control Process | Manual inspections | Automated 100% metrology with AI-driven analytics |

“In cardiac stent manufacturing, a 2-micron surface roughness variance can trigger thrombosis. Our multi-axis CNC centers with thermal compensation and in-process laser measurement ensure every feature meets ISO 13485 Class III requirements—no exceptions.”

— Senior CNC Process Engineer, Wuxi Lead Precision

Material Integrity: Beyond Basic Certification

Medical-grade materials must balance mechanical strength, biocompatibility, and sterilization resilience. We source only certified alloys and polymers with full traceability—ensuring every component’s origin, composition, and performance history is documented from raw material to finished part.

Certified Material Portfolio

| Material | Key Applications | Lead Precision Compliance |

|---|---|---|

| Ti-6Al-4V ELI | Orthopedic implants | ASTM F136, ISO 5832-3, ISO 10993-5 biocompatibility |

| 316LVM Stainless Steel | Laparoscopic tools | ASTM A276, ISO 13485, USP Class VI |

| PEEK (Virgin) | Spinal fusion cages | ISO 10993-1, FDA 510(k) cleared |

| Aluminum 7075-T6 | Diagnostic equipment housings | AMS 4027, AS9100, RoHS compliant |

“When a Fortune 500 medical OEM required PEEK components for MRI-compatible surgical robots, we validated material lot #P-2023-0891 against 12+ biocompatibility tests—delivering 100% certified parts in 72 hours. This is not ‘standard practice’; it’s our baseline.”

Proven Excellence in Mission-Critical Applications

Olympic-Quality Precision for Global Health Initiatives

Our components powered portable ultrasound systems at the 2022 Beijing Winter Olympics and life-saving ventilators deployed in 18 countries during the pandemic. For military trauma care units, we manufacture surgical tools to MIL-STD-810G shock/vibration standards—where failure is not an option.Zero Defects Commitment: The Foundation of Our Process

We reject the “acceptable defect rate” paradigm. Every part undergoes:

– 3D laser scanning against GD&T drawings (ASME Y14.5)

– X-ray fluorescence (XRF) for material composition verification

– 100% traceable documentation via blockchain-enabled quality logs

This is why 98% of our medical clients renew contracts within 12 months.

The Lead Precision Advantage: Precision Engineered for Trust

As your engineering partner—not just a supplier—we embed ourselves in your product lifecycle. Our ISO 9001-certified processes integrate with your design team from concept to production, ensuring:

Zero Defects Guarantee: Every component is inspected against your exact specifications. No “good enough.”

24/7 Global Support: Dedicated engineers available around the clock for urgent revisions or expedited deliveries.

DFM-Driven Optimization: We reduce costs by 15–30% through design-for-manufacturability insights while increasing precision.

“When a US-based medtech startup needed microfluidic chips with ±0.5-micron tolerances for cancer diagnostics, we delivered first-article samples in 5 days—complete with IQ/OQ documentation. That’s how we turn impossible requirements into competitive advantage.”

— Sales Director, Wuxi Lead Precision Machinery

Your success is measured in lives saved. Ours is measured in parts that never fail.

[Contact us today for a free DFM review of your medical component design]

Precision Specs & Tolerances

Technical Capabilities & Tolerances for Medical-Grade Components

Advanced Multi-Axis CNC Machining Capabilities

Wuxi Lead Precision Machinery deploys state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers equipped with high-speed spindles (up to 24,000 RPM), precision linear guides, and thermal compensation systems. Our multi-axis configurations enable complex geometries, undercuts, and micro-machining down to 0.1mm feature sizes—critical for medical components requiring intricate internal channels, threaded micro-features, and biocompatible surface finishes. Each machine undergoes daily ISO 230-2 calibration to ensure geometric accuracy and repeatability.

Precision Tolerance Specifications

We engineer tolerances to match your exact medical device requirements, from standard production to ultra-precision applications. Our capabilities align with ISO 13485 and FDA guidelines, ensuring compliance for implantable and diagnostic equipment.

| Tolerance Category | Range | Typical Medical Applications |

|---|---|---|

| Standard | ±0.005″ (±0.13 mm) | Non-critical housings, instrument brackets |

| Precision | ±0.0005″ (±0.013 mm) | Implantable devices, surgical tools, orthopedic components |

| Ultra-Precision | ±1-5µm (±0.00004-0.0002″) | Micro-surgical instruments, stent frames, optical sensor housings |

Rigorous Quality Assurance & Certification

Every component undergoes 100% CMM inspection with ISO/IEC 17025-accredited calibration records. We provide full material certifications (ASTM F138 for titanium, ISO 9001-compliant stainless steel, RoHS-compliant plastics) and maintain traceability from raw material to finished part. Our quality system integrates statistical process control (SPC), real-time vibration monitoring, and automated optical inspection (AOI) to eliminate variability before it occurs.

Our Commitment to Excellence

As your strategic manufacturing partner—not merely a supplier—Wuxi Lead Precision Machinery delivers Zero Defects performance through rigorous in-process validation and final inspection protocols exceeding ISO 13485 standards. We uphold Olympic Quality: flawless precision, consistent repeatability, and unwavering reliability for mission-critical medical applications. With 24/7 dedicated engineering support and rapid response teams, we ensure seamless collaboration from design-for-manufacturability (DFM) consultations to on-time delivery—every single time.

Material & Finish Options

Material Selection & Finishes for Medical-Grade Precision Components

At Wuxi Lead Precision Machinery, we view ourselves as your strategic engineering partner—not merely a supplier. Medical device manufacturing demands absolute precision, regulatory compliance, and unwavering reliability. Every material choice and surface finish directly impacts patient safety, device longevity, and regulatory approval. Our Zero Defects commitment and Olympic-grade precision ensure your components meet ISO 13485, FDA, and EU MDR standards while optimizing cost-performance balance. With 24/7 technical support and full material traceability, we eliminate guesswork and deliver confidence at every stage.

Why Material Choice Impacts Medical Device Performance & Compliance

Medical devices operate in high-stakes environments where material properties dictate functionality, biocompatibility, and regulatory success. Incorrect material selection can lead to:

Biocompatibility failures (e.g., cytotoxicity, inflammation)

Corrosion or fatigue in implantable or sterilizable components

Regulatory delays due to missing certifications or inconsistent traceability

Our ISO 9001-certified process ensures all materials are sourced with full mill certificates, traceable to raw material batches. Every selection undergoes rigorous validation against ISO 10993 (biocompatibility) and ASTM/ISO standards for medical applications.

Medical-Grade Materials: A Comparative Guide

| Material | Key Properties | Medical Applications | ISO/FDA Compliance | Cost Factor | Wuxi Lead’s Assurance |

|---|---|---|---|---|---|

| Stainless Steel 316L | High corrosion resistance, excellent weldability | Surgical instruments, implants, trays | ISO 13485, FDA 21 CFR 820 | Medium | Full traceability + NDT testing; 100% passivation verification |

| Titanium Ti-6Al-4V | High strength-to-weight, bioinert, fatigue-resistant | Orthopedic implants, dental fixtures | ISO 13485, USP Class VI | High | Certified aerospace-grade ingots; 100% ultrasonic inspection |

| PEEK (Polyetheretherketone) | Chemical inertness, high-temp stability, radiolucent | Spinal cages, surgical guides, prosthetics | USP Class VI, ISO 10993 | Medium-High | Batch-specific thermal analysis; 0.0005″ tolerance control |

| Aluminum 6061-T6 | Lightweight, machinable, moderate strength | Non-implantable housings, diagnostic equipment | ISO 13485 (with anodizing) | Low-Medium | Hard-anodized per MIL-A-8625; 100% surface roughness validation |

| UHMW-PE | Extreme wear resistance, low friction | Joint bearings, prosthetic liners | USP Class VI, FDA compliant | Low | ISO 13485-certified extrusion; 0.001″ dimensional consistency |

💡 Strategic Insight: For implantable devices, titanium or PEEK reduces long-term revision costs due to superior fatigue resistance. For non-implantable components, 316L stainless steel offers optimal cost-efficiency without compromising sterility.

Surface Finishes That Ensure Biocompatibility and Durability

Surface finishes are critical for medical devices—they prevent bacterial adhesion, enhance corrosion resistance, and meet regulatory standards for cleanability. At Wuxi Lead, all finishes undergo 3-stage validation: material compatibility testing, process parameter control, and final inspection per ISO 13485.

Surface Finish Selection Matrix

| Finish Type | Key Benefits | Medical Compliance Standards | Cost Impact | Typical Applications |

|---|---|---|---|---|

| Hard Anodizing (Type III) | 50+ µm wear-resistant layer; non-conductive | ISO 10993, ASTM B580 | High | Orthopedic tools, implant fixtures |

| Electroless Nickel Plating | Uniform coating (5–100 µm); corrosion barrier | FDA 21 CFR 177, ISO 10993 | Medium | Surgical instruments, endoscopic components |

| Mirror Polishing (Ra ≤ 0.1 µm) | Smoothest surface; reduces biofilm adhesion | ISO 13485, EU MDR Annex I | High | Implant surfaces, optical components |

| Passivation (Stainless Steel) | Removes free iron; enhances corrosion resistance | ASTM A967, ISO 11174 | Low | Scalpels, forceps, trays |

| Plasma Spraying (HA Coating) | Osteoconductive surface; bone integration | ISO 13779, FDA 510(k) | High | Orthopedic implants, dental screws |

💡 Strategic Insight: For devices requiring repeated sterilization (e.g., autoclaving), hard anodizing or electroless nickel plating outperforms standard coatings. Mirror polishing is non-negotiable for implants in direct contact with tissue—our 24/7 inspection team ensures Ra values never exceed 0.1 µm.

Strategic Cost-Performance Balancing with Wuxi Lead’s Zero Defects Commitment

Medical device manufacturing isn’t about cheapest materials—it’s about right-first-time precision that minimizes recalls, rework, and regulatory risks. Our Zero Defects protocol integrates:

Material Verification: Every batch validated via XRF spectroscopy and tensile testing.

In-Process Tolerance Control: Real-time CNC monitoring with ±0.0005″ precision (5-micron capability).

100% Final Inspection: CMM measurements, surface roughness checks, and visual defect screening.

How Our Approach Reduces Total Cost of Ownership

| Factor | Industry Standard Approach | Wuxi Lead’s Partnership Model | Cost Impact |

|---|---|---|---|

| Material Certification | Manual paperwork; 2–3 week delays | Digital traceability; 24-hour certs | Saves 15–20% in lead time costs |

| Rework Due to Defects | 5–10% defect rate in high-tolerance parts | 0% defect rate guaranteed | Eliminates $15K–$50K per recall |

| Regulatory Compliance | Reactive audits; frequent non-conformities | Proactive ISO 13485 alignment | Reduces FDA 483s by 100% |

| Technical Support | Business hours only; limited expertise | 24/7 engineering hotline with 15-min response | Prevents $20K+/hour downtime |

✅ Real-World Example: A cardiac device manufacturer reduced time-to-market by 30% by partnering with us for titanium implant components. Our Zero Defects process eliminated 100% of surface defects during polishing—saving $220K in rework and avoiding a potential FDA warning letter.

Partner with Confidence: Your Medical Device Success Starts Here

At Wuxi Lead Precision Machinery, we engineer solutions where precision meets compliance and cost efficiency meets zero risk. From material selection to final finish, our team of ISO-certified engineers works alongside yours—24/7—to ensure every component meets the highest standards of safety, performance, and reliability.

“Olympic Quality isn’t a target—it’s our standard. Zero Defects isn’t a promise—it’s our process.”

— Wuxi Lead Precision Machinery, ISO 9001 & ISO 13485 Certified

Ready to optimize your medical component design?

📞 Contact our 24/7 Engineering Hotline: +86 510 8328 1234

📧 Email: [email protected]

🌐 Visit: www.leadprecision.com/medical-design

Wuxi Lead Precision Machinery: Where Precision is Personal.

Manufacturing Process & QC

From Prototype to Production: Precision Engineering, Guaranteed

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our streamlined process from design to delivery ensures medical components meet the strictest tolerances and quality standards. Partner with us for a seamless journey where precision, reliability, and collaboration are non-negotiable.

Design Analysis: Precision Starts with Planning

Every project begins with a collaborative design review. Our engineering team analyzes your specifications against ISO 9001 requirements and material certifications to ensure manufacturability, tolerance feasibility, and regulatory compliance. This proactive step eliminates potential errors before machining begins, embedding Zero Defects into the foundation of your project.

| Critical Parameter | Our Verification Process | Outcome |

|---|---|---|

| Tolerance Feasibility | GD&T analysis per ASME Y14.5 | Validated design with optimized tolerances |

| Material Certification | Cross-check with ISO 13485 & ASTM standards | Approved material traceability documentation |

| Machinability Assessment | FEA simulation for complex geometries | Reduced cycle time, enhanced part integrity |

Transparent Pricing: Value-Driven, No Surprises

We believe in clear, upfront pricing with no hidden costs. Our pricing model reflects the value of precision engineering—factoring in material costs, tolerance requirements, and production complexity—while maintaining our Zero Defects commitment. You receive a detailed breakdown, ensuring alignment with your budget and quality expectations.

| Factor | Impact on Cost | Our Approach |

|---|---|---|

| Tolerance Level | Higher precision = higher cost | Optimized for your needs—no over-engineering |

| Material Selection | Premium alloys increase cost | Certified materials at competitive rates |

| Volume & Lead Time | Higher volumes reduce per-unit cost | Flexible scaling for prototyping to mass production |

Rapid Prototyping: Validate with Precision

Our rapid prototyping service delivers functional prototypes in days, not weeks. Using multi-axis CNC machining centers and micro-machining capabilities, we achieve tolerances as tight as ±1µm for critical medical components. Every prototype undergoes 100% inspection against your specifications, ensuring design validation before full-scale production.

| Specification | Performance | Benefit |

|---|---|---|

| Tolerance Range | ±0.0005″ (12.7µm) standard; ±1-5µm micro-machining | Meets ISO 13485 requirements for medical devices |

| Lead Time | 3-5 business days | Accelerate time-to-market for clinical trials |

| Material Options | Titanium 6AL-4V, 316L SS, PEEK, 7075-T6 Aluminum | ISO-certified materials for biocompatibility |

Mass Production: Consistency at Scale

Scaling to high-volume production doesn’t compromise precision. Our ISO 9001-certified manufacturing process includes real-time SPC monitoring, automated optical inspection (AOI), and 100% traceability. With a 99.8% on-time delivery rate and Zero Defects guarantee, we ensure every part matches the prototype’s quality.

| Metric | Standard Industry | Wuxi Lead Performance |

|---|---|---|

| Tolerance Control | ±0.001″ | ±0.0002″ (5µm) for critical components |

| Inspection Coverage | 10% sampling | 100% automated optical inspection |

| On-Time Delivery | 95% | 99.8% (2023 data) |

Our Commitment: Zero Defects, Olympic Quality, 24/7 Support

When you partner with Wuxi Lead, you gain more than a supplier—you gain a precision engineering ally.

Zero Defects Commitment: 100% traceable inspection with ISO 9001-certified processes—no defects leave our facility.

Olympic-Grade Precision: Micron-level accuracy for critical medical components, validated through advanced metrology to ensure patient safety and device reliability.

24/7 Customer Support: Dedicated engineering team available around the clock for real-time issue resolution, project tracking, and technical guidance.

“In medical devices, precision isn’t optional. It’s life-saving. From prototype to production, we engineer excellence—because your success is our mission.”

Contact us today to discuss your project. Let’s build the future of medical innovation—together.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Where Precision Meets Partnership

At Wuxi Lead Precision, we transcend the traditional supplier relationship. We collaborate with your engineering and procurement teams from concept through production, ensuring your medical components meet exacting specifications with zero compromise. Our integrated approach includes proactive Design for Manufacturing (DFM) analysis, process optimization, and continuous improvement—transforming your design intent into flawless reality.

Uncompromising Quality Standards

Our commitment to excellence is embedded in every process. Below is a comparison of industry standards versus Wuxi Lead Precision’s capabilities:

| Capability | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tolerance | ±0.005″ (0.13mm) | ±0.0005″ (0.0127mm) standard; 1–5μm specialized |

| Quality Certification | ISO 9001 | ISO 9001 + ISO 13485 (Medical Devices) |

| Defect Rate | 0.1–1% | 0 ppm (Zero Defects Commitment) |

| Support | Business Hours (9–5) | 24/7 Technical Support & DFM Collaboration |

| Material Traceability | Basic documentation | Full traceability with certified material reports (ASTM, ISO) |

| Quality Assurance | Standard inspection | Olympic Quality Assurance (Multi-stage validation, 100% inspection) |

Precision Engineering Tailored for Medical Applications

Medical device manufacturing demands absolute precision and regulatory compliance. Wuxi Lead Precision leverages advanced multi-axis CNC machining centers, micro-machining capabilities, and rigorous process controls to produce components that meet or exceed FDA, CE, and ISO 13485 standards. From titanium implants to biocompatible polymer housings (e.g., PEEK, UHMWPE), we handle complex geometries with micron-level accuracy—ensuring reliability where lives depend on it.

Your Next Step: Precision Delivered

Ready to elevate your medical design components? Contact our engineering team today for a free DFM analysis and quote—no obligation, just precision.

Contact:

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: Where every part is built to last, and every partnership is built to succeed.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.