Technical Contents

Engineering Guide: Medical Assembly Plymouth Mn

Engineering Insight: Precision in Medical Assembly – Plymouth, MN and Global Standards

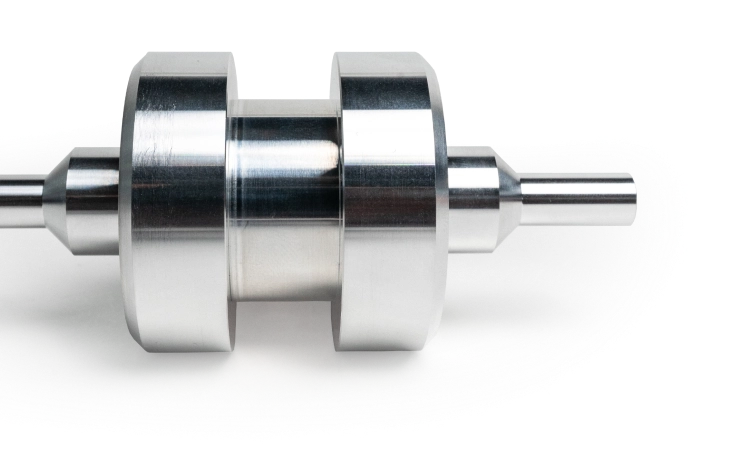

In the field of medical device manufacturing, precision is not merely a performance metric—it is a requirement for safety, reliability, and regulatory compliance. Medical assembly operations in locations such as Plymouth, Minnesota, represent critical hubs in the U.S. healthcare supply chain, where advanced components for surgical instruments, implantable devices, and diagnostic equipment are produced. These components demand micron-level tolerances, repeatable consistency, and absolute material integrity. At Wuxi Lead Precision Machinery, we understand that the success of medical assembly processes—whether in Plymouth or beyond—depends on the foundational precision of every machined part.

Our engineering team has spent over 15 years refining high-precision metal manufacturing techniques for some of the most demanding industries in the world. This includes supplying mission-critical components for Olympic-standard equipment and defense applications where failure is not an option. The same principles that ensure a military-grade actuator performs flawlessly in extreme environments are applied to the production of titanium bone screws or stainless steel cannulas used in minimally invasive surgery. Tolerance deviations of even 5 microns can lead to device malfunction, patient risk, or non-compliance with FDA or ISO 13485 standards.

At Lead Precision, we utilize multi-axis CNC machining, Swiss-type turning, and automated inspection systems—including coordinate measuring machines (CMM) and optical comparators—to ensure every component meets exact design specifications. Our process control systems are designed to support full traceability, cleanroom compatibility, and batch uniformity, which are essential for integration into medical assembly lines where automation and robotics depend on part interchangeability.

The synergy between U.S.-based medical assembly facilities and overseas precision manufacturers like Wuxi Lead is increasingly vital. As companies in Plymouth, MN, scale production to meet growing demand for advanced medical technologies, they require partners capable of delivering not only precision but also scalability and regulatory alignment. Our experience working under stringent quality frameworks allows us to seamlessly integrate into global supply chains, providing documented process validation, First Article Inspections (FAI), and PPAP documentation as required.

We do not manufacture generic parts—we engineer solutions where every micron is accounted for, every material specification is verified, and every production run supports the integrity of the final medical device. Whether supporting prototyping or high-volume production, Wuxi Lead Precision Machinery delivers the engineering rigor that medical assembly operations demand.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.001 mm to ±0.005 mm |

| Materials Processed | 316L Stainless Steel, Titanium (Gr 2, Gr 5), Inconel, Aluminum Alloys, MP35N |

| Maximum Part Size | Ø150 mm × 300 mm |

| CNC Equipment | 5-axis machining centers, Swiss lathes, multi-spindle automatics |

| Quality Standards | ISO 9001:2015, ISO 13485, ITAR Registered, FDA Compliant Documentation |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (customizable) |

| Secondary Operations | Passivation, laser marking, heat treatment, coating (per spec) |

Precision Specs & Tolerances

Technical Capabilities for Precision Medical Assembly Components

Wuxi Lead Precision Machinery delivers mission-critical metal components for the medical assembly sector, specifically addressing the stringent demands of facilities in Plymouth, MN, and beyond. Our technical infrastructure is engineered to support complex medical device manufacturing where zero-defect performance is non-negotiable. Central to our capability is a dedicated fleet of 5-axis CNC milling and turning centers, featuring Fanuc and Siemens controls. These systems enable single-setup machining of intricate geometries—such as orthopedic implant sockets, surgical instrument housings, and fluidic manifolds—eliminating cumulative error from multiple fixtures. This is critical for medical assemblies requiring hermetic seals or micron-level alignment, directly reducing scrap rates and accelerating time-to-market for our clients. All machining operations adhere to ISO 13485 protocols, with environmental controls maintaining ±0.5°C temperature stability in production zones to ensure thermal consistency.

Quality verification is non-optional in medical manufacturing. We deploy Zeiss and Hexagon Coordinate Measuring Machines (CMMs) for 100% first-article inspection and statistical process control (SPC) on high-volume runs. Our CMM cells operate under NIST-traceable calibration, with automated reporting integrated into client-specific quality documentation packages. This includes full GD&T validation, surface roughness analysis (Ra 0.2µm achievable), and material certification traceability. Every component undergoes dimensional verification against ASME Y14.5 standards before shipment, with digital records archived for full lifecycle traceability per FDA 21 CFR Part 820 requirements.

The following table details our standard tolerance capabilities for medical-grade materials:

| Feature Type | Standard Tolerance (mm) | Tight Tolerance (mm) | Materials Supported |

|---|---|---|---|

| Linear Dimensions | ±0.025 | ±0.005 | 316L/304L SS, Ti-6Al-4V, MP35N |

| Geometric (GD&T) | ±0.05 | ±0.01 | Co-Cr, Nitinol, Aluminum 7075 |

| Hole Position | ±0.03 | ±0.008 | PEEK (metal inserts), Inconel |

| Surface Roughness | Ra 1.6 | Ra 0.4 | All qualified medical alloys |

Our process excellence extends beyond equipment. Dedicated engineering teams collaborate with Plymouth-based medical assemblers during Design for Manufacturability (DFM) stages, identifying potential assembly conflicts early—such as interference in multi-part subassemblies or sterilization-induced stress points. We maintain AS9100-certified supply chain controls for raw materials, ensuring batch-specific material test reports (MTRs) accompany every shipment. With 15+ years serving global medical OEMs, we understand that compliance is foundational, but reliability is earned through repeatable execution. For Plymouth MN medical assembly partners requiring components where failure is not an option, Wuxi Lead provides certified precision from prototype to high-volume production, backed by real-time quality data transparency. This commitment ensures your assembly lines operate with uncompromised component integrity.

Material & Finish Options

Material Selection for High-Precision Medical Assembly Components

Selecting the appropriate material is critical in medical device manufacturing, where performance, biocompatibility, and long-term reliability are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for medical assembly applications, supporting clients in Plymouth, MN, and beyond with engineered solutions that meet stringent regulatory and functional demands. The three primary metals used in precision medical components—aluminum, stainless steel, and titanium—each offer distinct advantages depending on the application’s mechanical, chemical, and environmental requirements.

Aluminum is favored for its lightweight properties and excellent thermal and electrical conductivity. It is particularly suitable for non-implantable medical equipment housings, surgical tool frames, and portable diagnostic devices where weight reduction is essential. While aluminum is not inherently corrosion-resistant, it responds exceptionally well to anodizing, a process that enhances surface durability and wear resistance. Type II and Type III (hard coat) anodizing are commonly applied, with the latter offering superior thickness and hardness for high-wear environments.

Stainless steel remains the most widely used material in medical assembly due to its outstanding corrosion resistance, strength, and sterilization compatibility. Grades such as 316 and 316L are austenitic steels with molybdenum content, providing enhanced resistance to chlorides and making them ideal for repeated autoclave cycles. These materials are frequently used in surgical instruments, implantable device components, and fluid handling systems. Their ability to maintain integrity under repeated thermal and chemical stress makes stainless steel a cornerstone of medical-grade metal fabrication.

Titanium, particularly Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio and outstanding biocompatibility, making it the material of choice for implantable devices such as orthopedic fixation systems and dental prosthetics. It exhibits superior corrosion resistance in physiological environments and is non-magnetic, which is crucial for patients undergoing MRI procedures. Though more challenging to machine than aluminum or steel, titanium’s long-term performance in vivo justifies its use in critical applications.

Surface finishing plays a pivotal role in medical part performance. Anodizing aluminum not only improves wear resistance but also allows for color coding, aiding in device assembly and identification. For stainless steel and titanium, alternative finishes such as passivation, electropolishing, or bead blasting are typically used to optimize surface smoothness and reduce microbial adhesion.

Below is a comparative overview of key material properties relevant to medical assembly applications.

| Material | Typical Grade | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Finishes | Primary Medical Use |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 2.7 | 310 | Moderate (enhanced with anodizing) | Anodizing (Type II/III), bead blasting | Equipment housings, surgical tool bodies |

| Stainless Steel | 316L | 8.0 | 580 | Excellent | Passivation, electropolishing | Surgical instruments, fluid systems |

| Titanium | Ti-6Al-4V | 4.4 | 950 | Excellent | Anodizing, polishing, grit blasting | Implants, dental fixtures |

At Wuxi Lead Precision Machinery, we work closely with engineering teams in Plymouth, MN, and across the U.S. medical device sector to ensure optimal material and finish selection, combining precision manufacturing with regulatory compliance to deliver components that perform under the most demanding conditions.

Manufacturing Process & QC

Precision Medical Component Manufacturing: From Concept to Zero-Defect Production

Wuxi Lead Precision Machinery delivers certified, high-integrity metal components essential for advanced medical assembly operations, including critical facilities in Plymouth, MN. Our process is engineered for the stringent demands of the medical device sector, where failure is not an option. We operate under strict ISO 13485:2016 certification, ensuring every phase adheres to global regulatory standards and prioritizes patient safety above all else. Our integrated workflow transforms client specifications into flawless, production-ready parts through a meticulously controlled sequence.

The journey begins with collaborative engineering design. Our team works directly with Plymouth-based medical OEMs to refine CAD models, perform comprehensive DFM analysis, and select optimal biocompatible materials like 316L stainless steel or titanium alloys. This phase ensures manufacturability while meeting exacting functional and sterilization requirements. Next, precision prototyping validates the design. Utilizing advanced 5-axis CNC milling and turning centers, we produce functional prototypes for rigorous testing and design verification. This stage identifies potential issues early, preventing costly revisions later and confirming compatibility with downstream assembly processes. Only upon client sign-off does the seamless transition to volume production occur. Our automated, climate-controlled production cells run under real-time SPC monitoring, with every critical dimension measured in-process using calibrated CMMs and vision systems. Traceability is absolute, with full material certification and process documentation for every lot.

Key production capabilities supporting Plymouth medical assembly needs include:

| Parameter | Capability | Medical Relevance |

|---|---|---|

| Material Range | 316L SS, Ti-6Al-4V, MP35N, CoCr | Biocompatibility, corrosion resistance |

| Dimensional Tol. | ±0.005 mm (±0.0002″) | Critical for implant fitment & function |

| Surface Finish | Ra 0.4 μm (16 μin) achievable | Essential for sterilization & biointegration |

| Process Control | Full SPC, 100% CMM inspection | Zero-defect mandate compliance |

| Traceability | Lot/batch to serial level | Required for FDA UDI & recall management |

Achieving zero defects is not aspirational; it is our operational mandate. We implement poka-yoke (error-proofing) at every station, enforce rigorous first-article inspection protocols per AS9102, and maintain environmental controls exceeding ISO Class 8 standards where necessary. Our statistical process control systems analyze trends in real-time, enabling immediate corrective action before deviations occur. For Plymouth medical manufacturers, this translates to components that integrate seamlessly into final assembly lines, eliminating scrap, rework, and production delays. Partnering with Wuxi Lead ensures your medical devices meet the highest quality benchmarks from initial prototype through sustained volume production, delivering the regulatory confidence and performance reliability the healthcare industry demands.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

In the highly regulated and precision-driven world of medical device manufacturing, choosing the right partner is not just a matter of cost—it’s a strategic decision that impacts product reliability, regulatory compliance, and time-to-market. Wuxi Lead Precision Machinery stands as a trusted leader in custom metal manufacturing, delivering engineered solutions to global medical assembly operations, including advanced facilities in Plymouth, MN, and beyond. With over 15 years of specialization in high-precision CNC machining, sheet metal fabrication, and complex assembly integration, we provide the technical depth and quality assurance required by the medical industry.

Our facility in Wuxi, China, operates under strict ISO 13485 and ISO 9001 standards, ensuring every component meets the rigorous demands of medical applications. From prototype development to full-scale production, our engineering team collaborates closely with clients to optimize designs for manufacturability, cost-efficiency, and performance. Whether you require micro-precision housings, surgical instrument components, or custom enclosures for diagnostic equipment, Lead Precision delivers with consistency and speed.

We understand that medical OEMs in Plymouth and across the U.S. need more than just parts—they need a transparent, responsive, and technically capable offshore partner. That’s why we’ve built a U.S.-aligned operational model with real-time project tracking, bilingual engineering support, and dedicated account management. Our clients benefit from reduced lead times, scalable production capacity, and seamless logistics through our established shipping channels to North America.

Below are key capabilities that define our service offering for medical device manufacturers:

| Specification | Detail |

|---|---|

| Machining Tolerances | ±0.001 mm (±0.00004 in) |

| Materials Processed | Stainless Steel (304, 316L), Titanium, Aluminum, Inconel, PEEK |

| Processes | CNC Milling, Turning, Wire EDM, Laser Cutting, TIG/MIG Welding |

| Surface Finishes | Electropolishing, Passivation, Anodizing, Powder Coating |

| Quality Standards | ISO 13485, ISO 9001, RoHS, Full First Article Inspection (FAI) |

| Production Capacity | 24/7 High-Mix, Low- to High-Volume Runs |

| Lead Times | Prototype: 7–14 days; Production: 15–30 days (shipping included) |

Partnering with Wuxi Lead Precision Machinery means gaining access to advanced manufacturing technology, a quality-first culture, and a team committed to your success. We don’t just produce parts—we deliver precision-engineered solutions that support the integrity and performance of your medical devices.

For medical assembly operations in Plymouth, MN, and throughout the United States, the decision to outsource must balance cost, quality, and reliability. Lead Precision offers all three, backed by a proven track record with Tier 1 medical device manufacturers.

Contact us today at [email protected] to discuss your next project. Let our engineering team provide a detailed quote, DFM analysis, and production timeline tailored to your requirements. With Lead Precision, you gain more than a supplier—you gain a strategic manufacturing partner.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.