Technical Contents

Engineering Guide: Mcdonald Plastic Molding

Engineering Insight Precision Metal Components for Plastic Molding Applications

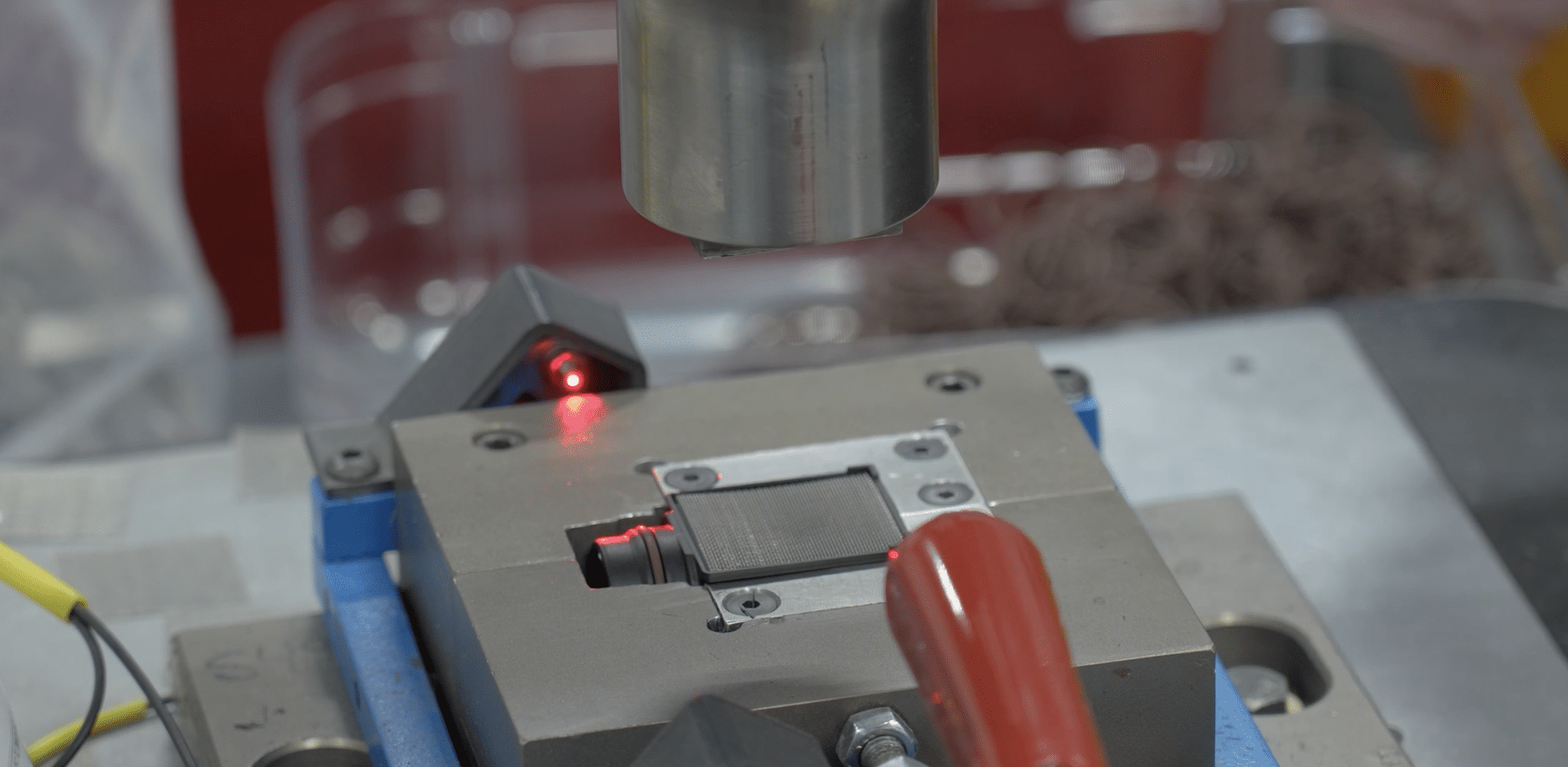

Within high-volume plastic molding operations, particularly those serving demanding sectors like consumer goods and packaging, the performance and longevity of the mold itself are paramount. While the focus often centers on the plastic resin and molding process parameters, the underlying metal components engineered to exacting standards are the unsung foundation of success. At Wuxi Lead Precision Machinery, we understand that microscopic deviations in mold bases, cavities, cores, ejector systems, or cooling channels directly translate to part defects, increased scrap rates, unplanned downtime, and compromised production efficiency. True precision in metal manufacturing isn’t merely a specification; it is the critical enabler of consistent, high-quality plastic output and optimal return on molding investment.

The consequences of inadequate metal precision are severe. Thermal distortion due to inconsistent material properties or poor heat treatment can warp critical mold surfaces during cycling. Dimensional inaccuracies exceeding tight tolerances lead to flash, short shots, or part ejection failures. Subsurface impurities or improper surface finishes accelerate wear, causing premature degradation of the mold’s critical geometry. These issues cascade into production delays, costly mold repairs, and ultimately, failure to meet stringent client quality requirements. Achieving the micron-level tolerances and superior surface integrity demanded by modern high-cavity or multi-material molding necessitates advanced CNC machining capabilities, rigorous material science expertise, and an uncompromising quality culture embedded throughout the manufacturing process.

Wuxi Lead Precision Machinery brings this level of precision capability to plastic molding partners. Our engineering heritage, forged through supplying critical components for Olympic timing systems requiring absolute reliability under global scrutiny and for military-grade actuators where failure is not an option, defines our approach. We apply this same discipline to every mold base, insert, and precision-machined element we produce. Our integrated facility utilizes state-of-the-art multi-axis CNC machining centers, coordinate measuring machines (CMMs) with sub-micron accuracy, and advanced metrology labs to validate every dimension and surface characteristic against the most stringent specifications. Material traceability, controlled heat treatment processes, and stringent in-process inspections are non-negotiable elements of our workflow.

The table below outlines core capabilities directly relevant to supporting high-performance plastic molding tooling:

| Specification Category | Capability Range | Relevance to Plastic Molding |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004 in) | Ensures perfect cavity/core alignment, prevents flash, guarantees part dimensional consistency |

| Surface Roughness (Ra) | 0.05 µm (2 µin) achievable | Minimizes part sticking, improves surface finish transfer, reduces wear |

| Material Expertise | Tool Steels (H13, S7, etc.), Stainless Steels, Aluminum Alloys | Optimized selection for thermal stability, wear resistance, and corrosion protection |

| Max. Machining Envelope | 2000 x 1200 x 1000 mm | Supports large, complex mold bases and multi-cavity systems |

| Process Validation | Full CMM reporting, Material Certificates, Heat Treat Certificates | Guarantees compliance, enables root cause analysis, ensures process stability |

Partnering with a precision metal manufacturer possessing demonstrable experience in mission-critical applications provides plastic molders with a fundamental competitive advantage. It ensures the metal foundation of the mold performs flawlessly over millions of cycles, directly contributing to higher yields, reduced total cost of ownership, and the ability to consistently deliver plastic parts meeting the highest global quality benchmarks. Precision metal isn’t just about the component; it’s about securing your entire molding operation’s success.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the exacting demands of high-performance industries, including aerospace, medical, automotive, and industrial equipment. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of complex, high-precision components with superior surface finish and dimensional accuracy. Our machining centers operate with simultaneous multi-axis movement, allowing for intricate geometries that would be unattainable with traditional 3-axis systems. This capability significantly reduces the need for multiple setups, minimizing human error and improving repeatability across production runs.

All machining operations are supported by in-house engineering expertise, utilizing the latest CAD/CAM software to optimize toolpaths, reduce cycle times, and ensure design intent is fully realized. Our 5-axis CNC systems are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to maintain consistent performance and detect anomalies before they impact quality. Materials commonly processed include aluminum alloys, stainless steel, titanium, tool steels, and specialty alloys, all machined to tight tolerances and finished to customer specifications.

Quality assurance is embedded throughout our manufacturing process. Every critical component undergoes comprehensive inspection using a state-of-the-art Coordinate Measuring Machine (CMM), ensuring compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM system provides full 3D measurement validation, generating detailed inspection reports traceable to international standards. These reports are available with every production batch, offering full transparency and supporting stringent regulatory compliance.

Our commitment to precision is reflected in the tolerances we consistently achieve across a range of features and dimensions. The following table outlines our standard and precision tolerance capabilities:

| Feature Type | Standard Tolerance (± mm) | Precision Tolerance (± mm) | Notes |

|---|---|---|---|

| Linear Dimensions | 0.05 | 0.01 | Up to 500 mm |

| Hole Diameter | 0.03 | 0.01 | Reamed or precision bored |

| Positional Tolerance | 0.10 | 0.03 | Per GD&T |

| Flatness | 0.05 / 100 mm | 0.01 / 100 mm | Critical sealing surfaces |

| Angular Dimensions | 0.1° | 0.05° | Measured via CMM |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | Machined; polished upon request |

These tolerances are maintained through continuous process validation, environmental control in inspection areas, and routine calibration of all equipment. Wuxi Lead Precision Machinery is equipped to support low-volume prototypes through high-mix production, delivering precision metal components that meet the most demanding technical and quality standards. Our technical capabilities are designed to serve partners like McDonald Plastic Molding with reliable, repeatable, and fully documented manufacturing performance.

Material & Finish Options

Material Selection for Precision Injection Molds: Aluminum, Steel, and Titanium

Selecting the optimal material for plastic injection molds is critical for balancing performance, longevity, and cost-effectiveness in high-volume production. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific resin, part geometry, and production volume. Aluminum excels in rapid prototyping and low-to-medium volume runs due to its superior thermal conductivity, which significantly reduces cycle times. Its ease of machining allows for faster lead times on complex cavities. However, aluminum’s lower hardness limits its use in abrasive resins or extended production, making it ideal for initial validation and bridge tooling where speed to market is paramount.

Tool steels remain the industry standard for high-volume production molds demanding exceptional wear resistance and dimensional stability. Grades like P20 offer good machinability and polishability for general-purpose applications, while H13 provides superior thermal fatigue resistance for molds subjected to high cavity pressures and temperature swings. For corrosive resins like PVC or flame-retardant materials, stainless variants such as S136 ensure long-term cavity integrity and part surface quality. Steel’s hardness directly correlates with mold life, with hardened tool steels sustaining millions of cycles under rigorous conditions.

Titanium presents a specialized solution for highly corrosive environments or extreme weight-sensitive applications, though its high cost and challenging machinability restrict widespread adoption. Its unparalleled corrosion resistance surpasses even stainless steel, making it viable for aggressive chemical processing within molds, yet economic factors typically favor optimized steel solutions for most plastic molding scenarios.

Surface finishing, particularly anodizing, is indispensable for enhancing aluminum mold performance. Type II sulfuric acid anodizing provides a standard corrosion-resistant layer, while Type III hardcoat anodizing delivers a dense, wear-resistant ceramic surface (50-100μm thickness) that dramatically extends the service life of aluminum molds in abrasive resin applications. This treatment maintains dimensional accuracy while improving release characteristics and reducing maintenance frequency.

The following table summarizes key material specifications for mold construction:

| Material Type | Hardness Range | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications | Cost Factor |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 95 HBW (Typical) | 167 | Low | Prototyping, Low-volume production | Low |

| Tool Steel P20 | 28-32 HRC | 28-36 | Moderate | Medium-volume production, General molds | Medium |

| Tool Steel H13 | 48-52 HRC | 24-30 | Good | High-pressure, High-temp production | High |

| Stainless Steel S136 | 48-52 HRC | 20-25 | Excellent | Corrosive resins (PVC, FR) | High |

| Titanium Grade 5 | 36 HRC (Typical) | 7.2 | Exceptional | Specialized corrosive/weight-critical | Very High |

Material choice directly impacts your mold’s thermal management, wear rate, and total cost of ownership. Wuxi Lead Precision Machinery engineers collaborate closely with clients to analyze resin properties, part complexity, and production targets, ensuring the selected material and finish—such as hardcoat anodizing for aluminum—maximize your operational efficiency and part quality. Contact our technical team for application-specific material validation.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect outcomes—critical for high-end custom metal manufacturing partners such as McDonald Plastic Molding. Our integrated workflow spans three core phases: Design, Prototyping, and Mass Production. Each stage is governed by strict quality protocols, advanced simulation tools, and real-time monitoring to ensure seamless scalability from concept to volume output.

Design begins with a collaborative engineering review, where our technical team aligns with the client’s functional, dimensional, and material requirements. Utilizing 3D CAD modeling and finite element analysis (FEA), we optimize part geometry for manufacturability, structural integrity, and tolerance control. This phase includes mold flow analysis when interfacing with plastic molding systems, ensuring metal components integrate flawlessly into final assemblies. Design for Assembly (DFA) and Design for Manufacturing (DFM) principles are applied rigorously to eliminate downstream inefficiencies.

Prototyping follows design finalization, serving as a physical validation step. We employ CNC machining and precision stamping to produce functional prototypes within 7–10 days, depending on complexity. These prototypes undergo comprehensive metrology testing using coordinate measuring machines (CMM), optical comparators, and surface finish analyzers. Dimensional reports, material certifications, and fit-check documentation are delivered for client approval. Any deviations trigger immediate design iteration, ensuring all specifications are met before progression.

Mass production is executed on fully automated, in-house production lines equipped with real-time SPC (Statistical Process Control) monitoring. Our facility runs multi-shift operations with redundant quality checkpoints at every process node. Each batch is traceable through a digital manufacturing execution system (MES), logging machine parameters, inspection data, and operator inputs. We maintain ISO 9001 and IATF 16949 certifications, and all processes comply with PPAP Level 3 requirements upon request.

Zero defects is not a target—it is our standard. This is achieved through predictive maintenance, 100% inline dimensional sampling on critical features, and automated visual inspection using machine vision systems. Non-conforming parts are quarantined instantly, and root cause analysis is conducted within 24 hours.

The following table outlines key performance specifications for our production process:

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Material Compatibility | Stainless Steel, Aluminum, Brass, Titanium, Alloy Steel |

| Tolerance Class | IT6–IT8 per ISO 286 |

| Production Capacity | Up to 500,000 units/month |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (after approval) |

| Quality Standard | Zero Defect PPM < 50 |

| Inspection Coverage | 100% critical features, 30% general features |

This disciplined approach ensures McDonald Plastic Molding receives components that meet exacting performance demands, integrate seamlessly into hybrid assemblies, and support high-yield molding operations.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Solutions in Plastic Molding

McDonald Plastic Molding demands metal components that deliver absolute dimensional stability, flawless surface finishes, and unwavering performance under demanding production cycles. Generic suppliers cannot consistently meet the exacting requirements inherent in high-precision plastic molding applications. Wuxi Lead Precision Machinery exists to bridge this gap, providing engineered metal solutions specifically tailored to elevate your molding process efficiency, part quality, and equipment longevity. We understand the critical interplay between mold steel integrity, cooling channel precision, and final plastic part consistency. Our dedicated focus on custom metal manufacturing for the molding industry ensures your components are not merely produced, but meticulously engineered for optimal function within your specific operational environment.

Our technical foundation is built upon advanced multi-axis CNC machining capabilities and rigorous process control. We specialize in transforming challenging materials like pre-hardened tool steels (P20, H13), stainless grades (420, 17-4PH), and specialty alloys into complex geometries with micron-level accuracy. Critical features such as conformal cooling channels, intricate cavity surfaces, and tight-tolerance ejector systems are manufactured to exact specifications, directly impacting cycle time reduction and minimizing part warpage or defects in your plastic output. This precision is non-negotiable for achieving consistent, high-quality molded parts at scale.

The following table details our core manufacturing capabilities relevant to plastic molding component production:

| Capability | Specification | Application Benefit for Plastic Molding |

|---|---|---|

| CNC Machining Centers | 5-Axis Simultaneous (Mazak, DMG) | Complex cavity/core geometries, undercuts, free-form surfaces |

| Linear Positioning Accuracy | ±0.002 mm | Ensures perfect mold alignment, eliminates flash |

| Surface Roughness (Ra) | As low as 0.2 µm (polished) | Superior plastic part finish, reduced release issues |

| Material Expertise | Tool Steels, Stainless, Aluminum | Optimized for wear resistance, corrosion protection, thermal management |

| Metrology Verification | CMM, OGP Vision, Roundness Tester | Guaranteed dimensional compliance to print, traceable reports |

| Max Work Envelope | 1200 x 800 x 750 mm | Supports large mold bases, frames, and inserts |

Partnering with Lead Precision means integrating a proactive engineering resource into your supply chain. We move beyond simple component supply to become a collaborative extension of your technical team. Our engineers engage early in the design phase, offering manufacturability insights to optimize your metal components for performance and cost-effectiveness. We implement stringent in-process quality checks and full final inspection protocols, providing comprehensive documentation for seamless traceability and quality assurance. This commitment to precision engineering and transparent communication minimizes risk, reduces time-to-market for new molds, and maximizes the uptime and output of your molding assets.

The complexity of modern plastic molding requires metal components manufactured to the highest standards of precision and reliability. Settling for less compromises your final product quality and operational efficiency. Initiate a technical consultation with Wuxi Lead Precision Machinery to discuss how our custom metal manufacturing expertise can directly enhance your molding process. Contact our engineering team directly at [email protected] to submit your specifications and begin the dialogue on achieving superior metal solutions for McDonald Plastic Molding. Let us demonstrate the Lead Precision difference through actionable engineering support and measurable results.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.