Technical Contents

Engineering Guide: Maximum Mold

Engineering Insight: The Non-Negotiable Precision of Maximum Mold in Critical Metal Manufacturing

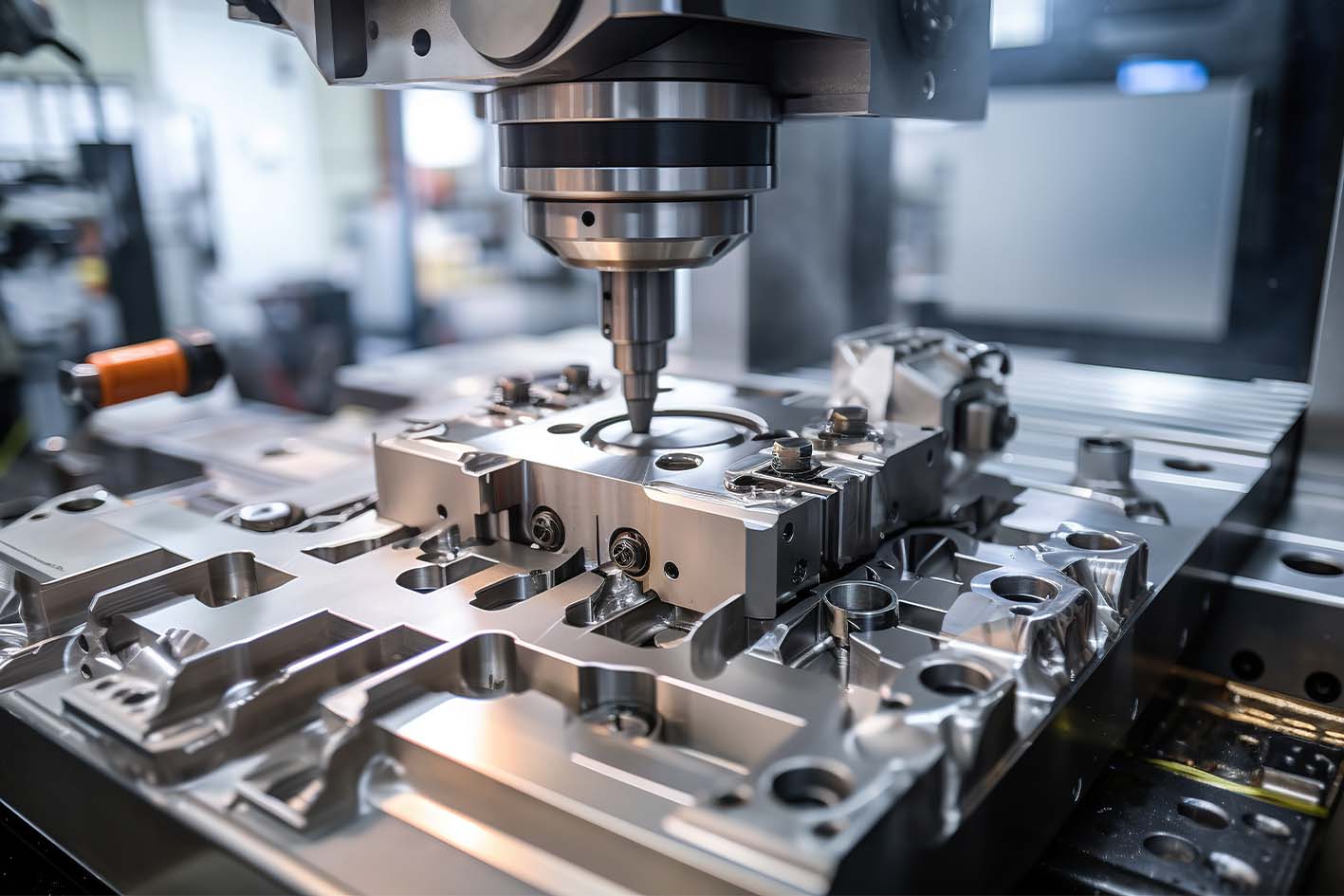

In high-stakes custom metal manufacturing, the term “maximum mold” transcends mere tooling—it represents the absolute ceiling of dimensional accuracy, thermal stability, and longevity required for mission-critical components. When failure is not an option—as in aerospace propulsion systems, defense ordnance, or precision medical devices—the mold itself becomes the foundational determinant of part integrity. Sub-micron deviations during cavity formation propagate exponentially through machining, assembly, and operational stress cycles, ultimately compromising performance, safety, and lifecycle costs. At Wuxi Lead Precision Machinery, we treat mold precision not as a target but as a non-negotiable engineering constant. Our CNC-machined molds consistently achieve tolerances unattainable through conventional methods, directly enabling our clients to meet Tier-1 aerospace and defense specifications where margins for error measure in millionths of a meter.

Our commitment to maximum mold precision is forged in real-world crucibles. We engineered molds for critical components in the Beijing Winter Olympics’ timing systems, where thermal fluctuations of 0.005°C could invalidate split-second results. Similarly, our molds for classified military applications demand zero-defect output under extreme environmental duress—proof that our processes withstand the most stringent validation protocols. This experience translates to every client: whether producing turbine blades enduring 1,500°C combustion or miniature surgical implants requiring biocompatible surface finishes, our molds deliver repeatability that eliminates scrap and accelerates time-to-market.

The technical foundation lies in our integrated approach to mold engineering. We combine multi-axis CNC grinding with in-process metrology, using granite CMMs to validate geometry at every machining stage. Material selection is equally critical; we deploy specialized tool steels and Inconel variants hardened to 60+ HRC while maintaining microstructural homogeneity. Below are representative capabilities for our maximum mold solutions:

| Specification Category | Performance Standard | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004″) | Zeiss CONTURA CMM |

| Surface Roughness (Cavity) | Ra 0.05 µm (2 µin) | Taylor Hobson Talysurf |

| Thermal Stability | Δ0.002 mm @ 25-150°C | Climate-Controlled CMM Chamber |

| Tool Steel Hardness | 58-62 HRC (Uniform) | Wilson Hardness Tester |

| Lead Time (Complex Mold) | 18-22 Weeks | ISO 9001 Traceable Schedule |

This level of control demands more than advanced machinery—it requires an engineering culture where every technician understands that a 2-micron variance can cascade into catastrophic field failure. Our team’s daily discipline, honed through Olympic and defense projects, ensures molds exceed client specifications before the first billet is cut. For industries where precision defines reliability, Wuxi Lead Precision Machinery delivers maximum mold performance as a baseline expectation. Contact us to discuss validation protocols for your next high-precision metal manufacturing challenge.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers precision-engineered metal components for high-performance industries including aerospace, medical devices, energy, and advanced automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining, enabling us to produce complex geometries with exceptional accuracy and surface finish. By integrating multi-axis simultaneous motion, we eliminate the need for multiple setups, reducing cycle times and minimizing cumulative tolerances. This results in superior part consistency and dimensional integrity across both prototype and high-volume production runs.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time tool wear compensation systems, ensuring consistent performance during extended operations. Materials we routinely process include titanium alloys, Inconel, stainless steel, aluminum, and specialty engineering alloys. Each machine is maintained to OEM specifications and operated by certified CNC programmers and machinists with over a decade of industry experience. We utilize advanced CAM software to optimize toolpaths, minimize thermal deformation, and maximize material removal rates without sacrificing precision.

Quality assurance is embedded throughout our manufacturing workflow. Every critical dimension is validated using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), which provides micron-level measurement accuracy under controlled environmental conditions. Our CMM inspection process includes first-article inspection reports (FAIR), production part approval protocols (PPAP), and in-process checks to ensure compliance with AS9100 and ISO 9001 standards. All inspection data is digitally archived for full traceability, supporting rigorous industry audits and long-term quality monitoring.

We specialize in tight-tolerance components where precision directly impacts performance and safety. Our process capability is demonstrated through consistent achievement of geometric and dimensional tolerances across diverse part configurations. The following table outlines our standard and maximum achievable tolerances under controlled production conditions.

| Feature Type | Standard Tolerance | Maximum Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 mm | ±0.005 mm | CMM, Micrometer, Caliper |

| Geometric Tolerance (GD&T) | ±0.015 mm | ±0.008 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Surface Roughness Tester |

| Hole Diameter (Drilled) | ±0.012 mm | ±0.006 mm | CMM, Air Gauge |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM, Vision System |

| Angular Features | ±0.005° | ±0.002° | CMM, Precision Sine Bar |

All tolerances are achievable on parts up to 500 mm in length, with material-dependent scalability. Our engineering team collaborates directly with clients during design for manufacturability (DFM) reviews to ensure optimal tolerance allocation and cost efficiency. At Wuxi Lead Precision Machinery, technical excellence is not just measured in microns—it is delivered through disciplined process control, advanced equipment, and an unwavering commitment to quality in every component we produce.

Material & Finish Options

Strategic Material Selection for High-Performance Molds

Material choice fundamentally dictates mold longevity, production efficiency, and final part quality in precision manufacturing. At Wuxi Lead Precision Machinery, we guide clients through data-driven decisions balancing performance requirements, production volume, and lifecycle costs. Aluminum, steel, and titanium each offer distinct advantages for specific applications, while anodizing significantly enhances surface properties. Selecting the optimal combination prevents costly downtime and ensures consistent output.

Aluminum alloys, particularly 7075-T6, excel in rapid prototyping and low-to-medium volume production. Their high thermal conductivity (120-180 W/m·K) enables faster cooling cycles, directly reducing part cycle times by up to 50% compared to steel. This material is ideal for complex geometries requiring quick iteration. However, aluminum’s lower hardness (150 HB) limits its use in abrasive materials or high-volume runs exceeding 10,000 cycles. Tool steel variants like H13 or S7 dominate high-volume, high-temperature applications. Offering exceptional hardness (48-52 HRC after heat treatment) and wear resistance, they withstand thousands of cycles with minimal deformation, especially under high injection pressures. The trade-off is slower thermal dissipation and higher initial machining costs. Titanium alloys (e.g., Ti-6Al-4V) serve niche, extreme-demand scenarios. Unmatched strength-to-weight ratio and corrosion resistance make them indispensable for aerospace or medical molds exposed to aggressive chemicals or requiring minimal thermal distortion. Yet, titanium’s high cost and challenging machinability restrict it to specialized, high-value production where its properties justify the investment.

Critical material properties are summarized below for direct comparison:

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Best For | Key Limitation |

|---|---|---|---|---|

| Aluminum 7075 | 150 HB | 120-180 | Prototyping, low-volume, fast cycles | Low wear resistance |

| Tool Steel H13 | 48-52 HRC | 25-35 | High-volume, high-temp production | Slower cooling, higher cost |

| Titanium Ti-6Al-4V | 36 HRC | 6.7 | Extreme corrosion/weight demands | Very high cost, difficult machining |

Anodizing is a critical secondary process, primarily for aluminum molds. Type II (sulfuric acid) anodizing provides moderate corrosion and wear resistance with color options, suitable for general use. For demanding environments, hardcoat Type III anodizing creates a dense, thick oxide layer (25-50 μm), dramatically improving surface hardness (up to 60 HRC equivalent) and abrasion resistance. This extends mold life in abrasive polymer applications and reduces galling. Proper sealing post-anodizing is essential to maximize corrosion protection. Note that anodizing is generally not applied to steel or titanium molds; alternative surface treatments like nitriding or PVD coatings are recommended for those substrates.

Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to match your specific production demands with the optimal material-finish combination. We analyze your part geometry, material, volume, and quality targets to prevent premature wear or thermal issues. Consult our engineering team early in the design phase to optimize mold performance and maximize your return on investment. Precision begins with the right foundation.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every successful custom metal manufacturing project begins with a rigorously engineered design phase. Our team of senior CNC engineers collaborates directly with clients to translate initial concepts into detailed, manufacturable designs. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Siemens NX, we ensure dimensional accuracy, material compatibility, and structural integrity from the earliest stage. Finite Element Analysis (FEA) and Design for Manufacturability (DFM) reviews are standard practice, allowing us to identify potential weaknesses, thermal stresses, or assembly issues before any metal is cut. This proactive engineering approach eliminates costly revisions and ensures that every component meets the exact functional and aesthetic requirements of high-end applications in industries such as aerospace, medical devices, and precision automation.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to precision prototyping—a critical checkpoint in our zero-defect philosophy. Using state-of-the-art 5-axis CNC milling, wire EDM, and high-tolerance turning centers, we produce fully functional prototypes that mirror the final production parts in both geometry and material properties. Each prototype undergoes comprehensive metrological validation using Zeiss CMMs, laser scanners, and surface roughness testers to verify conformance to GD&T specifications. Clients receive a detailed inspection report, including first-article inspection (FAI) documentation per AS9102 or PPAP standards when required. This iterative validation phase allows for design fine-tuning, fit-checks in assemblies, and performance testing under real-world conditions, ensuring that only perfected designs advance to mass production.

Mass Production: Consistency Through Advanced Process Control

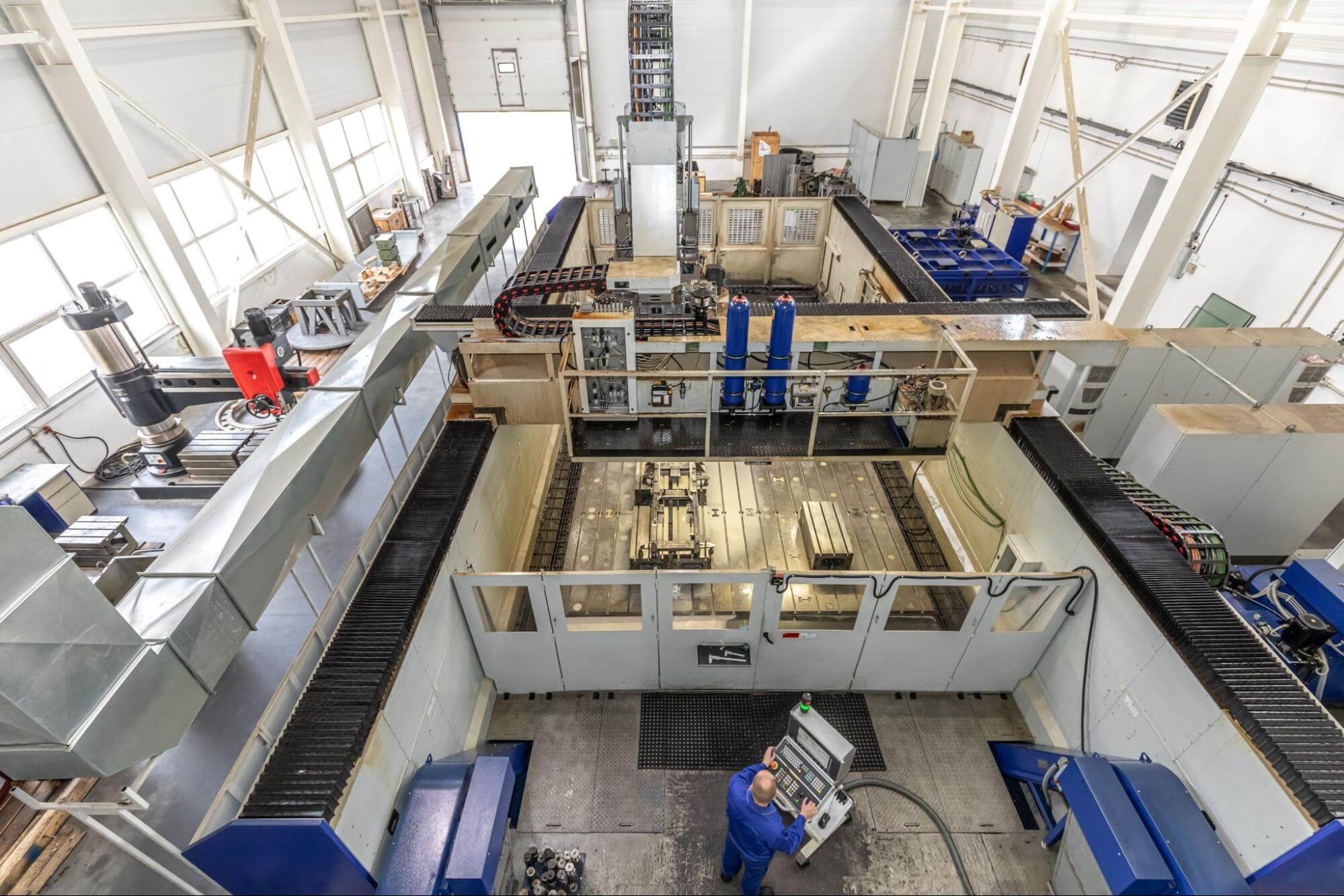

With prototype approval, Wuxi Lead transitions seamlessly into high-volume manufacturing with the same tooling, fixtures, and programming logic used in prototyping—ensuring complete process continuity. Our production floor integrates automated CNC cells, robotic part handling, and real-time in-process monitoring systems to maintain ±0.002 mm tolerances across batches of any size. Statistical Process Control (SPC) is implemented at every critical operation, with data logged and analyzed to detect trends before deviations occur. Each part is traceable via laser-etched serial numbers, and final inspection includes 100% critical dimension checks and batch sampling for non-critical features. This disciplined approach ensures zero-defect delivery, on time, every time.

Production Capabilities at Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.002 mm (±0.00008″) |

| Surface Roughness (Ra) | As low as 0.4 μm (16 μin) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24″) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK |

| CNC Equipment | 5-Axis Milling, CNC Turning, Wire EDM, Grinding |

| Quality Standards | ISO 9001:2015, IATF 16949, AS9100D (compliant) |

| Lead Time (Prototype) | 7–14 days depending on complexity |

| Lead Time (Mass Production) | 15–30 days for full batch delivery |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Mold Excellence

In high-stakes mold manufacturing, precision is non-negotiable. Wuxi Lead Precision Machinery operates at the intersection of advanced engineering and relentless quality control, delivering custom metal solutions where failure is not an option. Our ISO 9001-certified facility in Wuxi, China, leverages 20+ years of expertise to transform complex mold designs into production-ready assets. We specialize in high-cavity, multi-material, and micro-precision molds for aerospace, medical, and automotive sectors—where tolerances below ±0.0001″ and surface finishes down to Ra 0.025μm define success. Partnering with Lead Precision means accessing a vertically integrated workflow: from material sourcing (including proprietary tool steel treatments) to CMM-validated final inspection. Every mold undergoes rigorous first-article approval against your exact specifications, eliminating costly iterations.

Our technical capabilities are engineered for maximum mold longevity and performance. Below are key parameters we consistently achieve across client projects:

| Parameter | Lead Precision Capability | Industry Standard Benchmark |

|---|---|---|

| Tolerance Range | ±0.0001″ (2.5μm) | ±0.0005″ (12.7μm) |

| Cavity Count | Up to 128 cavities | Typically ≤ 32 cavities |

| Surface Finish | Ra 0.025μm (Mirror) | Ra 0.8μm (Standard Polish) |

| Tool Steel Hardness | HRC 52-58 (Pre-hardened) | HRC 30-45 |

| Lead Time Reduction | 22% faster vs. industry | Baseline |

This precision translates directly to your bottom line: reduced cycle times, extended mold life, and near-zero defect rates in high-volume production. We integrate seamlessly with your engineering team through secure PLM platforms, ensuring real-time collaboration from DFM analysis to final validation. Unlike commodity manufacturers, we prioritize risk mitigation—our molds undergo 72-hour stress testing under simulated production conditions, preempting failures before shipment.

The cost of mold imperfection extends far beyond initial tooling expenses. Downtime, scrap, and rework in automotive or medical production can escalate to six-figure hourly losses. Lead Precision eliminates this exposure through military-grade process discipline and proprietary thermal stabilization techniques. Our clients—from Tier-1 aerospace suppliers to Fortune 500 medical device innovators—rely on us because we treat your mold as the mission-critical asset it is.

Initiate your next mold project with engineering certainty. Contact our technical sales team at [email protected] to schedule a pre-engineering consultation. Provide your CAD files and production requirements, and we will deliver a detailed capability assessment within 48 hours—including tolerance stack analysis, material optimization recommendations, and a transparent timeline. Do not compromise on the foundation of your manufacturing process. Let Lead Precision engineer the mold that defines your product’s legacy.

Wuxi Lead Precision Machinery: Where Precision Becomes Performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.