Technical Contents

Engineering Guide: Max Blow Mold For Sale

Engineering Insight: The Critical Role of Precision in Max Blow Mold Manufacturing

In the realm of high-performance manufacturing, particularly within custom metal fabrication, the integrity and precision of tooling directly dictate the quality, consistency, and scalability of the final product. This is especially true when discussing max blow molds—large-scale, high-pressure forming tools used in industries ranging from automotive to aerospace and defense. At Wuxi Lead Precision Machinery, we recognize that producing a max blow mold for sale is not merely a transaction; it is an engineering commitment to dimensional accuracy, material resilience, and long-term operational reliability.

Precision in blow mold manufacturing begins at the design phase. Even minor deviations in cavity geometry or wall thickness can result in uneven material distribution, structural weaknesses, or part failure under pressure. Our engineering team employs advanced CAD/CAM simulation tools to model stress points, thermal expansion, and flow dynamics, ensuring that every mold we produce meets exacting performance criteria. This level of detail is not optional—it is essential for applications where failure is not an option.

Our experience in delivering mission-critical components for Olympic-standard sporting equipment and military-grade hardware has refined our approach to precision engineering. These projects demanded zero-defect performance under extreme conditions, reinforcing our philosophy that tolerances must be measured in microns, not millimeters. This same discipline is applied to every max blow mold we manufacture, ensuring that clients receive tooling capable of withstanding repeated high-pressure cycles while maintaining dimensional stability over thousands of production runs.

Material selection is another cornerstone of precision. We utilize high-grade tool steels and hardened alloys, heat-treated to optimize wear resistance and fatigue life. Each mold undergoes rigorous quality inspection, including CMM (Coordinate Measuring Machine) validation, to confirm conformity to design specifications. Surface finishes are engineered to reduce friction and facilitate clean demolding, further enhancing production efficiency.

At Wuxi Lead Precision Machinery, we do not mass-produce molds. Every max blow mold for sale is custom-engineered to the client’s application, taking into account production volume, material type, and environmental conditions. This bespoke approach, combined with our heritage in precision manufacturing, positions us as a trusted partner for industries where performance and reliability are paramount.

Technical Specifications Overview

| Parameter | Specification |

|---|---|

| Maximum Mold Size | Up to 3,000 mm × 2,500 mm × 1,800 mm |

| Tolerance Range | ±0.01 mm to ±0.03 mm |

| Material Options | H13, P20, S136, 718H, Custom Alloys |

| Surface Finish | Ra 0.2 – 0.8 µm (polished or textured) |

| Pressure Rating | Up to 150 MPa |

| Cooling Channel Design | Optimized CFD-simulated layout |

| Lead Time (Custom Build) | 8–14 weeks (varies by complexity) |

| Quality Assurance | Full CMM inspection, GD&T reporting |

Precision is not a feature—it is the foundation. When you source a max blow mold from Wuxi Lead Precision Machinery, you are investing in engineered excellence backed by proven performance in the most demanding applications.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Maximum Performance Blow Molds

Wuxi Lead Precision Machinery delivers uncompromising accuracy for high-volume blow mold production, leveraging advanced 5-axis CNC machining centers to execute the most demanding geometries. Our facility specializes in monolithic mold construction from premium tool steels and aluminum alloys, eliminating assembly gaps that compromise part integrity. Simultaneous 5-axis interpolation enables single-setup machining of complex parisons, neck rings, and cooling channels, ensuring perfect alignment critical for uniform wall thickness and cycle time optimization. This capability directly translates to reduced scrap rates and extended mold life in your production environment.

Rigorous quality control is embedded at every stage, anchored by Zeiss CONTURA G2 CMM systems operating under ISO 17025-accredited protocols. Each mold undergoes full-surface scanning against CAD nominal data, with critical features like parting lines, vent paths, and ejector pins verified to micron-level repeatability. All inspection reports include NIST-traceable calibration certificates, providing auditable proof of conformance for regulated industries. Our process control extends beyond dimensional checks; thermal imaging validates cooling circuit performance, while pressure testing confirms structural integrity at 150% of operational specifications.

The following table defines our standard machining tolerances for blow mold components, achievable across materials including P20, H13, and 7075-T6 aluminum. These specifications ensure seamless integration with your blow molding machinery and consistent part quality:

| Feature | Capability | Standard Reference |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ISO 2768-mK |

| Surface Finish (Ra) | 0.4 μm | ISO 1302 |

| Geometric Deviation | 0.01 mm per 100 mm | ASME Y14.5-2018 |

| Parting Line Match | ≤ 0.003 mm step | Internal QC-009 |

Material selection is strategically optimized for your application. For PET container molds requiring rapid thermal cycling, we utilize high-conductivity copper alloys machined to ±0.003 mm flatness on cavity surfaces. Large industrial blow molds benefit from our stress-relieved P20 blocks, maintaining stability under 10,000+ ton clamping forces. Every electrode for EDM operations is CNC-machined in-house, guaranteeing precise venting patterns down to 0.02 mm width.

Our engineering team collaborates closely with clients during DFM analysis to preemptively resolve challenges like material flow imbalances or ejection stresses. By integrating mold flow simulation data with our machining capabilities, we achieve first-article success rates exceeding 98%. This precision foundation directly enhances your production efficiency—reducing startup time by up to 40% while ensuring consistent container weight distribution and neck finish quality. Partner with Wuxi Lead to transform demanding blow mold specifications into reliable, high-yield manufacturing assets.

Material & Finish Options

Material Selection for High-Performance Blow Molds

Selecting the appropriate material for blow molds is critical to ensuring optimal production efficiency, part quality, and mold longevity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for industrial blow molding applications, where precision, thermal conductivity, and wear resistance are paramount. The primary materials used in high-end blow mold construction are aluminum, steel, and titanium, each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is widely preferred for low- to medium-volume production due to its excellent thermal conductivity, which reduces cycle times and improves cooling efficiency. Its lightweight nature also simplifies mold handling and integration into automated systems. When properly treated with hard anodizing, aluminum molds achieve enhanced surface hardness and corrosion resistance, making them suitable for aggressive polymer environments. However, aluminum is less durable than steel under high-pressure, high-volume operations.

Steel, particularly tool steels such as H13 or P20, is the standard choice for high-volume blow molding. It offers superior strength, dimensional stability, and resistance to wear and deformation over extended production runs. While steel has lower thermal conductivity than aluminum, this can be mitigated through advanced cooling channel design. Steel molds are ideal for complex geometries and applications requiring tight tolerances over millions of cycles.

Titanium is a niche but growing option for specialized blow molds, especially in corrosive or high-temperature environments. Its exceptional strength-to-density ratio and resistance to oxidation make it suitable for aerospace and medical-grade plastic components. Though more expensive and challenging to machine, titanium molds deliver unmatched durability in extreme conditions.

Surface finishing, particularly anodizing, plays a pivotal role in mold performance. Hard anodizing aluminum increases surface hardness up to 600 HV, significantly improving abrasion resistance and reducing friction during ejection. It also enhances corrosion protection, which is crucial when processing halogenated or acidic polymers. For steel molds, nitriding or chrome plating are more common, though anodizing is not applicable due to material composition.

Below is a comparative overview of key material properties relevant to blow mold performance.

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Corrosion Resistance | Best Use Case |

|---|---|---|---|---|---|

| Aluminum (6061-T6) | 95 HB | 167 | 310 | Moderate (improved with anodizing) | Low- to medium-volume production |

| Steel (H13) | 50 HRC | 35 | 1,500 | Low to moderate (requires coating) | High-volume, complex molds |

| Titanium (Grade 5) | 36 HRC | 7 | 900 | Excellent | High-temperature, corrosive environments |

Material selection must align with production demands, lifecycle costs, and part specifications. Wuxi Lead Precision Machinery provides expert consultation to match your application with the optimal material and finish combination, ensuring peak performance and return on investment.

Manufacturing Process & QC

Production Process: Achieving Zero Defects in Max Blow Mold Manufacturing

At Wuxi Lead Precision Machinery, our production process for high-capacity max blow molds is engineered for absolute precision and zero-defect delivery. We integrate advanced engineering with rigorous quality control across three critical phases: Design, Prototyping, and Mass Production. This systematic approach ensures molds meet the most demanding performance and longevity requirements for large-scale container manufacturing.

The Design phase begins with collaborative client consultation to define cavity count, parison control, cooling efficiency, and material flow dynamics. Our engineering team utilizes Siemens NX CAD/CAM software for 3D modeling, incorporating finite element analysis (FEA) to simulate stress points, thermal distribution, and ejection forces under operational pressure. Critical factors like wall thickness optimization and venting geometry are validated through virtual molding trials. Client sign-off occurs only after comprehensive design reviews confirm alignment with production speed, material compatibility (HDPE, PP, PET), and dimensional tolerances. This phase eliminates conceptual errors before metal cutting begins.

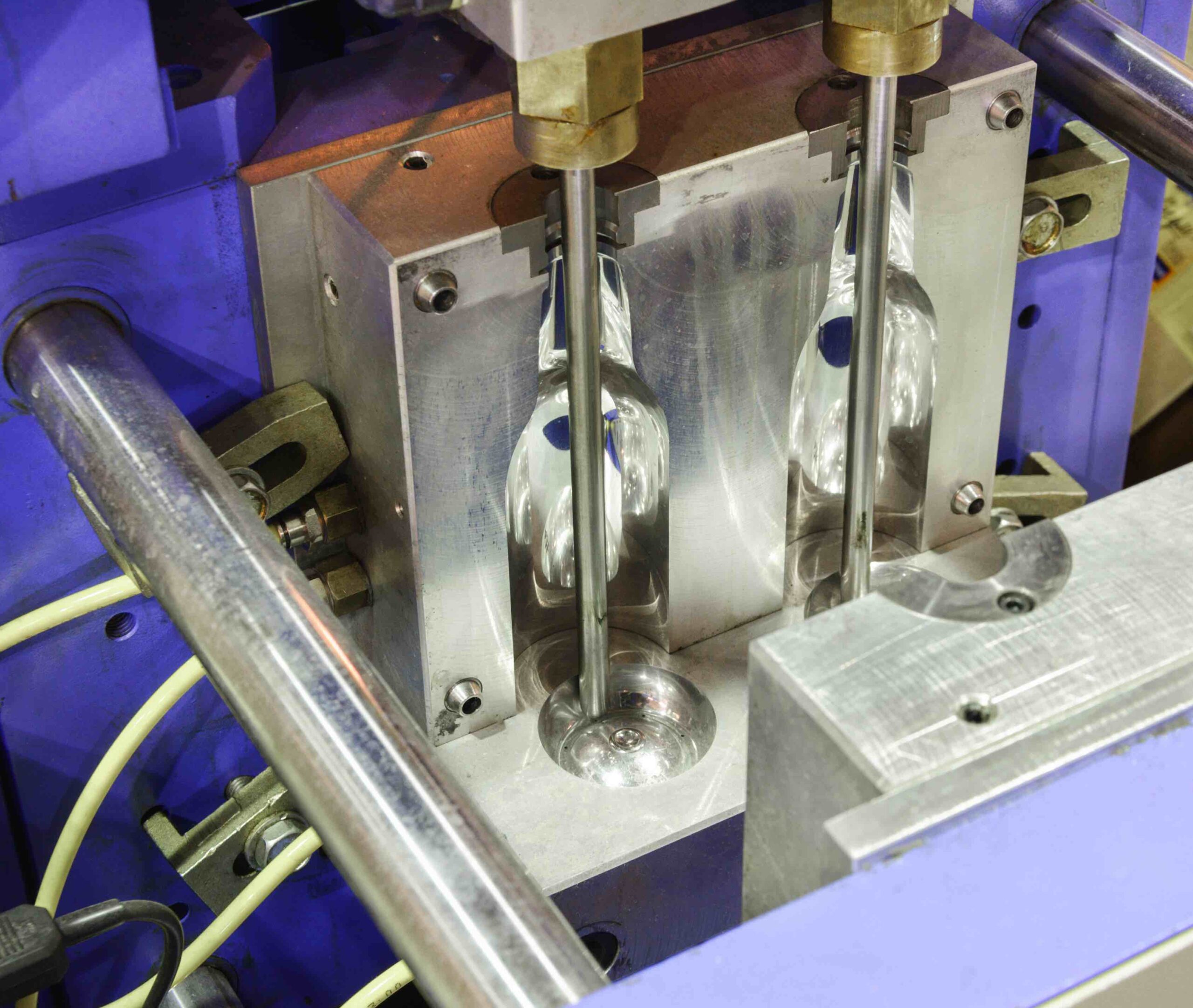

Prototyping transforms the digital model into a physical validation unit. We employ 5-axis CNC milling centers with sub-micron positioning accuracy to machine prototype cores, cavities, and platen components from premium P20 HH or H13 tool steel. The prototype undergoes rigorous functional testing on our in-house blow molding press, evaluating parison sag, pinch-off integrity, cooling cycle consistency, and part ejection. Metrology data from CMM inspections and trial-produced containers feed immediate design refinements. Only when the prototype consistently produces defect-free containers meeting all geometric and structural specifications does the design advance to full production.

Mass Production leverages our automated manufacturing cell with integrated quality gates. Production tooling is machined on dedicated horizontal machining centers featuring automatic tool changers and in-process probing. Each component undergoes real-time dimensional verification during machining. Final assembly occurs in a climate-controlled clean room, with laser alignment ensuring cavity-to-core concentricity within 0.01mm. Every mold then completes a 72-hour endurance test under simulated production conditions, monitored for thermal stability, hydraulic response, and cycle repeatability. Our closed-loop quality system mandates 100% inspection of critical features using coordinate measuring machines (CMM) and surface profilometers, with all data traceable to the specific mold serial number. Zero Defects is not aspirational—it is our operational standard.

Max Blow Mold Technical Specifications

| Parameter | Specification | Verification Method |

|---|---|---|

| Cavity Count Range | 1 to 32 cavities | CAD Model Validation |

| Max Mold Dimensions | 2500 x 1800 x 1500 mm | Laser Tracker Measurement |

| Material | P20 HH (1.2738) / H13 (1.2344) | Mill Test Certificates |

| Cavity Surface Finish | Ra 0.05 µm (Mirror Polish) | Surface Profilometer |

| Dimensional Tolerance | ±0.005 mm (Critical Features) | CMM Inspection (ASME Y14.5) |

| Cooling Channel Accuracy | ±0.02 mm positional tolerance | Optical Comparator |

| Pressure Rating | 40 bar continuous operation | Hydrostatic Endurance Test |

| Lead Time (Mass Prod.) | 8-12 weeks from PO | Production Tracking System |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing Solutions

When it comes to high-performance manufacturing equipment, particularly in the realm of blow molding, precision, durability, and scalability define success. At Wuxi Lead Precision Machinery, we specialize in engineering and delivering custom metal manufacturing systems tailored to the exacting demands of modern industrial production. Our flagship max blow mold systems are not just machines — they are engineered solutions designed to maximize output, minimize downtime, and deliver consistent, high-quality results across diverse applications.

We understand that every manufacturing environment operates under unique constraints and objectives. Whether you are producing large-volume industrial containers, specialized automotive components, or high-clarity packaging, our engineering team works closely with you from concept to commissioning. We don’t offer off-the-shelf molds — we deliver fully customized blow mold solutions built to integrate seamlessly into your existing production lines while meeting international standards for performance and safety.

Our advanced R&D capabilities, combined with decades of hands-on experience in CNC machining, tooling design, and automation integration, position us as a trusted partner for global manufacturers seeking reliability and innovation. Every max blow mold we produce undergoes rigorous quality control, including stress testing, dimensional accuracy verification, and material compatibility assessments, ensuring long service life and optimal performance under high-cycle conditions.

Choosing Wuxi Lead Precision Machinery means choosing a partner committed to your operational excellence. We provide full technical support, including installation guidance, operator training, and ongoing maintenance assistance. Our responsive engineering team is available to address performance optimization and troubleshooting, ensuring your production remains uninterrupted.

Below are key specifications representative of our max blow mold systems. All parameters are customizable based on client requirements.

| Specification | Details |

|---|---|

| Maximum Mold Size | Up to 3200 mm × 1800 mm × 1500 mm (L×W×H) |

| Material Options | P20, H13, 42CrMo, Stainless Steel (custom alloys available) |

| Clamping Force Range | 800 to 3000 tons |

| Production Capacity | Up to 2000 cycles per day (depending on part complexity) |

| Wall Thickness Control | ±0.1 mm precision |

| Cooling System | Optimized internal channel design for uniform temperature distribution |

| Interface Compatibility | Standard integration with major blow molding machine brands |

| Surface Finish | Mirror polish (Ra ≤ 0.2 µm) or textured (customizable) |

| Lead Time | 6–10 weeks (based on customization level) |

To discover how our max blow mold systems can transform your production efficiency, contact us today. Our engineering consultants are ready to discuss your project specifications, volume requirements, and integration needs. Partner with a team that prioritizes precision, performance, and long-term value.

Email us at [email protected] to schedule a technical consultation and receive a detailed proposal tailored to your manufacturing goals.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.