Technical Contents

Engineering Guide: Material Cutting Service Georgia

Engineering Insight: Precision as the Non-Negotiable Foundation for Material Cutting Services in Georgia

In Georgia’s rapidly evolving manufacturing landscape, particularly within aerospace, defense, and high-performance industrial sectors, the term “precision cutting” transcends mere marketing language. It represents the fundamental engineering requirement separating functional components from critical failures. For Georgia-based manufacturers and OEMs sourcing material cutting services, tolerances measured in thousandths of an inch directly impact assembly integrity, product lifespan, and ultimately, end-user safety. Sub-millimeter deviations in structural aerospace brackets or hydraulic manifolds for military vehicles can cascade into catastrophic system malfunctions under operational stress. The economic cost of rework or field failures driven by inadequate cutting precision far exceeds the initial service investment. This necessitates a cutting partner whose processes are engineered for repeatability at the micron level, not just nominal capability.

Wuxi Lead Precision Machinery operates at this critical precision threshold daily. Our CNC laser, waterjet, and plasma cutting systems are calibrated and maintained to sustain tolerances down to ±0.0004 inches (0.01 mm) consistently across production runs. This capability is not theoretical; it is rigorously proven through decades of supplying mission-critical components. We have manufactured precision-cut structural elements meeting the exacting dimensional stability requirements for Olympic venue infrastructure, where thermal expansion and load tolerances were non-negotiable. Similarly, our facility adheres to the stringent QA protocols demanded by Tier-1 defense contractors for armored vehicle subsystems, where material integrity and geometric accuracy are paramount for ballistic performance and crew safety. Our engineers understand that Georgia’s advanced manufacturers require more than just a machine shop – they need a partner whose quality management system is embedded in every process step, from material certification traceability to final inspection reporting.

The following table outlines the core precision capabilities underpinning our material cutting service for demanding Georgia applications:

| Parameter | Capability Range | Relevance for Georgia Manufacturers |

|---|---|---|

| Tolerance Range | ±0.0004″ (0.01 mm) to ±0.005″ (0.13 mm) | Ensures fit for aerospace assemblies & hydraulic systems |

| Material Thickness | Laser: 0.005″ – 1.0″; Waterjet: 0.060″ – 8.0″ | Covers thin-sheet avionics to thick military plate |

| Material Types | Aerospace Alloys (7075, 6061), Military Steels (4130, 4340), Titanium, Inconel | Matches Georgia defense & energy sector needs |

| Max Work Envelope | 4′ x 8′ (Laser), 6′ x 12′ (Waterjet) | Accommodates large structural components |

| Key Certifications | ISO 9001, AS9100 (Aerospace), ITAR Registered | Meets defense supply chain requirements |

Precision cutting in Georgia’s high-stakes manufacturing environment demands proven expertise, not just equipment. Wuxi Lead Precision Machinery delivers the documented process control, material science understanding, and quality rigor required for components where failure is not an option. Our Olympic and military project heritage provides the tangible evidence of capability that Georgia’s forward-looking manufacturers require when selecting a cutting service partner. The investment in true precision engineering today prevents systemic risk tomorrow.

Precision Specs & Tolerances

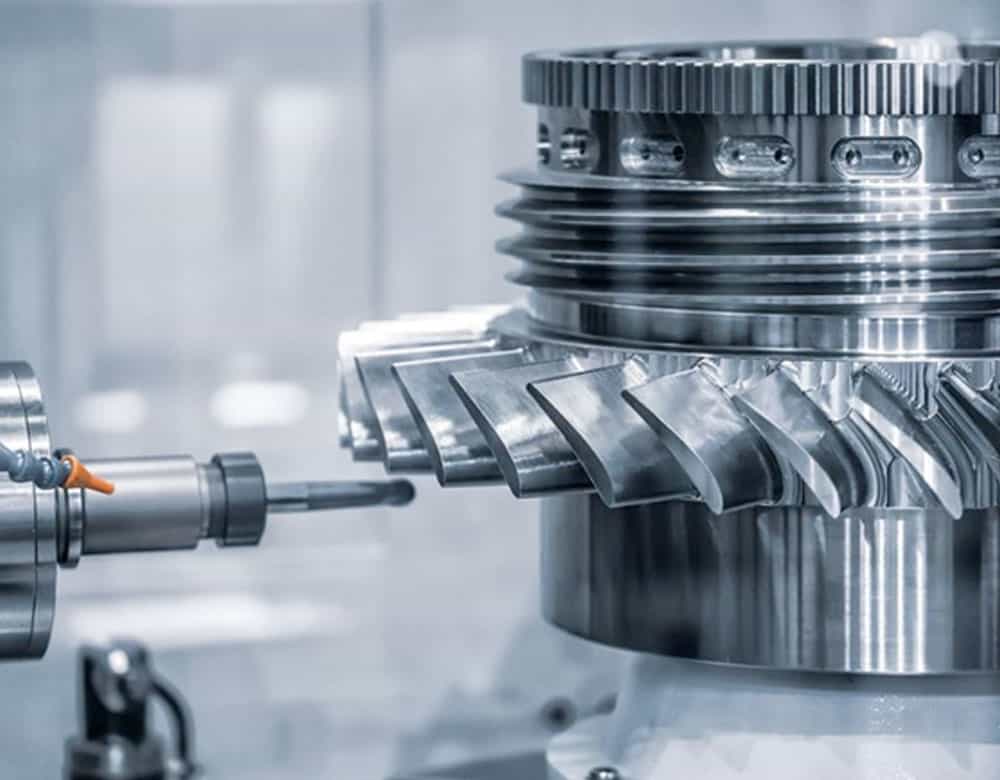

Wuxi Lead Precision Machinery delivers advanced material cutting services that meet the rigorous demands of high-performance industries including aerospace, automotive, energy, and medical device manufacturing. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to perform complex, multi-directional cuts with exceptional precision and surface finish. This level of machining flexibility allows for the production of intricate geometries and tight-tolerance components from a broad range of metals, including aluminum alloys, stainless steel, titanium, Inconel, and tool steels.

Our 5-axis CNC systems integrate simultaneous motion across all five axes, minimizing setup changes and ensuring optimal tool positioning throughout the cutting process. This results in reduced cycle times, improved accuracy, and enhanced repeatability across production runs. The ability to approach parts from virtually any angle eliminates the need for multiple fixtures and secondary operations, significantly improving overall efficiency and part consistency. Whether producing prototypes or high-volume batches, our machining centers maintain micron-level control, supporting both simple and highly complex material removal requirements.

To ensure every component meets exact design specifications, we employ a comprehensive quality control protocol centered around Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D measurement of critical dimensions, geometric tolerances, and surface characteristics. Each part undergoes rigorous in-process and final inspection, with detailed inspection reports available upon request. This metrology-backed validation process ensures compliance with ISO 9001 standards and customer-specific quality requirements.

We specialize in custom material cutting solutions tailored to client blueprints and performance needs. Our engineering team collaborates closely with clients to optimize designs for manufacturability, recommend appropriate materials, and ensure that tolerances are achievable within project timelines and cost parameters. With integrated CAD/CAM software and real-time machine monitoring, we maintain full traceability and process control from initial cut to final shipment.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC material cutting services:

| Feature | Typical Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 300 mm; ±0.01 mm beyond |

| Positional Tolerance | ±0.01 mm | Verified via CMM |

| Angular Accuracy | ±0.05° | Full 5-axis synchronization |

| Surface Roughness | Ra 0.8 µm (typical) | Adjustable per requirement |

| Geometric Tolerances (Flatness, Roundness) | 0.01 mm per 100 mm | Measured under controlled conditions |

| Repeatability | ±0.003 mm | Statistical process control applied |

All tolerances are achievable on parts up to 1200 x 800 x 750 mm in size, depending on material and geometry. Wuxi Lead Precision Machinery is committed to delivering precision-cut metal components that meet the highest standards of quality and performance, supporting global clients with reliable, scalable, and technically superior manufacturing solutions.

Material & Finish Options

Material Selection for Precision Cutting: Aluminum, Steel, and Titanium

Selecting the optimal material is foundational to achieving performance, cost-efficiency, and longevity in custom metal components. At Wuxi Lead Precision Machinery, we guide Georgia-based manufacturers through this critical decision, aligning material properties with application demands and finishing requirements. Understanding the distinct characteristics of aluminum, steel, and titanium ensures your project meets exacting tolerances and operational environments.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and inherent corrosion resistance. Aluminum machines rapidly, reducing production costs significantly. Its natural oxide layer provides decent environmental protection, but for enhanced durability and aesthetic control in Georgia’s variable climate, Type II or Type III sulfuric acid anodizing is highly recommended. Anodizing creates a hard, non-conductive surface layer that resists wear and corrosion while accepting diverse dye colors for identification or branding. This finish is essential for exterior components or parts requiring electrical insulation.

Carbon and alloy steels, including 4140, 1018, and 304/316 stainless, offer superior strength, hardness, and wear resistance for structural applications, tooling, and high-stress machinery parts. Steel provides excellent machinability across most grades and responds well to heat treatments like quenching and tempering to achieve specific mechanical properties. While stainless grades inherently resist corrosion, carbon steels require protective finishes such as powder coating, plating, or passivation to withstand Georgia’s humidity and industrial atmospheres. Steel remains the cost-effective choice for heavy-duty applications where weight is less critical than ultimate strength.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), deliver unparalleled strength-to-weight ratios combined with exceptional corrosion resistance in harsh environments, including saltwater and chemical exposure. This makes titanium indispensable for critical aerospace, medical implant, and marine components. However, titanium presents significant machining challenges due to low thermal conductivity and high reactivity, demanding specialized tooling, slower speeds, and rigid setups to prevent work hardening and tool failure. While titanium naturally forms a protective oxide layer, anodizing (typically Type II) is sometimes applied for color coding or minor wear enhancement, though it’s less common than with aluminum.

The following table summarizes key comparative properties to inform your Georgia-based project specifications:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Common Grades |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | Good (Anodized: Excellent) | Excellent | 6061-T6, 7075-T6 |

| Steel (Carbon) | 7.8 | 600 (1045 Annealed) | Fair (Requires Finish) | Good | 1018, 1045, 4140 |

| Steel (Stainless) | 8.0 | 515 (304 Annealed) | Very Good | Moderate | 304, 316 |

| Titanium | 4.5 | 900 (Ti-6Al-4V) | Excellent | Poor | Gr 2, Gr 5 (Ti-6Al-4V) |

Material choice directly impacts manufacturability, cost, and final part performance. Wuxi Lead Precision Machinery leverages advanced CNC cutting technologies and deep metallurgical expertise to machine all three materials to micron-level precision. Our Georgia-optimized logistics ensure seamless integration into your supply chain, while our engineering team provides consultative support on material suitability and finishing—like optimizing anodizing parameters for superior adhesion and color consistency—maximizing your component’s value and lifespan. Partner with us to transform your material selection into a competitive advantage.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect delivery in custom metal manufacturing. Serving global clients requiring advanced material cutting services, including those in strategic markets such as Georgia, our workflow integrates advanced technology with rigorous quality control to ensure every component meets exact specifications from concept to completion.

Design is the foundational phase, where engineering precision begins. Our technical team collaborates directly with client-supplied CAD/CAM files or develops detailed 3D models based on technical drawings and functional requirements. Utilizing SolidWorks, AutoCAD, and Siemens NX, we conduct design for manufacturability (DFM) analysis to optimize geometry, material selection, and tooling paths. This ensures structural integrity, cost-efficiency, and compatibility with high-speed CNC cutting systems. Thermal deformation compensation and stress-relief parameters are embedded at this stage to prevent post-processing distortion.

Prototyping follows design finalization, serving as a physical validation step. We employ 5-axis CNC machining, laser cutting, and waterjet systems to produce initial samples in the specified alloy—ranging from aerospace-grade aluminum to hardened tool steels. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and surface finish evaluation using profilometers. Clients receive detailed inspection reports, including GD&T analysis, enabling feedback integration before release to mass production. This iterative verification ensures compliance with ISO 2768 and client-specific tolerances.

Mass production is executed on fully automated, high-redundancy manufacturing lines. Our facility operates over 120 CNC machining centers, robotic material handling systems, and real-time monitoring via IoT-enabled sensors. Every cutting operation is governed by pre-loaded toolpath algorithms with in-process probing to detect tool wear or positional drift. Statistical process control (SPC) systems analyze data streams to preempt deviations, maintaining tolerances as tight as ±0.005 mm. Components are batch-tracked using RFID tags, ensuring full traceability from raw stock to final shipment.

Quality assurance is embedded at every phase, not treated as a final checkpoint. Our zero-defect protocol includes 100% visual inspection under magnification, ultrasonic testing for subsurface flaws in thick plates, and hardness validation per ASTM E18. Non-conforming parts are automatically quarantined through our QMS (ISO 9001:2015 certified), and root cause analysis is conducted within four hours of detection.

Below are key capabilities supporting our end-to-end production process.

| Specification | Detail |

|---|---|

| Material Compatibility | Aluminum, Stainless Steel, Carbon Steel, Titanium, Brass, Copper Alloys |

| Cutting Methods | CNC Milling, Laser Cutting, Waterjet, Plasma, EDM |

| Tolerance Range | ±0.005 mm to ±0.05 mm (depending on process) |

| Max Work Envelope | 3000 x 1500 x 800 mm (Laser/Waterjet) |

| Max Part Weight | 2,500 kg |

| Lead Time (Prototype) | 5–10 business days |

| Lead Time (Mass Production) | 15–25 days (batch-dependent) |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), AS9100 (aerospace) |

This disciplined progression from design to prototyping to full-scale production ensures Wuxi Lead Precision Machinery delivers flawless, repeatable results—meeting the exacting demands of advanced manufacturing clients worldwide.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Material Cutting Excellence in Georgia

Georgia’s manufacturing sector demands precision, speed, and unwavering reliability in material cutting services. As domestic capacity strains under complex project requirements, Wuxi Lead Precision Machinery delivers a strategic global partnership engineered for success. We specialize in high-tolerance metal cutting for aerospace, energy, and industrial OEMs—transforming your most challenging designs into flawless components. Forget supply chain bottlenecks or inconsistent quality. Our ISO 9001-certified facility in Wuxi, China, operates with the rigor of a Tier-1 supplier, providing Georgia-based manufacturers with a competitive edge through advanced capabilities and responsive collaboration.

Our technical expertise spans laser, waterjet, and plasma cutting across critical materials, including titanium, Inconel, aluminum alloys, and hardened steels. We tackle geometries and tolerances that strain conventional workshops, ensuring dimensional accuracy and surface integrity meet aerospace and medical standards. Below are core specifications defining our cutting service:

| Capability | Specification | Equipment Platform |

|---|---|---|

| Material Thickness Range | 0.5 mm – 150 mm | Laser: 6kW Trumpf |

| Waterjet: 60,000 PSI OMAX | ||

| Plasma: Hypertherm | ||

| Tolerance Control | ±0.005 mm (laser), ±0.1 mm (waterjet) | Fully CNC Integrated |

| Max Work Envelope | 4000 x 2000 mm | HAAS/DMG MORI Systems |

| Material Types Supported | Titanium, Inconel, Tool Steel, Aluminum | In-House Metallurgy Lab |

What sets Lead Precision apart is our engineered approach to partnership. We integrate seamlessly into your workflow through dedicated project engineering teams, real-time production tracking, and strict adherence to ITAR/NDAs. Time zone differences vanish with our U.S.-based technical liaison team, providing immediate responses during Eastern business hours. Every shipment undergoes rigorous CMM validation, with full material traceability and AS9100-compliant documentation—eliminating compliance risks for Georgia clients.

Do not compromise on precision or delivery when your reputation depends on flawless execution. Wuxi Lead Precision Machinery bridges global capability with localized accountability, ensuring your Georgia operations gain agility without sacrificing quality. We reduce your total cost of ownership through optimized nesting, reduced scrap rates, and on-time delivery exceeding 98.5%.

Initiate your precision cutting partnership today. Contact our technical sales team at [email protected] for a project-specific capability review and 48-hour quoting. Include your material specifications, CAD files, and volume requirements to receive a tailored solution analysis. Let Lead Precision become your strategic extension—where engineering excellence meets operational certainty. Your next breakthrough component starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.