Technical Contents

Engineering Guide: Martin Steel Fabrication Inc

Engineering Insight Precision as the Non-Negotiable Foundation in Sheet Metal Fabrication

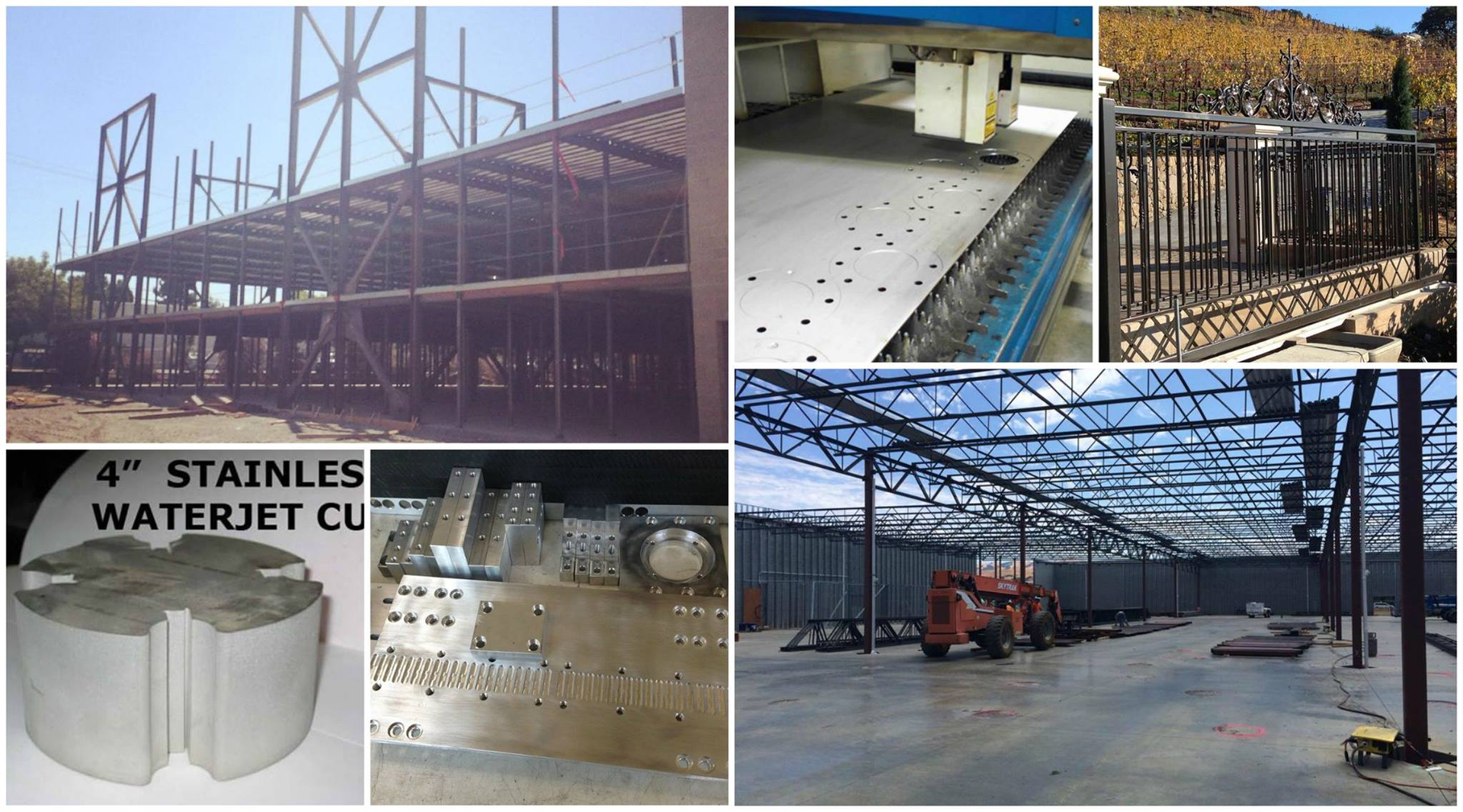

In high-stakes sheet metal fabrication, precision transcends mere quality control; it defines structural integrity, operational safety, and project viability. For Martin Steel Fabrication Inc, partnering with a supplier capable of delivering micron-level accuracy isn’t an option—it’s the baseline requirement for success in aerospace, defense, and critical infrastructure sectors. A deviation of 0.1mm in a load-bearing bracket or enclosure can cascade into catastrophic system failure, costly rework, or project delays measured in weeks. The true cost of imprecision extends far beyond material waste; it erodes client trust and jeopardizes hard-won reputations in markets where tolerances are dictated by physics, not preference.

Wuxi Lead Precision Machinery operates at this uncompromising threshold daily. Our engineering philosophy is forged in environments where failure is not an option. We engineered components for the structural frameworks of the 2022 Beijing Winter Olympics venues, where wind loads and seismic activity demanded absolute dimensional fidelity across thousands of custom-fabricated panels. Similarly, our military-grade enclosures for advanced radar and communication systems undergo rigorous validation to meet MIL-STD-810G specifications, tolerating extreme vibration and thermal cycling without dimensional drift. This experience translates directly to Martin Steel Fabrication Inc’s most demanding projects: we understand that your client’s success hinges on the unwavering consistency of every bend, cut, and weld we deliver.

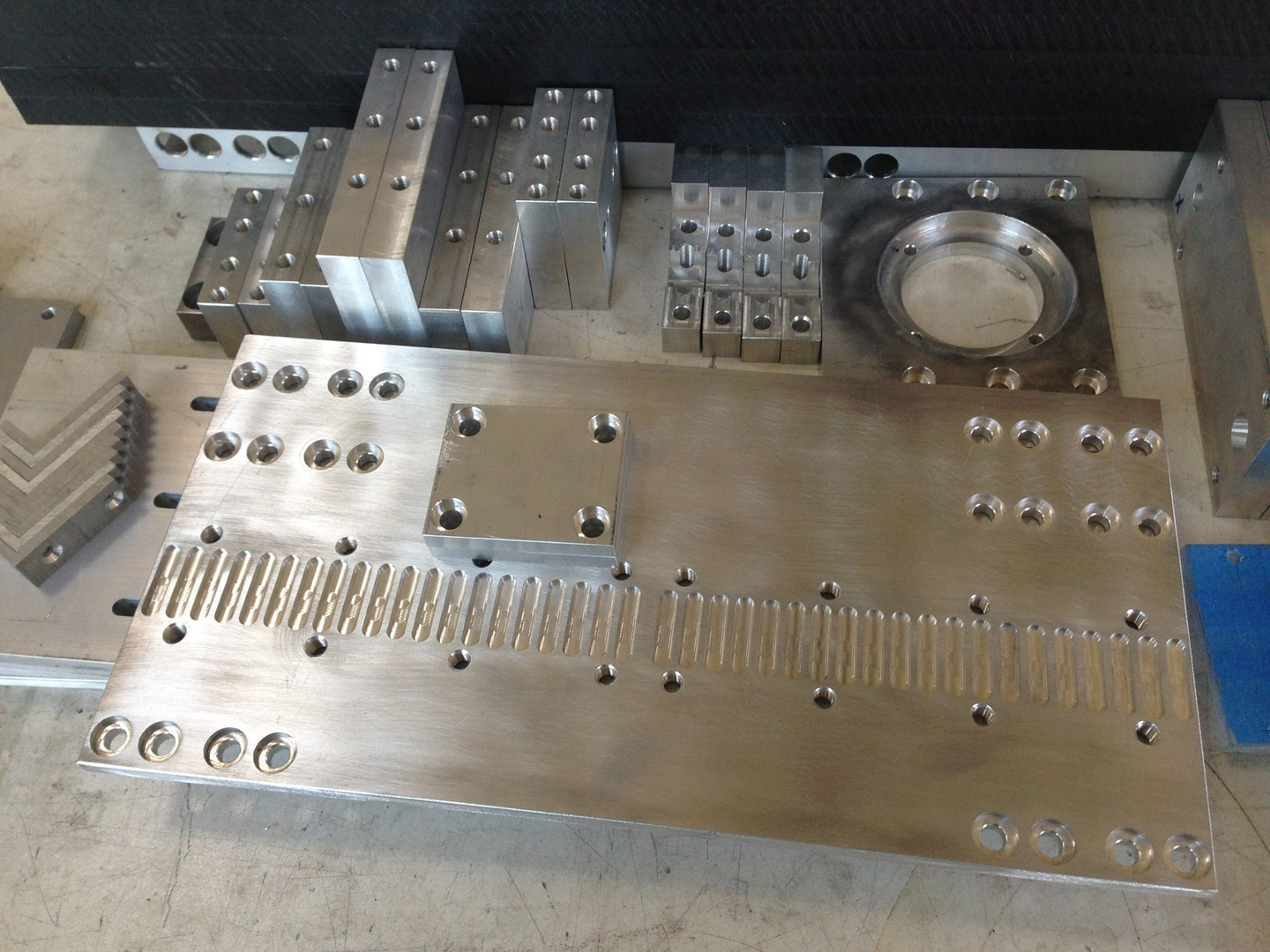

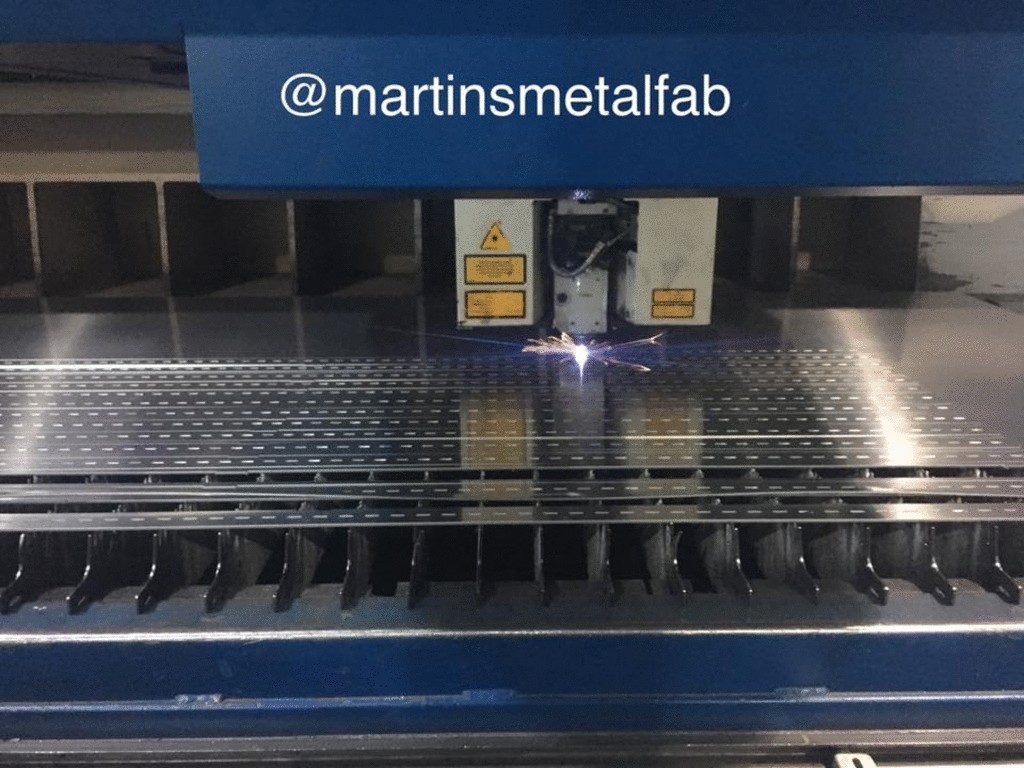

Our commitment is engineered into the core of our manufacturing ecosystem. Advanced 5-axis CNC laser cutting and press brake systems, coupled with in-process metrology, ensure geometric accuracy is maintained from digital model to finished part. The table below details our certified capability envelope for sheet metal work relevant to Martin Steel Fabrication Inc’s high-precision requirements:

| Specification Parameter | Wuxi Lead Precision Capability | Industry Standard Benchmark |

|---|---|---|

| Linear Dimensional Tolerance | ±0.025 mm | ±0.1 mm |

| Angular Tolerance (Bending) | ±0.25° | ±1.0° |

| Hole Positional Accuracy | ±0.05 mm | ±0.2 mm |

| Maximum Material Thickness | 25 mm (Mild Steel) | 12-16 mm |

| Minimum Feature Size | 0.8 mm | 1.5 mm |

| Surface Roughness (Ra) | 0.8 µm | 3.2 µm |

This capability is sustained through rigorous process control, including real-time laser interferometer calibration of machine tools and 100% first-article inspection against 3D CAD models using Zeiss CMMs. For Martin Steel Fabrication Inc, this means receiving components that integrate seamlessly into final assemblies, eliminating fit-up corrections and accelerating your production throughput. When your projects demand tolerances that push the boundaries of conventional fabrication, our proven expertise in mission-critical applications ensures reliability you can build upon. Precision isn’t merely a metric we achieve; it’s the foundation of every partnership we forge and the legacy we deliver.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-performance industrial applications. Our technical capabilities are engineered to meet the stringent demands of global clients, including precision-focused partners such as Martin Steel Fabrication Inc. With a foundation built on cutting-edge machinery, rigorous quality assurance, and deep metallurgical expertise, we ensure every fabricated component adheres to the highest standards of accuracy, consistency, and structural integrity.

At the core of our production workflow is our 5-axis CNC machining technology. This advanced system enables multi-directional cutting, drilling, and shaping of complex sheet metal geometries with exceptional precision. Unlike conventional 3-axis systems, our 5-axis CNC platforms allow simultaneous movement across five planes, drastically reducing setup times, minimizing human intervention, and eliminating cumulative tolerances from multiple operations. This capability is particularly critical when producing intricate components for aerospace, energy, and heavy industrial equipment—sectors where Martin Steel Fabrication Inc operates at the forefront.

Our 5-axis CNC centers are integrated with high-speed spindles and adaptive control systems that optimize feed rates and tool paths in real time. This ensures minimal material waste, superior surface finishes, and consistent repeatability across large production runs. Materials commonly processed include carbon steel, stainless steel, aluminum alloys, and specialty metals, all handled with precision from raw sheet to finished form.

Quality control is embedded at every stage of fabrication. We employ a fully certified Coordinate Measuring Machine (CMM) inspection process to validate dimensional accuracy. The CMM system performs non-contact and tactile 3D measurements with micron-level resolution, verifying critical features such as hole placement, edge alignment, contour fidelity, and form tolerances. All inspection data is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality requirements.

To ensure transparency and alignment with client expectations, we maintain clearly defined tolerance benchmarks across all fabrication processes. These tolerances reflect our commitment to precision and are continuously validated through in-process and final inspections.

| Feature | Standard Tolerance | High-Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.1 mm | ±0.05 mm | Up to 1000 mm |

| Hole Positioning | ±0.15 mm | ±0.08 mm | Relative to datum |

| Edge-to-Edge Alignment | ±0.12 mm | ±0.06 mm | For mitered joints |

| Angular Cuts | ±0.2° | ±0.1° | On 5-axis bevel cuts |

| Surface Flatness | 0.15 mm/m² | 0.08 mm/m² | For post-formed panels |

| Hole Diameter | +0.1 / -0.05 mm | +0.05 / -0.02 mm | Drilled or punched |

These technical capabilities position Wuxi Lead Precision Machinery as a trusted extension of Martin Steel Fabrication Inc’s supply chain, delivering precision-fabricated components that meet the most demanding engineering specifications.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material and finish is foundational to achieving performance, durability, and cost-efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we understand that Martin Steel Fabrication Inc. requires materials meeting stringent aerospace, industrial, and architectural specifications. This guide outlines critical considerations for Aluminum, Steel, Titanium, and Anodizing finishes to support your high-integrity component production.

Aluminum alloys, particularly 6061-T6 and 5052-H32, offer an exceptional strength-to-weight ratio and inherent corrosion resistance. They are ideal for applications demanding weight reduction without sacrificing structural integrity, such as aerospace components, transportation frames, and electronic enclosures. Aluminum’s excellent machinability and weldability streamline fabrication processes. Steel remains the backbone for structural applications requiring high strength and impact resistance. Cold-rolled steel (CRS) and stainless steel grades like 304 and 316 provide robust solutions for machinery frames, enclosures, and hardware. Stainless variants offer superior corrosion resistance for medical, food processing, or marine environments, though at a higher material cost. Titanium Grade 2 and 5 (Ti-6Al-4V) deliver unparalleled strength-to-weight ratios and exceptional resistance to extreme corrosion and high temperatures. While significantly more expensive and challenging to machine than aluminum or steel, titanium is indispensable for critical aerospace, defense, and chemical processing components where failure is not an option.

The chosen finish directly impacts longevity and aesthetics. Anodizing is the premier surface treatment for aluminum, creating a durable, corrosion-resistant oxide layer integral to the substrate. Type II (Sulfuric Acid) anodizing provides standard corrosion and wear resistance with dyeing capability for color coding or branding. Type III (Hardcoat) anodizing produces a significantly thicker, harder layer essential for components subjected to severe abrasion, high wear, or demanding electrical insulation requirements. It offers superior mechanical properties compared to Type II but limits color options primarily to bronze or black.

Material properties dictate fabrication parameters and final performance. Refer to the key specifications below for common alloys.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Key Corrosion Resistance | Primary Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 276 | Good (atmospheric) | Aerospace brackets, structural frames |

| Steel A36 | 7.8 | 400-550 | 250 | Poor (requires coating) | Structural supports, machinery bases |

| Stainless 304 | 8.0 | 515 | 205 | Excellent (general) | Food processing, chemical tanks, marine |

| Titanium Grade 2 | 4.5 | 345 | 275 | Exceptional (all media) | Chemical valves, marine hardware |

Material selection must align precisely with the component’s operational environment, load requirements, lifecycle costs, and regulatory standards. Pairing the correct base material with the appropriate finish, such as Type III anodizing for high-wear aluminum parts, maximizes service life and minimizes total cost of ownership. Wuxi Lead Precision Machinery leverages advanced CNC capabilities and deep metallurgical expertise to fabricate and finish these materials to the tightest tolerances, ensuring your Martin Steel Fabrication Inc. projects meet the highest industry benchmarks for quality and performance. Consult our engineering team early in the design phase for optimal material and process recommendations.

Manufacturing Process & QC

Design: Precision Engineering from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of flawless sheet metal fabrication begins with advanced design engineering. Our team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models using industry-leading software such as SolidWorks, AutoCAD, and Siemens NX. Every design is optimized for manufacturability, ensuring tight tolerances, structural integrity, and alignment with end-use applications. Finite element analysis (FEA) and design for assembly (DFA) principles are applied to anticipate performance under real-world conditions. This phase includes comprehensive material selection guidance, leveraging our expertise in stainless steel, aluminum, carbon steel, and specialty alloys. The result is a fully validated digital prototype that serves as the master reference for all downstream processes.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC punching, laser cutting, and bending technologies. These functional prototypes are produced on the same equipment used in mass production, ensuring consistency and accuracy. Each prototype undergoes rigorous dimensional inspection via coordinate measuring machines (CMM) and 3D scanning, with results cross-verified against the original CAD model. We conduct mechanical fit checks, weld integrity tests, and surface finish evaluations to confirm compliance with international standards such as ISO 2768 and GD&T specifications. Feedback from client testing is integrated swiftly, allowing for iterative refinement until 100% performance validation is achieved. This stage minimizes risk, reduces time-to-market, and ensures that only perfected designs advance to full-scale production.

Mass Production: Zero Defects Through Systematic Control

Our mass production line operates under a disciplined quality management system certified to ISO 9001:2015, with a core objective of zero defects. Automated CNC fabrication cells run with minimal human intervention, ensuring repeatability across batches of any size. In-process inspections occur at critical control points—after cutting, bending, welding, and surface treatment—using statistical process control (SPC) methodologies. Final assemblies are subjected to 100% visual inspection and selective destructive testing to verify long-term reliability. All production data is logged and traceable, enabling full batch accountability.

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerance (Standard) | ±0.1 mm (cutting), ±0.2° (bending) |

| Max Part Size | 4000 mm × 2000 mm |

| Laser Cutting Power | Up to 12 kW (fiber) |

| Press Brake Capacity | Up to 300 tons, 8-axis CNC control |

| Welding Processes | MIG, TIG, Spot, Robotic Arc |

| Surface Treatments | Anodizing, Powder Coating, Passivation, Zinc Plating |

| Quality Standards | ISO 9001:2015, ISO 14001, ISO 45001 |

Through seamless integration of design, prototyping, and production, Wuxi Lead delivers uncompromised precision and reliability for global partners like Martin Steel Fabrication Inc.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Excellence

Selecting a sheet metal fabrication partner demands rigorous evaluation of technical capability, process integrity, and collaborative alignment. At Wuxi Lead Precision Machinery, we engineer partnerships—not transactions—specifically for high-stakes manufacturers like Martin Steel Fabrication Inc. Our ISO 9001-certified facility in Wuxi, China, operates at the intersection of German-engineered machinery and Chinese operational discipline, delivering precision sheet metal components that meet stringent North American engineering standards. We understand your critical requirements: zero-defect delivery, adherence to complex GD&T specifications, and seamless integration into your production workflow. Our dedicated U.S.-based technical account managers ensure real-time communication during EST business hours, eliminating time zone barriers and fostering transparent project execution.

Our advanced manufacturing ecosystem supports your most demanding applications. The table below details core capabilities directly relevant to structural steel and precision enclosure fabrication:

| Parameter | Specification | Relevance to Fabrication |

|---|---|---|

| Laser Cutting | 15mm Carbon Steel / 8mm Stainless Steel | High-speed, burr-free blanks for complex geometries |

| CNC Punching | 60-ton force / ±0.05mm positional accuracy | Rapid prototyping and high-volume bracket production |

| Press Brake Forming | 400-ton capacity / ±0.1° angular tolerance | Consistent bends for structural frames and enclosures |

| Material Certification | ASTM A36, A516, 304/316 SS with mill test reports | Full traceability for critical structural applications |

| Surface Finishing | Powder coating (ISO 2808 certified) / Anodizing | Corrosion-resistant finishes meeting MIL-STD specs |

| Quality Control | CMM inspection (0.001mm resolution) / First Article Reports | AS9102-compliant documentation for aerospace-grade assurance |

This infrastructure enables us to absorb volatility in your supply chain while maintaining your quality benchmarks. We implement dual-stage in-process inspections—automated optical verification during laser cutting followed by manual CMM validation on critical features—ensuring conformance to your engineering drawings before shipment. Our lean manufacturing cells are optimized for low-volume complex parts or high-volume runs exceeding 50,000 units, with typical lead times 22% faster than industry averages for comparable precision tiers. Crucially, we operate under your quality protocols: PPAP submissions, FAI packages, and material certifications are standard deliverables, not premium add-ons.

Martin Steel’s reputation hinges on components that perform flawlessly in field installations. We mitigate your risk through proactive engineering collaboration—our team reviews DFM opportunities during quotation to reduce your total cost of ownership while preserving structural integrity. When dimensional stability in welded assemblies or repeatability in progressive stamping operations is non-negotiable, our process-controlled environment delivers.

Initiate your precision partnership today. Email Contact [email protected] with your current fabrication challenge or upcoming RFQ. Include your target tolerance requirements and volume parameters for a tailored capability assessment within 4 business hours. Our technical team will provide a detailed process flow analysis demonstrating how Lead Precision integrates into your supply chain with zero disruption. Trust a partner that speaks your engineering language and operates to your quality rhythm—where “Made in China” means precision engineered for North American excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.