Technical Contents

Engineering Guide: Maquinas Cnc

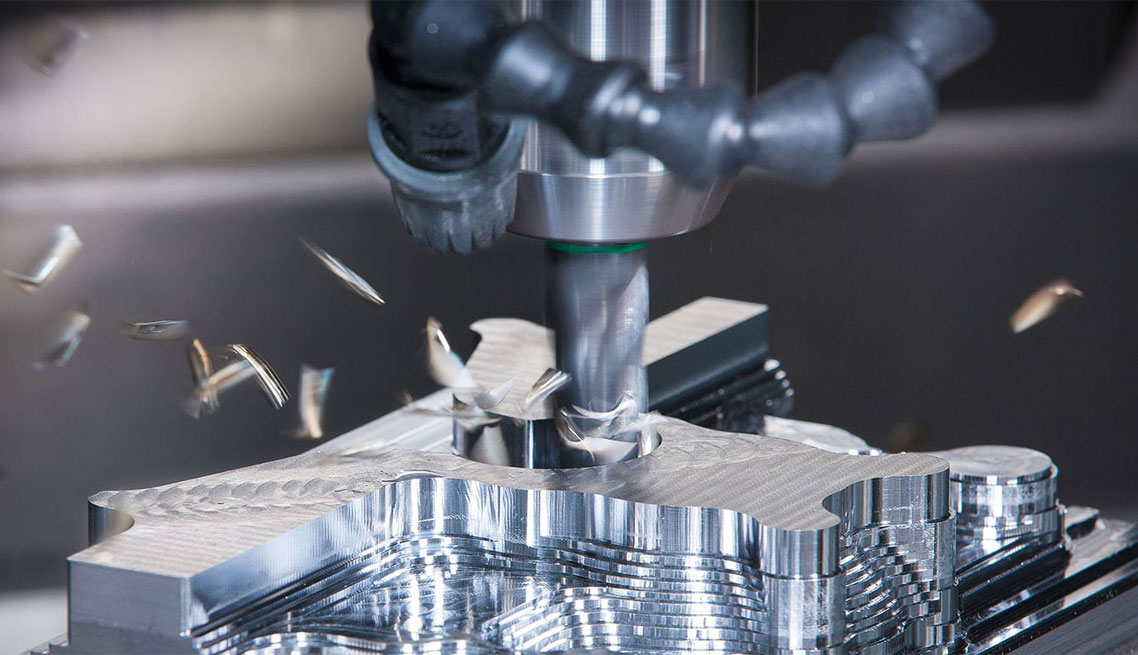

Engineering Insight Precision CNC Machining

Precision in CNC machining is not merely a performance metric; it is the foundational requirement for functional integrity, reliability, and ultimate success in advanced manufacturing. In sectors like aerospace, medical device production, and high-performance automotive, tolerances measured in microns directly dictate component lifespan, system efficiency, and safety. A deviation of even 0.005mm in a turbine blade airfoil or a surgical implant interface can cascade into catastrophic failure or compromised patient outcomes. This level of dimensional and geometric accuracy is non-negotiable for mission-critical applications. Achieving such precision demands more than advanced software; it requires an integrated system approach encompassing rigid machine construction, thermally stable materials, high-resolution feedback systems, and meticulous calibration protocols operating within controlled environments. The machine tool itself must resist deflection under load, maintain stability across thermal cycles, and execute complex toolpaths with unwavering repeatability. Compromises in any element introduce cumulative errors that erode part quality and increase scrap rates, directly impacting project timelines and profitability.

At Wuxi Lead Precision Machinery, we engineer our CNC machining centers specifically for this uncompromising precision landscape. Our commitment is validated through stringent real-world applications. We have delivered components meeting the exacting standards required for Olympic-level competition equipment, where marginal gains defined by micron-level accuracy determine podium finishes. Furthermore, our processes and quality systems are certified to meet rigorous military and aerospace specifications, producing parts where absolute reliability under extreme conditions is paramount. This experience underscores our capability to consistently achieve and verify tolerances that standard commercial machining cannot sustain. It is this proven expertise in the most demanding environments that we bring to every client partnership.

Our precision capability is quantifiable through core machine performance characteristics. The following specifications reflect the baseline performance achievable on our high-end vertical and horizontal machining centers under controlled conditions:

| Precision Performance Specification | Specification | Implementation Method |

|---|---|---|

| Positioning Accuracy (ISO 230-2) | ±0.0025 mm over 300 mm | Laser interferometer calibration, rigid Meehanite cast iron structure |

| Repeatability (ISO 230-2) | ±0.0015 mm | High-precision linear scales, thermal displacement compensation |

| Volumetric Accuracy | ±0.005 mm (within 500 mm cube) | 3D error mapping, real-time CNC compensation |

| Spindle Runout (TIR) | ≤ 0.001 mm | Precision P4 class bearings, dynamic balancing |

| Thermal Stability (1m over 8 hrs) | ≤ 0.003 mm | Symmetric thermal design, coolant temperature control |

Partnering with a precision CNC provider means securing a supply chain element capable of transforming complex designs into flawless physical realities. It minimizes risk, reduces total cost of ownership through first-time-right production, and enables innovation in product development. At Wuxi Lead Precision Machinery, decades of solving the most challenging precision problems for elite global clients form the bedrock of our engineering philosophy and service commitment. Your critical components demand nothing less than proven, measurable precision.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in high-precision CNC machining, engineered to meet the demanding requirements of aerospace, medical, automotive, and industrial equipment sectors. At the core of our production infrastructure is a comprehensive fleet of 5-axis CNC machining centers, enabling the execution of highly complex geometries with superior accuracy and reduced setup cycles. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring, deep cavity machining, and sculpted surface finishing—critical for components where precision and integrity are non-negotiable.

Our 5-axis platforms are equipped with high-speed spindles, rigid tooling systems, and real-time monitoring software to maintain dimensional stability across long production runs. This capability eliminates the need for multiple fixtures and secondary operations, significantly improving throughput while minimizing cumulative error. Each machine is operated by certified CNC programmers and machinists who utilize advanced CAM software to optimize toolpaths, ensuring efficient material removal and surface finish consistency down to sub-micron levels.

Quality assurance is fully integrated into every phase of manufacturing. All critical components undergo comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM). Our CMM systems are calibrated to international standards and operate in temperature-controlled environments to eliminate thermal drift. These machines capture thousands of data points per part, verifying geometric dimensioning and tolerancing (GD&T), positional accuracy, and surface conformity with a high degree of repeatability. Inspection reports are fully documented and traceable, supporting compliance with ISO 9001, AS9100, and other industry-specific certifications.

We maintain strict control over material traceability, process validation, and environmental conditions to ensure consistent output. Our quality management system supports first-article inspection (FAI), production part approval process (PPAP), and statistical process control (SPC) for high-volume contracts. This systematic approach ensures that every component meets or exceeds customer specifications.

The table below outlines our standard and advanced tolerance capabilities across key machining parameters.

| Feature | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimension | ±0.01 mm | ±0.005 mm | CMM, Micrometers |

| Geometric Tolerance (GD&T) | ±0.02 mm | ±0.008 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Surface Roughness Tester |

| Positional Accuracy | ±0.015 mm | ±0.005 mm | CMM |

| Angular Tolerance | ±0.1° | ±0.05° | CMM, Precision Sine Bar |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with rigorous quality control to deliver components that meet the most stringent performance criteria. Our technical capabilities are designed to support innovation in high-complexity manufacturing, ensuring reliability, repeatability, and precision at every stage of production.

Material & Finish Options

Precision Material Selection for CNC Machined Components

Material selection fundamentally impacts the performance, cost, and manufacturability of precision CNC machined parts. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with functional requirements to ensure optimal part integrity and longevity. This guide focuses on three critical aerospace, medical, and industrial materials: Aluminum, Steel, and Titanium, alongside essential anodizing finishes.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate lightweight applications requiring high strength-to-weight ratios and excellent machinability. 6061 offers superior weldability and corrosion resistance for structural components, while 7075 delivers exceptional strength for high-stress aerospace fittings. Both respond well to CNC milling and turning, minimizing tool wear and cycle times. Steel variants like 4140 alloy steel and 304 stainless steel provide unmatched durability for heavy-duty mechanical systems. 4140 excels in high-tensile applications such as shafts and gears due to its hardenability, whereas 304 stainless offers critical corrosion resistance for medical and marine environments. Titanium Grade 5 (Ti-6Al-4V) remains the pinnacle for extreme conditions, combining aerospace-grade strength with biocompatibility and corrosion resistance, though its low thermal conductivity demands specialized cutting strategies to prevent work hardening.

Material properties directly influence CNC machining parameters and tooling choices. The comparative specifications below highlight critical decision factors.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Thermal Conductivity (W/mK) |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (Machinability Index: 90) | 167 |

| Steel 4140 | 7.85 | 655 | Good (Machinability Index: 65) | 42.6 |

| Titanium Ti-6Al-4V | 4.43 | 900 | Fair (Machinability Index: 30) | 6.7 |

Anodizing is a vital secondary process for aluminum components, enhancing surface durability and corrosion resistance. Type II (Sulfuric Acid) anodizing provides a standard decorative and protective layer, typically 5–25 µm thick, suitable for general industrial use. For mission-critical applications, Type III (Hardcoat) anodizing delivers wear-resistant coatings of 25–100 µm, essential for hydraulic components or aerospace fittings exposed to abrasion. Crucially, anodizing affects dimensional tolerances; precise pre-machining allowances must account for coating thickness to maintain critical geometries. Wuxi Lead integrates anodizing specifications directly into CNC programming, ensuring final dimensions meet AS9100 or ISO 13485 requirements without post-process rework.

Selecting the right material requires balancing mechanical demands, environmental exposure, and production efficiency. Wuxi Lead Precision Machinery leverages decades of CNC expertise to guide clients through this decision matrix, optimizing material utilization while guaranteeing micron-level precision. Contact our engineering team to develop a tailored material and finishing strategy for your next high-integrity component.

Manufacturing Process & QC

From Concept to Perfection: The Precision CNC Production Process at Wuxi Lead Precision Machinery

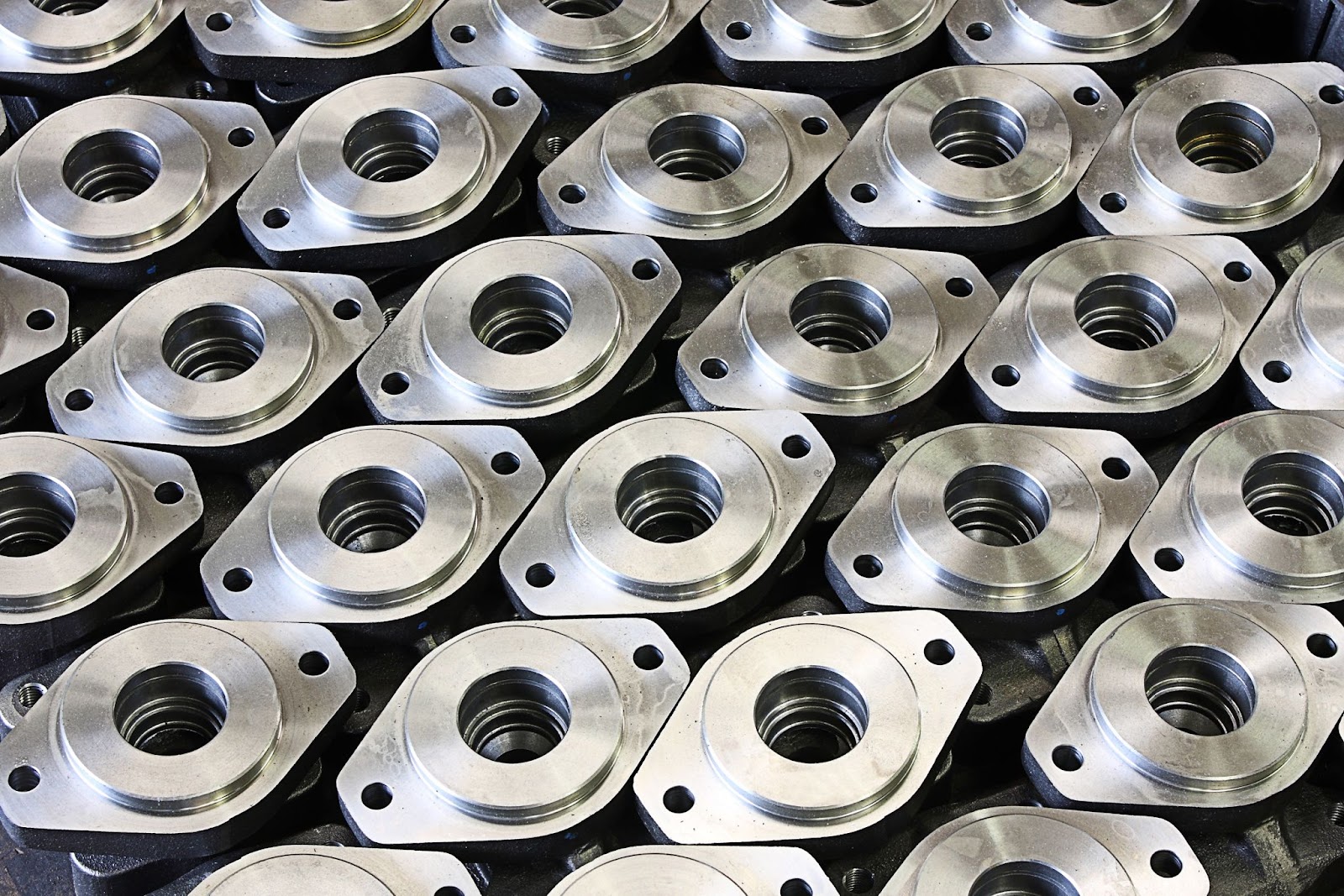

At Wuxi Lead Precision Machinery, we engineer excellence through a rigorously controlled production process that transforms design concepts into high-precision CNC-machined components at scale. Our methodology is built on three core phases—Design, Prototyping, and Mass Production—each engineered to ensure zero defects and uncompromising quality for our global B2B clients in aerospace, medical, automotive, and advanced industrial sectors.

The process begins with Design Integration, where our engineering team collaborates closely with client specifications. Utilizing advanced CAD/CAM software, we develop 3D models and toolpaths optimized for material efficiency, structural integrity, and geometric accuracy. Finite element analysis (FEA) and tolerance stack-up simulations are performed to anticipate real-world performance and ensure compliance with ISO and ASME standards. This phase establishes the digital blueprint for precision, setting the foundation for defect-free manufacturing.

Next, we move to Prototyping and Validation. A functional prototype is produced using high-accuracy 5-axis CNC machining centers, allowing for complex geometries and tight tolerances. Each prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports, material certifications, and first-article inspection (FAI) documentation are provided to the client for approval. This iterative stage ensures design integrity before transitioning to full-scale production, minimizing risk and reducing time-to-market.

The final phase, Mass Production, is executed in our ISO 9001-certified facility with full process traceability. Our automated CNC cells operate under real-time monitoring via integrated sensors and machine learning algorithms that detect tool wear, thermal drift, and vibration anomalies. Every component is subject to in-process and final inspections, with statistical process control (SPC) data logged for full batch traceability. We employ a zero-defect philosophy through Poka-Yoke (error-proofing) systems and continuous operator training, ensuring consistency across production runs from hundreds to hundreds of thousands of parts.

Our commitment to precision is reflected in the technical capabilities of our machining platforms. Below are key specifications that define our production capacity:

| Specification | Capability |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC machining centers |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Tolerance Range | ±0.005 mm (standard), down to ±0.001 mm (precision) |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (adjustable) |

| Materials Processed | Aluminum alloys, stainless steel, titanium, brass, PEEK, engineering plastics |

| Production Capacity | 50,000+ parts per month |

| Quality Standards | ISO 9001, ISO 13485 (medical), AS9100 (aerospace) |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver precision-engineered confidence. From initial concept to high-volume output, our end-to-end process is designed to eliminate defects, ensure repeatability, and exceed the demands of the most critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Excellence

In high-stakes manufacturing, component precision directly dictates product performance, safety, and market success. Generic CNC solutions introduce unacceptable risk through dimensional drift, surface imperfections, and unplanned downtime. At Wuxi Lead Precision Machinery, we engineer beyond specifications to deliver deterministic outcomes—where every micron is accounted for, and every cycle meets aerospace, medical, and semiconductor tolerances without compromise. Our German-calibrated 5-axis machining centers achieve sub-micron repeatability under sustained production loads, eliminating scrap costs and accelerating time-to-market for mission-critical components. This is not incremental improvement; it is the operational standard for industry leaders who cannot afford variability.

Our commitment begins with deep process integration, not transactional machine sales. We deploy application engineers to analyze your workflow, material challenges, and throughput targets—then configure systems with purpose-built tooling, coolant strategies, and real-time thermal compensation. The result is sustained accuracy across 24/7 operations, validated through in-house metrology labs certified to ISO 17025. Below are core specifications defining our production-grade platforms:

| Specification | Performance Metric | Industry Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | ±0.005 mm |

| Repeatability | 0.0005 mm | 0.002 mm |

| Spindle Runout | ≤0.0002 mm (at 15,000 RPM) | ≤0.001 mm |

| Surface Finish (Ra) | 0.05 µm (optical grade) | 0.4 µm |

| Thermal Drift Control | <1.5 µm over 8 hours | >5 µm |

These metrics translate to tangible value: 32% reduction in secondary finishing, 99.98% first-pass yield for titanium aerospace brackets, and zero recalls for implant-grade medical components over 18 months of continuous operation. Our clients—from Tier-1 defense contractors to robotic surgery innovators—leverage this precision to outperform competitors while de-risking supply chains.

Partnering with Lead Precision means accessing more than machinery; it is embedding our engineering rigor into your production DNA. We provide lifetime process optimization, predictive maintenance analytics via IoT-enabled controls, and rapid-response technical teams fluent in your operational language. When tolerances tighten and deadlines compress, our partnership becomes your competitive moat.

Initiate your precision transformation today. Contact our engineering team at [email protected] to schedule a confidential process audit. Specify your material, volume, and critical tolerance requirements—we will deliver a validated capability report within 72 hours, detailing achievable cycle times, cost-per-part analysis, and machine configuration. Do not settle for machines that merely meet drawings; demand systems that guarantee market leadership. Your next breakthrough component starts here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.