Technical Contents

Engineering Guide: Machinist Company

Engineering Insight: The Strategic Imperative of Precision in Modern Machining

Precision in custom metal manufacturing transcends basic dimensional accuracy; it is the foundational element determining product functionality, longevity, and ultimate success in demanding applications. For industries like aerospace, medical technology, and advanced automation, tolerances measured in microns directly impact safety, performance, and regulatory compliance. A variance of 0.001mm in a critical aerospace bearing raceway can accelerate wear exponentially, leading to catastrophic failure. Similarly, sub-micron inconsistencies in medical implant surfaces compromise biocompatibility and osseointegration. Precision is not merely a specification checkbox—it is a strategic investment mitigating field failures, reducing lifecycle costs, and enabling technological innovation that less capable processes cannot support. Achieving this level requires integrated mastery of material science, thermal dynamics, vibration control, and real-time process monitoring, far beyond standard workshop capabilities.

At Wuxi Lead Precision Machinery, we validate our precision engineering rigor through mission-critical projects where failure is not an option. Our manufacturing processes were rigorously tested producing timing system components for the Beijing Olympic Games, where nanosecond accuracy was non-negotiable for athletic record validation. We further apply this discipline to classified military programs, manufacturing guidance system housings and drone structural elements adhering to stringent MIL-STD-810G and AS9100D requirements. These engagements demand not only extreme tolerances but also unwavering repeatability across batches and resilience under extreme environmental stress—conditions that expose the limitations of conventional machining approaches. Our facility’s investment in temperature-stabilized metrology labs, in-process probing systems, and multi-axis Swiss-type lathes with sub-micron resolution forms the backbone of this capability.

The following table illustrates the tangible precision benchmarks achievable across application tiers, reflecting our operational reality:

| Application Tier | Typical Tolerance Range | Critical Parameter Example |

|---|---|---|

| Standard Industrial | ±0.025mm (±0.001″) | General bracket alignment |

| High-Performance | ±0.005mm (±0.0002″) | Hydraulic valve spool concentricity |

| Aerospace/Military | ±0.002mm (±0.00008″) | Turbine blade root profile |

| Lead Precision Elite | ±0.0005mm (±0.00002″) | Optical encoder disc runout |

Partnering with a manufacturer possessing validated high-precision expertise transforms engineering ambition into reliable reality. When your design pushes material limits or operates in unforgiving environments, the machining process must anticipate and compensate for thermal drift, micro-vibrations, and material anisotropy before the first chip is cut. Wuxi Lead Precision Machinery integrates decades of hands-on problem-solving—honed through Olympic and defense projects—into every custom component. We engineer not just to prints, but to the unspoken physics governing your product’s mission. Precision, rigorously defined and relentlessly executed, is the only acceptable standard for systems where performance is paramount. Let us demonstrate how our disciplined approach secures your competitive advantage.

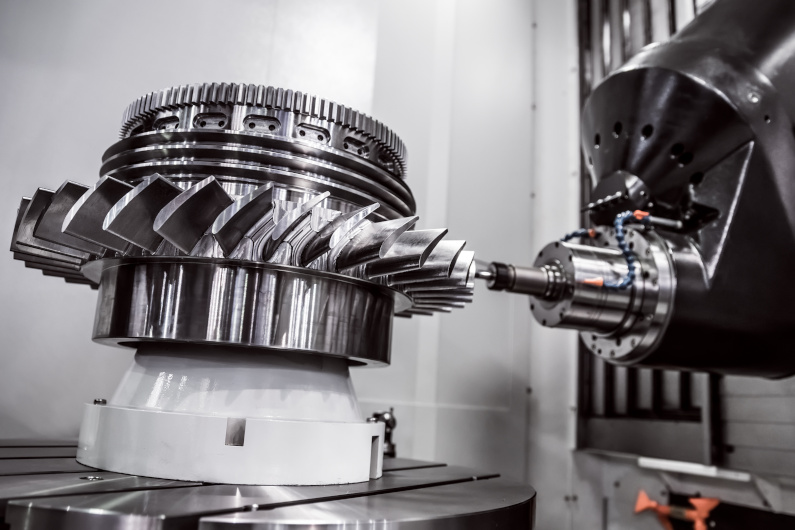

Precision Specs & Tolerances

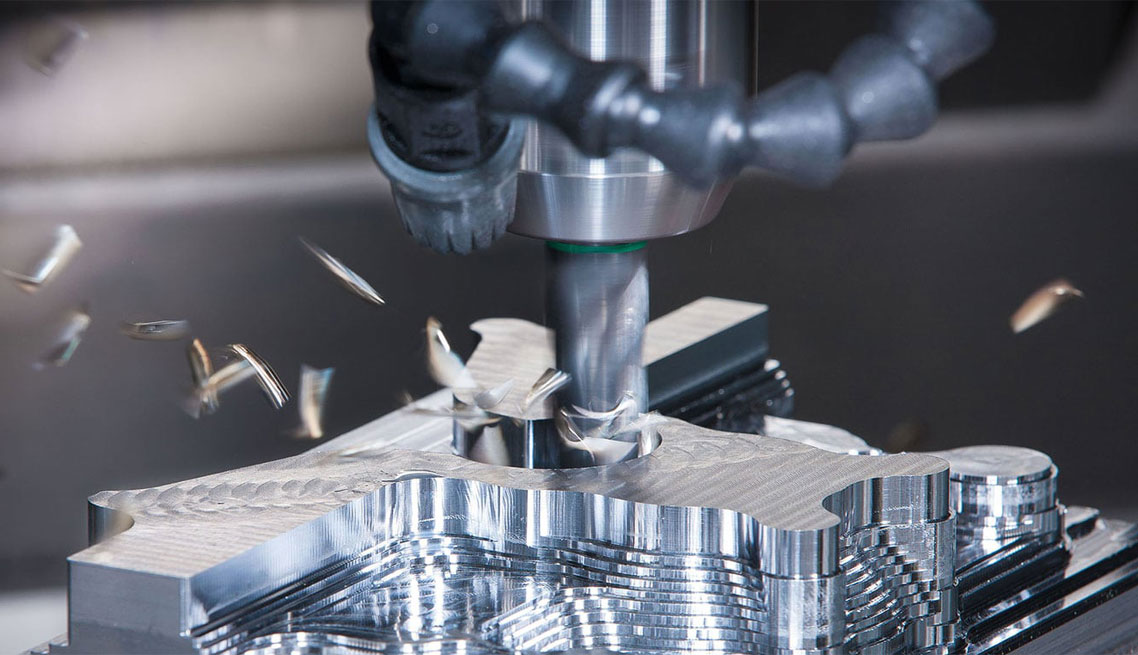

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for industries demanding uncompromising precision, including aerospace, medical, energy, and high-performance automotive sectors. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of highly complex geometries with superior surface finish and dimensional accuracy. Our machining centers operate with simultaneous multi-axis motion, allowing for intricate contouring, deep cavity machining, and reduced setup times—critical advantages for prototyping and low-to-medium volume production runs.

Each 5-axis CNC system is maintained to OEM specifications and operated by certified CNC programmers and machinists with over a decade of experience in precision engineering. We utilize industry-leading CAM software to generate optimized toolpaths, ensuring material integrity and process efficiency across a broad range of metals, including titanium, Inconel, aluminum alloys, stainless steel, and specialty composites. Our facility supports machining envelopes up to 1200 x 800 x 750 mm, accommodating both compact high-precision components and larger structural parts.

To guarantee consistency and compliance with international quality standards, every production batch undergoes rigorous quality control protocols anchored by a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM). This metrology-grade inspection system provides full 3D geometric dimensioning and tolerance (GD&T) verification with a measurement accuracy of ±1.5 + L/300 µm. Our CMM is integrated into the production workflow, enabling first-article inspection, in-process checks, and final certification reporting. All inspection data is archived for full traceability, meeting ISO 9001:2015 and AS9100 requirements.

In addition to CMM validation, we employ surface roughness testers, digital micrometry, optical comparators, and hardness testing to verify material and finish compliance. Our quality management system supports PPAP, FAI, and CPK reporting for customers requiring statistical process control documentation.

The following table outlines the standard tolerances we consistently achieve across our machining operations:

| Feature | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | Up to 300 mm; larger dimensions ±0.01 mm |

| Hole Diameter | +0.008 / -0.000 mm | +0.003 / -0.000 mm | Reamed and honed bores |

| Positional Tolerance | ±0.01 mm | ±0.005 mm | Relative to datum |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | Critical sealing surfaces |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | As-machined; polishing available |

| Angular Tolerance | ±0.05° | ±0.02° | Complex 5-axis features |

These capabilities are backed by continuous investment in equipment calibration, operator training, and process refinement. Wuxi Lead Precision Machinery is engineered to deliver precision, repeatability, and technical accountability across every custom manufacturing project.

Material & Finish Options

Material Selection Guide for Precision CNC Manufacturing

Selecting optimal materials is critical for achieving performance, cost efficiency, and longevity in custom metal components. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical demands, environmental exposure, and production constraints. Below we detail key considerations for aluminum, steel, and titanium alloys, alongside essential insights on anodizing finishes.

Aluminum alloys dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and corrosion resistance. Series 6061-T6 and 7075-T6 offer superior machinability, weldability, and fatigue resistance. Aluminum’s low density reduces component weight significantly while maintaining structural integrity under dynamic loads. However, its lower hardness compared to steel necessitates careful tolerance planning for high-wear interfaces.

Carbon and stainless steels remain indispensable for high-strength, high-temperature applications. Grade 304 stainless excels in corrosive environments like medical or marine equipment, while 4140 alloy steel provides exceptional toughness for hydraulic components and tooling. Steel’s higher density and thermal stability suit heavy-duty applications but increase machining time and tool wear versus aluminum. Always specify heat treatment requirements to ensure dimensional stability post-machining.

Titanium alloys, particularly Grade 5 (Ti-6Al-4V), deliver unmatched strength-to-weight performance in extreme conditions. Widely adopted in aerospace and biomedical sectors, titanium resists corrosion in saltwater and high-heat scenarios exceeding 600°C. Its biocompatibility makes it ideal for surgical implants. Note that titanium’s low thermal conductivity demands specialized cutting strategies to prevent work hardening and tool degradation during CNC operations.

Anodizing is a non-conductive electrochemical finish exclusively for aluminum, enhancing surface durability and aesthetics. Type II (sulfuric acid) anodizing creates a porous layer for dyeing and moderate wear resistance, while Type III (hard anodizing) yields thicker, harder coatings for severe abrasion resistance. Anodizing improves corrosion protection but adds dimensional tolerance considerations—typically 0.001–0.002 inches per surface. Specify required thickness (e.g., 25–50 μm for Type III) and color early in design to avoid rework.

Material Property Comparison for CNC Applications

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Relative Cost |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (90%) | Low |

| Stainless 304 | 8.0 | 515 | Moderate (45%) | Medium |

| Titanium Ti-6Al-4V | 4.4 | 900 | Poor (20%) | High |

Note: Machinability ratings based on AISI 1212 steel = 100%. Titanium requires rigid setups, sharp carbide tools, and reduced feed rates to avoid galling.

Material choice directly impacts CNC programming, tool selection, and cycle time. Wuxi Lead’s engineering team collaborates with clients to validate material suitability against functional requirements, ensuring optimal manufacturability and performance. Consult our specialists to refine your selection for mission-critical components.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process is engineered for precision, consistency, and zero-defect outcomes. We specialize in custom metal manufacturing for high-performance industries including aerospace, medical devices, and advanced automation. Our integrated workflow ensures seamless transition from concept to volume production, maintaining tight tolerances and uncompromising quality at every stage.

The process begins with Design Engineering, where our team collaborates closely with clients to translate technical specifications into manufacturable designs. Utilizing advanced CAD/CAM software and GD&T analysis, we optimize geometry, material selection, and tooling strategies. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to preempt potential issues, ensuring the design is both functionally robust and production-ready.

Once the design is finalized, we move to the Prototyping phase. This stage is critical for validating form, fit, and function. We employ high-speed CNC machining, precision turning, and multi-axis milling to produce functional prototypes within 7–10 days, depending on complexity. Materials are matched exactly to production intent—whether aluminum 7075-T6, stainless steel 316L, or titanium Ti-6Al-4V. Every prototype undergoes rigorous dimensional inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify compliance with ±0.005 mm tolerances. Feedback from testing is incorporated iteratively, ensuring flawless design lock before scaling.

With prototype approval, we transition to Mass Production using a lean manufacturing framework. Our facility in Wuxi operates over 40 CNC machining centers, including automated pallet systems and robotic part handling to ensure 24/7 uptime with minimal human intervention. Each production batch follows a documented process plan with embedded quality checkpoints. In-process inspections occur at 500-part intervals, and final inspection includes full first-article inspection (FAI) reporting per AS9102 standards.

To guarantee zero defects, we implement a closed-loop quality management system. Every component is traceable via laser marking and digital work orders. Non-conformance events trigger immediate root cause analysis and corrective action (8D reporting). Our quality control is certified to ISO 9001:2015 and IATF 16949 standards, with a historical defect rate below 25 PPM.

The table below outlines our standard production capabilities:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (custom finishes available) |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Inconel |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Production) | 2–4 weeks after prototype approval |

| Quality Standards | ISO 9001:2015, IATF 16949, AS9102 |

From design validation to high-volume output, Wuxi Lead Precision Machinery ensures every component meets the highest standards of precision and reliability. Our process is not just about manufacturing parts—it’s about delivering engineered confidence.

Why Choose Wuxi Lead Precision

Why Partner with Wuxi Lead Precision Machinery

In the demanding landscape of custom metal manufacturing, your choice of partner directly impacts product integrity, time-to-market, and operational resilience. Wuxi Lead Precision Machinery is engineered to be your strategic extension, not merely a supplier. We integrate advanced CNC capabilities with deep engineering expertise to solve complex production challenges where precision and repeatability are non-negotiable. Our ISO 9001:2015-certified facility in Wuxi, China, operates under statistically validated processes, ensuring every component meets aerospace, medical, and industrial OEM specifications without compromise. We eliminate the guesswork in high-mix, low-volume production through proactive collaboration—from DFM analysis to final inspection—reducing your risk exposure and accelerating project lifecycles.

Our technical infrastructure supports the most stringent requirements. Below are core capabilities defining our partnership value:

| Specification Category | Capability Detail |

|---|---|

| Material Range | Aluminum Alloys (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Inconel 718, Brass, Plastics (PEEK, Delrin) |

| Tolerance Capability | ±0.001 mm (0.00004″) for critical features; Geometric tolerancing (GD&T) fully supported |

| Max Work Envelope | 5-Axis Milling: 1,200 x 800 x 600 mm; Turning: Ø400 mm x 1,000 mm |

| Surface Finish | Ra 0.4 µm (16 µin) standard; mirror polishing to Ra 0.05 µm achievable |

| Certifications | ISO 9001:2015, ISO 13485 (medical devices), PPAP Level 3, FAI reporting |

We recognize that your supply chain vulnerabilities translate into production stoppages and reputational damage. Lead Precision mitigates this through transparent communication protocols, real-time production tracking via our client portal, and dedicated engineering support teams fluent in English and technical standards. Our facility leverages DMG MORI and MAZAK CNC milling centers alongside Star Swiss-type lathes, enabling seamless transitions from prototype to volume production with zero process revalidation delays. When your project demands micron-level accuracy in hardened tool steels or complex 5-axis geometries, our metrology suite—including Zeiss CMMs and optical comparators—provides full traceability to NIST standards.

Partnering with Lead Precision means accessing a culture where “good enough” is unacceptable. We invest in your success through rigorous first-article inspections, non-conformance root-cause analysis, and continuous process optimization tailored to your quality objectives. Our clients achieve 99.8% on-time delivery by embedding our systems into their procurement workflows, transforming supply chain uncertainty into a competitive advantage.

Initiate your precision manufacturing partnership today. Contact our engineering team directly at [email protected] to discuss technical requirements, capacity planning, or confidential project consultations. Specify your target tolerances, material grades, and annual volume for a tailored capability assessment within 24 business hours. Let Wuxi Lead Precision Machinery become the reliable cornerstone of your high-value production ecosystem.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.