Technical Contents

Engineering Guide: Machining Services Georgia

Engineering Insight: The Critical Role of Precision in Machining Services Georgia

In the evolving landscape of advanced manufacturing, precision is not merely a performance metric—it is a foundational requirement. For industries operating in Georgia’s growing industrial corridor, including aerospace, defense, and high-performance automotive sectors, the demand for tight-tolerance, repeatable, and reliable machining services has never been greater. As global supply chains reconfigure and nearshoring gains momentum, companies must ensure that their manufacturing partners—domestic or international—deliver engineering excellence without compromise.

At Wuxi Lead Precision Machinery, we understand that precision in machining extends beyond micron-level tolerances. It encompasses material integrity, geometric accuracy, surface finish consistency, and long-term component reliability under extreme operational conditions. Our decades of experience in custom metal manufacturing have been shaped by some of the most stringent quality demands in the world, including components for Olympic-standard equipment and mission-critical military applications. These projects demand zero-defect outcomes, where even a deviation of a few microns can result in system failure.

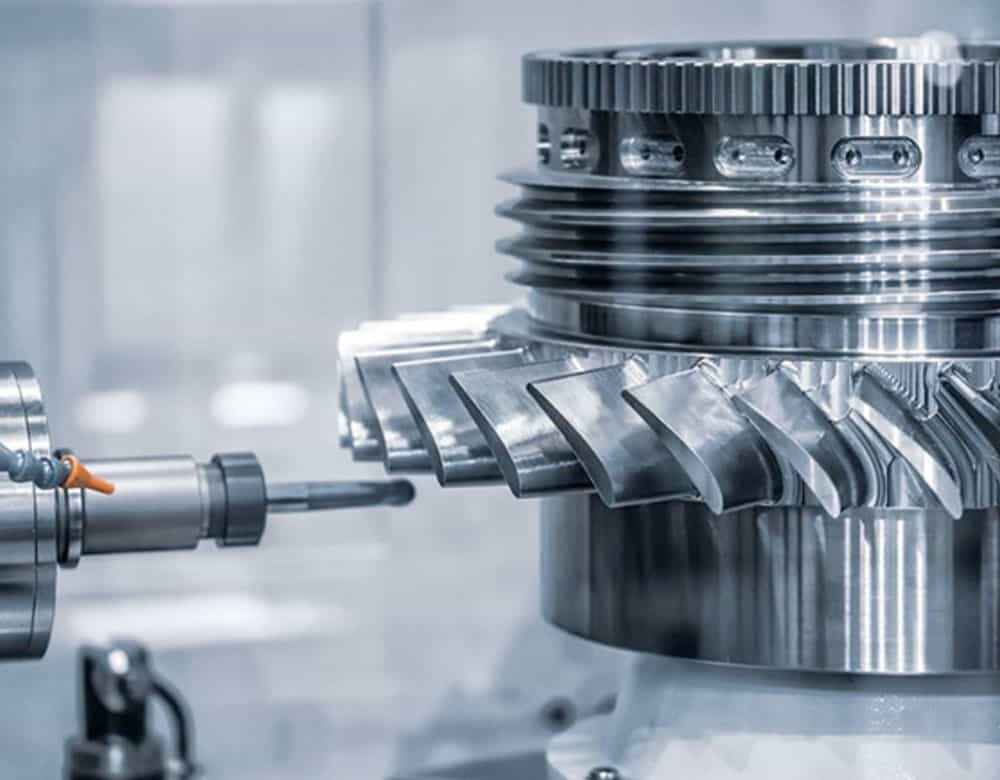

Our engineering approach begins with advanced CNC machining technologies—multi-axis milling, turning, and grinding systems—paired with rigorous in-process inspection protocols. Every component is validated using coordinate measuring machines (CMM), optical comparators, and surface profilometers to ensure compliance with ISO 2768 and customer-specific standards. We specialize in high-performance alloys such as titanium, Inconel, and hardened steels, materials commonly required in Georgia’s defense and energy sectors.

Beyond technology, precision is sustained through process discipline. At Wuxi Lead, we maintain full traceability from raw material sourcing through final inspection, with documented quality plans for every production run. Our ISO 9001:2015 and AS9100D certifications reflect our commitment to operational rigor, making us a trusted extension of engineering teams across North America.

For companies in Georgia seeking high-integrity machining services, the choice of a manufacturing partner must weigh not only capability but proven performance under pressure. Whether supporting rapid prototyping or high-volume production, precision is the non-negotiable standard.

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.002 mm (±0.00008 in) |

| Maximum Work Envelope | 2000 x 1200 x 1000 mm (78.7 x 47.2 x 39.4 in) |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Tool Steel, Brass |

| Surface Finish | Ra 0.2–1.6 µm (8–63 µin) |

| Quality Standards | ISO 9100D, ISO 2768, ISO 1302 |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester, Hardness Tester |

| Production Capacity | Prototype to 50,000 units/year |

Precision is not accidental—it is engineered. At Wuxi Lead Precision Machinery, it is the core of our identity and the benchmark of every part we deliver.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Metal Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding Georgia-based industries through integrated advanced manufacturing systems. Our core strength lies in multi-axis CNC machining, specifically leveraging state-of-the-art 5-axis vertical and horizontal machining centers. These systems execute complex geometries in a single setup, eliminating cumulative error from multiple fixtures and significantly reducing lead times. Capable of machining intricate contours, deep cavities, and organic forms from solid stock, our 5-axis platforms handle critical components for aerospace, defense, medical, and industrial automation sectors. Material versatility spans aerospace-grade aluminum alloys (7075-T6, 2024), stainless steels (17-4PH, 316L), titanium (Grade 5), and engineered plastics, all processed under stringent environmental controls to ensure dimensional stability.

Rigorous quality assurance is non-negotiable. Every critical component undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs, operating within ISO 17025 accredited processes, provide full 3D geometric dimensioning and tolerancing (GD&T) verification. This includes precise measurement of complex surfaces, positional tolerances, true profile, and form deviations down to micron-level accuracy. Inspection reports are generated in real-time, providing Georgia clients with immediate, actionable data traceable to NIST standards. Statistical process control (SPC) methodologies are embedded throughout production, enabling proactive correction and guaranteeing consistent part conformance batch after batch.

Our commitment to precision is quantifiable through achievable tolerances, reflecting our machine capabilities, environmental controls, and metrology rigor. The following table details standard and precision tolerance ranges for common materials and features:

| Feature Type | Material Group | Standard Tolerance (mm) | Precision Tolerance (mm) | Applicable Standard |

|---|---|---|---|---|

| Linear Dimensions | Aluminum Alloys | ±0.05 | ±0.0125 | ISO 2768-mK |

| Linear Dimensions | Stainless Steel | ±0.05 | ±0.0125 | ISO 2768-mK |

| Linear Dimensions | Titanium Alloys | ±0.05 | ±0.015 | ISO 2768-mK |

| Geometric (Flatness) | All Metals | 0.05/100mm | 0.0125/100mm | ISO 1101 |

| Geometric (True Pos) | Critical Features | Ø0.1 | Ø0.025 | ASME Y14.5 |

| Surface Finish (Ra) | Machined Surfaces | 1.6 µm (63 µin) | 0.4 µm (16 µin) | ISO 1302 |

Operating from our ISO 9001:2015 and AS9100D certified facility in Wuxi, China, we bridge global capability with Georgia’s engineering demands. Our dedicated project management team ensures seamless communication, time-zone alignment for critical milestones, and robust global logistics coordination. This integrated approach—combining 5-axis mastery, metrology-grade inspection, and disciplined process control—delivers components that meet the exacting standards of Georgia’s advanced manufacturing ecosystem, reducing client risk and accelerating time-to-market for mission-critical applications. Partner with Wuxi Lead for precision that performs, wherever your operations are based.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing the performance, durability, and cost-efficiency of the final component. For industries operating in demanding environments—such as aerospace, automotive, medical, and industrial equipment—choosing the right base material and surface treatment ensures long-term reliability and compliance with technical specifications. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining of aluminum, steel, and titanium, each offering distinct mechanical properties and application advantages.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications requiring lightweight components without sacrificing structural integrity. Grade 6061-T6 is commonly used for general-purpose parts, while 7075-T6 offers higher strength for aerospace-grade components. Aluminum responds exceptionally well to anodizing, a process that enhances surface hardness and wear resistance while allowing for color coding and improved aesthetics.

Steel, particularly alloy and stainless grades, delivers superior strength, toughness, and temperature resistance. 4140 steel is often selected for high-stress mechanical parts due to its hardenability and fatigue resistance. Stainless steel 304 and 316 are preferred in corrosive or sanitary environments, such as food processing or medical devices, due to their chromium oxide layer that resists rust and chemical exposure. While steel does not anodize, it can be treated with passivation, plating, or powder coating to improve surface performance.

Titanium, notably Grade 5 (Ti-6Al-4V), is the material of choice for extreme conditions where strength, light weight, and exceptional corrosion resistance are paramount. It maintains integrity at high temperatures and is biocompatible, making it indispensable in aerospace, defense, and medical implant applications. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s performance justifies its use in mission-critical components.

Anodizing is a key finishing process, especially for aluminum. It creates a durable, non-conductive oxide layer that increases surface hardness up to 60 HRC, significantly improving wear and corrosion resistance. Type II anodizing offers standard protection with optional dyeing, while Type III (hardcoat) provides thicker, more robust coatings for industrial use. Proper pre- and post-treatments ensure uniformity and adhesion, critical for components in dynamic or exposed environments.

Below is a comparative overview of key material properties:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 / 7075-T6 | 310 / 570 | 2.7 | Aerospace, automotive, electronics | Anodizing (Type II/III), powder coat |

| Steel | 4140 / 304 SS | 655 / 585 | 7.85 / 8.0 | Machinery, tools, structural | Passivation, plating, painting |

| Titanium | Ti-6Al-4V (Gr 5) | 900 | 4.43 | Aerospace, medical, marine | Anodizing, polishing, grit blast |

Selecting the optimal material and finish requires a detailed understanding of operational demands. Wuxi Lead Precision Machinery supports clients in Georgia and beyond with expert consultation, ensuring every machined part meets exacting performance and quality standards.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Delivery for Georgia Industry

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for Georgia manufacturers demanding uncompromising quality in custom metal components. Our integrated Design, Prototyping, and Mass Production workflow is engineered for zero defects, ensuring your specifications translate flawlessly into functional parts. This systematic approach eliminates costly iterations and guarantees supply chain reliability for your critical applications.

The process begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team partners with Georgia clients to scrutinize CAD models, identifying potential machining challenges, material constraints, or tolerance conflicts early. We optimize toolpaths, fixture strategies, and material selection using advanced CAM simulation, ensuring the design is not only feasible but optimized for high-yield, high-precision production. This proactive step prevents downstream errors and accelerates time-to-market. Following DFM validation, we proceed to Prototyping. Utilizing our high-accuracy CNC milling and turning centers, we produce functional prototypes with the same processes and materials intended for final production. Every prototype undergoes comprehensive metrology, including CMM inspection against the original CAD model and rigorous first-article inspection reports (FAIR). This phase validates form, fit, function, and critical tolerances, providing Georgia engineers with physical proof of concept before committing to volume runs. Client feedback at this stage is incorporated seamlessly, ensuring the final design meets all operational requirements.

Transitioning to Mass Production, our zero-defect mandate is enforced through statistical process control (SPC) and real-time monitoring. Each production batch initiates with a documented first-piece approval. Throughout the run, in-process inspections at defined intervals verify dimensional stability and surface integrity. Our CNC machines integrate probing systems for automatic tool wear compensation and part verification, while dedicated quality stations perform 100% critical feature checks on high-risk components. Material traceability is maintained from raw stock to finished part, and final inspection includes comprehensive dimensional reporting and non-destructive testing as specified. This closed-loop system, combined with operator certification and rigorous documentation, ensures consistent output meeting the highest AS9100 and ISO 9001 standards demanded by Georgia’s aerospace, medical, and industrial sectors.

Our commitment to zero defects is quantifiable through stringent process capability metrics. The following table outlines key performance specifications achievable across our production spectrum:

| Process Capability | Standard Performance | Tight Tolerance Option |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.2 µm (8 µin) |

| Geometric Tolerancing (GD&T) | Full capability per ASME Y14.5 | Complex profiles supported |

| Material Range | Aluminum, Steel, Stainless, Titanium, Brass, Plastics | Exotic alloys available |

| Process Control (Cpk) | ≥ 1.33 standard | ≥ 1.67 guaranteed |

This disciplined progression from validated design through proven prototyping to statistically controlled mass production delivers the defect-free components Georgia manufacturers require for mission-critical assemblies. Wuxi Lead Precision Machinery provides the precision, traceability, and reliability your operations depend on.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When sourcing high-performance machining services in Georgia, global manufacturers demand precision, consistency, and technical expertise—qualities that define Wuxi Lead Precision Machinery. As a leading custom metal manufacturing partner based in China, we deliver advanced CNC machining, milling, turning, and fabrication solutions engineered to meet the rigorous standards of aerospace, medical, energy, and industrial automation sectors. Our capabilities extend far beyond conventional machining, integrating tight-tolerance production, rapid prototyping, and scalable batch manufacturing for clients across North America and Europe.

At Wuxi Lead Precision Machinery, we understand the strategic importance of reliable overseas partnerships. That’s why we combine German-level precision with agile production cycles and full transparency at every stage. Our ISO 9001-certified facility is equipped with state-of-the-art HAAS, DMG MORI, and Makino CNC systems, ensuring micron-level accuracy and repeatability across all components. Whether you require complex geometries in titanium, stainless steel, aluminum, or exotic alloys, our engineering team collaborates directly with your design and procurement staff to optimize manufacturability, reduce lead times, and control costs—without compromising quality.

We specialize in producing mission-critical components where failure is not an option. From initial CAD review to final inspection and global logistics, our process is built on accountability, technical depth, and responsiveness. Our clients in Georgia and beyond rely on us not just as a vendor, but as an extension of their engineering capability—offering DFM feedback, material sourcing guidance, and real-time production updates.

Below are key specifications that define our machining capabilities:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 650 mm (47 x 31.5 x 25.6 in) |

| Tolerance Range | ±0.005 mm (±0.0002 in) |

| Spindle Speed | Up to 24,000 RPM |

| Materials Processed | Aluminum Alloys, Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Inconel 718, Tool Steels, Brass, Copper |

| CNC Equipment | 3-axis, 4-axis, 5-axis milling; CNC turning; Swiss-type machining |

| Secondary Operations | Deburring, polishing, anodizing, passivation, heat treatment, laser marking |

| Quality Assurance | CMM inspection, 2D/3D metrology, first article reporting, PPAP documentation |

| Lead Times | Prototypes: 7–10 days; Production: 15–25 days (varies by complexity) |

Our commitment to operational excellence is matched by our dedication to client partnership. For companies in Georgia seeking a dependable, high-precision manufacturing ally, Wuxi Lead Precision Machinery offers a compelling alternative to domestic outsourcing—combining cost efficiency with uncompromised quality.

Contact us today to discuss your next project. Email [email protected] to receive a detailed quote, technical consultation, or sample evaluation. Let us demonstrate how we can support your production goals with precision, reliability, and engineering integrity.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.