Technical Contents

Engineering Guide: Machining Quotes

Engineering Insight: The Critical Role of Precision in Machining Quotes

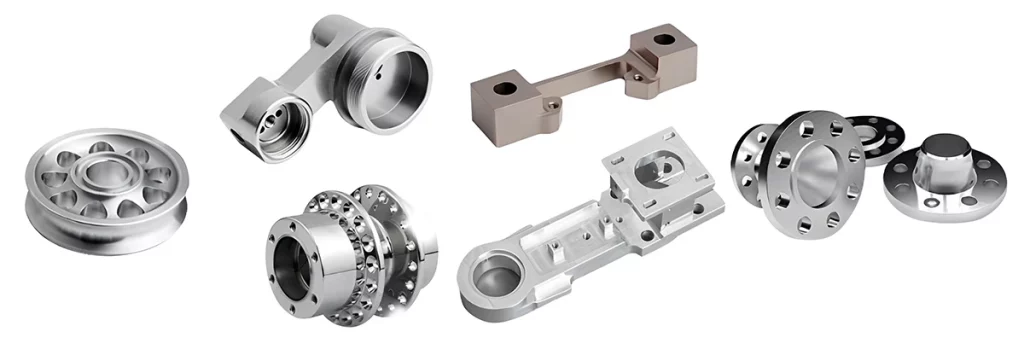

In the world of custom metal manufacturing, a machining quote is far more than a cost estimate—it is a technical commitment. At Wuxi Lead Precision Machinery, we understand that every component we produce must meet exacting standards, especially when serving high-stakes industries such as aerospace, defense, and advanced automation. Precision is not an optional add-on; it is the foundation upon which reliability, performance, and safety are built. This principle shapes how we approach every machining quote, ensuring that technical accuracy and manufacturing capability are fully aligned from the outset.

When engineers submit a request for a machining quote, they are initiating a partnership. The specifications provided—tolerances, surface finishes, material grades, and geometric complexities—are not just data points. They represent functional requirements that must be translated into physical reality. At Lead Precision, our quoting engineers conduct a full manufacturability analysis, assessing not only cost but also process feasibility, tooling requirements, and inspection protocols. This depth of technical review ensures that the quoted solution is not only achievable but repeatable across production runs.

Our experience in delivering components for Olympic-grade sports equipment and military-grade systems underscores our commitment to precision. These applications demand micron-level tolerances, flawless surface integrity, and full traceability. For example, structural components in high-performance athletic systems must withstand dynamic loads while maintaining dimensional stability, while defense applications often require materials such as titanium and Inconel to be machined with zero-defect tolerance. These projects have refined our ability to anticipate challenges and engineer robust solutions during the quoting phase.

Below is a summary of our standard precision capabilities, which are routinely applied to ensure that every quoted job meets or exceeds client expectations.

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 µm to Ra 3.2 µm (customizable) |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Positional Accuracy | ±0.003 mm (with laser calibration) |

| Inspection Equipment | CMM, Optical Comparators, Surface Profilometers |

| Process Control | ISO 9001:2015 Certified, Full Documentation Traceability |

Every machining quote from Wuxi Lead includes a detailed technical review, identifying critical-to-quality features and proposing optimal machining strategies. We integrate advanced 5-axis CNC technology with in-process gauging and post-process inspection to maintain control throughout production. This systematic approach minimizes risk and ensures that what is quoted is exactly what is delivered.

In high-performance manufacturing, trust is earned through consistency. Our clients rely on us because our quotes reflect not just pricing, but engineering integrity. When precision is non-negotiable, the machining quote becomes the first milestone in a precision-first journey.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

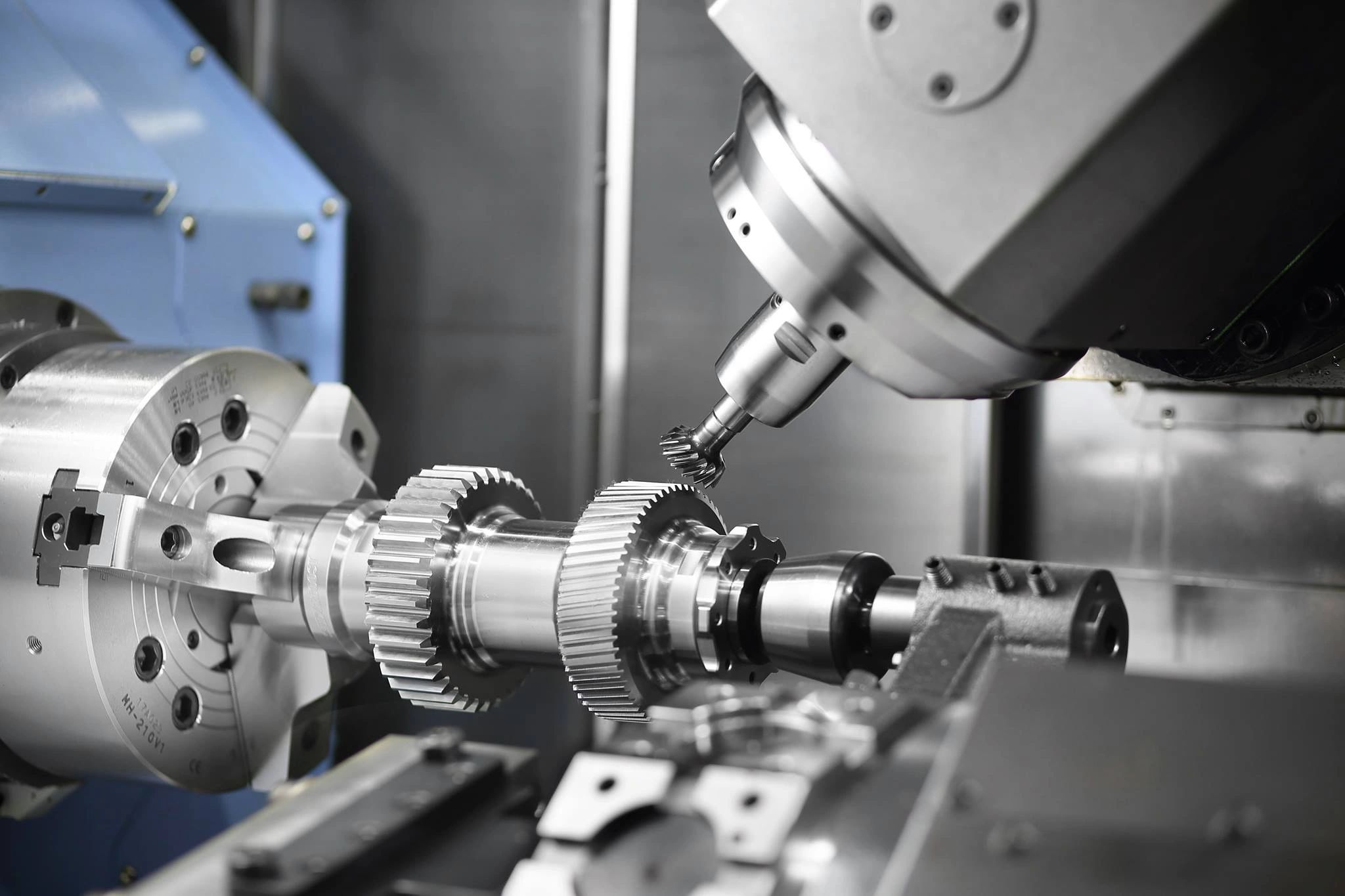

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding custom metal components. Our core strength lies in advanced multi-axis machining, specifically our dedicated fleet of state-of-the-art 5-axis CNC machining centers. Utilizing industry-leading equipment from Haas and DMG MORI, we achieve simultaneous 5-axis motion, enabling the production of intricate geometries, complex contours, and highly integrated features in a single setup. This capability eliminates cumulative error from multiple fixtures, significantly improves surface finish, reduces overall lead time, and ensures superior part accuracy critical for aerospace, medical, and high-performance industrial applications. Our programming expertise leverages Mastercam and Siemens NX CAM to optimize toolpaths for maximum efficiency and precision on materials ranging from aluminum alloys and stainless steels to titanium and hardened tool steels.

Precision manufacturing demands rigorous verification. Every critical dimension and feature undergoes comprehensive validation using our Zeiss and Hexagon Coordinate Measuring Machines (CMMs). These high-accuracy metrology systems provide full 3D inspection reports traceable to international standards, confirming dimensional conformance, geometric tolerances (GD&T), and surface integrity. Our AS9100-certified quality management system integrates CMM inspection protocols at defined stages within the manufacturing process, not merely as a final check. This proactive approach ensures deviations are identified and corrected early, guaranteeing that every component shipped meets or exceeds the stringent requirements specified in your machining quote and project documentation.

Understanding achievable tolerances is fundamental to accurate quoting and successful part realization. The table below outlines our standard and tight tolerance capabilities across common material groups. Achieving tighter tolerances often necessitates specific process validation, specialized tooling, and extended inspection time, directly impacting cost and lead time. We collaborate closely during the quoting phase to determine the optimal tolerance specification balancing your functional requirements with manufacturability and cost efficiency.

| Material Type | Standard Tolerance | Tight Tolerance | Process Validation Required |

|---|---|---|---|

| Aluminum Alloys | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) | Yes for Tight Tolerance |

| Carbon/Alloy Steels | ±0.012 mm (±0.0005″) | ±0.006 mm (±0.00025″) | Yes for Tight Tolerance |

| Stainless Steels | ±0.012 mm (±0.0005″) | ±0.006 mm (±0.00025″) | Yes for Tight Tolerance |

| Titanium Alloys | ±0.015 mm (±0.0006″) | ±0.008 mm (±0.0003″) | Yes for Tight Tolerance |

Standard tolerances reference ISO 2768-m (medium). Tight tolerances reference ISO 2768-f (fine) or specific customer GD&T callouts. All tolerances assume standard machining conditions; extreme geometries or thin walls may require specific evaluation. Our engineering team proactively reviews designs during quotation to identify potential tolerance challenges and recommend optimal solutions. This integrated approach to advanced 5-axis machining and metrology-backed quality assurance ensures the precision and reliability your critical applications demand, forming the technical foundation for every accurate and actionable quote we provide.

Material & Finish Options

Material Selection for High-Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the right material is critical in custom metal manufacturing, directly influencing part performance, durability, and cost. At Wuxi Lead Precision Machinery, we support clients in choosing optimal materials based on application requirements, environmental exposure, mechanical loads, and finishing needs. The most widely used materials in precision CNC machining are aluminum, steel, and titanium, each offering distinct advantages.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace, automotive, and consumer electronics applications where lightweight components are essential. The most common grade used in precision machining is 6061-T6, which provides good weldability and moderate strength. For higher strength demands, 7075-T6 is often selected, though it is less corrosion-resistant and more challenging to machine. Aluminum naturally forms a protective oxide layer, but for enhanced surface durability and aesthetic appeal, anodizing is recommended.

Steel offers superior strength, hardness, and wear resistance, making it suitable for structural components, tooling, and industrial machinery. Among the various steel types, 303, 304, and 316 stainless steels are frequently machined. 304 provides a balanced combination of corrosion resistance and formability, while 316 offers enhanced resistance to chlorides and marine environments due to molybdenum content. Carbon steels like 1018 and 4140 are used when high tensile strength and hardness are required, often followed by heat treatment and surface finishing processes such as passivation or plating.

Titanium, particularly Grade 5 (Ti-6Al-4V), is used in high-performance sectors such as aerospace, medical implants, and motorsports. It delivers exceptional strength-to-density ratio, outstanding corrosion resistance, and biocompatibility. However, titanium is more difficult to machine due to its low thermal conductivity and tendency to gall, requiring specialized tooling and slower cutting speeds. Despite higher material and machining costs, titanium’s performance in extreme environments justifies its use in mission-critical applications.

Surface Finishing: The Role of Anodizing

Anodizing is a key surface treatment for aluminum components, enhancing corrosion resistance, surface hardness, and aesthetic options. The process electrochemically thickens the natural oxide layer, allowing for dyeing in various colors (commonly black, red, and blue). Type II (sulfuric acid) anodizing is standard for decorative and moderate protective needs, while Type III (hardcoat) anodizing provides a thicker, wear-resistant layer suitable for industrial and aerospace applications. Anodizing does not work on steel or titanium, which require alternative finishes such as plating, passivation, or powder coating.

Below is a comparison of key mechanical and machining properties for common materials.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Machinability Rating | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 310 (6061-T6) | 2.7 | 6061, 7075 | Excellent | Aerospace, Electronics |

| Stainless Steel | 505 (304) | 8.0 | 304, 316, 303 | Good | Medical, Food Processing |

| Carbon Steel | 655 (4140, annealed) | 7.8 | 1018, 4140 | Moderate | Machinery, Automotive |

| Titanium | 900 (Ti-6Al-4V) | 4.5 | Gr 2, Gr 5 | Fair | Aerospace, Medical Devices |

Understanding material behavior and finish compatibility ensures optimal part design and longevity. Wuxi Lead Precision Machinery provides expert consultation to match your project requirements with the most suitable material and surface treatment combination.

Manufacturing Process & QC

Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our machining quote encompasses a rigorously defined production pathway designed to eliminate defects before they occur. We integrate precision engineering with proactive quality control across three critical phases: Design, Prototyping, and Mass Production. This structured approach ensures dimensional accuracy, material integrity, and functional reliability meet the exacting standards demanded by aerospace, medical, and advanced industrial sectors. Our commitment to Zero Defects is not aspirational; it is engineered into every step through validated processes and continuous verification.

Design Phase

Our process begins with comprehensive design review and manufacturability analysis. Our engineering team collaborates closely with your CAD data, applying Geometric Dimensioning and Tolerancing (GD&T) expertise to identify potential production risks early. We assess material selection, toolpath optimization, fixture requirements, and critical feature accessibility. This phase establishes the foundational quality parameters, ensuring the design is not only functional but inherently producible within our tight tolerance capabilities. Ambiguities are resolved upfront, preventing costly iterations later.

Prototyping Phase

Prototyping is our critical validation stage, not merely a sample run. Utilizing the same CNC equipment, tooling, and materials destined for mass production, we manufacture initial units under full production conditions. Every prototype undergoes rigorous First Article Inspection (FAI) per AS9102 or equivalent standards. Dimensional accuracy is held to ±0.0002 inches (±0.005 mm), with full material certification and non-destructive testing as required. This phase confirms process stability, validates metrology plans, and provides tangible evidence that the design intent translates flawlessly into physical reality. Client sign-off on prototypes is mandatory before scale-up.

Mass Production Phase

Transitioning to volume production, we deploy Statistical Process Control (SPC) and real-time in-process monitoring. Each critical dimension is tracked using control charts, with automated gaging integrated directly into machining cells where feasible. Our zero-defect mandate is enforced through layered inspections: 100% critical feature checks during initial runs, transitioning to AQL-based sampling only after sustained process capability (Cpk ≥ 1.67) is proven. Final inspection includes comprehensive CMM reports, surface finish verification, and material traceability documentation. Every component ships with full quality conformance records.

Our integrated process ensures consistency from the first prototype to the ten-thousandth part. The table below summarizes key capabilities across phases:

| Phase | Key Activities | Tolerance Capability | Inspection Protocol |

|---|---|---|---|

| Design | GD&T Analysis, DFM, Toolpath Simulation | Defined per drawing | Design Validation Report |

| Prototyping | FAI, Process Validation, Material Test | ±0.0002″ (±0.005mm) | Full AS9102 Report, CMM, NDT |

| Mass Production | SPC, In-Process Monitoring, Final QA | ±0.0004″ (±0.01mm) sustained | AQL Sampling, CMM Batch Reports, Traceability |

This disciplined progression—where design integrity informs prototyping rigor, which in turn validates mass production stability—forms the core of our zero-defect promise. Wuxi Lead delivers not just parts, but engineered certainty. Your quote reflects this uncompromising process, ensuring value through guaranteed quality and on-time delivery.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Custom Metal Manufacturing Excellence

When precision, reliability, and technical expertise define your project’s success, partnering with Wuxi Lead Precision Machinery ensures you are backed by a leader in high-end custom metal manufacturing. As a trusted name in the global industrial sector, we specialize in delivering CNC-machined components that meet the most stringent requirements across aerospace, automotive, medical, energy, and advanced automation industries. Our commitment to quality, advanced technological infrastructure, and customer-centric engineering approach make us the preferred partner for clients demanding excellence in every dimension.

At Wuxi Lead, we understand that a machining quote is more than a price tag—it’s a promise of capability, consistency, and collaboration. From prototype development to full-scale production, our team of senior CNC engineers and manufacturing specialists works closely with your design and engineering staff to optimize manufacturability, reduce lead times, and maintain strict compliance with international quality standards. Whether you require tight tolerances of ±0.002 mm, complex geometries, or materials ranging from aluminum and titanium to exotic alloys, our facility is equipped to execute with precision.

Our end-to-end manufacturing process integrates 5-axis CNC machining, multi-axis turning, milling, grinding, and advanced inspection technologies—including CMM, optical comparators, and surface roughness testers—ensuring every component meets exact specifications. All parts are produced under ISO 9001:2015-certified quality management systems, with full traceability and documentation available upon request.

We invite global OEMs, contract manufacturers, and engineering firms to experience the Wuxi Lead difference. By choosing us as your manufacturing partner, you gain access to scalable production capacity, agile project management, and engineering support that extends beyond the shop floor.

To initiate your next precision machining project, contact us today. Our engineering team is ready to review your drawings, provide a detailed machining quote, and support your timeline with rapid turnaround and transparent communication.

| Specification | Detail |

|---|---|

| Machining Processes | 5-Axis CNC Milling, CNC Turning, Multi-Tasking Machining, Surface & CNC Grinding |

| Materials Supported | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Brass, Copper, Tool Steels, Plastics (PEEK, Delrin) |

| Tolerance Capability | Up to ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Surface Finish | As fine as Ra 0.4 µm (16 µin) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reports (FAIR), PPAP, APQP Support |

| Lead Times | Prototype: 7–14 days; Production: 15–30 days (varies by complexity) |

| File Formats Accepted | STEP, IGES, DWG, DXF, PDF, SolidWorks, AutoCAD, PDF with GD&T |

For a comprehensive machining quote tailored to your project’s technical and logistical needs, email us at [email protected]. Let Wuxi Lead Precision Machinery be your trusted partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.