Technical Contents

Engineering Guide: Machining Parts High-Pressure Connection

Engineering Insight: Precision Imperatives in High-Pressure Connection Machining

High-pressure connections represent a critical failure point in demanding industrial systems across aerospace, energy, and defense. The integrity of these interfaces directly determines system safety, operational longevity, and environmental compliance. At pressures exceeding thousands of PSI, microscopic deviations in geometry, surface finish, or material consistency cease to be tolerable variations; they become potential initiation sites for catastrophic leaks, fatigue fractures, or seal extrusion. Achieving true reliability demands machining precision far beyond standard industrial tolerances. Every micron of concentricity error, every imperfection in the sealing surface profile, and every inconsistency in material grain structure under the contact zone can exponentially accelerate wear or trigger sudden, dangerous failure under cyclic stress. The machining process must therefore control not only dimensional accuracy but also residual stresses, microstructure homogeneity, and absolute surface integrity to ensure predictable performance at the operational limits.

Wuxi Lead Precision Machinery possesses deep, proven expertise in delivering components where failure is not an option. Our CNC machining centers, operating under stringent AS9100 and ISO 9001 frameworks, are calibrated and maintained to achieve micron-level repeatability consistently. This capability is not theoretical; it is rigorously validated through decades of supplying mission-critical parts. We engineered and manufactured complex manifold blocks and ultra-high-pressure couplings for the hydraulic systems supporting the Beijing Olympic Games infrastructure, where absolute reliability under immense public scrutiny was paramount. Furthermore, our facility routinely produces components for classified defense programs requiring sustained operation at extreme pressures exceeding 10,000 PSI in harsh environments, meeting exacting MIL-STD specifications. This experience ingrained a fundamental truth: precision in high-pressure connection machining is not a cost factor, but the essential foundation for risk mitigation and operational assurance.

The technical requirements for such components are exacting. The following table outlines key specifications achievable at Wuxi Lead Precision Machinery for critical high-pressure connection features:

| Parameter | Typical Capability | Critical Importance for High-Pressure Integrity |

|---|---|---|

| Pressure Rating | Up to 15,000 PSI | Defines material selection and structural design limits |

| Geometric Tolerance (Concentricity) | ≤ 0.005 mm (0.0002″) | Ensures uniform seal loading and prevents galling |

| Surface Roughness (Ra) | 0.2 – 0.4 µm (8-16 µin) | Critical for elastomer seal conformity and longevity |

| Dimensional Tolerance (Critical Diameters) | ±0.005 mm (±0.0002″) | Maintains precise interference fits for metal seals |

| Material Options | 17-4PH, 15-5PH, Inconel 718, Custom Alloys | High strength, corrosion resistance, fatigue performance |

| Non-Destructive Testing | 100% Fluorescent Penetrant, Optional X-Ray/UT | Guarantees absence of subsurface defects |

This level of precision engineering requires more than advanced machinery; it demands a culture of uncompromising process control, deep metallurgical understanding, and rigorous validation protocols. At Wuxi Lead, every high-pressure connection component undergoes multi-stage inspection, including CMM verification against 3D CAD models and stringent pressure testing protocols simulating real-world duty cycles. Partnering with a manufacturer possessing demonstrable experience in the most demanding applications ensures your high-pressure systems operate with the confidence demanded by modern industry. Precision here isn’t merely a specification—it is the absolute prerequisite for safety and performance.

Precision Specs & Tolerances

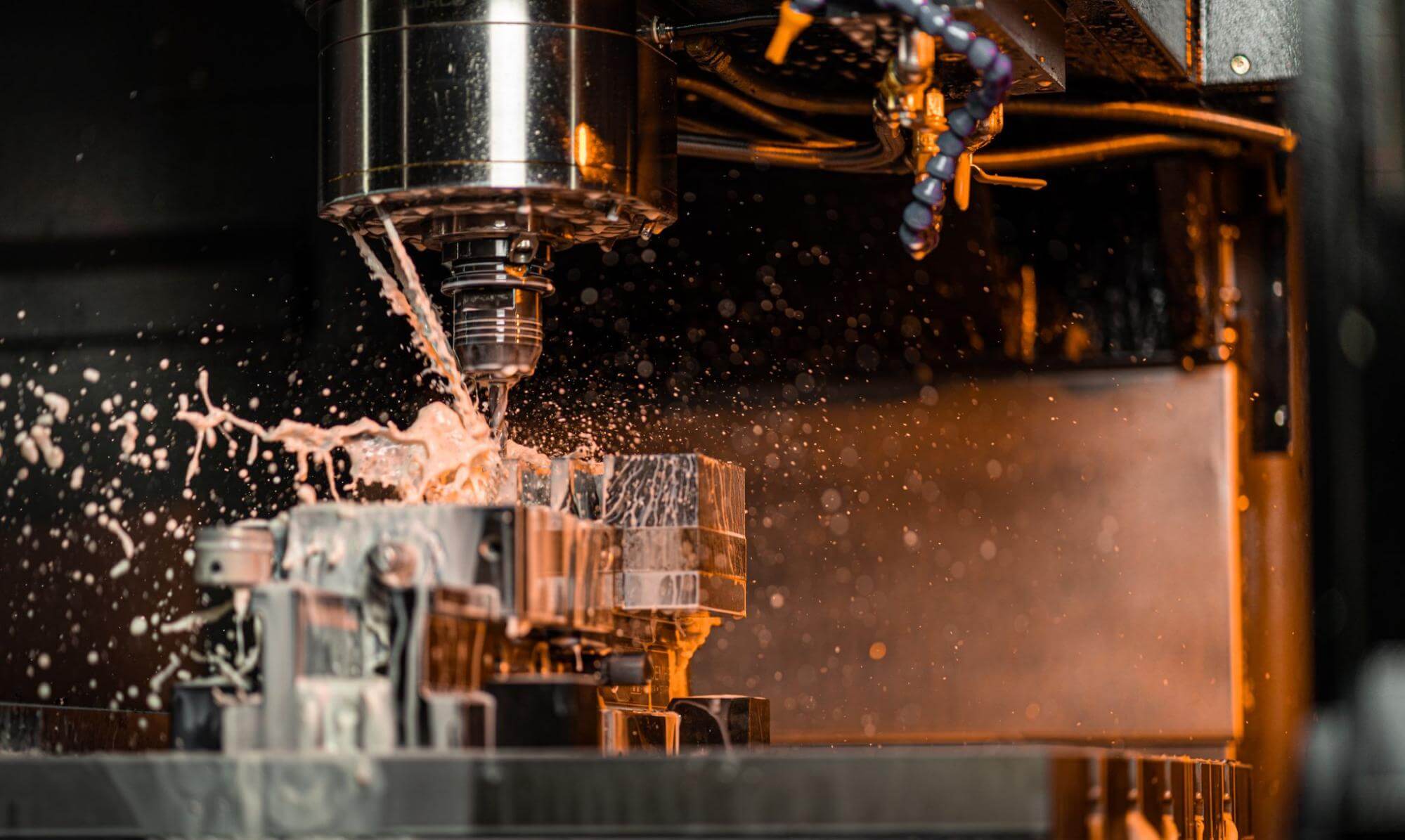

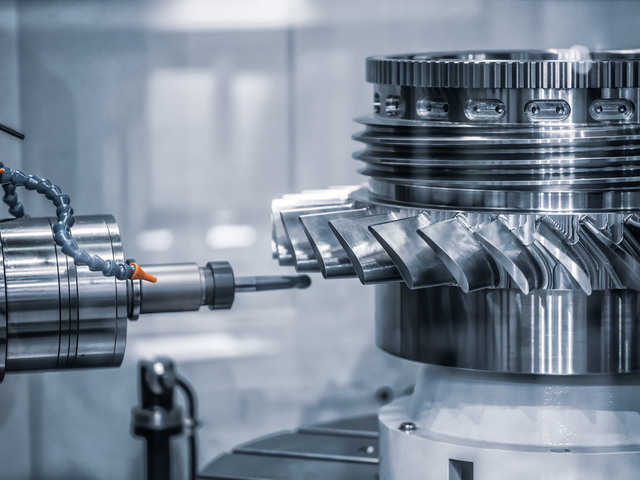

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the rigorous demands of high-pressure connection components. Our technical capabilities are engineered to support industries such as oil & gas, aerospace, hydraulics, and energy, where precision, durability, and leak-free performance are non-negotiable. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface integrity. These multi-axis systems allow simultaneous machining from five different directions, minimizing setup changes and ensuring tight alignment across intricate features typical in high-pressure fittings, manifolds, and connectors.

Our 5-axis CNC technology supports a wide range of materials, including stainless steel (304, 316, 17-4 PH), alloy steels, titanium, Inconel, and aluminum alloys—materials selected for their strength, corrosion resistance, and performance under extreme pressure and temperature conditions. The dynamic range of motion and high spindle accuracy ensure that even the most challenging internal profiles, tapered threads, and sealing surfaces are machined to exacting specifications. This capability is critical in high-pressure applications where any dimensional deviation can compromise system integrity.

To maintain consistency and reliability across every production run, we implement a rigorous quality control protocol anchored by Coordinate Measuring Machine (CMM) inspection. Each component undergoes comprehensive dimensional verification, with inspection reports traceable to international standards. Our CMM systems provide micron-level measurement accuracy, validating critical features such as thread pitch, bore concentricity, face perpendicularity, and sealing surface flatness. This data-driven approach ensures full compliance with ASME, API, and customer-specific engineering requirements.

In addition to advanced equipment and inspection, our engineering team works closely with clients during the design-for-manufacturability phase to optimize part geometry, reduce cycle times, and enhance performance under operational stress. From prototype to high-volume production, we maintain tight process control, in-process checks, and final audit procedures to guarantee that every machined part exceeds the functional demands of high-pressure systems.

The following table outlines our standard machining tolerances for high-pressure connection components:

| Feature | Standard Tolerance | Tight Tolerance (Optional) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | Up to 300 mm |

| Hole Diameter | +0.015 / -0.005 mm | +0.008 / -0.002 mm | Reamed/precision bored |

| Positional Tolerance | ±0.03 mm | ±0.015 mm | GD&T compliant |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm | As required |

| Angular Tolerance | ±0.1° | ±0.05° | 5-axis controlled |

| Thread Accuracy | Class 6H (ISO) | Class 4H | Internal/external threads |

These capabilities, combined with our commitment to precision and quality, position Wuxi Lead Precision Machinery as a trusted partner in the production of mission-critical high-pressure connection components.

Material & Finish Options

Material Selection for High-Pressure Connection Components

Selecting the optimal material for high-pressure connection components is a safety-critical engineering decision. Performance under extreme stress, resistance to environmental degradation, and compatibility with sealing systems dictate long-term reliability. At Wuxi Lead Precision Machinery, we prioritize materials that balance mechanical integrity, manufacturability, and lifecycle cost for demanding applications in aerospace, oil and gas, and hydraulic systems.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio essential for weight-sensitive applications. While 7075-T6 provides higher tensile strength (approximately 572 MPa), 6061-T6 offers superior weldability and corrosion resistance in marine environments. Aluminum’s lower density reduces inertial loads in dynamic systems but requires careful design to mitigate fatigue under cyclic pressure. Its thermal conductivity also aids in dissipating heat from friction points during assembly.

Carbon and alloy steels, such as 4140 and 4340, deliver unmatched tensile strength and hardness for ultra-high-pressure scenarios exceeding 10,000 PSI. 4140 steel, heat-treated to 28-32 HRC, provides excellent toughness and resistance to galling, making it ideal for threaded connections in subsea manifolds. Stainless steels like 316L are preferred where chloride exposure exists, though their lower yield strength compared to alloy steels necessitates larger component dimensions. Steel’s susceptibility to corrosion mandates stringent surface finishing protocols.

Titanium Grade 5 (6Al-4V) excels in corrosive, high-temperature environments where weight savings and non-magnetic properties are paramount. With a yield strength of 880 MPa and immunity to seawater corrosion, it outperforms steel in offshore chemical injection systems. However, titanium’s propensity for galling during assembly requires precision thread tolerancing and specialized lubricants. Its high cost is justified only when aluminum lacks sufficient strength or steel cannot withstand the environment.

Surface finishing is non-negotiable for pressure integrity. Anodizing is the standard for aluminum components:

Type II (Sulfuric Acid): Provides basic corrosion resistance (5-25 μm thickness) for non-critical hydraulic fittings.

Type III (Hard Anodizing): Essential for high-pressure interfaces, delivering 50-70 μm thickness, enhanced wear resistance, and sealing capability up to 15,000 PSI.

Steel components require nitriding, phosphate coating, or electroless nickel plating to prevent hydrogen embrittlement and seal micro-porosity. Titanium typically uses acid etching or laser texturing to optimize sealant adhesion, as anodizing offers minimal pressure-sealing benefit.

Comparative Material Specifications for High-Pressure Connections

| Material | Typical Yield Strength (MPa) | Corrosion Resistance | Max Recommended Pressure (PSI) | Anodizing Compatibility |

|---|---|---|---|---|

| Aluminum 7075-T6 | 503 | Moderate | 8,000 | Excellent (Type III) |

| Steel 4140 (HT) | 655 | Low (uncoated) | 20,000+ | Not applicable |

| Stainless 316L | 170 | High | 10,000 | Poor |

| Titanium Gr5 | 880 | Exceptional | 15,000 | Limited value |

Material selection must align with ASME B31.3 or ISO 10400 standards for pressure design. Wuxi Lead Precision Machinery validates all material-finish combinations through rigorous hydrostatic and pneumatic testing, ensuring zero leakage at 1.5x operational pressure. Partner with us to engineer connections where failure is not an option.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, the production of high-pressure connection machining parts follows a rigorously controlled, end-to-end process designed for precision, reliability, and zero defects. Every component is engineered to perform under extreme operational stresses, making consistency and quality non-negotiable. Our approach integrates advanced design protocols, precision prototyping, and scalable mass production—all aligned with international quality standards such as ISO 9001 and AS9100.

The process begins with collaborative design engineering. Our technical team works closely with clients to analyze application requirements, including pressure ratings, media compatibility, temperature range, and installation environment. Utilizing 3D CAD modeling and finite element analysis (FEA), we simulate mechanical behavior under load to optimize geometry, material selection, and sealing integrity. This phase ensures that design flaws are identified and corrected before any metal is cut, reducing risk and accelerating time to market.

Once the design is validated, we proceed to prototyping. Using CNC milling and turning centers with sub-micron accuracy, we produce functional prototypes from the intended production-grade materials—typically high-strength alloys such as 316 stainless steel, Inconel 718, or titanium. These prototypes undergo full performance testing, including pressure cycling, leak testing, and dimensional inspection via coordinate measuring machines (CMM). Feedback from testing is integrated into final design adjustments, ensuring the part meets or exceeds operational specifications.

With prototype approval, we transition to mass production. Our facility in Wuxi operates over 50 CNC machines, including multi-axis lathes and milling centers, enabling high repeatability and tight tolerance control. Each production run is governed by a documented quality plan, including first-article inspection reports (FAIR), in-process checks, and final inspection. We implement Statistical Process Control (SPC) to monitor critical dimensions in real time, ensuring process stability and immediate correction of deviations.

All components are traceable through our ERP system, with full material certifications and inspection data archived for every batch. Cleanroom assembly and ultrasonic cleaning are employed where required, particularly for aerospace and semiconductor applications.

The result is a zero-defect manufacturing outcome—achieved not through inspection alone, but through a proactive, systems-driven process that embeds quality at every stage.

| Specification | Detail |

|---|---|

| Material Options | 316/304 Stainless Steel, Inconel 718, Titanium, Alloy Steel |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on geometry) |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm (standard), customizable |

| Pressure Rating | Up to 15,000 psi (application-dependent) |

| Testing Protocols | Hydrostatic testing, Helium leak testing, CMM inspection |

| Production Capacity | 5,000–50,000 units/month (scalable) |

| Certifications | ISO 9001, AS9100, Material Test Reports (MTR), FAIR |

Wuxi Lead Precision Machinery delivers high-integrity machining parts for critical high-pressure systems, combining engineering depth with manufacturing excellence to ensure every component performs flawlessly in the field.

Why Choose Wuxi Lead Precision

Elevate Your High-Pressure Connection Performance Through Precision Partnership

In the demanding realm of high-pressure fluid and gas systems, the integrity of every machined connection point is non-negotiable. Failure is not an option where extreme pressures, corrosive media, and critical safety margins converge. Wuxi Lead Precision Machinery exists to transform this challenge into your competitive advantage. We are not merely a supplier; we are your dedicated engineering partner for mission-critical metal components, bringing decades of specialized expertise in high-pressure connection machining directly to your most complex projects. Our commitment extends beyond meeting specifications to ensuring absolute reliability, longevity, and seamless integration within your demanding assemblies.

Partnering with Lead Precision means accessing a vertically integrated manufacturing ecosystem engineered for uncompromising quality in high-stress applications. Our facility operates under stringent ISO 9001:2015 and IATF 16949 quality management systems, with processes rigorously validated for aerospace, energy, and advanced industrial sectors. We specialize in machining complex geometries from challenging materials including stainless steels (316L, 17-4PH), nickel alloys (Inconel 625, 718), titanium grades, and specialized carbon alloys, ensuring optimal performance under extreme pressure cycles and harsh environments. Advanced CNC multi-axis machining centers, coupled with in-house metrology utilizing CMMs, optical comparators, and pressure testing capabilities, guarantee dimensional accuracy and functional integrity down to micron-level tolerances. Traceability is absolute, from raw material certification through final inspection documentation.

Our engineering collaboration begins at the design stage. We proactively engage to optimize manufacturability, suggest material enhancements for specific pressure/temperature profiles, and identify potential failure points before metal is cut. This proactive engineering partnership mitigates risk, accelerates time-to-market, and significantly reduces total cost of ownership by eliminating field failures and costly rework. We understand that your reputation hinges on the flawless performance of every connection we produce.

Lead Precision High-Pressure Connection Machining Capabilities

| Parameter | Capability Range | Key Technology/Control |

|---|---|---|

| Material Expertise | Stainless Steels, Nickel Alloys, Titanium, Specialized Carbon Alloys | Material Certification & Lot Traceability |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | Multi-Axis CNC Machining (Milling/Turning) |

| Surface Finish | Ra 0.4 µm (16 µin) and finer | Precision Grinding & Polishing |

| Pressure Testing | Up to 15,000 PSI (Custom Configurations) | Hydrostatic & Pneumatic Test Rigs |

| Quality Assurance | Full CMM Reporting, Material Certs, NDT Options | ISO 9001:2015 / IATF 16949 Certified |

The cost of a compromised connection far exceeds the investment in precision manufacturing. When system integrity, operational safety, and long-term reliability are paramount, settle for nothing less than a proven partner with deep expertise in high-pressure dynamics. Wuxi Lead Precision Machinery delivers the engineering rigor, process control, and unwavering commitment your critical applications demand. Initiate a confidential technical consultation today. Contact our engineering sales team directly at [email protected]. Provide your project specifications and timeline, and we will respond within 24 business hours with a detailed capability assessment and actionable next steps. Secure your supply chain with precision you can trust. Partner with Lead Precision for connections that perform, under pressure.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.