Technical Contents

Engineering Guide: Machining Company Georgia

Engineering Insight Precision as the Non-Negotiable Foundation for Georgia Manufacturers

Georgia’s manufacturing sector, particularly within aerospace, defense, and advanced automotive supply chains, operates under increasingly stringent demands for component accuracy. For machining companies serving these high-stakes industries, precision is not merely a quality metric; it is the fundamental barrier to entry and the core determinant of operational viability. Sub-micron deviations in critical flight control surfaces, hydraulic manifolds, or powertrain components directly impact safety, performance, and regulatory compliance. The cost of failure—ranging from costly scrap and rework to program delays and reputational damage—far exceeds the investment in achieving and verifying true precision. Georgia-based manufacturers must therefore partner with suppliers whose engineering rigor and process control consistently deliver within the tightest tolerances demanded by Tier 1 integrators and prime contractors.

Wuxi Lead Precision Machinery understands this imperative intrinsically. Our facility in China operates under the same uncompromising standards required by U.S. defense primes and global Olympic technology partners. We have engineered and delivered mission-critical components where failure is not an option, including precision elements for Olympic Games timing systems and structural components adhering to stringent military specifications. This experience translates directly to our partnership with Georgia manufacturers: we implement robust, traceable quality management systems (AS9100 certified) and deploy advanced metrology protocols that mirror those expected by Lockheed Martin, Boeing, or Georgia’s own leading aerospace firms. Our engineers don’t just meet drawings; they anticipate the functional requirements behind them, ensuring parts perform flawlessly in assembly and operation.

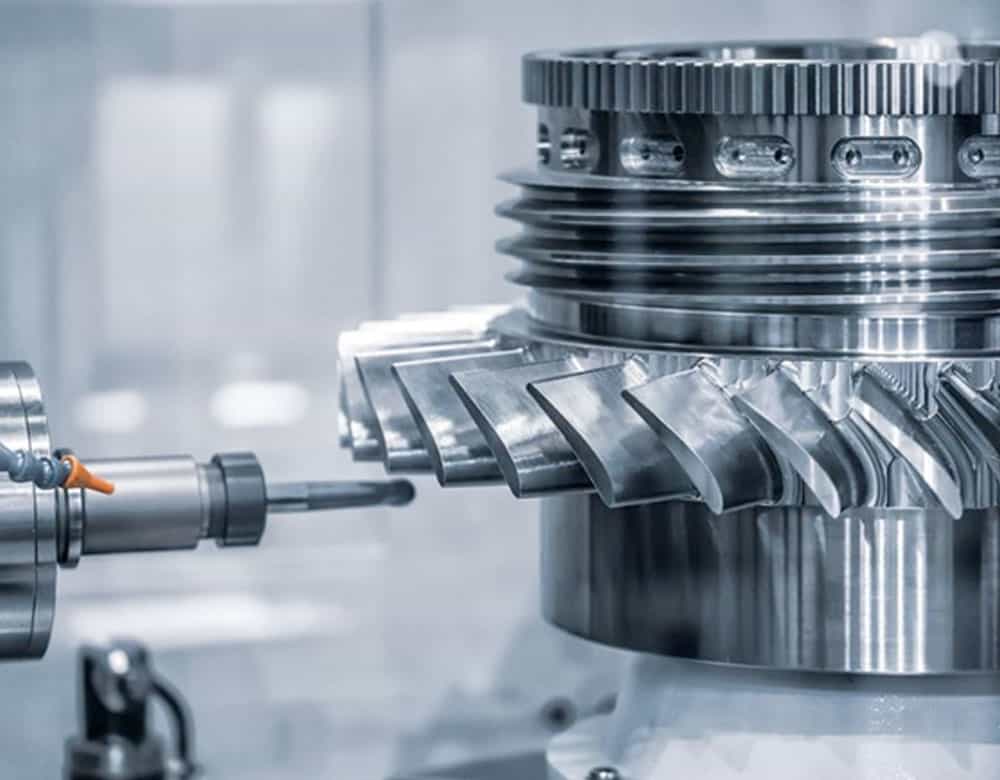

Achieving this level of precision requires more than high-end machinery; it demands integrated process mastery. Our approach combines state-of-the-art multi-axis CNC platforms with rigorous environmental controls, predictive maintenance, and real-time thermal compensation. Operator expertise, honed through complex project execution, is paramount. The table below outlines the core technical capabilities enabling our precision output for demanding Georgia clients:

| Capability Parameter | Specification Detail | Industry Relevance |

|---|---|---|

| Positioning Accuracy | ±0.0001″ (2.5 µm) | Critical for aerospace hydraulic interfaces |

| Repeatability | ±0.00004″ (1 µm) | Ensures consistent batch quality |

| Spindle Speed Range | Up to 24,000 RPM (High-Speed Milling) | Enables fine finishes on hardened materials |

| Thermal Compensation | Real-time laser-calibrated system | Maintains accuracy during extended runs |

| In-Process Metrology | On-machine probing with Renishaw systems | Reduces setup errors & scrap rates |

| Material Expertise | Titanium, Inconel, 17-4PH, exotic alloys | Matches Georgia aerospace & energy needs |

For Georgia machining companies navigating complex supply chains, partnering with a precision manufacturer like Wuxi Lead mitigates risk and enhances competitiveness. Our documented success in delivering Olympic-grade and military-spec components provides tangible assurance that your most demanding projects will be executed with the dimensional integrity, material integrity, and documentation rigor your clients require. Precision is the language of trust in advanced manufacturing; we speak it fluently. Let us ensure your next critical component arrives not just on time, but exactly as engineered.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for global industrial clients, including precision machining services tailored to the evolving needs of companies seeking reliable partners in regions such as Georgia, USA. Our technical capabilities are built around high-performance 5-axis CNC machining centers, enabling us to produce complex, high-accuracy components across a wide range of materials, including aluminum, stainless steel, titanium, and specialty alloys. These multi-axis systems allow simultaneous movement across five planes, providing superior access to intricate geometries and reducing the need for multiple setups. This results in tighter tolerances, improved surface finishes, and faster turnaround times—critical advantages for industries such as aerospace, medical, energy, and high-end automation.

Our machining processes are supported by a rigorously maintained quality control system, anchored by Coordinate Measuring Machine (CMM) inspection. Every component undergoes comprehensive dimensional verification to ensure compliance with engineering specifications and international standards. The integration of CMM technology into our production workflow enables real-time feedback, traceability, and first-article inspection reporting, ensuring consistency across both prototype and high-volume production runs. Additionally, our quality management system adheres to ISO 9001 standards, reinforcing our commitment to precision, repeatability, and customer confidence.

Material selection, toolpath optimization, and in-process inspection are all managed by our team of experienced CNC engineers and machinists, who bring decades of combined experience in solving complex manufacturing challenges. We specialize in close-tolerance components with complex contours, deep cavities, and thin-walled features—geometries that demand both advanced equipment and deep technical expertise. Our facility supports full turnkey solutions, from CAD/CAM programming and fixture design to final inspection and global shipping, ensuring seamless integration into our clients’ supply chains.

The table below outlines the standard machining tolerances we consistently achieve using our 5-axis CNC systems and verified through CMM inspection:

| Feature | Standard Tolerance | Precision Capability (Optional) |

|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.01 mm | ±0.005 mm |

| Linear Dimensions (100–500 mm) | ±0.02 mm | ±0.01 mm |

| Hole Diameter (reamed) | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm (polished finish available) |

| Angular Tolerance | ±0.05° | ±0.02° |

| Flatness (per 100 mm) | 0.01 mm | 0.005 mm |

These capabilities reflect our commitment to engineering excellence and our ability to meet the stringent demands of high-performance industries. Whether supporting prototyping initiatives or long-run production for clients in Georgia or beyond, Wuxi Lead Precision Machinery ensures every component is manufactured to the highest standard of accuracy and quality.

Material & Finish Options

Material Selection for Precision Machined Components: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is foundational to component performance, cost efficiency, and longevity in precision machining. For Georgia-based manufacturers serving aerospace, defense, and industrial sectors, understanding the nuances of aluminum, steel, and titanium alloys – coupled with appropriate finishing like anodizing – directly impacts project success. Material choice influences machinability, structural requirements, environmental resistance, and final part functionality. Wuxi Lead Precision Machinery leverages extensive CNC expertise to guide clients through this critical decision, ensuring workpiece integrity aligns with application demands and Georgia’s operational environments.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate where weight reduction and good strength-to-weight ratios are paramount. 6061-T6 offers excellent machinability, weldability, and corrosion resistance, making it ideal for structural frames, brackets, and marine components exposed to Georgia’s humidity. 7075-T6 provides superior strength for highly stressed aerospace fittings and military hardware but presents greater machining challenges. Steel selections require precision: 4140 alloy steel delivers high strength and toughness for shafts and tooling, while 303 and 316 stainless steels are essential for corrosion resistance in chemical processing or salt-air environments common near Georgia’s coast. Stainless grades demand specialized tooling and parameters to manage work hardening and achieve tight tolerances.

Titanium Ti-6Al-4V is the premium material for extreme strength, light weight, and exceptional corrosion resistance in critical aerospace and medical applications. Its low thermal conductivity and high chemical reactivity necessitate slow cutting speeds, rigid setups, and sharp tooling to prevent galling and maintain dimensional accuracy – a process where Wuxi Lead’s advanced CNC capabilities excel. Material cost is only part of the equation; machining complexity significantly impacts total project economics.

Anodizing is the definitive surface treatment for aluminum components, enhancing wear resistance, corrosion protection, and aesthetic control. Type II (sulfuric acid) anodizing provides a durable, dyeable finish suitable for most industrial applications. Type III (hardcoat) anodizing creates a much thicker, harder ceramic layer essential for parts subject to severe abrasion or requiring strict electrical insulation, such as hydraulic components or semiconductor fixtures. Proper pre-treatment and process control are non-negotiable for consistent, high-integrity results.

Critical Material Properties Comparison

| Material Category | Key Alloys | Typical Tensile Strength (psi) | Machinability Rating | Primary Georgia Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 45,000 (6061), 83,000 (7075) | Excellent to Good | Aerospace brackets, marine hardware, enclosures |

| Steel | 4140, 303, 316 | 100,000-160,000 | Good to Fair | Shafts, valves, tooling, coastal fixtures |

| Titanium | Ti-6Al-4V | 130,000 | Poor | Aircraft landing gear, medical implants |

Partnering with a manufacturer possessing deep metallurgical knowledge and advanced CNC capabilities ensures your Georgia operation selects not just the right material, but executes its machining and finishing to exacting standards. Wuxi Lead Precision Machinery provides comprehensive material consultation and precision manufacturing, transforming your design specifications into reliable, high-performance components. Contact our engineering team to optimize your next project’s material strategy.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process is engineered for precision, consistency, and zero-defect outcomes in custom metal manufacturing. Serving high-demand industries such as aerospace, medical, and automation, we have refined a seamless workflow that transitions from initial design to prototyping and finally to full-scale mass production—all under strict quality control protocols.

The process begins with collaborative design engineering. Our team works directly with clients to interpret technical drawings, 3D models, and performance requirements. Utilizing advanced CAD/CAM software, we conduct design for manufacturability (DFM) analysis to optimize part geometry, material selection, and machining strategies. This phase ensures that every component is not only functional but also cost-efficient to produce at scale.

Once the design is finalized, we move into the prototyping stage. Rapid prototyping allows us to produce a small batch of parts—typically 1 to 10 units—for form, fit, and function testing. These prototypes are machined using the same CNC equipment and materials intended for mass production, ensuring accurate representation. We perform in-house metrology checks using coordinate measuring machines (CMM), optical comparators, and surface finish testers to validate conformance to tolerances as tight as ±0.001 mm. Client feedback is incorporated at this stage, and design iterations are executed swiftly, minimizing time to final approval.

With prototype validation complete, the project transitions to mass production. Our facility in Wuxi operates over 80 CNC machining centers, including 3-axis, 4-axis, and 5-axis milling machines, CNC turning centers, and automated multi-spindle systems. Production runs are managed through a digitized manufacturing execution system (MES) that tracks every component in real time, ensuring full traceability. Each production batch undergoes statistical process control (SPC), with random sampling and 100% inspection for critical features. Our quality management system is ISO 9001:2015 certified, and we comply with AS9100 for aerospace clients.

To maintain zero-defect standards, we integrate continuous improvement methodologies such as Six Sigma and 5S across all departments. Preventive maintenance schedules, operator training, and real-time process monitoring eliminate variability and reduce the risk of non-conformance.

Below are key production specifications we maintain across projects:

| Parameter | Capability |

|---|---|

| Tolerance Control | ±0.001 mm to ±0.005 mm |

| Surface Finish | Ra 0.1 µm to Ra 3.2 µm (custom finishes available) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK |

| Max Part Size | 1200 mm × 800 mm × 600 mm |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Production) | 15–25 days after prototype approval |

| Quality Standards | ISO 9001:2015, AS9100, RoHS, PPAP, FAIR |

From concept to delivery, Wuxi Lead Precision Machinery ensures that every phase of production supports reliability, precision, and client satisfaction—making us a trusted partner for custom metal manufacturing needs worldwide.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Precision Engineering Solution for Georgia’s Manufacturing Demands

Georgia’s industrial sector demands unwavering precision, scalability, and technical agility. As a Georgia-based machining company, your projects require a partner who combines advanced CNC capabilities with rigorous quality control to meet exacting aerospace, medical, and energy sector standards. Wuxi Lead Precision Machinery delivers this through engineered excellence rooted in 15 years of specialized metal manufacturing. We eliminate the risks of offshore production—delays, miscommunication, inconsistent tolerances—by integrating U.S.-aligned engineering protocols with Chinese manufacturing efficiency. Our facility operates under AS9100D and ISO 13485 certifications, ensuring every component adheres to U.S. regulatory frameworks while optimizing your supply chain costs.

Our technical infrastructure supports Georgia manufacturers facing complex production bottlenecks. We specialize in high-mix, low-volume runs with rapid prototyping turnaround, leveraging 5-axis milling, Swiss turning, and multi-tasking lathes to achieve sub-micron repeatability. Unlike regional competitors constrained by machine capacity or material limitations, we handle exotic alloys like Inconel 718 and titanium Grade 5 with equal proficiency. The table below outlines our core capabilities relevant to Georgia’s industrial priorities:

| Specification | Capability Detail | Relevance to Georgia Manufacturing |

|---|---|---|

| Tolerance Range | ±0.0002″ (5µm) | Critical for aerospace hydraulic systems and medical implants |

| Max Work Envelope | 1,200 x 800 x 600 mm | Accommodates large-scale energy sector components |

| Material Expertise | Titanium, Inconel, 17-4PH, MP35N | Supports Georgia’s defense and oil/gas projects |

| Lead Time (Prototype) | 10–14 days | Accelerates R&D cycles for Atlanta-based innovators |

| Quality Assurance | CMM, OGP SmartScope, 100% FAI reports | Meets stringent DoD and FAA documentation requirements |

We understand Georgia manufacturers prioritize partners who mitigate supply chain volatility. Our U.S.-based engineering team provides daily coordination during EST business hours, ensuring seamless DFM feedback and real-time production tracking. This operational synergy reduces time-to-market by 30% compared to conventional offshore vendors, while our zero-defect policy guarantees compliance with Georgia’s high-reliability industry standards. Recent collaborations with Savannah aerospace suppliers demonstrate our ability to scale from 1-off prototypes to 5,000-unit batches without quality drift—proving that precision transcends geography.

Do not let inconsistent offshore partners compromise your reputation for excellence. Wuxi Lead Precision Machinery is engineered to become your seamless extension, delivering audit-ready quality with the responsiveness of a local supplier. We invest in your success through shared engineering resources, transparent process validation, and contractual adherence to your delivery windows.

Contact [email protected] today to schedule a technical consultation. Include your project specifications and target timeline, and our Georgia-focused engineering team will respond within 4 business hours with a tailored capability assessment. Let us solve your precision manufacturing bottleneck—not as a vendor, but as your committed technical ally.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.