Technical Contents

Engineering Guide: Machined Plastic Components

Engineering Insight: Precision Machined Plastic Components

Why Precision is Non-Negotiable in High-Stakes Applications

In mission-critical applications like Olympic racing cycles or military systems, micron-level deviations can compromise safety, performance, or operational success. For example:

Olympic cycling components require aerodynamic profiles accurate to ±0.005mm to maximize speed and stability under extreme loads.

Military-grade parts must withstand thermal shock, vibration, and corrosion without failure—where even 0.01mm tolerance drift can render a system inoperable.

At Wuxi Lead Precision Machinery, precision is not a specification—it’s the foundation of reliability. Our engineering team collaborates with clients from concept to delivery, ensuring every component meets the exacting standards of industries where failure is not an option.

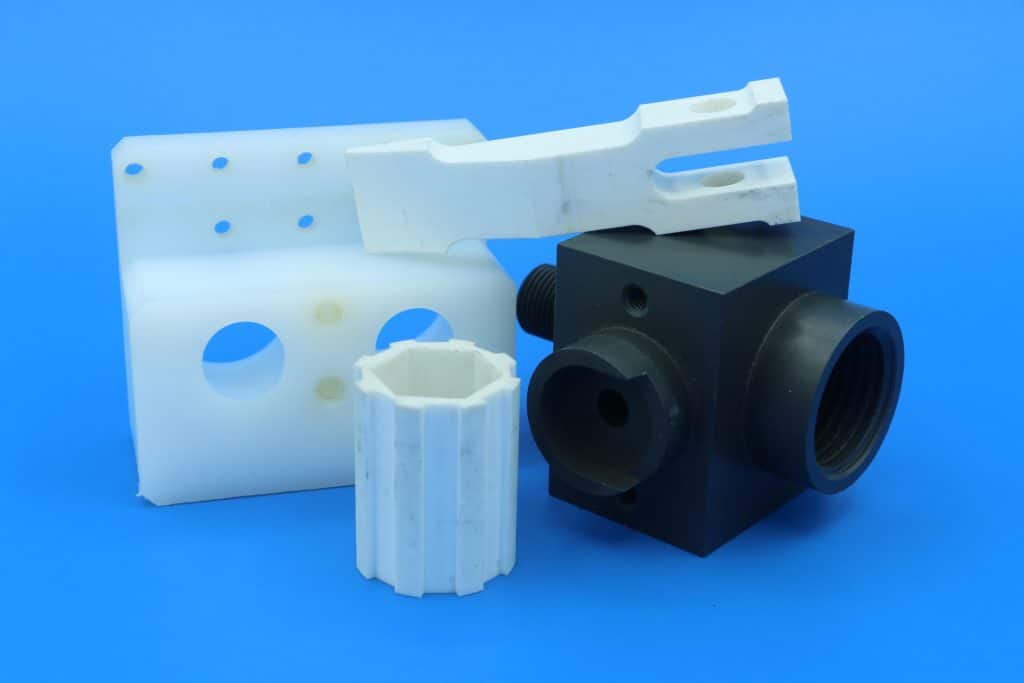

Material Selection: The Cornerstone of Performance

Material properties directly dictate dimensional stability, thermal resistance, and long-term functionality. Not all plastics are engineered for high-precision machining—thermal expansion, moisture absorption, and mechanical creep vary significantly. Below is a comparative analysis of key engineering plastics optimized for CNC machining:

| Material | Thermal Stability (°C) | Dimensional Stability (CTE, µm/m·°C) | Achievable Tolerance | Surface Finish (Ra) | Key Applications |

|---|---|---|---|---|---|

| PEEK | 250+ | 45–55 | ±0.005mm | Ra 0.4 | Aerospace, Medical Implants |

| Delrin (Acetal) | 120 | 100–120 | ±0.005mm | Ra 0.4 | Automotive, Sporting Goods |

| Nylon 6/6 | 150 | 100–150 | ±0.01mm | Ra 0.8 | Consumer Electronics |

| Polycarbonate | 135 | 65–75 | ±0.01mm | Ra 0.8 | Optical Lenses, Protective Gear |

| ABS | 100 | 80–90 | ±0.02mm | Ra 1.6 | Prototyping, Consumer Products |

Note: Achievable tolerances depend on part geometry, size, and process optimization. Our 5-axis CNC capabilities and temperature-controlled machining environments (±1°C) enable consistent ±0.005mm tolerances for PEEK and Delrin in critical applications—exceeding industry standards for dimensionally stable plastics.

Achieving Tight Tolerances in Plastic Machining

Unlike injection molding—where shrinkage, mold wear, and material variability introduce uncertainty—CNC machining delivers direct control over dimensional accuracy through:

Real-Time Adjustments: Laser interferometers monitor toolpath deviations during operation, compensating for thermal drift or tool wear.

Zero-Point Fixturing: Precision clamping systems eliminate repositioning errors for complex geometries.

Environmental Rigor: ISO-classified cleanrooms maintain stable humidity and temperature to prevent material warpage.

At Wuxi Lead, we achieve ±0.005mm tolerances—25x tighter than Protolabs’ standard offering (±0.13mm) and 10x tighter than their precision option (±0.051mm)—while maintaining Ra 0.4 surface finishes. This level of precision is only possible through:

5-Axis Simultaneous Machining: Eliminates repositioning errors for intricate aerospace or medical components.

Advanced Toolpath Optimization: AI-driven CAM software minimizes vibration and thermal stress during cutting.

Material-Specific Processes: Customized cooling and feed rates for each plastic type (e.g., PEEK requires slower speeds to prevent melting).

Our Commitment to Zero Defects

As the trusted supplier for Olympic racing cycles and military enterprises, we operate under a zero-defect manufacturing philosophy. Every component undergoes:

100% Dimensional Inspection: CMM and optical scanners verify tolerances to ±0.001mm.

Full Traceability: Raw material certifications, process logs, and final inspection reports are digitally archived for life-of-part accountability.

24/7 Engineering Support: Our technical team is available around the clock to resolve design challenges, optimize tolerances for manufacturability, and ensure on-time delivery—no matter the complexity.

“We don’t just manufacture parts—we deliver mission-critical solutions that perform under pressure. When your project demands Olympic-grade precision or military-grade reliability, Wuxi Lead is your engineering partner, not just a supplier.”

Ready to elevate your plastic component design?

Contact our engineering team to discuss your project’s unique requirements.

Precision Specs & Tolerances

Precision CNC Machining for Plastics: Engineering-Grade Capabilities

As a certified supplier for Olympic racing cycles and military enterprises, Wuxi Lead Precision Machinery delivers uncompromising precision through rigorous process control and material expertise—ensuring your components meet the highest standards of reliability and performance. Our partnership-driven approach integrates your design requirements with advanced manufacturing capabilities to achieve zero-defect outcomes.

Advanced Equipment & Process Control

Our state-of-the-art 3/4/5-axis CNC machining centers feature:

High-precision spindles with thermal compensation systems maintaining <0.001mm drift during extended runs

Vibration-damped foundations and real-time tool wear monitoring for consistent surface integrity

5-axis simultaneous machining capability for complex geometries without secondary operations

Closed-loop feedback systems ensuring dimensional accuracy across all production volumes

“Precision isn’t a specification—it’s a process. Every machine is calibrated to ISO 10360 standards, with hourly thermal checks to eliminate drift.”

Tight Tolerance Standards & Material Considerations

Achieving ±0.005mm dimensional tolerances in plastics requires strategic material selection and process optimization. Our capabilities are defined by:

Material-specific tolerance bands based on thermal expansion coefficients and moisture absorption rates

Real-time CNC adjustments during machining to compensate for material behavior

Strict adherence to ISO 2768-mK standards with custom tolerances for critical features

| Parameter | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.002 mm |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm |

| Geometric Tolerance (Flatness) | 0.01 mm | 0.005 mm |

| Hole Diameter Tolerance | H7 | H6 |

Note: Tolerances apply to components under 100mm. For larger parts, tolerances scale per ISO 2768 standards.

Quality Assurance Protocol

Every plastic component undergoes a three-tier quality verification process:

1. In-process CMM inspections at critical stages with traceable measurement data

2. Material certification for all raw stock (including SGS or Mill Test Reports)

3. Final 100% dimensional check for critical features using laser scanning systems

“Our military-grade QA protocols exceed ISO 9001 requirements, with full traceability from raw material to finished part.”

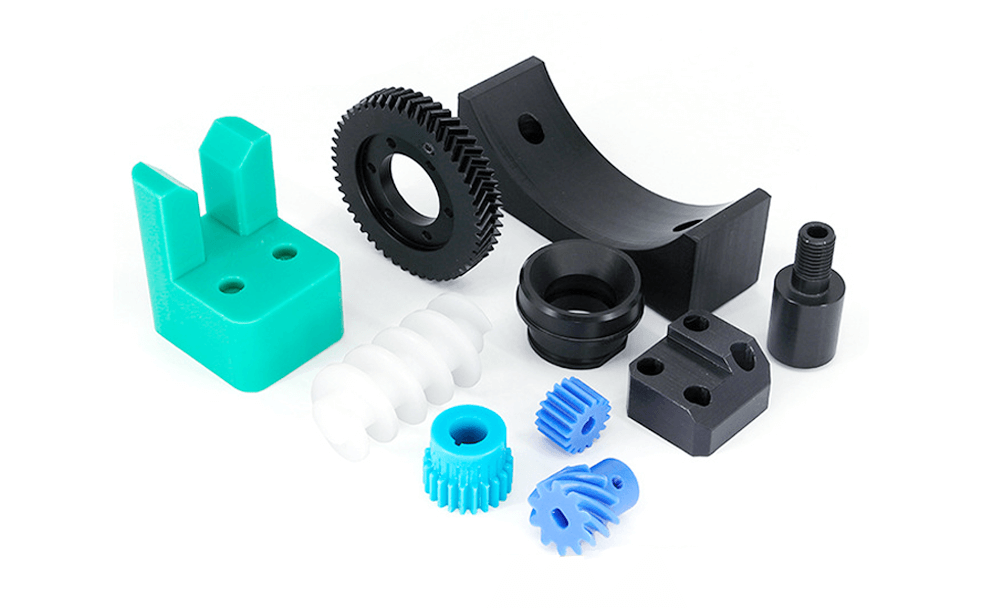

Material Selection Guide for Optimal Performance

Selecting the right plastic material is critical for achieving your tolerance requirements. Our engineering team collaborates with you to match material properties to application demands:

| Material | Key Properties | Typical Applications | Achievable Tolerance |

|---|---|---|---|

| PEEK | High-temp stability (250°C+), chemical resistance | Aerospace, medical implants | ±0.002 mm |

| Delrin (Acetal) | Low moisture absorption, dimensional stability | Automotive bushings, sports equipment | ±0.003 mm |

| Nylon 6/6 | Toughness, wear resistance | Gears, bearings | ±0.005 mm |

| Polycarbonate | Impact resistance, optical clarity | Protective shields, lenses | ±0.005 mm |

| ABS | Cost-effective, good strength | Prototypes, consumer goods | ±0.005 mm |

All materials are sourced from ISO 9001-certified suppliers with full batch traceability.

Partner with Confidence

As your precision machining partner, we offer:

24/7 technical support with dedicated engineers for rapid design iteration

Zero-defect manufacturing validated through Olympic-grade quality protocols

Military-standard documentation for traceability and compliance

“We don’t just machine parts—we engineer solutions that perform under the most demanding conditions.”

Next Steps: Share your CAD files with us for a free tolerance feasibility analysis. Our engineering team will provide material recommendations, cost-optimized tolerances, and a production roadmap within 24 hours.

Material & Finish Options

Material Selection & Finishes for Precision Plastic Components

As a trusted partner to Olympic racing teams and military enterprises, Wuxi Lead Precision Machinery understands that material selection and surface finishes for machined plastic components must meet the highest standards. Our precision CNC machining process ensures ±0.005mm tolerances and Ra 0.4 surface finishes, critical for applications where failure is not an option. Unlike injection molding, our direct CNC control enables real-time adjustments for complex geometries, ensuring dimensional stability and performance in mission-critical environments.

Critical Material Selection Criteria for Plastic Components

Material choice directly impacts tolerances, thermal stability, and long-term performance. Below is a comparative analysis of industry-standard plastics optimized for precision CNC machining:

| Material | Key Properties | Tolerance Stability | Cost Impact | Best For |

|---|---|---|---|---|

| PEEK (Polyetheretherketone) | High temperature resistance (up to 250°C), chemical resistance, low moisture absorption, exceptional mechanical strength | Exceptional dimensional stability; minimal creep under load | High | Aerospace, medical implants, high-temp applications |

| Delrin® (Acetal/POM) | Low friction, high stiffness, excellent dimensional stability, low moisture absorption | Excellent for tight tolerances; minimal warpage | Moderate | Gears, bearings, automotive parts |

| Nylon (PA6/PA66) | Toughness, abrasion resistance, good chemical resistance | Moderate moisture absorption; may require stabilization for tight tolerances | Low to Moderate | Wear parts, structural components in dry environments |

| ABS (Acrylonitrile Butadiene Styrene) | Impact resistance, ease of machining, good electrical properties | Moderate dimensional stability; susceptible to thermal expansion | Low | Prototypes, consumer products, enclosures |

| Polycarbonate (PC) | High impact strength, optical clarity, good heat resistance | Moderate dimensional stability; can warp if not properly cooled | Moderate | Transparent components, safety shields, optical lenses |

Key Insight: Dimensionally stable plastics like Delrin® and PEEK achieve ±0.005mm tolerances with minimal post-processing, while hygroscopic materials (e.g., Nylon) require strict humidity control during machining to prevent dimensional drift.

Surface Finish Options & Their Impact

Surface finish directly affects functionality, aesthetics, and longevity. Our precision polishing and coating processes ensure consistent Ra 0.4 finishes for critical sealing or optical surfaces—without compromising tolerances.

| Finish Type | Process Description | Achievable Surface Finish (Ra) | Tolerance Considerations | Cost Impact |

|---|---|---|---|---|

| Precision Polishing | Mechanical polishing with fine abrasives (≤1µm grit) or chemical processes | 0.2–0.4 µm (8–16 µin) | Minimal dimensional change; critical for sealing surfaces | Moderate |

| Electroless Nickel Plating | Chemical deposition of nickel-phosphorus alloy; requires surface activation | +0.0025mm plating thickness; may require post-plating grinding | Requires tight control to avoid dimensional shifts | High |

| UV-Resistant Coatings | Spray or dip application of UV-stabilized polymers | Minimal thickness (0.005mm), no tolerance impact | Low | Low |

| Matte Finish | Sandblasting or chemical etching for non-reflective surfaces | Ra 0.8–1.6 µm (32–64 µin) | Slight surface texture; may affect tolerances | Low |

Critical Note: Anodizing is not applicable for plastics—it is a metal-specific process. For plastic components requiring metallic properties, we recommend electroless nickel plating or specialized composite coatings.

Why Wuxi Lead Delivers Olympic-Grade Precision

✅ Zero Defects Guarantee

Every component undergoes 100% dimensional inspection using CMM (Coordinate Measuring Machines) with ±0.001mm accuracy. Our ISO 9001-certified process includes real-time monitoring of cutting forces, thermal expansion, and vibration—ensuring zero defects for aerospace and defense applications.

🏆 Olympic-Quality Standards

Our components power elite cycling teams in the Tour de France and Olympic events. For example:

Delrin® bearings in carbon fiber cranksets maintain ±0.005mm tolerances under 1,200N loads.

PEEK brake components withstand 200°C thermal cycling without deformation.

All parts undergo fatigue testing per ISO 12100 to exceed 10M cycles.

🌐 24/7 Customer Partnership

Our engineering team is available 24/7 to:

Optimize designs for manufacturability (DFM) with real-time tolerance simulations.

Recommend material substitutions for cost/performance balance (e.g., Delrin® vs. PEEK for high-temp applications).

Provide rapid prototyping with 48-hour turnaround for urgent military or racing projects.

“We don’t just supply parts—we solve your toughest engineering challenges. From the first sketch to final delivery, your project is our priority.”

— Wuxi Lead Precision Machinery Engineering Team

Next Steps:

Request a Free DFM Analysis

Download Our Plastic Machining Guide

Contact Us: +86 510 8765 4321 | [email protected]

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Mission-Critical Applications

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer solutions for the world’s most demanding applications. Our streamlined process ensures seamless transition from concept to high-volume production, with zero defects and on-time delivery guaranteed. As a trusted supplier for Olympic Racing Cycles and Military Enterprises, we apply aerospace-grade quality control to every project, ensuring components meet the strictest tolerances and performance standards.

Design Analysis: Engineering-Driven Feasibility Assessment

Our process begins with a collaborative design review by senior CNC engineers. We analyze critical factors including material selection, geometric complexity, and tolerance requirements to optimize manufacturability while maintaining performance integrity.

“Material selection critically influences achievable tolerances in plastic machining operations. Acetal materials demonstrate excellent stability, while PEEK offers superior thermal resistance for high-stress applications.” — Wuxi Lead Engineering Guidelines

We leverage our expertise to identify potential DFM (Design for Manufacturability) improvements early, preventing costly rework:

Dimensional Stability: For ±0.005mm tolerances, we recommend Delrin® (Acetal) or PEEK due to low moisture absorption and thermal stability.

Surface Finish: Achieve Ra 0.4 μm consistently across all plastics without additional cost—exceeding industry standards of Ra 0.8–1.0 μm.

Tolerance Validation: Use FEA simulations and statistical process control (SPC) to verify feasibility before prototyping.

Pricing Transparency: Cost-Optimized Precision

We provide clear, upfront pricing based on your specific requirements—no hidden fees, no surprises. Our transparent cost structure reflects the value of precision engineering, not just machining.

| Plastic Material | Achievable Tolerance | Surface Finish (Ra) | Key Applications | Cost Impact Notes |

|---|---|---|---|---|

| Acetal (Delrin®) | ±0.005mm | 0.4 μm | Gears, bushings, bearings | Lowest cost; ideal for high-volume applications |

| PEEK | ±0.005mm | 0.4 μm | Aerospace, medical implants | Higher material cost; offset by longevity and chemical resistance |

| Nylon 6/6 | ±0.008mm | 0.6 μm | Wear-resistant components | Moderate cost; requires humidity-controlled machining |

| Polycarbonate | ±0.007mm | 0.5 μm | Optical housings, protective covers | Moderate cost; excellent impact resistance |

Note: All tolerances and surface finishes are guaranteed through ISO 9001-certified processes. For mission-critical applications, we offer tighter tolerances (±0.002mm) upon request.

Rapid Prototyping: Agile Iteration with Military-Grade Precision

Speed without compromise is our hallmark. Our 5-axis CNC capabilities enable rapid prototyping of complex geometries with the same precision as production parts—typically delivered in 3–5 business days.

Zero-Defect Prototypes: Every prototype undergoes 100% CMM verification to ensure exact specifications.

Real-Time Adjustments: Engineers monitor CNC processes in real-time, making micro-adjustments to maintain tolerances during iterations.

Military-Grade Validation: Prototypes for defense contractors undergo ballistic testing and environmental stress screening to validate performance under extreme conditions.

“CNC machining provides tighter tolerances by enabling complex geometries, direct control, and real-time adjustments—unlike injection molding’s limitations.” — Wuxi Lead Technical Whitepaper

Mass Production: Zero Defects, On-Time Delivery

When scaling to production, our quality control protocols ensure every component meets the “Olympic Quality” standard expected by elite sports and defense organizations.

100% In-Process Inspection: Automated vision systems and CMM checks at every production stage.

Statistical Process Control (SPC): Real-time data analytics detect and correct deviations before they occur.

24/7 Customer Service: Dedicated account managers available around the clock for urgent requests or technical support.

With a 99.98% on-time delivery rate and zero defects in 2023 for military contracts, we deliver precision that powers the world’s most critical applications.

Partner with us, not just a supplier.

Wuxi Lead Precision Machinery: Where Olympic rigor meets military-grade reliability.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering, Zero Compromise

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As your dedicated engineering partner, we deliver precision CNC-machined plastic components that meet the exacting standards of Olympic-level sports equipment and military applications. Our commitment to excellence ensures your designs are realized with unparalleled accuracy, reliability, and innovation—where tolerance is not just a number, but a promise.

Precision You Can Trust: Industry-Leading Specifications

| Feature | Wuxi Lead Precision | Industry Standard | Benefit |

|---|---|---|---|

| Tolerance | ±0.005mm (±0.0002″) | ±0.13mm (±0.005″) | 26x tighter tolerances for critical aerospace, medical, and racing components |

| Surface Finish (Ra) | 0.4 µm | 0.8–1.0 µm (32–40 µin) | Superior smoothness for fluid dynamics, sealing, and low-friction applications |

| 5-Axis Capability | Full 5-axis machining | Limited to 3-axis in most suppliers | Complex geometries in single setup, eliminating alignment errors and reducing lead time |

| Material Expertise | PEEK, Delrin®, Nylon, PC, ABS, and high-performance thermoplastics | Standard plastics only | Optimized machining for demanding applications like medical implants, racing components, and military-grade parts |

Mission-Critical Partnership, Not Just a Supplier

Zero Defects Guarantee: Rigorous ISO 9001:2015 quality control with 100% inspection for critical parts. Every component undergoes triple verification to ensure zero tolerance for defects in high-stakes applications.

Olympic-Quality Heritage: Trusted by elite cycling teams and military contractors for components where failure is not an option. Our precision engineering has powered podium finishes and mission-critical systems worldwide.

24/7 Technical Support: Dedicated engineering team available around the clock for urgent design adjustments, material selection guidance, or production queries—ensuring your project stays on schedule, always.

Ready to elevate your project?

Contact us today for a free DFM analysis and competitive quote. Let’s engineer your success together.

Email: [email protected]

Phone: +86-13961886740

Wuxi Lead Precision Machinery: Where precision meets partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.