Technical Contents

Engineering Guide: Machine Shop San Francisco Ca

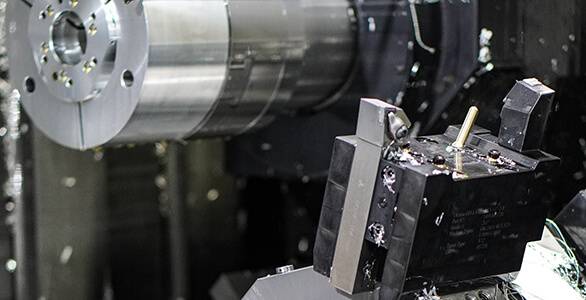

Engineering Insight: The Critical Role of Precision in Modern Machine Shop Operations – A San Francisco CA Perspective

In the high-stakes world of advanced manufacturing, particularly within the competitive landscape of a machine shop in San Francisco, CA, precision is not merely a performance metric—it is the foundation upon which reliability, compliance, and innovation are built. As industries ranging from aerospace and medical technology to defense and clean energy demand increasingly complex components, the margin for error narrows to microns. At Wuxi Lead Precision Machinery, we understand that true precision engineering transcends machinery; it embodies process control, material science, and decades of applied expertise.

San Francisco’s position as a nexus for technological innovation places unique demands on local and global manufacturing partners. Startups and established firms alike require rapid prototyping, low-volume high-mix production, and strict adherence to AS9100, ISO 13485, and ITAR standards. While local machine shops serve vital roles in agility and responsiveness, global partners with proven precision capabilities offer scalability without compromise. This is where Wuxi Lead distinguishes itself—not only through state-of-the-art CNC machining centers but through a legacy of delivering mission-critical components under the most stringent requirements.

Our engineering team has supported applications where failure is not an option. From components used in Olympic-level athletic equipment—where consistency and performance margins are measured in thousandths of an inch—to precision-machined parts integrated into military-grade communication systems, our work reflects a commitment to dimensional accuracy, material integrity, and repeatable quality. These projects demand more than advanced 5-axis milling or Swiss turning; they require a culture of continuous improvement, rigorous inspection protocols, and full traceability from raw material to finished part.

At the core of our precision capability is a vertically integrated manufacturing ecosystem. We employ multi-axis CNC machines with sub-micron positioning accuracy, automated inspection via coordinate measuring machines (CMM), and real-time process monitoring to ensure every part meets exact specifications. Whether producing titanium aerospace housings or stainless steel medical implants, our processes are designed to achieve and sustain tolerances that align with the most demanding engineering drawings.

The following table outlines key specifications that define our precision manufacturing capacity:

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.0001″ (2.5 µm) |

| Maximum Work Envelope | 2000 x 1000 x 800 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Plastics |

| CNC Equipment | 5-Axis Milling, CNC Turning, Swiss Machining, Wire EDM |

| Quality Standards | ISO 9001, AS9100D, ITAR Registered, ISO 13485 Support |

| Surface Finish | As fine as Ra 0.4 µm (16 µin) |

Precision is not an isolated function—it is the result of integrated engineering insight, disciplined process control, and a relentless focus on client success. For machine shops and OEMs in San Francisco, CA, partnering with a global leader like Wuxi Lead Precision Machinery ensures that innovation is never constrained by manufacturing limitations.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions meeting the stringent requirements of aerospace, medical, and high-tech industries. Our core strength lies in sophisticated 5-axis CNC machining, enabling the production of geometrically complex components with exceptional accuracy and surface finish in a single setup. This capability significantly reduces lead times, minimizes handling errors, and ensures superior part integrity compared to multi-setup 3-axis processes. We expertly machine a wide spectrum of materials including titanium alloys, Inconel, stainless steels, aluminum alloys, and engineered plastics, adhering strictly to international standards and client-specific material certifications.

Our production floor integrates state-of-the-art 5-axis CNC machining centers from industry leaders, featuring high-speed spindles, robust construction for heavy cutting, and integrated probing systems for precise in-process verification. These machines handle work envelopes up to 1200 x 800 x 750 mm, accommodating substantial components while maintaining micron-level precision. Advanced CAM software drives efficient toolpath generation and simulation, optimizing cycle times and ensuring collision-free machining for the most intricate geometries. Material handling and fixturing solutions are meticulously designed to maintain rigidity and thermal stability throughout the machining cycle, critical for achieving consistent results on demanding projects.

Quality assurance is non-negotiable. Every critical dimension undergoes rigorous inspection using calibrated Coordinate Measuring Machines (CMM) featuring tactile and optical probes. Our CMMs operate within a temperature-controlled metrology lab, ensuring measurement stability and traceability to NIST standards. Full first-article inspection reports (FAIR) and comprehensive dimensional reports are standard deliverables, providing clients with complete verification data against original CAD models and engineering drawings. This systematic approach to quality control guarantees that every component shipped meets or exceeds specified tolerances and functional requirements.

The following table details our standard achievable geometric and dimensional tolerances under controlled production conditions. Tighter tolerances are attainable for critical features upon engineering review and process validation.

| Feature Type | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | Typical for milled/turned features |

| Geometric (GD&T) | ±0.010 mm (±0.0004″) | Position, Profile, Runout |

| Surface Roughness | Ra 0.4 µm (16 µin) | Achievable on critical surfaces |

| Hole Diameter | H7 / g6 | Standard fit classes |

| Flatness | 0.010 mm per 100 mm | Over specified surface area |

These capabilities translate directly into tangible value for San Francisco CA machine shops and their end clients. We provide reliable capacity augmentation for complex, high-mix production runs, reduce total cost of ownership through optimized manufacturing processes, and deliver components ready for immediate assembly – mitigating supply chain risks and accelerating time-to-market. Partner with Wuxi Lead Precision Machinery for precision manufacturing where uncompromising quality meets advanced technical execution.

Material & Finish Options

Material selection is a critical step in precision manufacturing, directly influencing performance, durability, and cost-efficiency of end components. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-performance industries including aerospace, medical, and industrial automation. Our expertise enables us to guide clients in selecting the optimal combination of base materials and surface finishes tailored to application demands.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications where weight reduction is essential without compromising structural integrity. The most commonly used grade, 6061-T6, offers good weldability and moderate strength, making it ideal for prototyping and production across diverse sectors. For more demanding environments, 7075-T6 provides superior strength, often used in aerospace components, though with reduced corrosion resistance compared to 6061.

Steel remains the backbone of heavy-duty applications due to its high tensile strength, wear resistance, and affordability. Among the various types, 4140 and 1018 steels are frequently specified. 4140, an alloy steel, delivers excellent toughness and response to heat treatment, making it suitable for shafts, gears, and tooling. 1018, a low-carbon steel, is valued for its machinability and weldability, commonly used in jigs, fixtures, and structural parts. Stainless steel grades such as 304 and 316 offer enhanced corrosion resistance, critical in medical and marine environments.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice when extreme strength-to-density ratio and resistance to high temperatures and corrosion are required. It is extensively used in aerospace, defense, and biomedical implants. Despite higher material and machining costs, titanium’s long-term performance in aggressive environments justifies its use in mission-critical applications.

Surface finishing plays a pivotal role in enhancing both functional and aesthetic properties. Anodizing, especially Type II and Type III (hardcoat), is a widely used electrochemical process for aluminum. It increases surface hardness, improves wear resistance, and allows for color coding through dye integration. Type III anodizing produces a thicker, more durable oxide layer, suitable for parts exposed to high abrasion or corrosive conditions.

Below is a comparative overview of key material properties and anodizing specifications:

| Material / Finish | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Key Advantages |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Enclosures, brackets, automotive | Lightweight, corrosion resistant, easy to machine |

| Aluminum 7075-T6 | 572 | 2.8 | Aerospace, military components | High strength, excellent fatigue resistance |

| Steel 4140 | 655 | 7.85 | Shafts, tooling, machinery parts | High toughness, heat-treatable |

| Steel 1018 | 440 | 7.87 | Jigs, fixtures, low-stress parts | Good machinability, weldable |

| Titanium Ti-6Al-4V | 900 | 4.43 | Aircraft, medical implants | Exceptional strength-to-weight ratio, biocompatible |

| Anodizing (Type II) | N/A | N/A | Decorative, moderate protection | Corrosion resistance, aesthetic finish |

| Anodizing (Type III) | N/A | N/A | High-wear, industrial parts | Extreme durability, abrasion resistance |

Selecting the right material and finish requires a thorough understanding of operational conditions, lifecycle requirements, and cost targets. Wuxi Lead Precision Machinery supports clients through every phase of this decision-making process, ensuring optimal performance and value in every manufactured component.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for custom metal components, ensuring seamless transition from initial concept to flawless volume output. Our integrated workflow eliminates traditional handoff errors and guarantees adherence to the most demanding specifications required by advanced industries, including those served by precision machine shops in San Francisco, CA.

The process initiates with collaborative Design Finalization and DFM Analysis. Our engineering team works directly with client CAD models, performing comprehensive Design for Manufacturability reviews. We identify potential machining constraints, material optimization opportunities, and tolerance stack-up risks before any metal is cut. This proactive analysis, utilizing advanced simulation software, prevents costly revisions later and establishes the foundation for zero-defect production. Client approval of the finalized, manufacturable design package is the mandatory gateway to prototyping.

Prototyping and Process Validation follows immediately. We produce initial physical samples using the exact CNC equipment, tooling, and materials designated for mass production. Each prototype undergoes metrology-grade inspection against all critical dimensions and surface finish requirements. First-article inspection reports (FAIRs) are generated, detailing GD&T compliance and material certifications. Crucially, this phase validates not only the part geometry but also the entire machining program, fixture design, and inspection protocol. Client sign-off on the prototype and its documentation confirms process readiness.

Zero-Defect Mass Production leverages the validated process under stringent statistical process control (SPC). Every production run begins with a documented first-piece inspection. Real-time SPC monitoring tracks key process variables and critical dimensions on the shop floor. Our closed-loop correction system automatically triggers holds for any parameter approaching tolerance limits, enabling immediate adjustment before non-conforming parts are produced. Full traceability, from raw material heat numbers to individual machine tool performance data, is maintained. Final inspection employs a risk-based sampling plan exceeding AQL 0.65, with 100% critical feature verification. Continuous in-process measurement ensures only conforming parts advance.

This disciplined progression – design validation, physical prototype verification, and SPC-driven volume manufacturing – is our guarantee of zero defects. We eliminate guesswork through data, ensuring every component shipped meets the exacting standards expected by leading California manufacturers.

Wuxi Lead Precision Capability Summary

| Parameter | Capability | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.0001″ (2.5 µm) standard | CMM, Optical Comparator, Height Gauges |

| Surface Finish | Ra 0.1 µm (4 µin) achievable | Profilometer, Comparison Standards |

| Materials | Aluminum, Stainless, Titanium, Inconel, Brass, Plastics | Material Certificates (MTRs) |

| Max Part Size | 800 x 500 x 400 mm (32″ x 20″ x 16″) | Laser Tracker, CMM Validation |

| Inspection Coverage | 100% Critical Features, SPC Sampling | FAIR, PPAP, Real-time SPC Charts |

Our commitment to this structured, data-driven process ensures San Francisco machine shops receive consistently perfect components, on time, enabling their own success in demanding high-tech markets. Partner with Wuxi Lead for manufacturing execution you can trust implicitly.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When sourcing precision metal components for high-performance applications, global engineering firms and advanced manufacturers trust Wuxi Lead Precision Machinery as a strategic partner. Based in China but serving clients across North America—including machine shops in San Francisco, CA—we deliver precision, reliability, and scalability that meet the strictest industry standards. Our ISO-certified manufacturing facility combines cutting-edge CNC technology with decades of engineering expertise to produce complex, mission-critical parts for aerospace, medical, robotics, and industrial automation sectors.

As a machine shop in San Francisco, CA, your reputation depends on delivering quality, meeting tight deadlines, and maintaining cost efficiency. Partnering with Wuxi Lead Precision enhances your competitive edge by providing access to high-precision, low-defect-rate components manufactured under rigorous quality controls. Whether you require low-volume prototypes or high-volume production runs, our end-to-end manufacturing solutions are tailored to your specifications, ensuring seamless integration into your workflow.

Our facility is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, Swiss-type lathes, and multi-tasking machines capable of handling complex geometries and tight tolerances. We specialize in aluminum, stainless steel, titanium, brass, and exotic alloys, supporting a wide range of surface finishes and secondary operations including anodizing, passivation, and precision grinding. With in-house design and engineering support, we collaborate closely with clients to optimize part manufacturability, reduce lead times, and lower total production costs.

We understand the unique demands of precision machining in high-tech markets. That’s why we maintain strict adherence to AS9100 and ISO 9001 standards, with full traceability, first-article inspection (FAI) reporting, and PPAP documentation available upon request. Every component is inspected using state-of-the-art CMMs, optical comparators, and surface roughness testers to ensure compliance with your engineering requirements.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling and turning |

| Tolerances | ±0.0002″ (5 µm) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr 2, Gr 5), Brass, Inconel, PEEK |

| Max Work Envelope | 2000 x 1000 x 800 mm |

| Surface Finishes | As-machined, bead blast, anodize (Type II & III), passivation, powder coating |

| Quality Standards | ISO 9001:2015, AS9100D, RoHS compliant |

| Lead Times | 7–15 days for prototypes, 15–25 days for production |

Partnering with Wuxi Lead Precision is more than outsourcing—it’s about building a reliable supply chain alliance. We communicate proactively, provide real-time production updates, and ensure consistent quality across every batch. For machine shops in San Francisco, CA, and beyond, we offer a scalable, cost-effective extension of your manufacturing capacity without compromising on precision or integrity.

Contact us today to discuss your next project. Email [email protected] and connect with our engineering team to receive a fast, detailed quotation and technical consultation. Let Wuxi Lead Precision become your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.