Technical Contents

Engineering Guide: Machine Shop Salt Lake City

Engineering Insight: The Critical Role of Precision in Modern Machine Shop Operations

In the competitive landscape of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. For machine shops serving high-stakes industries such as aerospace, defense, and advanced medical technology, even micron-level deviations can result in catastrophic system failures or costly rework. This is especially true in regions like Salt Lake City, where growing demand for high-integrity components in both commercial and government sectors places increasing pressure on manufacturing partners to deliver flawless results.

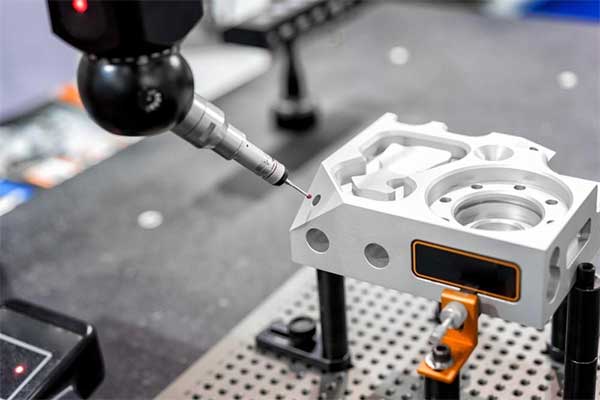

At Wuxi Lead Precision Machinery, we understand that precision extends beyond tight tolerances. It encompasses material integrity, geometric consistency, dimensional stability under thermal load, and repeatable accuracy across production runs. Our engineering team employs state-of-the-art CNC machining centers, coordinate measuring machines (CMM), and advanced metrology systems to ensure every component meets or exceeds customer specifications. With over 15 years of experience in high-precision manufacturing, we have supported mission-critical applications—including components used in Olympic-level sports engineering and certified military-grade systems—where failure is not an option.

Our work with international defense contractors and elite performance equipment developers has reinforced a key principle: precision must be engineered into the process, not inspected into it. This means rigorous process validation, real-time tool wear compensation, environmental controls, and full traceability from raw material to final inspection. For machine shops in dynamic markets like Salt Lake City, partnering with a supplier that maintains this level of engineering discipline ensures supply chain resilience and long-term program success.

Below is a summary of our core precision manufacturing capabilities:

| Specification | Performance Level |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Spindle Speed | 24,000 rpm |

| Surface Finish (Ra) | As low as 0.2 µm |

| Tolerance Range | ±0.003 mm to ±0.025 mm (depending on geometry and material) |

| Materials Processed | Aluminum Alloys, Titanium, Inconel, Stainless Steel, Tool Steels, and Exotic Alloys |

| Quality Certification | ISO 9001:2015, AS9100D (Aerospace) |

Precision manufacturing is not a one-size-fits-all solution. At Lead Precision, we tailor our processes to the functional requirements of each component, whether it’s a lightweight titanium bracket for a high-altitude drone or a corrosion-resistant manifold for subsea deployment. Our experience with Olympic engineering programs has taught us how marginal gains—achieved through micron-level accuracy—can define performance leadership. Similarly, our military-grade production runs demand full documentation, lot traceability, and adherence to MIL-STD protocols.

For machine shops in Salt Lake City and beyond, the future of manufacturing lies in precision, consistency, and technical partnership. Wuxi Lead Precision Machinery stands ready to support this evolution with proven engineering excellence and a relentless commitment to quality.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered to meet the rigorous demands of Salt Lake City’s aerospace, medical, and industrial sectors. Our core strength lies in high-precision 5-axis CNC machining, utilizing state-of-the-art DMG MORI and MAZAK platforms with integrated Heidenhain controls. These systems enable complex geometries, tight tolerances, and reduced setup times for components requiring multi-faceted accuracy. With a maximum work envelope of 1,200 x 800 x 750 mm and spindle speeds up to 24,000 RPM, we efficiently machine intricate parts from single setups—eliminating cumulative error risks inherent in 3-axis processes. Our engineers leverage Mastercam and Siemens NX CAM software to optimize toolpaths, ensuring minimal material waste and superior surface finishes down to Ra 0.4 µm. This capability is critical for Salt Lake City manufacturers producing turbine blades, surgical implants, and hydraulic manifolds where angular precision directly impacts performance.

Material versatility underpins our service offering. We routinely process challenging alloys including Inconel 718, Ti-6Al-4V, 17-4 PH stainless steel, and aerospace-grade aluminum 7075-T6. Each material undergoes strict in-process verification via thermal growth compensation systems, maintaining dimensional stability even during extended machining cycles. Our facility adheres to ISO 14644-1 Class 8 cleanroom standards for medical device production, ensuring particulate control for critical components.

Quality assurance is non-negotiable. Every component undergoes full CMM inspection using Zeiss CONTURA systems with calibrated accuracy of ±(2.5 + L/300) µm. Dimensional reports include GD&T analysis per ASME Y14.5, with real-time SPC data accessible to clients via our secure portal. First-article inspections (FAI) follow AS9102 standards for aerospace clients, while PPAP Level 3 documentation is standard for automotive and industrial contracts. This closed-loop QC process ensures zero defects reach your assembly line—proven by our 99.87% on-time delivery rate for repeat aerospace partners in the Intermountain West.

Precision Tolerance Specifications

| Feature Type | Standard Capability | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | ±0.0025 mm (±0.0001″) | CMM / Optical Comparator |

| Geometric (GD&T) | ±0.01 mm (±0.0004″) | ±0.005 mm (±0.0002″) | CMM with Probe Calibration |

| Surface Finish | Ra 0.8 µm (32 µin) | Ra 0.4 µm (16 µin) | Profilometer |

| Hole Concentricity | Ø0.025 mm (Ø0.001″) | Ø0.012 mm (Ø0.0005″) | CMM / Air Gaging |

Our Salt Lake City clients benefit from seamless integration of design-for-manufacturability (DFM) analysis during quoting. We identify potential production risks early—such as thin-wall deflection or deep-cavity tool access—reducing NRE costs by up to 30%. With 24/7 production capacity and dedicated project managers fluent in English and Mandarin, Wuxi Lead provides the responsive, technically rigorous partnership Utah’s advanced manufacturers require. Let us handle your most complex metal fabrication challenges with uncompromised precision.

Material & Finish Options

Material Selection for High-Precision CNC Manufacturing

Selecting the appropriate material is a critical step in custom metal manufacturing, directly influencing part performance, durability, and cost-efficiency. For machine shops in Salt Lake City and beyond serving aerospace, medical, and industrial automation sectors, aluminum, steel, and titanium represent the core materials used in precision CNC machining. Each offers distinct mechanical properties, machinability characteristics, and compatibility with finishing processes such as anodizing.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Grade 6061-T6 is particularly common in structural and mechanical applications due to its weldability and moderate strength. It responds exceptionally well to anodizing, forming a durable oxide layer that enhances surface hardness and wear resistance. This makes anodized aluminum ideal for components exposed to harsh environments or requiring aesthetic consistency.

Steel, particularly alloy and stainless grades such as 4140 and 304/316, delivers superior strength, hardness, and wear resistance. These properties make steel the preferred choice for high-stress applications including tooling, shafts, and industrial machinery components. While stainless steel offers inherent corrosion resistance, it does not anodize like aluminum. Instead, finishes such as passivation, polishing, or powder coating are typically used to enhance surface performance and appearance.

Titanium, especially Grade 5 (Ti-6Al-4V), is essential in high-performance industries where extreme strength-to-density ratios and resistance to elevated temperatures are required. Commonly used in aerospace and medical implants, titanium is challenging to machine due to its low thermal conductivity and high chemical reactivity with cutting tools. However, its biocompatibility and resistance to corrosion in saline and acidic environments justify its use in mission-critical applications. Titanium can be anodized, though the process differs from aluminum and is often used for color coding or minor surface protection rather than wear enhancement.

The table below summarizes key mechanical and finishing properties of these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Yes (Type II & III) | Enclosures, heat sinks, brackets |

| Steel (Alloy) | 655–1000 | 7.85 | 4140, 4340 | No | Shafts, tooling, high-load parts |

| Stainless Steel | 505–700 | 8.0 | 304, 316 | No | Medical devices, food processing |

| Titanium | 900–1000 | 4.5 | Ti-6Al-4V (Gr 5) | Yes (decorative/protective) | Aerospace, implants, marine components |

Understanding the interplay between material properties and finishing options ensures optimal part design and longevity. At Wuxi Lead Precision Machinery, we support global clients—including machine shops in Salt Lake City—with expert material selection, precision CNC machining, and advanced surface treatment services tailored to your engineering requirements.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production flow for custom metal components demanded by advanced manufacturers in regions like Salt Lake City. Our methodology eliminates ambiguity between design intent and physical output, ensuring seamless scalability from prototype to high-volume production while enforcing zero-defect standards. The process begins with collaborative design finalization. Our engineering team conducts mandatory Design for Manufacturability (DFM) analysis using Siemens NX and SolidWorks, identifying potential machining conflicts, material waste, or tolerance stack-ups before any metal is cut. This phase includes material certification validation and fixture strategy development, reducing downstream rework by up to 70%.

Prototyping transitions validated designs into physical verification. We utilize 5-axis milling and wire EDM on HAAS and DMG MORI equipment to produce 1–5 functional units within 10–15 business days. Each prototype undergoes comprehensive CMM inspection against ASME Y14.5 GD&T standards, with full metrology reports shared digitally for client sign-off. Critical characteristics like thread engagement, sealing surfaces, and dynamic clearances are stress-tested under simulated operational loads. Only after formal client approval do we advance to mass production, locking all process parameters in our MES system to prevent deviation.

Mass production leverages statistical process control (SPC) at every workstation. Our facility employs real-time tool wear monitoring, automated in-process gaging, and 100% first-article inspection. All critical dimensions are sampled hourly using Zeiss CONTURA CMMs, with data fed into predictive analytics software to detect drift before it impacts parts. Final inspection includes non-destructive testing (NDT) for aerospace/medical components and full material traceability via blockchain-secured batch records. This closed-loop system ensures every component meets the exact specifications defined in the prototyping phase, with defect rates consistently below 50 PPM.

Key Production Capabilities

| Parameter | Specification | Equipment/Standard |

|---|---|---|

| Materials | 6061-T6, 7075, 304/316 SS, Inconel 718 | Mill Test Reports (MTRs) |

| Tolerances | ±0.0002″ (5µm) positional | ASME Y14.5-2018 GD&T |

| Max Work Envelope | 2000 x 1000 x 800 mm | 5-axis DMG MORI DMU 85 mono |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | ISO 1302 compliant |

| Lead Time (Mass) | 4–6 weeks for 500+ units | JIT/Lean compliant |

Zero defects are non-negotiable. We achieve this through embedded quality gates—not end-of-line checks—and empower every operator to halt production for anomaly investigation. For Salt Lake City partners requiring complex, high-reliability metal parts, our process delivers bankable consistency across any volume. Contact our engineering team to implement this workflow for your next project, with seamless time-zone coordination and real-time production visibility.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your operations demand precision, reliability, and scalability in custom metal manufacturing, partnering with Wuxi Lead Precision Machinery means aligning with a global leader built on engineering integrity and advanced production capabilities. As a trusted provider of high-end CNC-machined components, we serve industries where performance cannot be compromised—automotive, aerospace, energy, medical, and industrial automation. Our facility in Wuxi, China, operates under stringent international quality standards, delivering parts that meet exacting specifications for clients across North America, including precision-focused machine shops in Salt Lake City.

Our collaboration model is designed for seamless integration with your supply chain. Whether you require low-volume prototyping or high-volume production runs, our team of senior CNC engineers and manufacturing specialists ensures every component is machined to micron-level accuracy. We specialize in complex geometries, tight-tolerance parts, and multi-axis machining using premium-grade materials such as aluminum alloys, stainless steel, titanium, and specialty alloys. Our facility is equipped with state-of-the-art 5-axis CNC centers, Swiss-type lathes, and automated inspection systems, enabling rapid turnaround without sacrificing quality.

What sets Lead Precision apart is our commitment to transparency, technical support, and responsive communication. From initial design review to final delivery, we provide real-time updates, detailed inspection reports, and full traceability documentation. Our engineering team actively engages in Design for Manufacturability (DFM) analysis to optimize your components for cost-efficiency and performance, reducing lead times and minimizing waste.

We understand the unique challenges faced by machine shops in competitive markets like Salt Lake City. That’s why we offer flexible production scheduling, JIT (Just-in-Time) delivery options, and scalable capacity to support your fluctuating demand cycles. By outsourcing precision components to Lead Precision, you gain access to advanced manufacturing technology and engineering expertise—without the overhead of capital investment or extended lead times.

For high-integrity metal parts that perform under real-world conditions, trust a partner that speaks your language—engineering excellence.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Machining Processes | 5-Axis CNC Milling, CNC Turning, Multi-Spindle Machining, Swiss Machining |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials Handled | Aluminum Alloys, Stainless Steel, Titanium, Brass, Inconel, Tool Steels |

| Standard Surface Finishes | As-machined, Anodizing (Type II & III), Passivation, Powder Coating |

| Quality Standards | ISO 9001:2015, Full CMM Inspection, First Article Inspection (FAI), PPAP |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Contact us today to discuss your next project. Email [email protected] and connect with our engineering team for a technical consultation tailored to your Salt Lake City operations. Let Wuxi Lead Precision Machinery be your offshore extension for precision, performance, and partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.