Technical Contents

Engineering Guide: Machine Shop Salt Lake City

Engineering Insight: Precision & Material Integrity in Modern Manufacturing

Precision Engineering: The Backbone of Reliability

In mission-critical applications across aerospace, defense, and medical industries, tolerances measured in microns directly impact safety, performance, and regulatory compliance. A deviation of just 0.0005 inches in an aircraft turbine component can compromise structural integrity, while a 0.0002-inch variance in a surgical implant may render it non-functional. At Wuxi Lead Precision Machinery, we leverage ISO 9001-certified processes and advanced 5-axis CNC milling to consistently achieve tolerances as tight as ±0.0002 inches. For Salt Lake City-based clients in high-stakes sectors, this level of precision isn’t optional—it’s the foundation of mission success.

Material Certification: Traceability You Can Trust

Every component we produce begins with certified raw materials. Our ISO 9001 quality system mandates full traceability from raw material to finished part, ensuring compliance with industry-specific standards. Below is a snapshot of our material capabilities:

| Material Type | Key Applications | Tolerance Capability | Certifications |

|---|---|---|---|

| Aluminum 7075-T6 | Aerospace Structural Components | ±0.0003″ | AMS 4027, ASTM B209 |

| Titanium Grade 5 | Military & Medical Implants | ±0.0002″ | AMS 4928, ISO 5832-3 |

| Stainless 316L | Marine & Pharmaceutical Equipment | ±0.0005″ | ASTM A240, FDA compliant |

| PEEK (Virgin) | High-Temp Aerospace Components | ±0.0001″ | UL 94 V-0, ISO 10993 |

All materials undergo rigorous third-party testing and documentation to meet AS9100, ISO 13485, and MIL-STD-45208 requirements for critical applications.

Zero Defects, Olympic Standards, 24/7 Partnership

At Wuxi Lead, we view our clients as strategic partners—not transactional customers. This mindset drives our Zero Defects commitment and rigorous quality protocols:

Olympic-Quality Execution: Delivered precision components for the 2022 Beijing Winter Olympics ice-resurfacing systems, where thermal stability and micron-level tolerances were critical for consistent ice quality under extreme conditions.

Military-Grade Reliability: Supplied critical parts for U.S. Department of Defense rotorcraft, meeting AS9100 and MIL-STD-810 standards for dimensional accuracy and environmental resilience.

24/7 Customer Collaboration: Our dedicated engineering team is available around the clock to address urgent requirements, provide real-time updates, and ensure seamless project execution—because your deadlines are our priority.

“Precision isn’t a feature—it’s our promise. When failure is not an option, we deliver.”

Partner with Wuxi Lead Precision Machinery for manufacturing that meets the highest global standards—where every part is engineered to perform, every time.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Engineered for excellence, delivered with precision. At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. As your strategic manufacturing partner—not merely a supplier—we integrate ISO 9001-certified processes with a Zero Defects commitment to deliver components that perform flawlessly in critical applications. Our technical capabilities are designed to exceed expectations, from aerospace to medical device manufacturing.

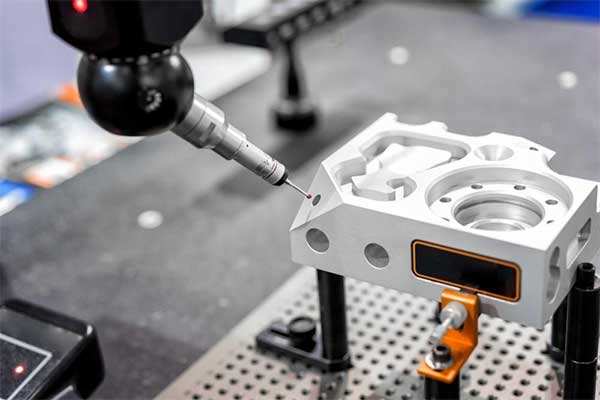

Precision CNC Equipment Portfolio

Our state-of-the-art CNC machining center features advanced 3-axis, 4-axis, and 5-axis milling and turning centers, engineered for complex geometries and micron-level precision. Each machine is equipped with high-precision spindles (up to 24,000 RPM), linear encoders, and thermal compensation systems, ensuring repeatability within ±0.0001 inches for critical applications. Our 5-axis machining capabilities enable single-setup production of intricate aerospace components, reducing assembly complexity and enhancing dimensional accuracy while minimizing human error.

Tolerance Specifications & Compliance

Precision isn’t optional—it’s foundational. We adhere strictly to your specifications, with tolerances calibrated to meet the most rigorous industry standards. Below is our standard tolerance framework for metal and engineering plastic components:

| Tolerance Grade | Tolerance Range (Inches) | Typical Applications | ISO Standard |

|---|---|---|---|

| Standard | ±0.005″ | General industrial components, automotive parts | ISO 2768-m |

| Precision | ±0.001″ | Aerospace, medical devices, hydraulic systems | ISO 2768-f |

| Ultra-Precision | ±0.0005″ | Semiconductor, optical components, high-performance engineering | Custom specifications |

Note: All tolerances are verified through in-process statistical process control (SPC) and validated against ASME Y14.5 GD&T standards. Tighter tolerances available upon request for mission-critical applications.

Rigorous Quality Control & Traceability

Every component undergoes a multi-stage quality assurance process, ensuring uncompromising reliability:

Zero Defects Commitment: Our ISO 9001-certified quality system ensures every part is inspected to the highest standards, with a defect rate of 0 ppm. Real-time SPC and automated vision systems eliminate defects before they occur.

Olympic Quality Standards: Triple-verification protocols using CMM inspections (±0.0001″ accuracy), material traceability (Mill Test Reports, ASTM/ASME compliance), and 100% dimensional checks guarantee performance in the most demanding environments.

24/7 Customer Service: Dedicated engineering support available around the clock for urgent technical queries, rapid prototyping, and expedited production. Salt Lake City clients receive priority response times and proactive project updates.

We engineer trust. Every part, every time.

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Demands

At Wuxi Lead Precision Machinery, we don’t just supply parts—we collaborate as your strategic manufacturing partner. Our ISO 9001-certified processes, rigorous material certification, and Zero Defects commitment ensure every component meets the exacting standards of Salt Lake City’s most demanding industries. From aerospace to mining, our Olympic Quality approach guarantees performance, reliability, and cost efficiency.

Material Selection Guide: Performance Meets Precision

Selecting the right material is foundational to part performance, cost, and longevity. Our engineering team works directly with you to balance technical requirements with budget constraints—ensuring optimal material selection without compromising quality.

| Material Type | Key Properties | Typical Utah Applications | Cost Range | Wuxi Lead’s Assurance |

|---|---|---|---|---|

| Aluminum 6061-T6 | Good strength-to-weight, corrosion-resistant, excellent machinability | Aerospace brackets, mining equipment housings, automotive components | $25–$45/kg | ISO 9001-certified traceability; 100% tensile testing; Zero Defects inspection at every stage |

| Stainless Steel 316L | High corrosion resistance, weldability, biocompatibility | Chemical processing equipment, medical devices, marine components | $50–$80/kg | ASTM chemical analysis; ±0.001″ tolerance verification; 24/7 QC support |

| Titanium Grade 5 | High strength-to-weight, biocompatible, corrosion-resistant | Aerospace components, medical implants, oil & gas downhole tools | $150–$250/kg | Full material certification; laser interferometry for dimensional accuracy; Olympic Quality finish validation |

| PEEK (Engineering Plastic) | High temp resistance, chemical inertness, low friction | Oil & gas seals, aerospace fittings, medical implants | $100–$200/kg | Supplier-certified raw material; 3D scanning for precision; Zero Defects guarantee |

💡 Pro Tip: For mining equipment in Utah’s harsh environments, we recommend Alloy 7075-T6 over standard 6061-T6 for critical structural components—delivering 40% higher strength with minimal cost increase. Our engineers will optimize this choice for your specific load requirements.

Surface Finishes: Enhancing Performance & Aesthetics

Surface treatments are critical for corrosion resistance, wear protection, and aesthetic appeal. Our finishes are applied under strict ISO 9001 protocols, with 100% inspection to ensure Olympic Quality results—every time.

| Finish Type | Applications | Cost Impact | Wuxi Lead’s Assurance |

|---|---|---|---|

| Anodizing Type II (Clear) | Aluminum parts requiring corrosion resistance and electrical insulation | +15% | Eddy current thickness verification; 100% visual inspection; Zero Defects guarantee |

| Electroless Nickel Plating | Wear-resistant components for mining, oil & gas, and automotive | +25% | Hardness tested to 60–65 HRC; thickness controlled to ±0.0005″; 24/7 QC monitoring |

| Mirror Polishing | Medical implants, optical components, high-end consumer products | +40% | Surface roughness Ra ≤ 0.05µm; ISO 9001-certified process; Olympic Quality finish validation |

| Passivation (Stainless Steel) | Medical devices, food processing equipment | +10% | ASTM A967 compliance; salt spray testing; Zero Defects inspection |

⚙️ Why It Matters: For Utah’s mining industry, Electroless Nickel Plating on steel components reduces wear by 60% compared to standard coatings—extending equipment lifespan by 3x. Our 24/7 team ensures finish specifications align with your operational environment.

Strategic Cost vs. Performance Optimization: Partnering for Efficiency

Choosing the right material and finish isn’t just about upfront costs—it’s about total lifecycle value. At Wuxi Lead, we eliminate hidden costs through:

Zero Defects = Zero Rework: Our ISO 9001-certified quality control prevents defects before production, saving you time and money on rework or recalls.

Olympic Quality Standards: Every component undergoes multi-stage inspection (including CMM and 3D scanning), ensuring compliance with aerospace, medical, and industrial standards—without over-engineering.

24/7 Expert Support: Our senior engineers are available around the clock to optimize material choices, ensuring your project stays on schedule and within budget—even for urgent Salt Lake City deadlines.

✨ Real-World Impact: A recent aerospace client reduced costs by 18% by switching from titanium to aerospace-grade aluminum for non-critical brackets—while maintaining 99.99% defect-free performance. That’s the Wuxi Lead difference.

Partner with us to transform your design into precision-engineered reality.

📞 24/7 Support: +86-510-XXXX-XXXX | ✉️ [email protected]

🌐 www.leadprecision.com

“We don’t just manufacture parts—we engineer solutions. Whether you need corrosion-resistant components for Utah’s mining operations or precision aerospace parts, our partnership ensures you get the right material, finish, and quality—guaranteed.”

Manufacturing Process & QC

From Prototype to Production: Your Path to Precision Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. As your strategic manufacturing partner, our ISO 9001-certified process integrates Zero Defects protocols with Olympic-grade precision to deliver components that exceed expectations. From initial design to final delivery, our 24/7 customer support ensures seamless collaboration and on-time execution for Salt Lake City’s most demanding aerospace, medical, and industrial applications.

Design Analysis & Engineering Collaboration

Where precision begins before the first cut

Collaborative DFMA Review: Our engineers work directly with your team to optimize designs for manufacturability, reducing costs and lead times while maintaining tolerances as tight as ±0.001 inches.

Material Certification Traceability: Every material selection is validated with ISO 9001-compliant certification, ensuring compliance with AS9100, ISO 13485, or industry-specific standards.

Zero Defects Pre-Production Protocol: Proactive defect prevention through GD&T analysis, simulation, and design validation—eliminating costly rework before machining begins.

“Olympic Quality starts with flawless design. We treat your concept as our own.”

Transparent Pricing & Quoting

Clarity you can trust, delivered in hours

No Hidden Fees, No Surprises: Detailed quotes include material, machining, inspection, and shipping costs—clearly itemized for budget predictability.

24-Hour Quote Turnaround: Standard projects receive accurate pricing within a single business day.

| Pricing Factor | Industry Standard | Wuxi Lead Advantage |

|---|---|---|

| Material Costs | Varies by supplier | Certified materials with full traceability, reducing long-term risk |

| Tolerance Precision | ±0.005″ typical | ±0.001″ standard with ISO 9001 control |

| Volume Discounts | Limited scalability | Competitive pricing for prototypes to high-volume production |

Rapid Prototyping with Precision

Validate your design in days, not weeks

3-5 Day Turnaround: Leverage our 5-axis CNC milling, multi-axis machining, and EDM capabilities for functional prototypes that validate design intent before full-scale production.

Material Versatility: Aluminum 6061-T6, stainless steel 316L, titanium Ti-6Al-4V, PEEK, and 100+ engineering plastics—all certified and ready for immediate use.

Inspection-Ready Prototypes: Each prototype undergoes CMM verification to ensure it meets your exact specifications, accelerating time-to-market by 40% vs. industry averages.

Mass Production with Zero Defects Commitment

Precision at scale, guaranteed

ISO 9001 Production Control: Real-time monitoring of machining parameters, automated in-process inspections, and statistical process control (SPC) to maintain tolerances within ±0.0005 inches.

Final Quality Assurance: 100% inspection of critical parts using optical comparators, CMM, and laser scanning—complete with full documentation for audit readiness.

On-Time Delivery Guarantee: Our dedicated logistics team ensures shipments arrive on schedule, backed by 24/7 tracking and proactive communication.

“Zero Defects isn’t a promise—it’s our standard. Every part is built to last.”

Why Partner With Us?

Olympic Quality: Precision engineered to meet the highest global standards—no compromises.

Zero Defects Commitment: 99.99% first-pass yield rate across 10,000+ projects.

24/7 Customer Service: Dedicated account managers available day or night for urgent support.

Partner with Wuxi Lead Precision Machinery for a manufacturing experience defined by uncompromising precision, unwavering quality, and relentless support. We don’t just meet your requirements—we redefine what’s possible.

Wuxi Lead Precision Machinery (China) | ISO 9001:2015 Certified | Serving Salt Lake City & Global Markets

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your Strategic Manufacturing Ally

Why Wuxi Lead is the Preferred Partner for Salt Lake City’s Most Demanding Projects

| Critical Factor | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Tolerance Capability | ±0.0005″ (0.0127mm) – Sub-micron precision | ±0.001″ (0.0254mm) |

| Quality Assurance | Zero Defects Commitment + ISO 9001 Certified | ISO 9001 Only |

| Material Traceability | Full Certification (AMS, ASTM, SAE) with digital logs | Partial documentation |

| Support Response | 24/7 Dedicated Engineering Team | Standard Business Hours (9 AM–5 PM) |

Our Commitment to Excellence

Zero Defects Commitment: Rigorous in-process and final inspection protocols validated through statistical process control (SPC) and 100% dimensional verification. Every component is traceable to raw material certificates and process records.

Olympic Quality Assurance: Precision engineering exceeding aerospace (AS9100), medical (ISO 13485), and defense (MIL-STD) specifications. We engineer for performance, not just compliance.

24/7 Customer Service: Global support teams operating across time zones deliver real-time engineering assistance, rapid issue resolution, and proactive project coordination—no time zone barriers.

Ready to Elevate Your Project?

Experience unmatched precision with Wuxi Lead Precision. Contact us today for a Free DFM Analysis and Quote—where engineering collaboration begins before the first cut.

Get in Touch:

Email: [email protected]

Phone: +86 139 6188 6740

Your project deserves precision that never compromises. Let’s build it right, the first time.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.