Technical Contents

Engineering Guide: Machine Shop Quotes Online

Engineering Insight: The Critical Role of Precision in Online Machine Shop Quotes

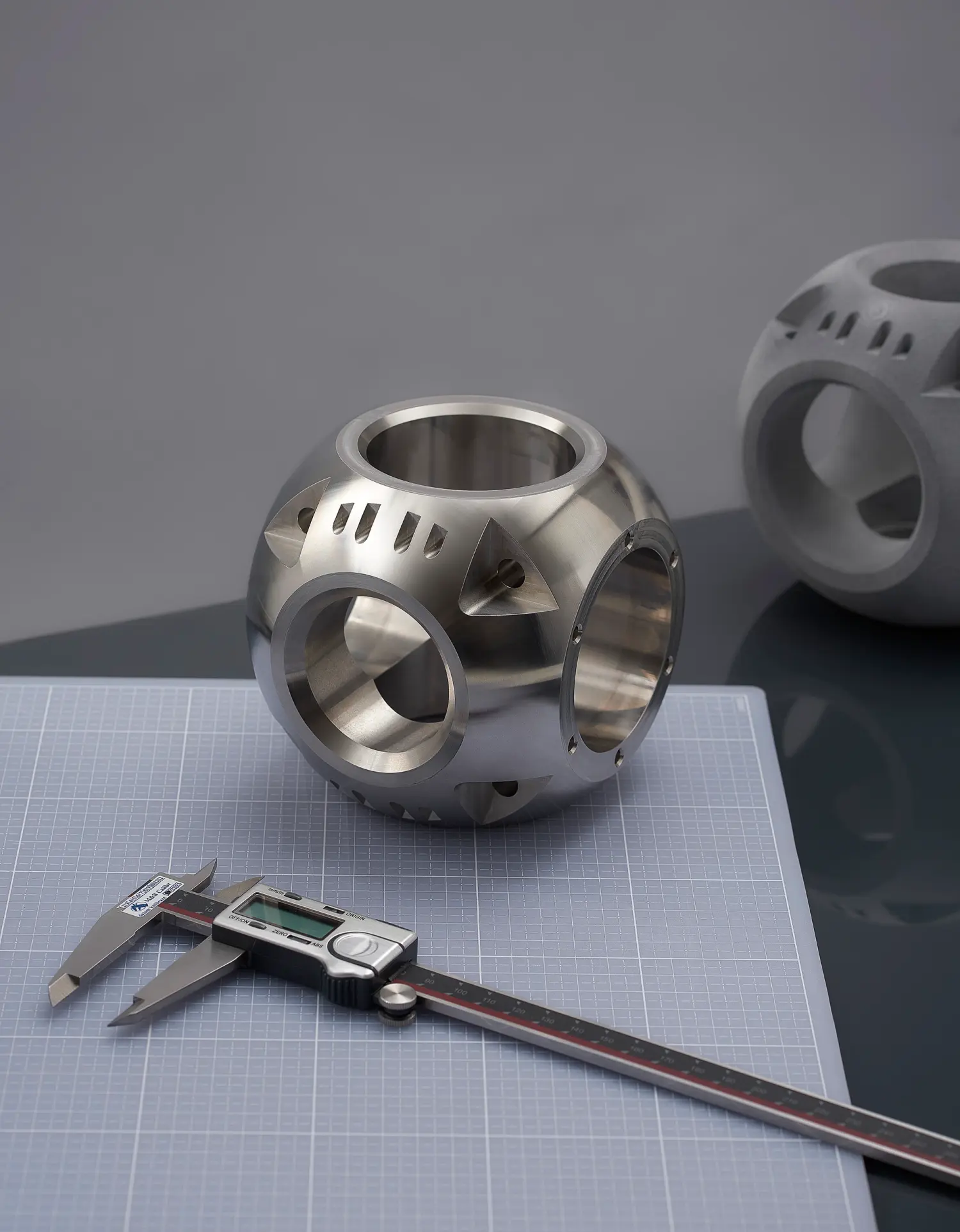

In the high-stakes world of custom metal manufacturing, precision is not merely a quality objective—it is a foundational requirement. When sourcing machine shop quotes online, engineering teams and procurement managers must evaluate more than just lead times and unit costs. They must assess the supplier’s demonstrated capability to deliver consistent dimensional accuracy, surface integrity, and material performance under exacting specifications. At Wuxi Lead Precision Machinery, we understand that every micron matters—especially when components are destined for aerospace, defense, or high-performance industrial systems.

Our experience in delivering mission-critical parts for Olympic-standard equipment and military-grade applications has reinforced a simple truth: precision begins long before the first cut. It starts with accurate engineering interpretation, robust process planning, and a culture of zero-defect manufacturing. When clients request machine shop quotes online, we do not respond with generic pricing models. Instead, we conduct a thorough technical review of CAD models, material selections, tolerances, and functional intent. This engineering-first approach ensures that the quote reflects not just cost, but capability, reliability, and long-term performance.

Many online quoting platforms emphasize speed over scrutiny, often leading to misaligned expectations. At Lead Precision, we balance digital efficiency with human expertise. Our quoting engineers analyze geometric dimensioning and tolerancing (GD&T), assess fixturing challenges, and evaluate secondary operations such as heat treatment or precision grinding. This depth of analysis prevents costly revisions, reduces scrap rates, and ensures first-time-right production—critical for low-volume, high-complexity orders common in advanced manufacturing sectors.

Our facility in Wuxi integrates state-of-the-art CNC machining centers with in-house metrology labs equipped with coordinate measuring machines (CMM) and optical comparators. This enables real-time verification of critical features, ensuring compliance with ISO 2768-mK and customer-specific inspection protocols. Whether machining titanium alloys for defense subsystems or aluminum enclosures for precision instruments, our process control guarantees repeatability across batches.

Below is a summary of our core machining capabilities and precision standards:

| Specification | Detail |

|---|---|

| Machining Tolerances | ±0.005 mm (standard), down to ±0.001 mm (tight-tolerance) |

| Surface Finish | Ra 0.4 μm (typical), down to Ra 0.1 μm (polished/precision ground) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, Tool Steels |

| Max Work Envelope | 1200 x 800 x 600 mm (4-axis), 800 x 500 x 500 mm (5-axis) |

| Certifications | ISO 9001:2015, ITAR-registered (pending), Military Drawing Compliant |

| Secondary Operations | Heat treatment, anodizing, passivation, precision grinding, thread rolling |

Precision is not an add-on—it is engineered into every stage of production. When evaluating machine shop quotes online, discerning buyers look beyond the price per unit. They seek partners with proven technical depth, stringent quality controls, and a track record in high-reliability industries. Wuxi Lead Precision Machinery delivers that assurance, combining advanced manufacturing technology with decades of applied engineering excellence.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising quality for the most demanding custom metal manufacturing projects. Our technical foundation is built upon advanced multi-axis machining and rigorous metrology, ensuring components meet exacting global standards from prototype through high-volume production. We specialize in transforming complex 3D CAD models into high-integrity metal parts with exceptional repeatability, directly supporting efficient online quotation processes through proven capability transparency.

Our core machining capability centers on a modern fleet of 5-axis CNC milling and turning centers from industry leaders like DMG MORI and MAZAK. These machines feature travel ranges up to 1200 x 800 x 600 mm with integrated high-speed spindles (up to 24,000 RPM) and robust rotary tables capable of handling workpieces up to 500 kg. This configuration enables complete machining of intricate geometries—such as impellers, orthopedic implants, aerospace structural brackets, and fluid system manifolds—in a single setup. We routinely machine challenging materials including titanium alloys (Ti-6Al-4V), Inconel 718, hardened tool steels (up to 60 HRC), aluminum alloys (7075-T6), and specialty brasses, minimizing secondary operations and distortion risks inherent in multi-setup processes.

Precision is non-negotiable. Every critical dimension undergoes verification using our Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMMs), operating within a climate-controlled metrology lab maintained at 20°C ±0.5°C. Our CMMs feature VAST XT gold probes and PC-DMIS software for full 3D geometric dimensioning and tolerancing (GD&T) analysis, including complex profile, position, and runout checks. All measurements are traceable to national standards via certified reference artifacts, with comprehensive inspection reports provided as standard. This integrated quality loop ensures dimensional conformity and process stability, forming the bedrock of reliable online quoting where tolerance expectations are clearly defined and consistently met.

The following table details our standard and achievable tolerance capabilities across common feature types, reflecting our machine performance and inspection rigor:

| Feature Type | Standard Capability | Tight Capability (Achievable) | Measurement Method |

|---|---|---|---|

| Linear Dimension | ±0.010 mm | ±0.005 mm | CMM, High-Precision Mic |

| Geometric (Flatness) | 0.020 mm | 0.008 mm | CMM, Optical Flat |

| Geometric (Roundness) | 0.010 mm | 0.005 mm | CMM, Roundness Tester |

| Positional (Holes) | ±0.015 mm | ±0.008 mm | CMM |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Profilometer |

This documented capability profile allows our engineering team to rapidly assess project feasibility during the online quote phase. We avoid overpromising by aligning quoted tolerances with our verified machine performance envelopes and inspection capacity. Clients receive accurate, realistic pricing based on achievable manufacturing parameters—not theoretical ideals—accelerating project launch while guaranteeing the precision their applications demand. Partner with Wuxi Lead for technical depth you can measure.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the right material is critical in achieving optimal performance, durability, and cost-efficiency in custom metal components. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC machining of aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages. Understanding the characteristics of these materials ensures that your design meets functional requirements while minimizing production complexity.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Grade 6061-T6 is particularly common for prototyping and production parts, offering good machinability and weldability. Its lightweight nature reduces overall system mass without sacrificing structural integrity, making it ideal for dynamic or portable applications.

Steel, particularly alloy and stainless grades such as 4140 and 304/316, delivers superior strength, wear resistance, and thermal stability. Stainless steels provide excellent corrosion resistance, making them suitable for medical devices, food processing equipment, and marine environments. While heavier than aluminum, steel’s robustness ensures long-term reliability under high stress or elevated temperatures.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme performance applications. With a strength comparable to many steels but at nearly half the density, titanium excels in aerospace, defense, and biomedical sectors. It maintains integrity under high temperatures and exhibits outstanding resistance to fatigue and corrosion—even in saltwater environments. However, its high cost and challenging machinability require experienced CNC processing to avoid tool wear and dimensional inaccuracies.

Surface finish selection further enhances performance and aesthetics. Anodizing is a key post-processing option for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing allows for color dyeing and is commonly used for consumer and industrial parts. Type III (hardcoat) anodizing delivers a thicker, more durable layer suitable for high-wear environments.

Below is a comparative overview of key material properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HB) | Common Grades | Key Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 | 95 | 6061-T6, 7075-T6 | Aerospace, Electronics |

| Stainless Steel | 7.9 | 505–760 | 150–200 | 304, 316, 17-4PH | Medical, Marine, Food Equipment |

| Alloy Steel | 7.8 | 655 | 210 | 4140, 4340 | Automotive, Industrial |

| Titanium | 4.5 | 900 | 340 | Ti-6Al-4V (Grade 5) | Aerospace, Defense, Medical |

Choosing the appropriate material and finish directly impacts component lifecycle, assembly compatibility, and operational success. At Wuxi Lead, we support clients in evaluating these factors to ensure precision, consistency, and value in every manufactured part.

Manufacturing Process & QC

Production Process: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our online quoting process is the initial step in a rigorously defined production journey engineered for Zero Defects. We understand that a competitive quote is meaningless without the capability to deliver flawless components consistently. Our integrated workflow ensures every stage builds upon the last, transforming your digital design into high-integrity metal parts, whether for a single prototype or full-scale production.

The process begins with meticulous Design Review and DFM Analysis. Upon receiving your CAD files through our online portal, our engineering team conducts a comprehensive assessment. We verify geometric feasibility, material suitability, and potential manufacturability issues before quoting. This proactive analysis prevents costly errors downstream and ensures the quote accurately reflects achievable precision, not theoretical ideals. Critical tolerances, surface finishes, and material certifications are confirmed at this stage, forming the bedrock of our Zero Defects commitment.

Prototyping is not merely a formality; it is the critical validation phase. Using the exact production-grade CNC equipment and materials specified for your project, we manufacture initial samples. Each prototype undergoes rigorous First Article Inspection (FAI) against your original specifications. Dimensional verification is performed using calibrated Coordinate Measuring Machines (CMMs), surface roughness testers, and optical comparators. Material test reports and process documentation are generated, creating a full digital thread traceable to your order. Only after your formal sign-off on these validated prototypes do we proceed to mass production, eliminating assumptions.

Mass production leverages the proven parameters from prototyping within a closed-loop quality management system. Our state-of-the-art CNC machining centers operate under real-time process monitoring. In-process inspections at defined intervals, combined with final 100% functional and dimensional checks against the FAI baseline, guarantee consistency. Statistical Process Control (SPC) data is continuously analyzed, enabling immediate corrective action if trends approach tolerance limits. This systematic approach, embedded from quoting through shipment, is how we achieve Zero Defects – protecting your timeline, reputation, and bottom line.

The following table summarizes key capabilities underpinning this process:

| Parameter | Capability Range | Quality Control Method |

|---|---|---|

| Materials | Aluminum Alloys, Stainless Steels (303, 304, 316, 17-4PH), Titanium, Brass, Copper, Plastics | Material Certificates (MTRs), Spectrographic Analysis |

| Tolerances | ±0.005 mm (0.0002″) standard; ±0.001 mm (0.00004″) achievable | CMM, Optical Comparator, Micrometers, Gauges |

| Surface Finish | Ra 0.8 µm (32 µin) standard; Ra 0.2 µm (8 µin) achievable | Surface Roughness Testers, Visual Standards |

| Max Part Size | 1200 x 800 x 600 mm (47 x 31 x 24 in) | Laser Trackers, Large-Volume CMM |

| Inspection | 100% Critical Dimensions, SPC on Key Features | CMM Reports, FAI Documentation, SPC Charts |

This seamless integration of design validation, prototyping rigor, and production control, initiated by an accurate online quote, ensures Wuxi Lead delivers components that meet exacting specifications without compromise. Trust precision engineered for zero failure.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that in high-performance industries such as aerospace, automotive, medical, and industrial automation, precision is non-negotiable. When sourcing custom metal components, every micron matters—and so does every timeline. That’s why global manufacturers trust us as their strategic partner for end-to-end CNC machining, milling, turning, and precision fabrication services. Our commitment to excellence begins the moment you request a machine shop quote online and continues through delivery and beyond.

We are not just another contract manufacturer. At Lead Precision, we engineer solutions. Our facility in Wuxi, China, is equipped with state-of-the-art CNC centers, 5-axis machining platforms, and advanced quality control systems, enabling us to deliver complex parts with tolerances as tight as ±0.002 mm. Our team of senior CNC engineers and manufacturing specialists works closely with your design and engineering staff to optimize manufacturability, reduce lead times, and ensure full compliance with international standards including ISO 9001:2015 and AS9100D.

Whether you’re prototyping a new product or scaling up for high-volume production, our online quoting system streamlines the process without sacrificing technical depth. Upload your CAD files, specify materials and finishes, and receive a detailed, transparent quote—backed by engineering insight. But don’t stop at the quote. Engage directly with our technical sales team to refine your design for cost-efficiency, material performance, and long-term reliability.

We specialize in challenging alloys such as titanium, Inconel, stainless steel, aluminum, and specialty composites—materials commonly used in mission-critical applications. Our vertical integration allows us to control every stage of production, from raw material sourcing to final inspection, ensuring consistency and traceability across batches.

Below are key capabilities that define our service offering:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis to 5-axis CNC milling, CNC turning, multi-spindle machining |

| Tolerances | ±0.002 mm (±0.00008″) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Inconel 718, Brass, Copper, Tool Steels |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6″) |

| Surface Finishes | As-machined, anodizing (Type II & III), passivation, powder coating, polishing, bead blasting |

| Quality Standards | ISO 9001:2015, AS9100D, GD&T compliant, First Article Inspection (FAI) available |

| Lead Times | As fast as 7 days for prototypes, 15–25 days for production runs |

Ready to experience precision you can trust? Contact us today at [email protected] to speak with a senior engineer or request your machine shop quote online. Let Wuxi Lead Precision Machinery become your reliable partner in precision manufacturing—where quality, speed, and technical excellence converge.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.