Technical Contents

Engineering Guide: Machine Shop In Los Angeles Ca

Engineering Insight: Precision as the Non-Negotiable Foundation for Los Angeles Manufacturing

Los Angeles remains a critical hub for advanced aerospace, defense, medical device, and entertainment technology manufacturing. Within this demanding ecosystem, the term “precision” transcends marketing jargon; it is the absolute bedrock upon which project success, regulatory compliance, and long-term client trust are built. For machine shops operating in Los Angeles CA, achieving and consistently maintaining micron-level tolerances is not merely desirable—it is a non-negotiable requirement dictated by the stringent specifications of these high-stakes industries. Components failing to meet exacting dimensional, geometric, or surface finish standards can trigger catastrophic system failures, costly recalls, or project delays measured in months, not days. The complexity inherent in modern LA-based projects—often involving exotic alloys, intricate geometries, and zero-defect mandates—demands a manufacturing partner whose entire operational philosophy is engineered around precision mastery from raw material to final inspection.

Wuxi Lead Precision Machinery understands these pressures intimately. We have engineered solutions for applications where failure is inconceivable, including critical components for Olympic infrastructure projects demanding flawless performance under global scrutiny and precision subsystems integrated into classified military platforms requiring absolute reliability in extreme environments. This experience instills a rigorous, process-driven approach that permeates every facet of our operations. Our CNC machining centers, operating within tightly controlled environmental conditions, are calibrated and maintained to exceed ISO 2768-mK standards. Advanced metrology suites featuring multi-sensor CMMs, optical comparators, and surface profilers provide continuous verification, ensuring every part conforms to the most demanding blueprints before shipment. This commitment translates directly to tangible value for Los Angeles clients: reduced scrap rates, accelerated time-to-market, and the confidence that complex components will integrate seamlessly into final assemblies.

The following table illustrates the precision capabilities essential for high-end Los Angeles manufacturing projects and how Wuxi Lead Precision Machinery consistently exceeds baseline expectations:

| Spec Category | Wuxi Lead Precision Capability | Typical Industry Standard for High-End LA Work |

|---|---|---|

| Dimensional Tolerance | ±0.00004 inches (1 micron) | ±0.0002 inches (5 microns) |

| Geometric Tolerance | IT5 Grade or better | IT7 Grade |

| Surface Roughness (Ra) | 0.4 μm (16 μin) achievable | 1.6 μm (63 μin) typical spec |

| Material Complexity | Full capability with Inconel, Titanium, MP35N, Beryllium Copper | Standard aerospace alloys (7075, 6061) |

| Process Certification | AS9100D, ISO 9001:2015, NADCAP | ISO 9001:2015 common |

Choosing a manufacturing partner for Los Angeles CA projects requires looking beyond geography. While local proximity offers logistical advantages, the ultimate determinant of success is proven precision capability under real-world production conditions. Wuxi Lead Precision Machinery delivers the uncompromising accuracy, rigorous quality systems, and deep experience with mission-critical applications that Los Angeles innovators require. We partner with forward-thinking LA engineering teams not as a distant supplier, but as an integrated extension of their precision manufacturing capability—ensuring complex metal components meet the exacting standards demanded by the world’s most challenging industries, regardless of where the final assembly occurs. Precision, reliably delivered, is the only metric that truly matters.

Precision Specs & Tolerances

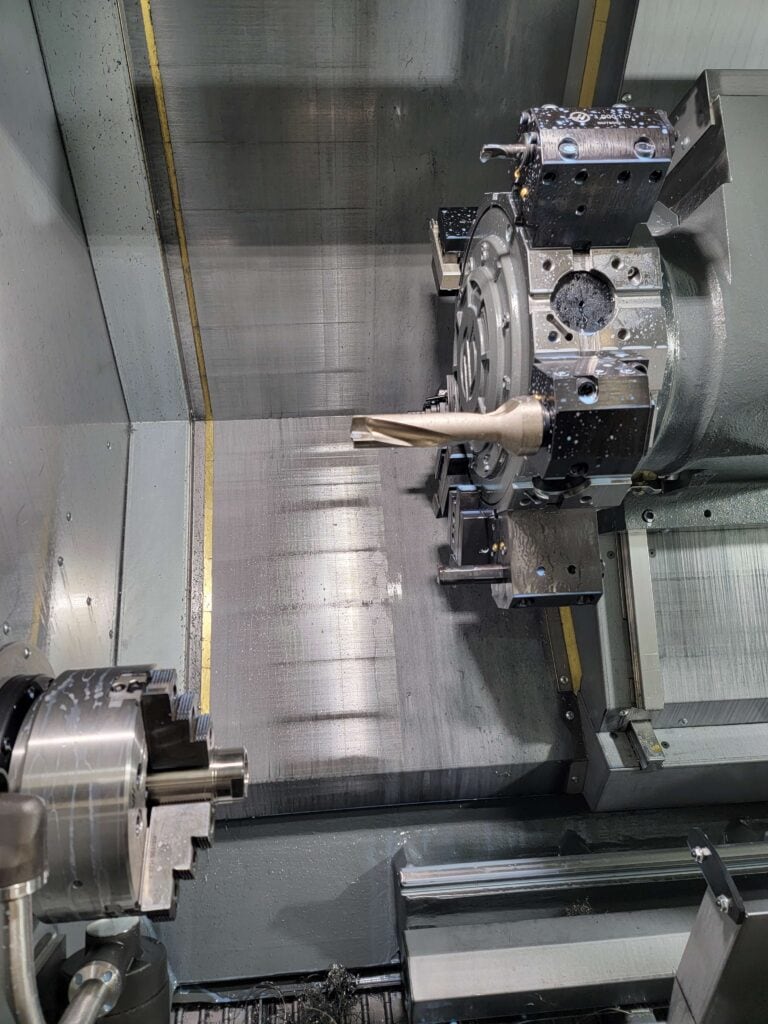

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for global clients requiring precision, consistency, and technical excellence. Our capabilities are built around state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with superior accuracy and surface finish. Designed for industries such as aerospace, medical, automotive, and industrial automation, our machining center supports the production of high-integrity components where tight tolerances and repeatable performance are non-negotiable.

At the core of our technical infrastructure is a full suite of 5-axis CNC machining centers. These systems allow simultaneous movement across five axes, providing unmatched flexibility in contouring and multi-sided machining without the need for multiple setups. This not only reduces cycle time and potential for human error but also ensures dimensional consistency across high-mix, low-volume, and large-scale production runs. Our machines are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to maintain optimal cutting conditions and prolong tool life.

Material versatility is a key strength. We routinely work with aluminum alloys, stainless steel, titanium, tool steels, and high-performance engineering metals such as Inconel and Hastelloy. Each material is processed using optimized toolpaths and cutting strategies tailored to its mechanical properties, ensuring minimal thermal distortion and maximum part integrity. Our programming team utilizes advanced CAM software to generate efficient, collision-free toolpaths, supporting both prototype development and full production scaling.

Quality assurance is integrated at every stage of manufacturing. All critical dimensions are verified using a Zeiss coordinate measuring machine (CMM), providing metrology-grade inspection with micron-level precision. The CMM system enables full first-article inspection (FAI) reporting, geometric dimensioning and tolerancing (GD&T) validation, and batch sampling in compliance with ISO 9001 standards. In addition to CMM, we employ surface roughness testers, optical comparators, and calibrated hand tools to ensure comprehensive quality control.

The table below outlines our standard machining tolerances, reflecting our commitment to precision and repeatability.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.025 mm | ±0.010 mm | Depending on geometry and material |

| Linear Dimensions (100–500 mm) | ±0.050 mm | ±0.025 mm | Measured at controlled ambient temperature |

| Hole Diameter | +0.025 / -0.000 mm | +0.010 / -0.000 mm | Reamed or precision bored |

| Positional Tolerance | ±0.025 mm | ±0.010 mm | Per GD&T, verified via CMM |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved with fine finishing passes |

| Angular Tolerance | ±0.1° | ±0.05° | Critical for mating surfaces and assemblies |

Our technical capabilities are reinforced by a process-driven culture focused on continuous improvement and on-time delivery. For engineering teams in Los Angeles and across North America, Wuxi Lead offers a reliable offshore partner with the precision, scalability, and quality systems required for mission-critical metal components.

Material & Finish Options

Material Selection for Precision Machined Components: Aluminum Steel Titanium

Material selection fundamentally impacts performance cost and manufacturability for Los Angeles precision machine shops serving aerospace medical and defense sectors. Choosing correctly between aluminum steel and titanium requires understanding application demands including strength weight corrosion resistance and thermal properties. Wuxi Lead Precision Machinery provides expert guidance ensuring optimal material pairing with your project requirements and our advanced CNC capabilities.

Aluminum alloys particularly 6061-T6 and 7075-T6 dominate aerospace and electronics due to their exceptional strength-to-weight ratio and machinability. 6061 offers good corrosion resistance and weldability making it ideal for structural components. 7075 provides superior strength for highly stressed parts like fittings though it is less corrosion resistant. Aluminum’s low density reduces component weight significantly a critical factor in aircraft and unmanned systems prevalent in Southern California manufacturing. Its excellent thermal conductivity also benefits heat sink applications.

Carbon and alloy steels such as 4140 4340 and 1018 remain essential for applications demanding high strength wear resistance and structural integrity. 4140 steel is a versatile workhorse for shafts gears and tooling requiring heat treatment. 4340 offers higher toughness for critical aerospace landing gear components. 1018 provides good machinability for lower-stress parts and prototypes. Steel’s higher density compared to aluminum is offset by its superior hardness and fatigue resistance under heavy loads common in industrial machinery.

Titanium Grade 5 (Ti-6Al-4V) is the premier choice for extreme environments demanding exceptional strength-to-weight ratio outstanding corrosion resistance and biocompatibility. Its use is critical in medical implants aerospace fasteners and marine components where failure is not an option. While significantly more expensive and challenging to machine due to low thermal conductivity and work hardening characteristics titanium’s performance justifies its use in high-value LA-area applications. Wuxi Lead employs specialized tooling and processes to machine titanium efficiently.

Anodizing is the standard surface finish for aluminum components enhancing corrosion resistance wear properties and providing an excellent base for adhesion. Type II Sulfuric Acid Anodizing offers good general protection and dyeing capability for identification. Type III Hardcoat Anodizing delivers a much thicker denser layer for severe wear resistance required in hydraulic systems or military hardware. Proper anodizing specification directly impacts part longevity in Southern California’s varied operational environments. Titanium requires alternative finishes like passivation or specialized coatings as anodizing processes differ fundamentally.

Material properties guide critical machining decisions. The following table provides key comparative specifications for common alloys:

| Material | Typical Alloy | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 2.7 | 310 | Good | Excellent (A) |

| 7075-T6 | 2.8 | 572 | Fair | Good (B) | |

| Steel | 4140 | 7.85 | 655 | Moderate | Fair (C) |

| 1018 | 7.87 | 440 | Low | Good (B) | |

| Titanium | Ti-6Al-4V | 4.43 | 900 | Excellent | Poor (D) |

Selecting the optimal material and finish requires balancing performance needs with production efficiency. Wuxi Lead Precision Machinery leverages deep metallurgical expertise and state-of-the-art CNC machining centers to transform your specified aluminum steel or titanium material into mission-critical components meeting the exacting standards of Los Angeles industry. Contact our engineering team for material consultation tailored to your next precision project.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we deliver precision-engineered metal components tailored to the exacting standards required by advanced manufacturing sectors, including aerospace, medical, and high-performance automotive industries. Our production process is meticulously structured to ensure zero defects and consistent quality from concept to full-scale delivery. Designed to support machine shops in Los Angeles, CA, and across North America, our integrated workflow combines engineering rigor with advanced manufacturing technology.

The process begins with Design Engineering, where our team collaborates closely with client specifications. Using advanced CAD/CAM software, we develop detailed 3D models and technical drawings that account for material behavior, tolerances, and functional performance. This stage includes Design for Manufacturability (DFM) analysis to optimize part geometry, reduce production risk, and ensure seamless transition into prototyping.

Prototyping follows as a critical validation phase. We produce functional prototypes using CNC machining, turning, and multi-axis milling to verify form, fit, and function. These prototypes undergo rigorous in-house inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. Feedback from this stage is incorporated into final design adjustments, ensuring that the part meets all performance criteria before entering mass production.

Mass Production is executed on our fully automated CNC production lines, where lean manufacturing principles and real-time quality monitoring eliminate variability. Each component is machined from certified materials—including aluminum alloys, stainless steel, titanium, and specialty alloys—with tolerances held to ±0.0002″. Our production cells operate under strict environmental and procedural controls, with Statistical Process Control (SPC) systems continuously tracking key parameters to detect and correct deviations instantly.

Throughout the entire process, our Zero Defects philosophy is enforced through multi-stage inspection protocols. First-article inspections, in-process checks, and final batch validation ensure complete conformance to AS9100 and ISO 9001 standards. All parts are traceable via serialized documentation, including material certifications and inspection reports.

The table below outlines key capabilities and specifications that define our production excellence:

| Parameter | Specification |

|---|---|

| Machining Tolerance | ±0.0002″ (5 µm) |

| Surface Finish | As low as Ra 0.4 µm (16 µin) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK |

| Production Capacity | Up to 50,000 units/month (scalable) |

| Quality Standards | ISO 9001, AS9100D, PPAP, FAI compliant |

| Lead Time (Prototype) | 7–10 business days |

| Lead Time (Mass Production) | 15–25 business days (volume-dependent) |

By integrating precision engineering with disciplined process control, Wuxi Lead ensures that every component shipped meets the highest standards of reliability and performance—critical for machine shops in Los Angeles, CA, where uptime and quality are non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Manufacturing Excellence

Los Angeles manufacturers demand precision, reliability, and seamless collaboration—especially in high-stakes sectors like aerospace, medical devices, and defense. At Wuxi Lead Precision Machinery, we bridge the Pacific without compromising on quality, speed, or communication. Our ISO 9001:2015 and AS9100D-certified facility in China operates as an extension of your engineering team, eliminating the traditional barriers of offshore manufacturing. We understand LA’s exacting standards: zero-defect tolerance, rapid prototyping cycles, and strict compliance with ITAR and DFARS. Our US-based project managers work within your timezone, ensuring real-time updates, transparent documentation, and engineering alignment at every stage. This isn’t offshoring—it’s strategic partnership engineered for California’s innovation ecosystem.

We specialize in turning complex, low-volume to mid-volume metal components into reality, leveraging 5-axis milling, Swiss turning, and multi-tasking centers to achieve micron-level accuracy. Our process integrates seamlessly with your CAD/CAM workflows, with full DFM support to optimize cost and lead time before a single chip is cut. Unlike generic suppliers, we prioritize material traceability, in-process CMM verification, and first-article inspection reports aligned to your specifications. Every component undergoes rigorous validation against ASME Y14.5 standards, ensuring fit, function, and regulatory compliance upon arrival at your LA facility.

Technical Capabilities at a Glance

| Specification | Capability Detail |

|---|---|

| Material Expertise | Aluminum 7075-T6, Titanium Grade 5, Inconel 718, Stainless 316L, Tool Steels |

| Tolerance Range | ±0.005 mm (±0.0002″) for critical features |

| Max Work Envelope | 5-axis: 1,200 x 800 x 750 mm; Swiss: Ø42 mm |

| Surface Finish | Ra 0.4 µm (16 µin) achievable |

| Certifications | ISO 9001:2015, AS9100D, ITAR Registered |

| Lead Time (Prototype) | 10–15 business days from approved drawing |

When you partner with Lead Precision, you gain a strategic ally invested in your project’s success—not just a vendor. Our engineers collaborate early to identify cost-saving opportunities without sacrificing performance, whether you’re scaling a medical implant or validating an aerospace subassembly. We absorb the complexity of international logistics, customs clearance, and quality assurance, delivering consignments directly to your Los Angeles dock with full documentation. This precision-focused approach has made us the trusted choice for Tier 1 suppliers across Southern California’s innovation corridor.

Don’t let geographic distance compromise your production timeline or quality benchmarks. Contact us today to discuss how Lead Precision can become your integrated manufacturing solution. Email [email protected] with your project specifications, and our US-based engineering team will respond within 4 business hours. Let’s build the future of precision manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.