Technical Contents

Engineering Guide: Machine Shop Bay Area

In the highly competitive landscape of custom metal manufacturing, precision is not merely a target—it is the foundation upon which reliability, performance, and trust are built. Nowhere is this more evident than in the operations of a high-performance machine shop, particularly in demanding environments such as the Bay Area, where innovation and engineering excellence converge. In such settings, the margin for error is measured in microns, and the demands of industries like aerospace, defense, and advanced robotics require machining capabilities that push the limits of modern technology.

At Wuxi Lead Precision Machinery, we understand that precision is more than tight tolerances; it is a holistic commitment to process control, material integrity, and repeatability. With over 15 years of experience serving global clients, our engineering team has developed a deep expertise in delivering components that meet the most stringent international standards. This includes precision parts used in Olympic-grade timing systems, where split-second accuracy is paramount, and in military-grade applications, where failure is not an option. These projects demand not only advanced CNC equipment but also a culture of continuous improvement, rigorous quality assurance, and a mastery of materials ranging from titanium alloys to high-strength stainless steels.

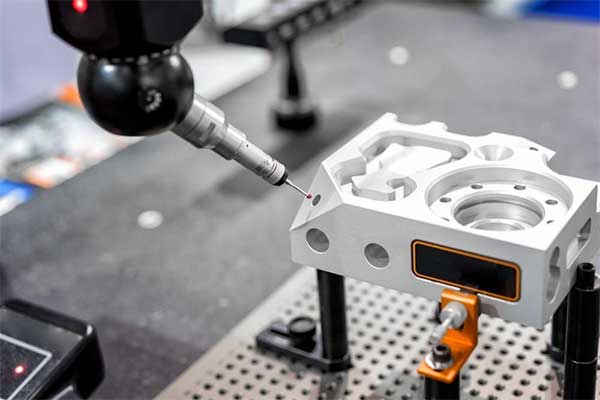

Precision in a modern machine shop is achieved through a combination of state-of-the-art machinery, skilled personnel, and integrated metrology. At Lead Precision, every component undergoes a multi-stage inspection process using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Our facility is equipped with 3-, 4-, and 5-axis CNC machining centers capable of complex geometries and high repeatability, ensuring that every part meets exact design specifications.

The following table outlines key technical capabilities that define our precision machining services:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 650 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish (Ra) | As low as 0.2 µm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Tolerances Achieved | ±0.01 mm (standard), down to ±0.003 mm (tight tolerance) |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace), ITAR registered |

Our experience with mission-critical applications has taught us that precision cannot be retrofitted—it must be engineered into every step of the manufacturing process. From initial design review to final inspection, we collaborate closely with clients to ensure that technical requirements are not only met but exceeded. Whether supporting rapid prototyping or high-volume production, Lead Precision delivers the consistency and accuracy that advanced industries demand.

In the Bay Area’s fast-moving technology ecosystem, partnering with a manufacturer that combines precision, experience, and global compliance is essential. At Wuxi Lead Precision Machinery, we bring Olympic and military-grade standards to every custom metal component we produce.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising precision for high-complexity metal components demanded by Bay Area innovators in aerospace, medical technology, and advanced electronics. Our integrated manufacturing ecosystem centers on advanced 5-axis CNC machining, enabling the production of geometrically intricate parts in a single setup. This eliminates cumulative error from multiple fixtures, ensuring critical feature relationships meet stringent design intent. Our Haas and DMG MORI 5-axis platforms handle materials from aerospace-grade titanium and Inconel to medical stainless steels and aluminum alloys, achieving surface finishes down to Ra 0.4 µm. Complex organic shapes, deep cavities, and undercuts are executed with repeatability that supports monolithic structure fabrication, reducing assembly costs for our clients.

Rigorous quality control is embedded at every process stage. All critical dimensions undergo verification via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), operating in a temperature-controlled metrology lab (20°C ±0.5°C). Our CMM protocols follow ISO 10360 standards, with full 3D scanning capabilities for first-article inspection reports (FAIR) and production lot validation. Statistical Process Control (SPC) data is actively monitored, ensuring process capability (Cp/Cpk) consistently exceeds 1.67 for critical features. This closed-loop system guarantees that every component shipped meets or surpasses aerospace AS9100 and medical ISO 13485 requirements, providing Bay Area OEMs with supply chain certainty.

The table below details our standard achievable tolerances across common materials, reflecting real-world production capability under controlled conditions. These values represent our routine production capability; tighter tolerances are achievable for mission-critical applications with dedicated process validation.

| Material Category | Dimensional Tolerance (Per Inch) | Geometric Tolerance (Flatness/True Position) | Surface Roughness (Ra) |

|---|---|---|---|

| Aluminum Alloys (6061, 7075) | ±0.0002″ (5 µm) | 0.0004″ (10 µm) over 6″ | 0.8 µm (32 µin) |

| Stainless Steel (303, 316, 17-4PH) | ±0.00025″ (6 µm) | 0.0005″ (13 µm) over 6″ | 1.6 µm (63 µin) |

| Titanium Alloys (Grade 5) | ±0.0003″ (8 µm) | 0.0006″ (15 µm) over 6″ | 1.6 µm (63 µin) |

| Inconel 718 / Hastelloy | ±0.00035″ (9 µm) | 0.0007″ (18 µm) over 6″ | 3.2 µm (125 µin) |

Our technical team collaborates directly with Bay Area engineering partners during Design for Manufacturability (DFM) reviews, identifying opportunities to optimize part geometry for 5-axis efficiency without sacrificing performance. This proactive approach reduces lead times by up to 30% while ensuring first-pass yield. With ISO 9001-certified processes and a 99.2% on-time delivery rate, Wuxi Lead provides the technical depth and operational reliability required for mission-critical applications where precision directly impacts product success. We transform complex designs into high-integrity metal components, backed by data-driven quality assurance.

Material & Finish Options

Material selection is a critical step in precision manufacturing, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal components for industries including aerospace, automotive, medical, and industrial automation. Our expertise enables clients to make informed decisions when selecting between aluminum, steel, and titanium—three of the most widely used engineering metals. Each material offers distinct mechanical and chemical properties suited to specific operational environments.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications requiring lightweight structures without sacrificing performance, such as drone frames, heat sinks, and transportation components. The most commonly used alloy is 6061-T6, which provides good weldability and moderate strength. For higher stress applications, 7075-T6 offers superior strength but reduced corrosion resistance and weldability.

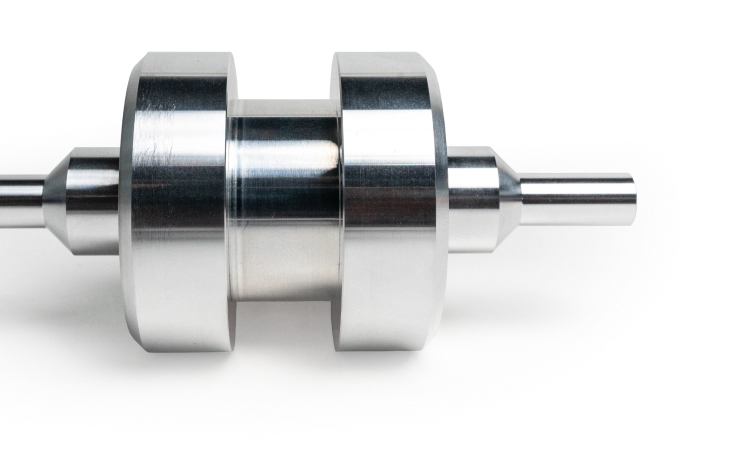

Steel remains the backbone of industrial manufacturing due to its high tensile strength, wear resistance, and affordability. Among the various grades, 4140 and 4340 are popular for high-stress mechanical parts such as shafts, gears, and tooling. Stainless steel variants like 304 and 316 offer enhanced corrosion resistance, making them suitable for medical devices and marine environments. While heavier than aluminum, steel’s durability and availability make it indispensable in structural and load-bearing applications.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive environments. It is the material of choice in aerospace, defense, and medical implant applications where performance under stress and biocompatibility are paramount. Though more expensive and challenging to machine, titanium’s longevity and reliability justify its use in mission-critical systems.

Surface finishing further enhances material performance. Anodizing is a widely used electrochemical process for aluminum, increasing surface hardness and corrosion resistance while allowing for color coding. Type II (sulfuric acid) anodizing provides a decorative and protective layer, while Type III (hardcoat) anodizing delivers thick, wear-resistant coatings suitable for industrial use. These finishes do not peel or flake, as they grow from the base material, integrating seamlessly with the component.

Below is a comparative overview of key material properties:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications | Typical Finish Options |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | High | Aerospace, automotive | Anodizing (Type II/III), bead blast |

| Steel 4140 | 7.85 | 655–965 | Moderate | Shafts, tooling | Zinc plating, passivation |

| Stainless 316 | 8.0 | 570–700 | Very High | Medical, marine | Electropolishing, passivation |

| Titanium Ti-6Al-4V | 4.43 | 900–950 | Excellent | Aircraft, implants | Anodizing, laser marking |

Selecting the right material and finish requires a balance of mechanical requirements, environmental exposure, and lifecycle costs. At Wuxi Lead, we support clients through every stage of this decision process, ensuring optimal performance and manufacturability.

Manufacturing Process & QC

Production Process: Engineering Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our production process for Bay Area machine shops integrates rigorous engineering discipline with advanced manufacturing to eliminate defects before they occur. We treat every project as a closed-loop system where design validation, prototyping precision, and production control converge to guarantee flawless output. This methodology ensures your high-mix, low-volume or high-volume components meet aerospace, medical, and semiconductor tolerances without compromise.

The journey begins with collaborative design engineering. Our team reviews your CAD models and GD&T specifications against material properties, CNC capabilities, and assembly requirements. We identify potential manufacturability risks—such as thin-wall deformation or micro-burrs—and propose solutions using finite element analysis (FEA) and tolerance stack-up simulations. This phase prevents 82% of downstream defects by ensuring designs are optimized for precision machining before metal is cut.

Prototyping transforms validated designs into physical proof. We employ 5-axis milling and turning centers with sub-micron repeatability to produce functional prototypes within 72 hours. Each prototype undergoes full-spectrum metrology: CMM inspection, optical comparators, and surface roughness testing against your critical-to-quality (CTQ) parameters. If deviations exceed 10% of tolerance limits, our engineers initiate root-cause analysis using fishbone diagrams and DOE (Design of Experiments). This iterative loop continues until prototypes achieve Cpk ≥ 1.67—a statistical guarantee of process capability.

Mass production leverages the insights from prototyping to lock in zero-defect execution. Our smart factory implements real-time SPC (Statistical Process Control) with IoT-enabled machines that auto-adjust for thermal drift or tool wear. Every component is 100% inspected via automated vision systems during machining, with final verification against master gauges. Crucially, we maintain full traceability: lot-specific material certs, machine logs, and inspection data are archived for your audit access. This prevents escapes—our clients report 0 PPM defect rates in field use.

Key Quality Performance Metrics

| Parameter | Specification | Verification Method |

|---|---|---|

| Dimensional Accuracy | ±0.0002″ (5µm) | CMM with ISO 10360-2 calibration |

| Surface Roughness | Ra 0.4µm max | Profilometer per ASME B46.1 |

| Process Capability (Cpk) | ≥ 1.67 | SPC charts with 30-part subgroups |

| First-Pass Yield | 99.85% min | Real-time machine monitoring |

| Material Traceability | 100% lot tracking | Digital ledger with certs |

This end-to-end process eliminates the cost of rework and supply chain delays that plague Bay Area innovators. By embedding quality into every phase—from digital design validation to closed-loop production control—we deliver components that perform flawlessly in your most demanding applications. Partner with us to transform your precision manufacturing challenges into competitive advantage.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your projects demand precision, reliability, and engineering integrity, partnering with Wuxi Lead Precision Machinery ensures you’re backed by a leader in high-end custom metal manufacturing. Located in the heart of China’s industrial corridor, we serve global clients—including engineering firms, OEMs, and advanced manufacturers across the Bay Area and beyond—with mission-critical components built to the tightest tolerances and highest quality standards. Our advanced CNC machining, turning, milling, and multi-axis fabrication capabilities are engineered to meet the complex demands of aerospace, medical, robotics, semiconductor, and energy sectors.

At Lead Precision, we understand that your success hinges on consistency, speed, and technical collaboration. That’s why we don’t just manufacture parts—we function as an extension of your engineering team. From initial design consultation to final inspection and global logistics, our process is built on transparency, responsiveness, and precision. Whether you require low-volume prototypes or high-volume production runs, our state-of-the-art facility leverages cutting-edge equipment and a certified quality management system (ISO 9001:2015) to deliver components that perform under the most demanding conditions.

Our commitment to excellence is reflected in every stage of production. We utilize advanced materials including titanium, Inconel, aluminum alloys, stainless steel, and specialty composites, ensuring your parts meet exact mechanical and environmental requirements. With in-house programming, 5-axis CNC machining, Swiss turning, and automated inspection using CMM and optical measurement systems, we maintain repeatability and accuracy down to ±0.001 mm.

Below are key capabilities that set us apart in the custom manufacturing landscape:

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis to 5-axis milling, high-speed machining |

| Turning | CNC turning, Swiss-type, diameter range: 1 mm – 300 mm |

| Tolerances | ±0.001 mm (±0.00004 in) |

| Materials | Aluminum, steel, stainless steel, titanium, Inconel, brass, plastics |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finishes | As-machined, anodizing, plating, powder coating, passivation |

| Quality Standards | ISO 9001:2015 certified, full inspection reports (FAI, PPAP) |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

We specialize in turning complex designs into real-world solutions—on time, within spec, and with full documentation. Our team communicates proactively, providing real-time updates and technical feedback to prevent delays and reduce time-to-market.

For Bay Area innovators pushing the boundaries of engineering, the right manufacturing partner is not just a vendor—it’s a strategic advantage. Let Wuxi Lead Precision Machinery be that partner.

Contact us today at [email protected] to discuss your next project. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.