Technical Contents

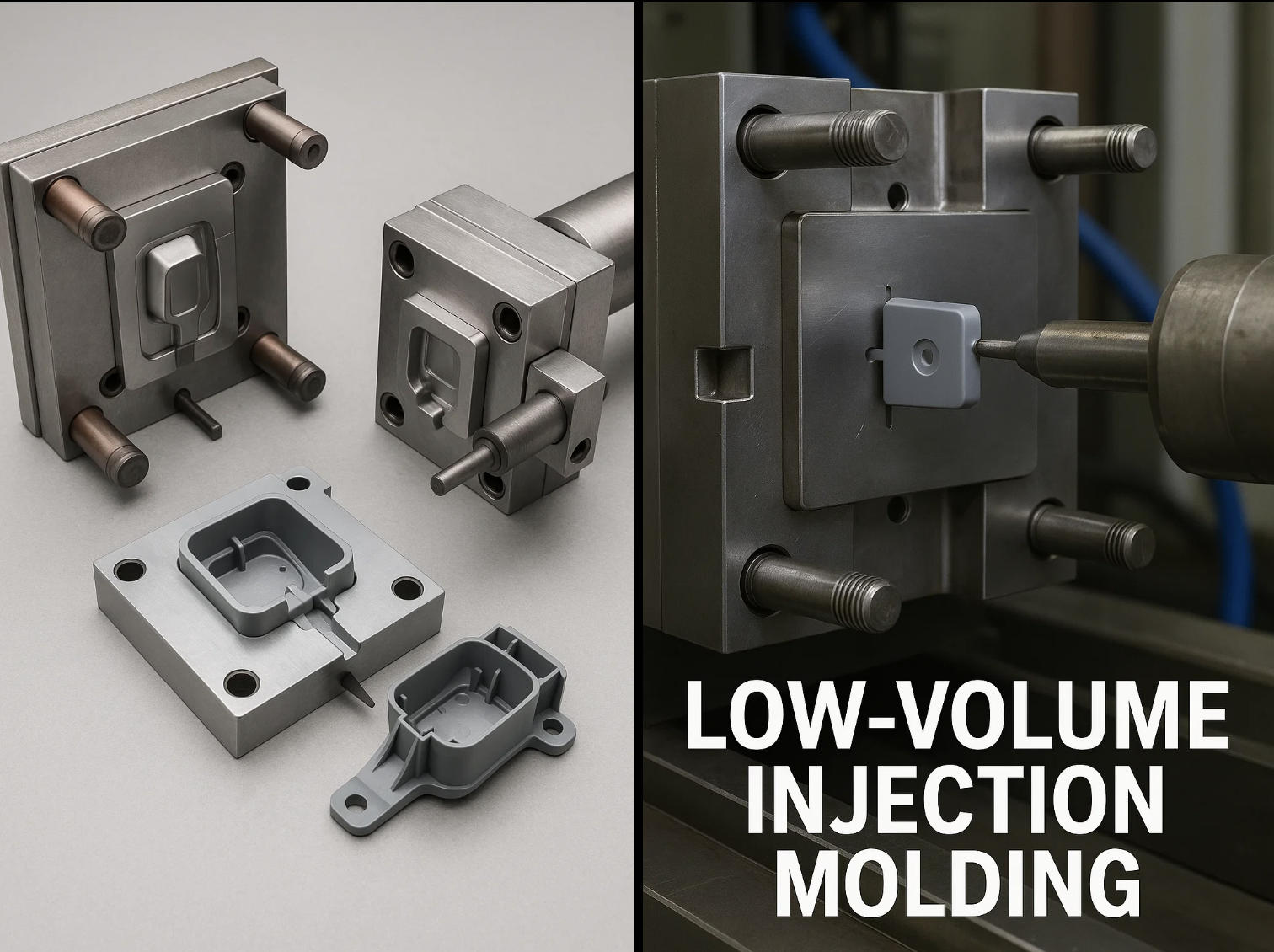

Engineering Guide: Low Volume Plastic Injection Molding

Engineering Insight: The Critical Role of Precision in Low Volume Plastic Injection Molding

In the realm of low volume plastic injection molding, precision is not merely a performance metric—it is the foundation of functional integrity, repeatability, and long-term reliability. At Wuxi Lead Precision Machinery, we approach each low volume production run with the same engineering rigor applied to high-volume manufacturing, ensuring that even limited batches meet exacting specifications required by industries such as aerospace, defense, and advanced medical devices.

Low volume plastic injection molding serves a unique purpose in product development and niche manufacturing. It enables rapid prototyping, pilot production, and bridge tooling while minimizing upfront investment. However, the reduced quantity does not diminish the demand for accuracy. On the contrary, when producing components for validation or small-scale deployment, dimensional consistency, material integrity, and surface finish must be flawless—each part must perform identically under real-world conditions.

Our engineering team leverages decades of experience in custom metal manufacturing to design and fabricate molds with micron-level tolerances. This expertise is directly transferable to plastic molding, where mold geometry, cooling channel placement, and gate design profoundly influence part quality. At Lead Precision, we employ advanced CNC machining, EDM, and real-time process monitoring to ensure mold precision, which directly translates into part consistency across every cycle.

Our track record includes mission-critical projects for Olympic-standard equipment and military-grade components, where failure is not an option. These applications demand materials and processes that withstand extreme environments, mechanical stress, and long service life. The same standards are applied to our low volume plastic molding services—every mold is treated as a high-performance system, not just a tool.

Material selection is equally critical. We work with engineering-grade thermoplastics such as PEEK, PPS, and ULTEM, which offer superior thermal stability, chemical resistance, and mechanical strength. Combined with precise control over injection parameters—pressure, temperature, and cooling rate—we ensure that each molded component meets or exceeds design intent.

Below is a summary of key specifications we maintain in low volume plastic injection molding operations:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on part geometry) |

| Mold Material | H13, S136, 420 Stainless Steel, or P20 (hardened as required) |

| Surface Finish | SPI A1 to SPI C3, including textured, polished, or as-machined |

| Part Weight Range | 0.1 g to 500 g |

| Cycle Time Control | ±0.5 seconds repeatability |

| Material Compatibility | ABS, PC, POM, PEEK, PPS, PA6/66, PP, PE, and LCP |

| Tooling Life | 10,000 to 100,000 cycles (prototype to production-grade) |

At Wuxi Lead Precision Machinery, we understand that low volume does not mean low expectation. Our integrated approach—merging precision metal fabrication with advanced molding science—ensures that every component we produce is a testament to engineering excellence.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Injection Mold Tooling

Wuxi Lead Precision Machinery specializes in the high-precision metal manufacturing essential for successful low-volume plastic injection molding programs. Our core expertise lies not in molding plastics directly, but in producing the critical metal components—mold bases, cavities, cores, inserts, and precision guides—that form the heart of the injection mold itself. The accuracy and durability of these metal elements directly dictate the quality, consistency, and longevity of the plastic parts produced. We understand that low-volume production demands exceptional tooling precision to minimize scrap, reduce trial-and-error cycles, and ensure part conformity from the very first shot, even with demanding geometries or stringent tolerances.

Our technical foundation is built upon advanced 5-axis CNC machining centers. This capability is non-negotiable for modern mold manufacturing. 5-axis technology allows us to machine complex, contoured mold surfaces—such as those required for automotive lighting lenses, medical device housings, or intricate consumer electronics—in a single setup. This eliminates cumulative errors inherent in multi-setup processes, significantly improves surface finish, and achieves geometric accuracies impossible with 3-axis machines. We utilize hardened tool steels (e.g., H13, S7), pre-hardened steels (P20), and specialty alloys, machining them to the exacting specifications required for optimal thermal management, wear resistance, and part ejection within the mold. Material integrity and dimensional stability under injection pressure and thermal cycling are paramount, and our processes are rigorously controlled to ensure these properties.

Quality assurance is integrated at every stage, culminating in comprehensive Coordinate Measuring Machine (CMM) inspection. Every critical feature of the machined mold components undergoes 100% verification against the original CAD model and engineering drawings. Our Zeiss and Hexagon CMMs provide micron-level accuracy in capturing complex 3D geometries, verifying true positions, profiles, and critical datums. This metrology data is not just a final check; it feeds directly back into our process control, enabling immediate corrections and continuous improvement. We provide full inspection reports, giving customers transparent verification that their mold components meet the required specifications before assembly and mold tryout.

The precision achievable with our integrated 5-axis machining and CMM validation is quantifiable. Below are representative tolerance capabilities for finished mold components, reflecting our standard for low-volume, high-integrity applications. Actual tolerances are always defined by specific project requirements and material considerations.

| Feature Type | Standard Capability | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM |

| Geometric Position | ±0.015 mm | ±0.008 mm | CMM |

| Profile of Surface | 0.020 mm | 0.010 mm | CMM |

| Angular Features | ±0.05° | ±0.02° | CMM / Optical Comparator |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

This level of metal component precision ensures molds perform reliably during low-volume production runs, minimizing downtime for adjustments and guaranteeing that the final plastic parts meet the dimensional and aesthetic requirements critical to your application. We translate complex designs into robust, high-fidelity metal tooling, forming the essential foundation for your successful plastic injection molding outcomes.

Material & Finish Options

Material Selection for Low Volume Plastic Injection Molding Tooling

In low volume plastic injection molding, selecting the appropriate tooling material is critical to balancing performance, durability, and cost. While the molded part may be plastic, the mold itself must be manufactured from high-precision metal alloys capable of maintaining dimensional stability under repeated thermal cycling and mechanical stress. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for injection molds, leveraging aluminum, steel, and titanium based on production requirements, part complexity, and service life expectations.

Aluminum is a preferred choice for prototyping and low-volume production runs due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall cycle time during molding. Aluminum molds are significantly lighter and less expensive to machine than steel, making them ideal for applications requiring rapid turnaround and cost efficiency. However, aluminum’s lower hardness limits its use to runs typically under 10,000 cycles, especially when processing abrasive or glass-filled resins.

Steel, particularly tool steels like P20, H13, and S136, offers superior hardness, wear resistance, and longevity. These properties make steel molds suitable for higher precision applications and extended production life, often exceeding 100,000 cycles with proper maintenance. While initial machining costs and lead times are higher, the durability of steel ensures consistent part quality over time. Steel is recommended when surface finish fidelity, tight tolerances, and resistance to wear are paramount.

Titanium is less common in standard mold construction but offers unique advantages in specialized applications. Its high strength-to-density ratio, corrosion resistance, and thermal stability make it suitable for molds exposed to aggressive environments or where weight reduction is critical. Though more expensive and challenging to machine, titanium can be a strategic choice for niche, high-performance tooling where conventional materials fall short.

Surface finishing, particularly anodizing, plays a vital role in enhancing mold performance—especially with aluminum. Anodizing increases surface hardness, improves wear resistance, and enhances corrosion protection. Type II (sulfuric acid) and Type III (hard coat) anodizing are commonly applied, with Type III providing a thicker, more durable oxide layer suitable for molds subject to frequent use. Anodized surfaces also support superior release characteristics, reducing the need for mold release agents and minimizing part defects.

Below is a comparative overview of key material properties relevant to mold tooling:

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Finishes |

|---|---|---|---|---|---|

| Aluminum (7075) | 15–20 | 500–570 | 130–150 | 5,000–10,000 | Anodizing (Type II/III) |

| Steel (P20) | 28–32 | 900–1,100 | 28–30 | 50,000–100,000 | Polishing, Chrome Plating |

| Steel (H13) | 45–50 | 1,200–1,400 | 25–30 | 100,000+ | Nitriding, PVD Coating |

| Titanium (Ti-6Al-4V) | 35–40 | 900–1,000 | 6–7 | 20,000–50,000 (specialized) | Anodizing, DLC Coating |

Material and finish selection must align with project-specific demands. At Wuxi Lead Precision Machinery, we work closely with clients to engineer mold solutions that optimize performance, cost, and lead time for low volume plastic injection molding applications.

Manufacturing Process & QC

Precision-Driven Low Volume Plastic Injection Molding: The Wuxi Lead Process

At Wuxi Lead Precision Machinery, we leverage our core expertise in custom metal manufacturing to deliver exceptional low volume plastic injection molding. Our process is engineered for zero defects, ensuring your complex, high-value plastic components meet stringent specifications from initial concept to final part. This integrated approach, rooted in metal precision, minimizes risk and maximizes yield for demanding applications.

The process commences with collaborative Design for Manufacturability (DFM) Analysis. Our engineering team, fluent in both plastic behavior and critical metal tooling requirements, rigorously reviews your CAD model. We focus on optimizing wall thickness, gate location, draft angles, and material selection before tooling begins. This phase identifies potential weaknesses like sink marks, warpage, or ejection issues, translating your design intent into a robust manufacturing plan. Our metal machining heritage ensures we anticipate how mold steel performance impacts plastic flow and part quality, preventing costly revisions later.

Precision Prototyping follows, utilizing rapid steel tooling fabricated in-house on our advanced CNC machining centers. Unlike soft tooling, these production-intent molds, crafted from high-grade P20 or H13 tool steel, replicate the exact thermal and mechanical conditions of full production. We produce functional prototypes for rigorous validation – testing fit, form, function, and assembly under real-world conditions. This critical step confirms the DFM adjustments and provides tangible parts for customer approval, significantly de-risking the transition to volume production. Material consistency and process stability are validated early, eliminating surprises.

Zero-Defect Mass Production is executed on our monitored presses within a controlled environment. Our proprietary process control system, developed from decades of metal machining precision, continuously tracks and adjusts key parameters: melt temperature, injection pressure, cooling time, and clamp force. Every cycle is verified against the approved prototype. Statistical Process Control (SPC) charts monitor critical dimensions in real-time, triggering immediate intervention if trends approach tolerance limits. Full first-article inspection and AQL 1.0 final inspection guarantee conformity. This systematic rigor, underpinned by our metal fabrication discipline, ensures consistent part quality batch after batch, achieving true zero-defect output for your low-volume requirements.

Our integrated metal-to-plastic capability is fundamental to this success. The precision of the mold base, cavities, and cores – manufactured to exacting metal standards – directly dictates part accuracy and longevity. Below are key specifications reflecting our mold construction quality:

| Specification Category | Precision Standard | Material Options | Quality Control Method |

|---|---|---|---|

| Mold Base Construction | ±0.005 mm flatness | Pre-hardened P20, H13, Stainless | CMM Verification after machining |

| Cavity/Core Tolerances | ±0.002 mm (critical) | NAK80, S136, M316 | Optical Comparator + Master Gauges |

| Surface Finish | SPI A1 (VDI 3400 12) | Mirror Polish, Textures (Mold-Tech) | Profilometer + Visual Inspection |

| Cooling Circuit | Optimized Flow Analysis | Beryllium Copper Inserts (critical) | Thermal Imaging Validation |

| Expected Lifespan | 100,000+ cycles (P20) | Custom Hardfacing (wear areas) | In-Process Wear Monitoring |

This disciplined progression – from intelligent design through validated prototyping to rigorously controlled production – transforms low volume plastic injection molding from a potential risk into a reliable, high-quality solution. Wuxi Lead’s metal manufacturing foundation ensures your plastic components are produced with the same uncompromising precision we apply to every custom metal part.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Low Volume Plastic Injection Molding Excellence

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, low volume plastic injection molding solutions tailored to the exacting demands of advanced manufacturing industries. As a trusted name in custom metal manufacturing, we extend our engineering expertise into plastic component production, offering clients a seamless integration of mold design, material science, and precision fabrication. Whether you are developing prototypes, pilot runs, or niche production batches, our capabilities are engineered to ensure repeatability, quality, and speed to market.

Our low volume injection molding service is ideal for industries such as medical devices, aerospace, automotive R&D, and industrial automation—where precision, material compliance, and design validation are non-negotiable. We understand that small batch production requires the same rigor as high-volume lines, which is why every project at Lead Precision begins with collaborative engineering. Our team works closely with your design specifications to optimize part geometry, select appropriate resins—including engineering-grade and medical-certified plastics—and produce molds with tight tolerances that meet ISO and ASTM standards.

We combine state-of-the-art CNC machining with in-house mold-making to ensure full control over quality and lead times. Our facility in Wuxi, China, operates under strict quality management protocols, with real-time process monitoring and first-article inspection reports available upon request. This end-to-end oversight allows us to deliver consistent part quality, even across complex geometries and multi-cavity molds.

Below are the key technical specifications of our low volume plastic injection molding capabilities:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 50 to 1,000 tons |

| Shot Weight Capacity | 10 g to 2,000 g |

| Tolerance Capability | ±0.02 mm (standard), ±0.005 mm (tight) |

| Mold Material | P20, 718H, S136, 420 Stainless, Aluminum (7075) |

| Resin Compatibility | ABS, PC, PP, PE, POM, PA (Nylon), PEEK, PVC |

| Secondary Operations | Ultrasonic welding, insert molding, threading |

| Lead Time (Mold + First Parts) | 15 to 25 days, depending on complexity |

| Production Volume Range | 100 to 10,000 units per batch |

| Quality Standards | ISO 9001:2015, RoHS, FDA (upon request) |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to technical excellence and responsive service. We bridge the gap between prototype and production, ensuring your low volume runs are scalable, cost-effective, and fully documented. Our engineers support DFM analysis, rapid tooling, and material testing to de-risk your development cycle and accelerate time to validation.

For a personalized consultation and a fast quote, contact us today at [email protected]. Let Lead Precision be your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.