Technical Contents

Engineering Guide: Low-Cost Injection Molding

Engineering Insight: The Role of Precision in Low-Cost Injection Molding

In the competitive landscape of custom metal manufacturing, achieving true cost efficiency in injection molding extends far beyond minimizing material usage or reducing cycle times. At Wuxi Lead Precision Machinery, we understand that sustainable low-cost injection molding is fundamentally driven by precision engineering. While the term “low-cost” may imply compromise, in high-end industrial applications, it signifies optimized performance—where accuracy, repeatability, and process control converge to reduce waste, rework, and long-term operational expenses.

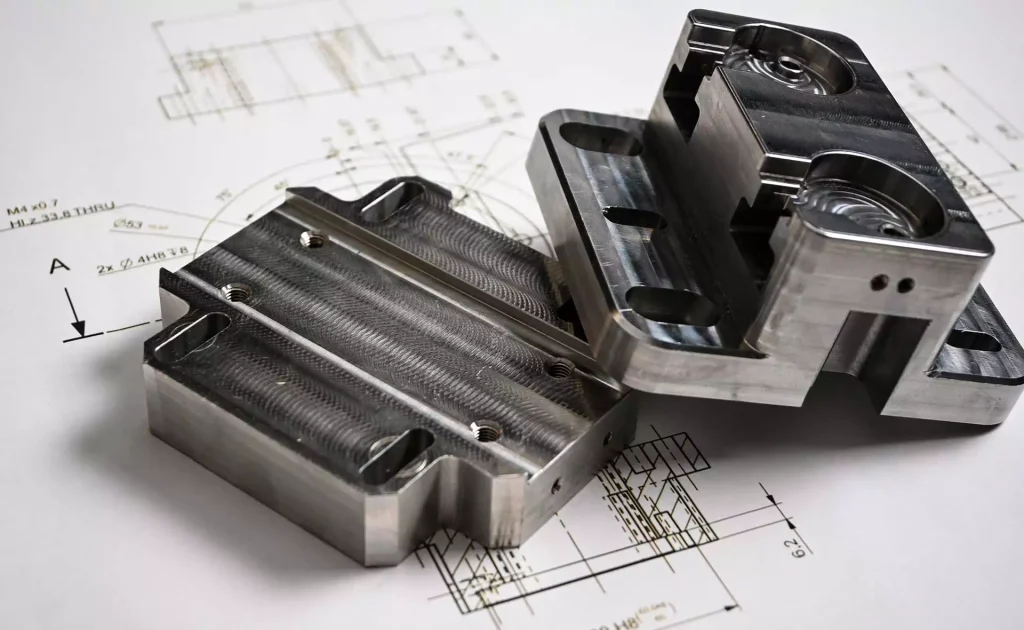

Precision in injection molding begins at the tooling stage. Even minor deviations in mold geometry can result in part inconsistencies, increased scrap rates, and costly downstream corrections. At Lead Precision, our engineering team leverages advanced CNC machining and metrology systems to ensure mold tolerances are maintained within ±0.002 mm, a standard developed through years of delivering mission-critical components for Olympic-grade equipment and military defense systems. These high-stakes applications demand zero-failure performance, a philosophy we apply to every client project—regardless of scale.

Our experience in high-precision sectors has taught us that upfront investment in exacting tool design directly correlates to lower total production costs. Precision molds exhibit longer service life, require fewer adjustments, and support stable, high-yield runs. This reduces downtime and maintenance, two of the most significant hidden costs in injection molding. Furthermore, tight process control enables consistent wall thickness, optimal gate placement, and minimized flash—factors that enhance part integrity while conserving material.

Beyond tooling, our integrated approach includes real-time monitoring of injection pressure, temperature, and cooling cycles. By maintaining tight control over these parameters, we achieve uniform part quality across batches, even in high-volume production. This level of consistency is essential for clients in aerospace, medical devices, and automotive industries, where regulatory compliance and reliability are non-negotiable.

At Wuxi Lead Precision Machinery, we redefine “low-cost” not as a reduction in quality, but as an optimization of value through precision. Our track record in delivering components for Olympic timing systems and military-grade enclosures underscores our capability to meet the most stringent standards—standards we bring to every low-cost injection molding project.

Technical Specifications – Precision Injection Molding at Lead Precision

| Parameter | Specification |

|---|---|

| Mold Tolerance | ±0.002 mm |

| Material Compatibility | PEEK, ABS, PC, Nylon, PPS, LCP, and filled variants |

| Part Weight Range | 0.1 g – 1,200 g |

| Clamping Force | 50–2,500 tons |

| Production Capacity | Up to 5 million parts/year per mold |

| Quality Control | ISO 9001, In-process SPC, CMM inspection |

| Lead Time (Standard Mold) | 25–35 days |

| Secondary Operations | Ultrasonic welding, insert molding, surface finishing |

Precision is not an add-on—it is the foundation of cost-effective, scalable manufacturing. At Lead Precision, we engineer it into every process.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Injection Molding Efficiency

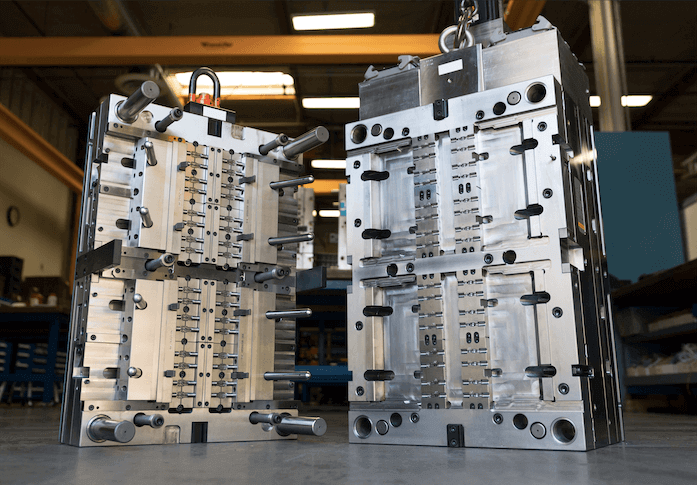

Wuxi Lead Precision Machinery specializes in the high-precision metal manufacturing essential for achieving true low-cost injection molding. While injection molding processes form plastic parts, the cost efficiency and longevity of the entire operation are fundamentally determined by the quality, accuracy, and durability of the metal tooling components – molds, cores, cavities, and inserts. Our core competency lies in producing these critical metal elements to exacting standards, directly enabling reduced cycle times, minimized scrap rates, extended mold life, and ultimately, lower per-part costs for our clients. We bridge the gap between the promise of low-cost molding and its practical, sustainable execution through advanced metal fabrication.

Our primary manufacturing platform is a comprehensive suite of state-of-the-art 5-axis CNC machining centers. This technology is non-negotiable for complex mold geometries demanded by modern, cost-optimized injection molding. 5-axis capability allows us to machine intricate contours, deep pockets, undercuts, and fine details in a single setup. This eliminates cumulative errors from multiple fixtures, significantly improves surface finish critical for part ejection and appearance, and drastically reduces overall machining time compared to 3-axis alternatives. The result is mold components that fit together perfectly, require minimal hand finishing, and deliver consistent performance from the first shot, accelerating time-to-market and reducing total production costs.

Rigorous quality control is embedded at every stage, culminating in comprehensive inspection using calibrated Coordinate Measuring Machines (CMM). Every critical dimension, geometric feature, and surface profile of machined mold components is verified against the original CAD model and engineering specifications. Our CMM protocols go beyond simple dimensional checks; they validate complex geometries, positional tolerances, and surface relationships essential for mold function. This systematic, data-driven inspection ensures that components meet the stringent requirements necessary for stable, high-yield injection molding processes, preventing costly downtime and rework during production.

The precision achievable with our integrated 5-axis CNC and CMM systems is quantifiable. We consistently deliver dimensional and geometric accuracy critical for mold performance and part quality. The following table details our standard tolerance capabilities for machined mold components:

| Tolerance Class | Dimensional Range | Linear Tolerance (µm) | Geometric Tolerance (µm) |

|---|---|---|---|

| Standard Production | < 200 mm | ± 12 | 10 |

| Standard Production | 200 – 500 mm | ± 18 | 15 |

| Precision Machining | < 200 mm | ± 6 | 5 |

| Precision Machining | 200 – 500 mm | ± 10 | 8 |

| Ultra-Precision (CMM Verified) | < 200 mm | ± 3 | 2 |

These capabilities are not theoretical; they are the foundation of reliable, cost-effective injection molding. By manufacturing metal components to these tight tolerances, Wuxi Lead ensures optimal mold alignment, consistent cooling channel placement, precise gate functionality, and superior wear resistance. This precision directly translates to reduced cycle times, elimination of flash, minimized part warpage, extended mold service life, and significantly lower total cost of ownership for your injection molding operations. We provide the metal integrity that makes low-cost molding a sustainable reality.

Material & Finish Options

Material Selection for Low-Cost Injection Molding in Custom Metal Manufacturing

Selecting the appropriate material is critical in achieving cost-effective, high-performance injection molding tooling. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that balance durability, precision, and economic efficiency. For low-cost injection molding applications, aluminum, steel, and titanium each offer distinct advantages depending on production volume, part complexity, and environmental demands.

Aluminum is often the preferred choice for prototyping and short-run production due to its excellent machinability and thermal conductivity. Its lightweight nature reduces cycle times and energy consumption during molding operations. While not as wear-resistant as steel, modern aluminum alloys such as 7075 and 6061 provide sufficient strength for thousands of cycles when properly treated. This makes aluminum ideal for rapid tooling where speed to market and reduced initial costs are priorities.

Steel, particularly pre-hardened and tool-grade steels like P20 and H13, remains the standard for high-volume production molds. Its superior hardness and resistance to wear ensure long service life under continuous operation. While initial machining costs are higher and lead times longer, the per-unit cost decreases significantly over large production runs. Steel molds also maintain dimensional stability under high pressure and temperature, making them suitable for engineering-grade plastics and complex geometries.

Titanium is less commonly used in standard injection molding but offers unique benefits in specialized applications. Its exceptional strength-to-density ratio and corrosion resistance make it suitable for molds exposed to aggressive environments or where weight reduction is critical. However, titanium’s high material and machining costs limit its use to niche, high-value production scenarios.

Surface finishing, particularly anodizing, plays a vital role in enhancing mold performance. Anodizing increases surface hardness, improves wear resistance, and provides electrical insulation. For aluminum molds, Type II (sulfuric acid) and Type III (hardcoat) anodizing are widely used. Type III anodizing delivers a thick, durable oxide layer that significantly extends tool life in abrasive molding conditions.

The following table summarizes key mechanical and thermal properties of the three materials discussed:

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Typical Mold Life (cycles) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 7075 | 570 | 150 | 130 | 1,000 – 10,000 | Prototyping, low-volume runs |

| P20 Steel | 900 – 1100 | 280 – 320 | 30 | 50,000 – 100,000+ | Medium to high-volume production |

| Titanium Ti-6Al-4V | 900 – 1,000 | 340 | 7.2 | 10,000 – 50,000 | Corrosive environments, aerospace |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production goals, budget constraints, and performance requirements. Our expertise ensures optimal mold longevity and part quality in every low-cost injection molding project.

Manufacturing Process & QC

Production Process: Achieving Zero Defects in Low-Cost Injection Molding

Wuxi Lead Precision Machinery executes a rigorously controlled production process for custom metal injection molding, transforming complex designs into high-volume, zero-defect components while optimizing cost efficiency. This integrated workflow eliminates waste and rework, ensuring true low-cost ownership through precision engineering rather than compromised quality.

The Design Phase begins with comprehensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients to refine part geometry, material selection, and gating strategies using advanced simulation software. This critical step identifies potential flow issues, sink marks, or stress concentrations before tooling begins, preventing costly revisions and ensuring the design is inherently manufacturable to tight tolerances. Material compatibility and thermal behavior are modeled to predict final part performance accurately.

Prototyping transitions validated designs into physical reality using rapid tooling techniques. Wuxi Lead employs precision CNC-machined prototype molds, often within 15 working days, to produce functional parts for rigorous testing. Dimensional inspection, material property verification, and assembly trials occur against the original CAD model. This stage is not merely validation; it is a vital opportunity to fine-tune process parameters like injection pressure, temperature profiles, and cooling cycles under real production conditions. Any deviations trigger immediate design or process adjustments, ensuring the mass production phase launches with a perfected recipe.

Mass Production leverages fully automated, high-pressure molding cells monitored by Statistical Process Control (SPC) systems. Each cycle is scrutinized in real-time for pressure, temperature, and fill time deviations exceeding 0.5%. In-line vision systems and automated coordinate measuring machines (CMM) perform 100% critical feature checks on initial runs and continuous random sampling. Our proprietary closed-loop control system dynamically adjusts parameters to maintain stability, ensuring every component meets the specified tolerances consistently. Preventative maintenance schedules, calibrated to mold cycle counts, guarantee tooling integrity and surface finish longevity, directly supporting the zero-defect objective. This disciplined approach minimizes scrap rates to below 0.1% and maximizes machine uptime.

The table below summarizes key process specifications enabling this zero-defect, cost-optimized output:

| Parameter | Specification Range | Control Method | Target Outcome |

|---|---|---|---|

| Dimensional Tolerance | ±0.002 mm to ±0.05 mm | In-line CMM + SPC | < 0.1% Scrap Rate |

| Material Temperature | 150°C – 350°C (precise) | Closed-loop thermal control | Consistent flow |

| Cycle Time Stability | ±0.3 seconds | Real-time pressure monitoring | 98%+ OEE |

| Surface Roughness (Ra) | 0.1 µm – 1.6 µm | Automated vision inspection | Zero visual defects |

| First Pass Yield | ≥ 99.5% | Integrated SPC dashboard | Zero rework required |

This seamless integration of design validation, rapid prototyping refinement, and tightly controlled mass production forms the foundation of Wuxi Lead’s low-cost injection molding capability. We achieve sustainable cost leadership not through reduction in standards, but through elimination of process variation and waste, delivering true zero-defect performance at scale.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Value in Low-Cost Injection Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, cost-effective injection molding solutions tailored to the rigorous demands of global manufacturing. As a trusted leader in custom metal manufacturing based in China, we combine advanced engineering, lean production methodologies, and decades of technical expertise to help businesses reduce costs without compromising quality. Our low-cost injection molding services are designed for high-volume production, rapid turnaround, and seamless integration into your supply chain.

We understand that in today’s competitive industrial landscape, cost efficiency and reliability are paramount. That’s why we’ve engineered our processes to minimize waste, optimize cycle times, and deliver consistent part quality across every production run. From initial design consultation to final delivery, our team works closely with clients to refine part geometry, select optimal materials, and ensure mold longevity—resulting in lower per-unit costs and faster time to market.

Our state-of-the-art facility is equipped with fully automated CNC machines, high-speed injection molding presses, and in-house tooling capabilities. This vertical integration allows us to maintain complete control over quality, lead times, and pricing. Whether you require prototype tooling or large-scale production molds, we offer scalable solutions that adapt to your volume needs and budget constraints.

We serve industries ranging from automotive and medical devices to industrial equipment and consumer electronics, providing components that meet international standards for dimensional accuracy, surface finish, and structural integrity. All parts are manufactured under ISO 9001-certified processes, with full traceability and rigorous inspection protocols.

By partnering with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic manufacturing ally committed to your success. Our engineering team provides ongoing support, including design for manufacturability (DFM) analysis, mold flow simulation, and lifecycle cost modeling to ensure optimal performance and cost savings over the long term.

Below are key specifications that define our low-cost injection molding capabilities:

| Specification | Detail |

|---|---|

| Clamping Force Range | 50 to 2,500 Tons |

| Shot Weight Capacity | 1 to 5,000 grams |

| Tolerance | ±0.02 mm (standard), ±0.005 mm (precision) |

| Materials Supported | ABS, PC, PP, PA (Nylon), POM, PBT, PPS, and high-performance engineering plastics |

| Mold Base Standards | HASCO, DME, LKM, or custom |

| Surface Finishes | SPI-S1 to SPI-A1, texture, polishing, coating |

| Production Volume | 1,000 to 1,000,000+ units per year |

| Lead Time (Mold) | 15 to 30 days, depending on complexity |

| Quality Standards | ISO 9001:2015, RoHS, REACH compliance |

Contact us today to discover how Wuxi Lead Precision Machinery can transform your injection molding requirements into a competitive advantage. Send your inquiries, RFQs, or design files to [email protected] and receive a detailed proposal within 24 hours. Let us help you achieve precision, scalability, and cost leadership—every time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.