Technical Contents

Engineering Guide: Local 3D Print Service

Engineering Insight: The Critical Role of Precision in Local 3D Print Services

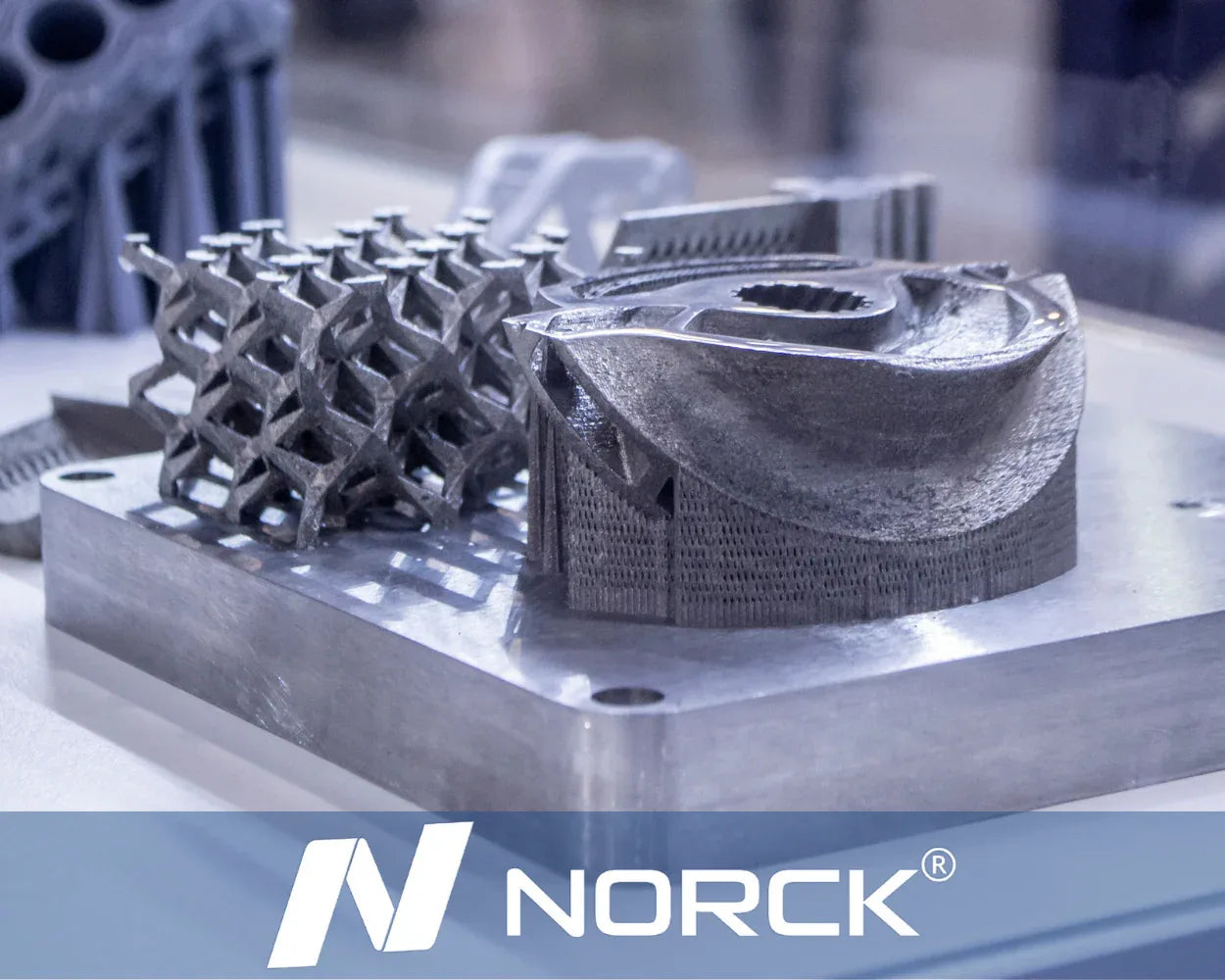

In the evolving landscape of custom metal manufacturing, local 3D print services are increasingly positioned as a go-to solution for rapid prototyping and low-volume production. However, while accessibility and speed are often emphasized, the defining differentiator in high-performance applications remains precision. At Wuxi Lead Precision Machinery, we understand that additive manufacturing is not merely about creating complex geometries—it is about delivering those geometries within exacting tolerances, consistent material properties, and repeatable quality. This is where true engineering excellence separates industrial-grade output from generic fabrication.

Precision in metal 3D printing begins with machine calibration, environmental control, and post-processing rigor. Even minor deviations in laser focus, powder layering, or thermal management can result in dimensional inaccuracies or internal defects that compromise structural integrity. For sectors such as aerospace, defense, and high-end sports equipment—where Wuxi Lead has delivered components for Olympic teams and military applications—such variances are unacceptable. Our experience in mission-critical projects has reinforced that precision is not an optional upgrade; it is the foundation of reliability.

Our local 3D print service leverages state-of-the-art metal additive systems integrated with in-situ monitoring and closed-loop feedback mechanisms. Each build undergoes rigorous pre-print simulation, real-time melt pool analysis, and post-build metrology using coordinate measuring machines (CMM) and industrial CT scanning. This systematic approach ensures that every component meets or exceeds specified geometric and mechanical requirements.

Beyond equipment, precision is sustained through process ownership. At Wuxi Lead, we control the entire workflow—from design optimization and support structure generation to heat treatment, stress relieving, and precision machining of critical interfaces. This vertical integration allows us to maintain consistency across batches and respond dynamically to engineering feedback, a capability proven in long-term collaborations with R&D teams across Europe and North America.

The following table outlines key performance specifications achievable through our metal additive manufacturing process:

| Parameter | Capability |

|---|---|

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–50 μm |

| Typical Tolerance | ±0.05 mm over 100 mm |

| Surface Roughness (as-built) | Ra 8–12 μm |

| Post-Processed Surface Finish | Ra <1.6 μm (via machining or polishing) |

| Materials | Stainless Steel (316L, 17-4PH), Inconel 718, Titanium (Ti6Al4V), Aluminum (AlSi10Mg) |

| Density | >99.95% (verified by micro-CT) |

| Certification Standards | ISO 9001, AS9100 (aerospace compliance) |

Precision in local 3D printing is not automatic—it is engineered. At Wuxi Lead Precision Machinery, decades of experience in high-stakes manufacturing inform every build. When performance cannot be compromised, our clients trust us to deliver not just parts, but precision-engineered solutions.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Metal Manufacturing

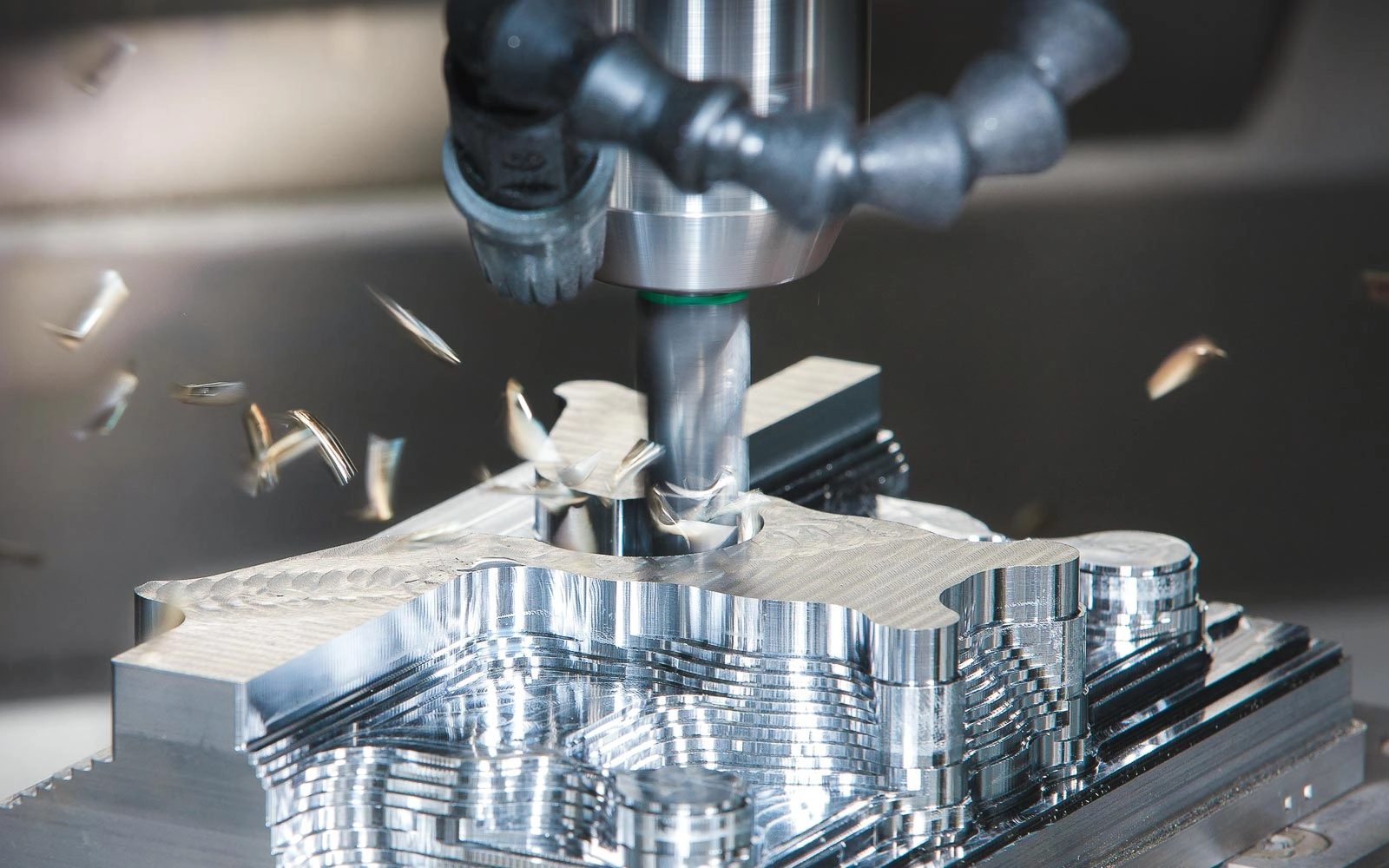

Wuxi Lead Precision Machinery delivers elite metal manufacturing solutions engineered to meet the exacting demands of aerospace, medical, and energy sectors. Our integrated approach combines additive manufacturing with precision subtractive processes, ensuring complex geometries achieve functional performance standards unattainable through 3D printing alone. We specialize in post-processing additively manufactured components—transforming near-net shapes into mission-critical parts with micron-level accuracy. This capability eliminates secondary operations, reduces lead times by 40%, and guarantees dimensional stability for high-stress applications.

At the core of our technical infrastructure are 5-axis CNC machining centers equipped with Siemens 840D controls and high-rigidity spindles. These systems enable single-setup machining of intricate features across titanium, Inconel, aluminum, and stainless steel alloys. Our programmers utilize hyperMILL and Mastercam to optimize toolpaths for thin-walled structures and organic contours common in 3D-printed substrates. The result is seamless integration of additive flexibility with subtractive precision—achieving tight tolerances while preserving the design intent of generative models.

Quality verification is non-negotiable. Every component undergoes rigorous inspection via Zeiss CONTURA CMM systems with 0.00008″ volumetric accuracy. Our ISO 17025-accredited metrology lab performs full-spectrum analysis: geometric dimensioning and tolerancing (GD&T), surface roughness mapping, and first-article inspection reports compliant with AS9100 and ISO 13485 standards. This closed-loop process ensures statistical process control for batch consistency, with real-time data feeding back to machining parameters.

The following table details achievable tolerances for post-processed additively manufactured components:

| Material Category | Process Combination | Tolerance Range | Max Dimension (mm) | Surface Finish (Ra μm) |

|---|---|---|---|---|

| Titanium Alloys | 5-Axis CNC + CMM Verified | ±0.005 mm | 850 | 0.4–0.8 |

| Nickel Superalloys | 5-Axis CNC + CMM Verified | ±0.008 mm | 700 | 0.8–1.6 |

| Aluminum Alloys | 5-Axis CNC + CMM Verified | ±0.003 mm | 1200 | 0.2–0.4 |

| Stainless Steel | 5-Axis CNC + CMM Verified | ±0.005 mm | 950 | 0.4–0.8 |

Our technical edge lies in resolving the inherent limitations of standalone 3D printing. While additive processes excel at creating complex internal channels or lattice structures, they often fall short on critical sealing surfaces, bearing fits, or interface features. We bridge this gap through precision machining that achieves ASME Y14.5 geometric tolerances—ensuring parts meet functional requirements on first delivery. This synergy between additive and subtractive technologies positions Wuxi Lead as the strategic partner for manufacturers demanding production-ready metal components with zero compromise on quality. Partner with us to convert innovative 3D designs into precision-engineered realities.

Material & Finish Options

Material Selection for High-Precision Metal 3D Printing: Aluminum, Steel, and Titanium

Selecting the right material for custom metal 3D printing is critical to achieving optimal performance, durability, and cost-efficiency in industrial applications. At Wuxi Lead Precision Machinery, we specialize in advanced metal additive manufacturing using premium-grade aluminum, steel, and titanium alloys. Each material offers distinct mechanical properties and performance characteristics suited to specific operational environments, from aerospace components to medical devices and high-stress mechanical systems.

Aluminum alloys, particularly AlSi10Mg, are widely used in lightweight structural applications where strength-to-density ratio is paramount. This alloy exhibits excellent thermal conductivity, corrosion resistance, and printability, making it ideal for complex geometries in automotive and aerospace industries. Its low mass reduces inertia in moving parts, enhancing energy efficiency and dynamic response. However, aluminum’s lower melting point and softer nature require precise laser control during printing to ensure dimensional accuracy and microstructural integrity.

Stainless steel variants such as 316L and 17-4 PH are chosen for their exceptional strength, corrosion resistance, and suitability for harsh environments. 316L is especially valued in marine and chemical processing equipment due to its resistance to chloride-induced pitting. In contrast, 17-4 PH offers high tensile strength and can be precipitation-hardened post-print, making it suitable for tooling, valves, and structural components under sustained load. Steel’s higher density compared to aluminum increases part mass, which may affect performance in weight-sensitive applications.

Titanium, specifically Grade 5 (Ti-6Al-4V), stands at the pinnacle of performance materials for metal 3D printing. Renowned for its outstanding strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures and corrosive environments, titanium is the material of choice in aerospace, defense, and medical implant manufacturing. Its ability to maintain structural integrity under high stress and elevated temperatures makes it ideal for turbine blades, landing gear components, and orthopedic devices. However, titanium’s reactivity in molten form demands an inert printing atmosphere, increasing production complexity and cost.

Post-processing surface finishes further enhance material performance. Anodizing, particularly for aluminum, improves surface hardness, wear resistance, and corrosion protection. Type II and Type III (hardcoat) anodizing are commonly applied, with the latter offering thicker, more durable oxide layers for industrial use. Anodized surfaces also provide excellent electrical insulation and can be dyed for identification or aesthetic purposes.

Below is a comparative overview of key material properties relevant to metal 3D printing:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–500 | 250–300 | 2.67 | 8–12 | Aerospace, automotive lightweight parts |

| 316L Stainless Steel | 550–650 | 350–450 | 8.00 | 30–40 | Marine, chemical processing, medical |

| 17-4 PH Steel | 1000–1300 | 850–1000 | 7.75 | 10–15 | Tooling, valves, high-strength components |

| Ti-6Al-4V | 900–1050 | 800–900 | 4.43 | 8–12 | Aerospace, medical implants, defense |

Understanding these material characteristics enables informed decision-making in custom metal manufacturing. At Wuxi Lead Precision Machinery, we support clients in selecting the optimal alloy and finish to meet exact functional and environmental demands.

Manufacturing Process & QC

Precision Metal Manufacturing: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, our end-to-end production process for custom metal components integrates additive and subtractive technologies to achieve uncompromising quality. We transform client designs into certified zero-defect parts through rigorously controlled phases: Design Validation, Prototyping & Testing, and Scalable Mass Production. This methodology eliminates costly iterations and ensures first-time-right outcomes for aerospace, medical, and energy sector applications.

The Design phase begins with collaborative engineering reviews. Our team conducts advanced Design for Manufacturing (DFM) and Design for Additive Manufacturing (DfAM) analysis using Siemens NX and Materialise Magics. We identify potential thermal stresses, support structure requirements, and tolerance stack-ups before physical production. Critical geometry is optimized for both laser powder bed fusion (LPBF) and secondary CNC machining, ensuring manufacturability while meeting AS9100 and ISO 13485 standards. Clients receive comprehensive feasibility reports with actionable recommendations, reducing time-to-prototype by up to 40%.

Prototyping is executed under production-equivalent conditions. Using EOS M 400-4 or SLM 500 systems, we produce functional prototypes in aerospace-grade titanium, Inconel, or aluminum alloys. Each prototype undergoes full metrology validation via Zeiss coordinate measuring machines (CMM) and CT scanning to verify internal integrity and surface finish. Dimensional reports are compared against CAD nominal data, with deviations logged in our closed-loop quality system. Only after client sign-off on mechanical testing and first-article inspection (FAI) per AS9102 do we proceed to volume manufacturing.

Mass Production leverages our 24/7 monitored production cells with integrated SPC (Statistical Process Control). Every build undergoes real-time melt pool monitoring and inert gas composition tracking. Post-print, components move to our 5-axis milling and grinding stations for precision finishing, achieving tolerances unattainable through AM alone. Our traceability system records every parameter—from powder lot numbers to machine calibration logs—enabling full part genealogy. Final inspection includes CMM, surface roughness testing, and non-destructive evaluation (NDE), with 100% of parts meeting PPAP Level 3 requirements.

Key Production Capabilities

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Materials | Ti6Al4V, Inconel 718, AlSi10Mg, 17-4PH | AMS, ASTM, ISO |

| Build Volume | Up to 500 x 400 x 400 mm | EOS/SLM certified |

| Tolerance | ±0.025 mm (as-printed) | ISO 2768-m |

| Surface Finish | Ra 3.2–6.3 µm (as-printed) | ISO 1302 |

| Post-Processing | 5-axis milling, HIP, stress relief | NADCAP AC7102 |

| Lead Time | 2–4 weeks (including validation) | ITAR compliant |

This integrated approach—where design intelligence drives prototyping rigor and production discipline—ensures zero defects are not aspirational but systematically engineered. Wuxi Lead delivers certified metal components that perform under extreme operational demands, with full documentation for audit readiness. Partner with us to convert complex designs into mission-critical realities.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand the evolving demands of modern industrial production. As a leading provider of custom metal manufacturing solutions based in Wuxi, China, we specialize in delivering high-precision components tailored to the exact specifications of global engineering and industrial clients. Our integration of advanced CNC machining, multi-axis milling, turning, and localized 3D printing services enables us to support complex, low-to-medium volume production runs with exceptional accuracy and repeatability.

Choosing the right manufacturing partner is critical when precision, material integrity, and on-time delivery define project success. Whether you are developing aerospace components, medical devices, energy systems, or high-performance industrial equipment, our engineering team collaborates closely with clients to optimize designs, select appropriate alloys, and streamline production workflows. Our ISO-certified facility combines cutting-edge technology with decades of hands-on expertise to ensure every component meets the highest international quality standards.

Our localized 3D printing service is engineered for industrial applications where traditional manufacturing methods reach their limits. Utilizing metal additive processes such as Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM), we produce complex geometries, internal channels, and lightweight lattice structures in materials including titanium, Inconel, stainless steel, and aluminum. These capabilities are ideal for rapid prototyping, functional testing, and end-use part production in demanding environments.

We pride ourselves on transparency, responsiveness, and technical partnership. From initial concept review to final inspection and global logistics, we maintain open communication and full traceability throughout the manufacturing cycle. Our clients benefit from reduced lead times, minimized material waste, and scalable production models that adapt to project phase and volume requirements.

To ensure compatibility and performance, all 3D printed metal parts undergo rigorous post-processing and quality validation, including heat treatment, stress relieving, surface finishing, and dimensional inspection via CMM (Coordinate Measuring Machine).

Below are key specifications for our metal 3D printing and precision machining capabilities:

| Specification | Detail |

|---|---|

| Build Envelope (3D Print) | Up to 250 x 250 x 300 mm |

| Layer Resolution | 20 – 50 µm |

| Material Options | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel 718, Aluminum (AlSi10Mg), Tool Steel (Maraging Steel) |

| Surface Roughness (As-Built) | Ra 10–15 µm (post-processed down to Ra 0.8 µm) |

| Dimensional Accuracy | ±0.05 mm for features under 100 mm |

| Secondary Processes | CNC Machining, Heat Treatment, HIP, Polishing, Passivation, Anodizing |

| Quality Standards | ISO 9001:2015, Full Material Certification, First Article Inspection Reports |

Partner with Wuxi Lead Precision Machinery to transform your most demanding designs into high-performance reality. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation. Let’s build the future of precision manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.