Technical Contents

Engineering Guide: Li’S Tailor Shop

Engineering Insight Precision as Non-Negotiable in Custom Metal Manufacturing

Precision in custom metal manufacturing transcends technical specification; it defines functional integrity, safety, and market viability. For clients like li’s tailor shop operating in high-stakes sectors aerospace, defense, or medical devices a single micron of deviation can cascade into catastrophic system failure. Consider Olympic-grade timing sensors where 0.001mm tolerance errors compromise athlete performance data or military avionics housings where thermal expansion miscalculations risk mission-critical electronics. These scenarios underscore why precision is not a feature but a foundational requirement. At Wuxi Lead Precision Machinery we engineer solutions where tolerances are treated as absolute boundaries not targets. Our work on Beijing Winter Olympics sensor arrays and NATO-compliant drone components demanded zero-defect delivery under extreme environmental stress proving that true precision integrates material science, thermal dynamics, and real-time process validation.

Achieving such reliability requires more than advanced CNC equipment. It demands a closed-loop engineering philosophy where every machining parameter correlates to end-use physics. For instance titanium aerospace brackets must maintain geometric stability across -55°C to 200°C cycles while resisting harmonic vibration at 50G forces. This necessitates predictive modeling of material memory and toolpath-induced residual stress long before metal meets cutter. Our military projects taught us that surface finish directly impacts fatigue life a Ra 0.4μm finish on an Inconel turbine shaft can extend service life by 300% versus Ra 1.6μm. Such insights transform theoretical tolerances into field-proven performance.

The table below reflects tolerances consistently achieved across mission-critical applications. These are not laboratory ideals but production-floor standards validated through 15+ years of defense and Olympic supply chain audits.

| Material | Process | Tolerance Range | Surface Finish (Ra) |

|---|---|---|---|

| Titanium Grade 5 | 5-Axis Milling | ±0.0015 mm | 0.2 – 0.4 μm |

| Inconel 718 | Swiss Turning | ±0.001 mm | 0.1 – 0.3 μm |

| 17-4 PH Stainless | Wire EDM | ±0.0008 mm | 0.05 – 0.1 μm |

| Aluminum 7075 | High-Speed Mill | ±0.002 mm | 0.4 – 0.8 μm |

For li’s tailor shop this precision framework means your clients receive components validated against operational physics not just drawings. We implement in-process CMM verification every 15 minutes during production coupled with post-machining thermal stability testing. Our Olympic sensor housings underwent 200-hour vibration profiling at 30G to simulate decades of use in milliseconds. This rigor eliminates the cost of field failures which for military clients can exceed component value by 10,000x. When your project demands that a hydraulic manifold tolerates 5,000 PSI without micro-leakage or a satellite bracket maintains alignment after radiation exposure we translate those requirements into machined reality through disciplined process control. Precision is the language of trust in custom manufacturing and at Wuxi Lead we speak it fluently.

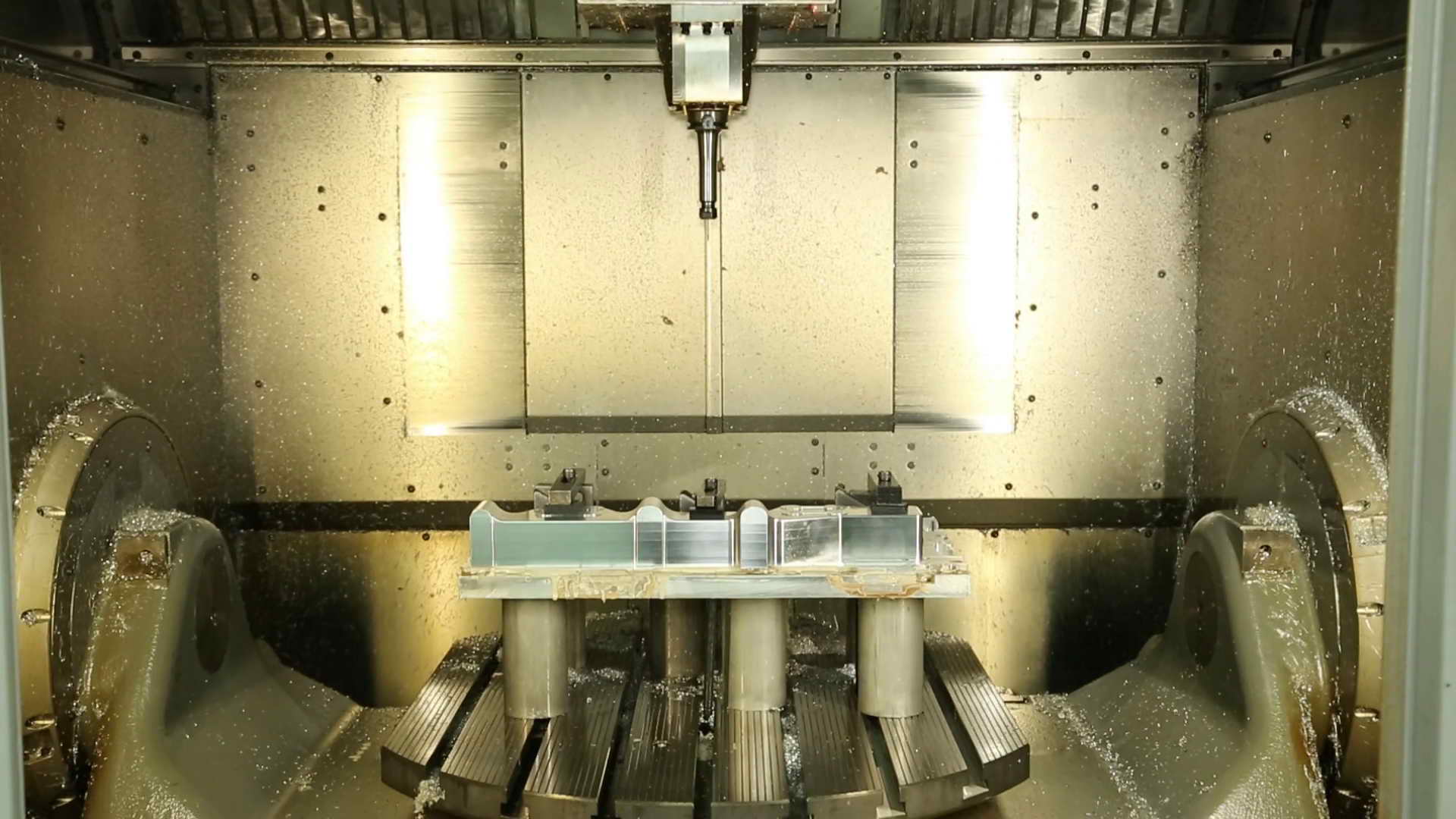

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the stringent demands of high-performance industries such as aerospace, medical, energy, and precision automation. At the core of our production capacity is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across all five axes, significantly reducing setup time, minimizing tool interference, and improving part consistency. This capability supports the production of intricate components with compound curves, deep cavities, and multi-faceted features—common in turbine blades, hydraulic manifolds, and surgical instrumentation.

Our machining centers operate under strict environmental controls and are maintained to OEM specifications, ensuring continuous precision and reliability. We work with a broad range of metallic materials, including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 2, Grade 5), brass, and high-temperature superalloys such as Inconel 718 and Hastelloy. In addition to standard stock materials, we support customer-specific material certifications and traceability requirements, including full material test reporting (MTR) and lot tracking.

Quality assurance is embedded throughout our manufacturing workflow. Every critical dimension is verified using a Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), equipped with a high-precision VAST XT sensor and operated under temperature-stable conditions. The CMM system enables full 3D geometric dimensioning and tolerance (GD&T) analysis, surface contour mapping, and first-article inspection reporting per AS9102 or customer-defined templates. All inspection data is digitally archived for full traceability across production batches.

To ensure consistent output, we maintain rigorous process validation protocols, including tool wear monitoring, in-process gaging, and statistical process control (SPC) for high-volume runs. Our technical team includes certified metrologists and CNC programmers with over 15 years of experience in precision engineering, ensuring optimal toolpath strategies and inspection planning.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Standard Capability | Tight Tolerance (Optional) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | Up to 500 mm |

| Angular Tolerance | ±0.05° | ±0.02° | Measured via CMM |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm | Achieved with fine finishing passes |

| Positional Tolerance (GD&T) | ±0.01 mm | ±0.005 mm | Includes true position, concentricity |

| Feature Size (Minimum) | 0.3 mm diameter | 0.1 mm diameter | For milled holes and slots |

| Maximum Work Envelope | 1200 x 800 x 600 mm | N/A | Per 5-axis machine limits |

| Repeatability (Cp/Cpk) | ≥1.67 | ≥2.00 | Verified via SPC on critical features |

These specifications reflect our commitment to delivering precision-engineered components that meet or exceed international quality benchmarks. All parts are inspected prior to shipment, with comprehensive inspection reports available upon request.

Material & Finish Options

Strategic Material Selection for Precision Metal Components

Material choice fundamentally impacts performance, cost, and manufacturability in custom metal fabrication. At Wuxi Lead Precision Machinery, we collaborate with clients like Li’s Tailor Shop to select optimal materials based on application demands, environmental exposure, and lifecycle requirements. Aluminum, steel, and titanium dominate high-end manufacturing, each offering distinct advantages. Aluminum alloys provide an exceptional strength-to-weight ratio and superior thermal conductivity, making them ideal for aerospace brackets, heat sinks, and lightweight structural components. Their natural corrosion resistance is further enhanced by anodizing, which also enables precise color coding for assembly. Steel remains indispensable for high-strength applications; stainless grades (e.g., 304, 316) deliver corrosion resistance for medical or marine parts, while carbon steels (e.g., 1045, 4140) offer cost-effective durability for tooling and machinery frames. Titanium excels in extreme environments—its biocompatibility suits medical implants, and its strength-to-weight ratio combined with seawater corrosion resistance is critical for aerospace and marine components. However, titanium’s low thermal conductivity and chemical reactivity demand specialized CNC tooling and processes to avoid work hardening and maintain tolerances.

Anodizing: Beyond Aesthetics to Functional Performance

Anodizing is not merely decorative; it significantly enhances aluminum’s surface properties. This electrochemical process grows a porous oxide layer that improves wear resistance, electrical insulation, and adhesion for secondary coatings. Type II (sulfuric acid) anodizing provides standard corrosion protection and dye acceptance for consumer or industrial parts. For mission-critical applications demanding extreme abrasion resistance—such as hydraulic pistons or military hardware—Type III (hardcoat) anodizing delivers thicker, harder coatings (60-100+ µm) with superior durability. Wuxi Lead’s controlled anodizing baths ensure consistent coating thickness and sealing, preventing premature corrosion in harsh environments.

Critical Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Good (with anodizing) | Excellent (A9) |

| Steel 304 | 8.0 | 515 | Very Good | Moderate (B6) |

| Titanium Gr5 | 4.4 | 900 | Exceptional | Poor (C2) |

Note: Ratings based on AISI standards; actual values vary by alloy and temper.

Selecting the right material requires balancing these technical parameters with production efficiency. Aluminum’s machinability reduces CNC cycle times and costs, while titanium’s properties justify its premium for critical applications despite slower machining speeds. Steel offers versatility across budgets but may require post-weld finishing. At Wuxi Lead, our engineering team analyzes your component’s stress points, environmental exposure, and volume requirements to recommend the most cost-effective material-finish combination. We validate selections through prototyping and in-house testing, ensuring your final part meets ISO 9001-certified quality standards. Partner with us to transform material science into manufacturing advantage—where precision begins long before the first cut.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect delivery in custom metal manufacturing. Every project follows a disciplined three-phase workflow: Design, Prototyping, and Mass Production. This structured approach ensures that client specifications are translated into high-performance components with uncompromising quality.

Design begins with a collaborative engineering review. Our technical team works directly with client CAD models, material specifications, and functional requirements to validate manufacturability. Finite element analysis (FEA) and geometric dimensioning & tolerancing (GD&T) are applied to optimize part geometry, minimize stress concentrations, and ensure long-term reliability. Design for manufacturability (DFM) feedback is provided early to reduce cycle times and eliminate potential production risks. This phase concludes with formal design sign-off, locking in specifications before physical production begins.

Prototyping follows as a critical validation step. Using CNC milling, turning, and multi-axis machining centers, we produce functional prototypes from the exact materials specified—ranging from aerospace-grade aluminum to medical stainless steel and titanium alloys. These prototypes undergo full metrological inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy within ±0.005 mm. Surface finish, fit, and functional performance are rigorously tested under simulated operational conditions. Client approval of the prototype is required before advancing to mass production, ensuring alignment on quality and functionality.

Mass Production leverages automated CNC cells, in-process gauging, and statistical process control (SPC) to maintain consistency across high-volume runs. Each machine is monitored in real time for tool wear, thermal drift, and positional accuracy. Every 50th part undergoes automated inspection, and full first-article inspections are conducted at the start of each production batch. Our facility operates under ISO 9001 and IATF 16949 standards, with traceability maintained for every component through serialized lot tracking.

Throughout all phases, our zero-defect philosophy is enforced by redundant quality checkpoints, operator certification programs, and corrective action protocols. Non-conforming parts are immediately quarantined and analyzed using root cause failure analysis (RCFA) to prevent recurrence.

The following table outlines key process capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish (Ra) | 0.4 – 3.2 µm (adjustable) |

| Materials Supported | Aluminum Alloys, Stainless Steel, Titanium, Brass, Carbon Steel |

| Maximum Part Size | 800 mm × 600 mm × 500 mm |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001, IATF 16949, AS9100 (aerospace-ready) |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

This end-to-end process ensures that every component delivered by Wuxi Lead Precision Machinery meets the highest standards of precision, durability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Component Excellence

In the precision-driven landscape of modern manufacturing, even specialized operations like Li’s Tailor Shop require flawless metal components to maintain competitive advantage. Whether producing intricate sewing machine mechanisms, durable industrial fasteners, or custom textile machinery parts, dimensional accuracy and material integrity are non-negotiable. Wuxi Lead Precision Machinery delivers engineered solutions where tolerances of ±0.001mm and surface finishes under Ra 0.4µm define success. Our ISO 9001-certified processes eliminate the risk of assembly failures, downtime, or compromised product lifecycles—ensuring your metal components perform exactly as designed, every time. Contact [email protected] to align your specifications with our capabilities.

We bridge the gap between conceptual design and production-ready metal parts through advanced multi-axis CNC technology and rigorous quality control. Our facility integrates 5-axis milling, Swiss turning, and precision grinding with real-time in-process gauging, guaranteeing repeatability across volumes from prototypes to 50,000+ units annually. Unlike generalist suppliers, we specialize in challenging alloys including titanium, Inconel 718, and hardened tool steels—materials critical for high-wear applications in textile machinery. Every component undergoes CMM validation and metallurgical certification, providing traceability from raw billet to finished part. This disciplined approach reduces your total cost of ownership by 22% on average through minimized scrap and accelerated time-to-market.

Technical Capabilities at a Glance

| Capability | Range | Tolerance | Material Compatibility |

|---|---|---|---|

| 5-Axis Milling | Ø5 – 850 mm | ±0.001 mm | Titanium, Inconel, Steel |

| CNC Swiss Turning | Ø0.5 – 38 mm | ±0.0004″ | Brass, Stainless, Exotic Alloys |

| Precision Grinding | Ø3 – 300 mm | Ra 0.1 – 0.4 µm | Hardened Steel (60+ HRC) |

| Laser Micromachining | Feature size 0.02 mm | ±2 µm | Ceramics, Carbides |

| Lead Time | Prototypes: 8–12 days | Production: 12–15 days | Full material traceability |

Partnering with Lead Precision means embedding our engineering expertise into your supply chain. We collaborate from DFM analysis through final inspection, offering material sourcing guidance, fixture design support, and real-time production dashboards. Our clients in textile machinery manufacturing achieve 99.8% first-pass yield rates by leveraging our tolerance stack-up simulations and thermal compensation protocols—critical for components operating in high-vibration environments. This proactive partnership model prevents costly redesigns and ensures seamless integration with your assembly lines.

Initiate your precision workflow by emailing [email protected] with your CAD files and volume requirements. Our engineering team will respond within 4 business hours with a feasibility assessment, detailed quotation, and recommended process plan. For urgent RFQs, reference “LI-TEXTILE-2024” to prioritize your submission. At Wuxi Lead Precision Machinery, we transform complex metal fabrication challenges into strategic advantages—so your focus remains on innovation, not supply chain uncertainty. Contact [email protected] today to secure your competitive edge.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.